Aluminum content control method

A control method, a technology of aluminum content, applied in the field of steelmaking and refining, to achieve the effect of increasing production costs, simple control method, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

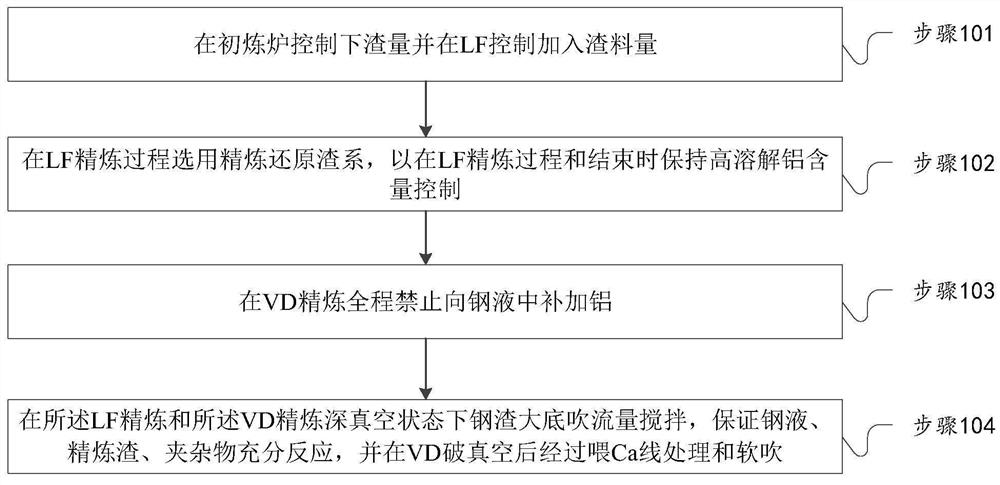

Method used

Image

Examples

Embodiment 1

[0043] The steel type is X70 pipeline steel, the tapping volume is 213t, and the production process is "converter + LF refining + VD refining + wire feeding + soft blowing".

[0044] (1) The content of dissolved aluminum [Al]s in molten steel at the end of LF refining is controlled at 0.071%, and the mass percentage of refining slag components after LF refining slag is: CaO%: 56.68%, Al 2 o 3 %: 26.79%, MgO %: 6.72%, SiO 2 %: 4.59%, (FeO%+MnO%): 0.66%, the amount of slag is 12.52Kg / t steel, the flow rate of bottom blowing argon gas is 2.50NL / (min·t steel) strong stirring desulfurization, LF refining is finished in molten steel The sulfur content of the product is reduced to 14ppm;

[0045] (2) Aluminum is not added to molten steel throughout the VD vacuum refining process. After VD refining, the dissolved aluminum [Al]s content in molten steel is controlled at 0.039%, and the deep vacuum stage of VD vacuum refining process is 2.00NL / (min· t steel) the amount of argon is blo...

Embodiment 2

[0049] The steel grade is E36-Z35, the tapping volume is 301t, and the production process is "converter + LF refining + VD refining + wire feeding + soft blowing".

[0050] (1) The content of dissolved aluminum [Al]s in molten steel at the end of LF refining is controlled at 0.082%, and the mass percentage of refining slag components after slagging is: CaO%: 53.64%, Al 2 o 3 %: 27.32%, MgO %: 7.32%, SiO 2 %: 7.14%, (FeO%+MnO%): 0.69%, the amount of slag is 10.49Kg / t steel, the flow rate of bottom blowing argon gas is 3.50NL / (min·t steel) strong stirring desulfurization, LF refining is finished in molten steel The sulfur content of the product is reduced to 20ppm;

[0051] (2) Aluminum is not added to the molten steel during the VD vacuum refining process. After the VD refining process, the dissolved aluminum [Al]s content in the molten steel is controlled at 0.035%, and the deep vacuum stage of the VD vacuum refining process is 2.00NL / (min· t steel) the amount of argon is b...

Embodiment 3

[0055] The steel grade is 45Mn2V, the tapping amount is 100t, and the production process is "electric furnace + LF refining + VD refining + wire feeding + soft blowing".

[0056] (1) The content of dissolved aluminum [Al]s in molten steel at the end of LF refining is controlled at 0.065%, and the mass percentage of refining slag components after slagging is: CaO%: 53.75%, Al 2 o 3 %: 28.23%, MgO %: 7.56%, SiO 2 %: 6.74%, (FeO%+MnO%): 0.66%, the amount of slag is 13.23Kg / t steel, the flow rate of bottom blowing argon gas is 3.50NL / (min·t steel) strong stirring desulfurization, LF refining is finished in molten steel The sulfur content is reduced to 15ppm;

[0057] (2) Aluminum is not added to molten steel throughout the VD vacuum refining process. After VD refining, the dissolved aluminum [Al]s content in molten steel is controlled at 0.022%, and the deep vacuum stage of VD vacuum refining process is 2.00NL / (min· t steel) the amount of argon is blown and stirred at the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com