Concurrent high-sulfur bauxite desulfurization roasting process and device

A technology of high-sulfur bauxite and roasting process, which is applied to the preparation of aluminum compounds, alkali metal aluminates/aluminum oxide/aluminum hydroxide, inorganic chemistry, etc., to ensure desulfurization reaction temperature and reaction time, and ensure kinetic characteristics , the effect of reducing the likelihood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

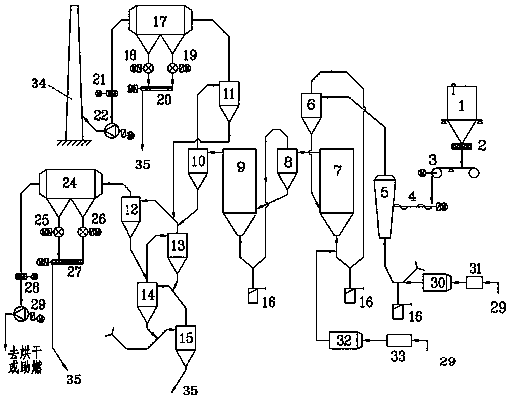

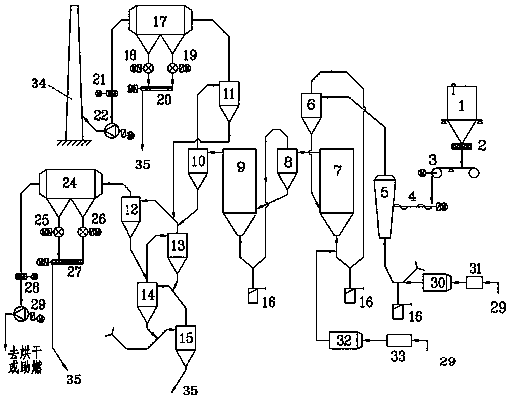

[0036] Embodiment 1: as attached figure 1 As shown, a downstream high-sulfur bauxite desulfurization roasting device, including raw bauxite feeding system, Venturi feeding system, desulfurization roasting system, desulfurization roasting dust collection system, cyclone cooling system, cooling dust collection system, a primary fuel supply system and a secondary fuel supply system, the raw bauxite feeding system includes a raw meal feeding bin 1, a rotor weighing feeder 2, a belt feeder 3 and a screw feeder machine 4; the rotor weighing feeder 2 is set at the lower end of the raw material feeding bin 1, the belt feeder 3 is located below the rotor weighing feeder 2, and the belt feeder 3 is connected to the inlet of the screw feeder 4 The feed port, the feed port of the screw feeder 4 is connected to the feed port of the Venturi dryer 5.

[0037] The Venturi feeding system includes a Venturi drier 5 and a primary cyclone separator 6, the inlet of the Venturi drier 5 is connecte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com