Washing tower for ship tail gas treatment

A technology for ship exhaust and scrubbers, which is applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems affecting desulfurization efficiency, large hull space, and short flue gas residence time, and achieves reduction of tower body space, The effect of reducing equipment size and reducing hull space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0026] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

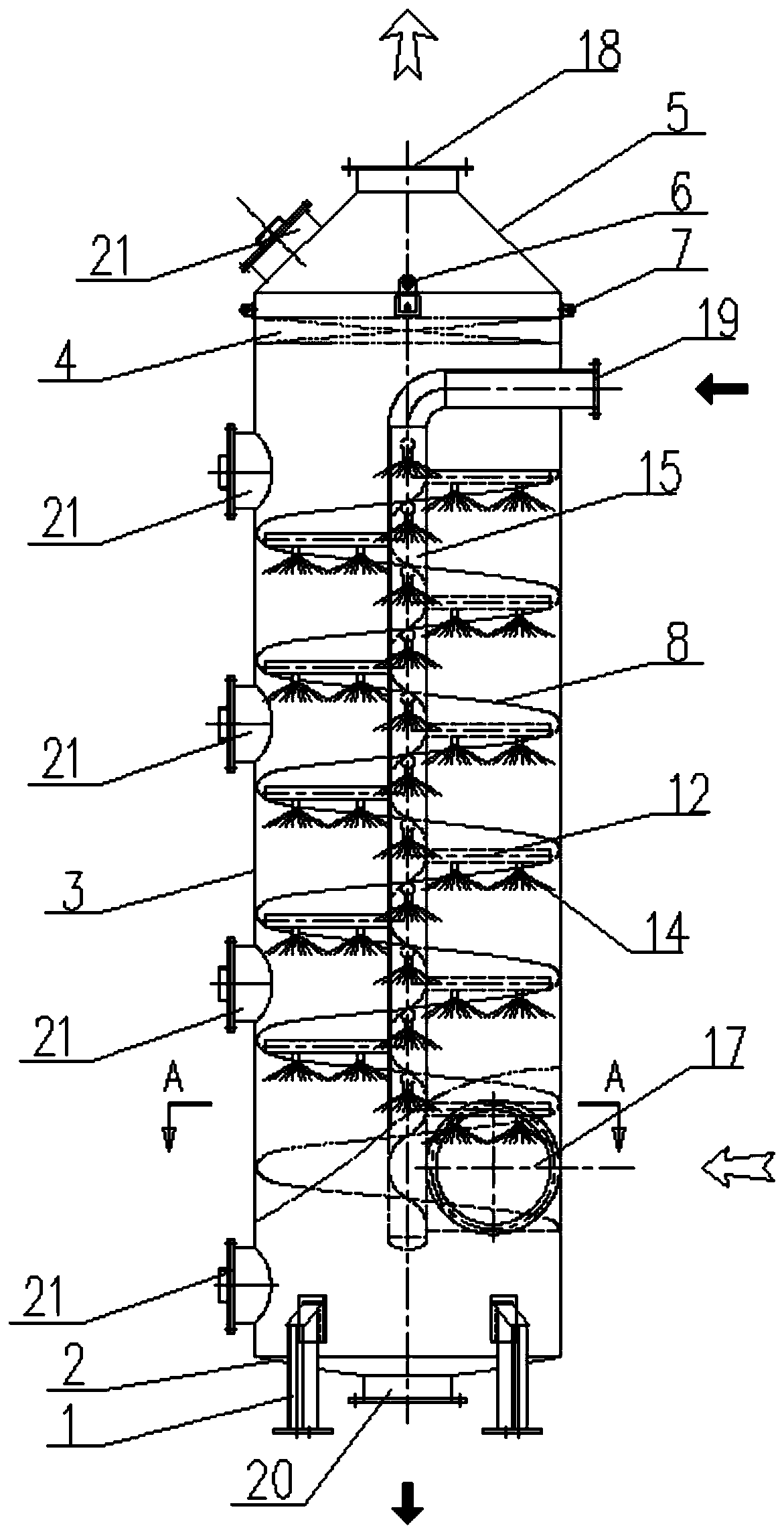

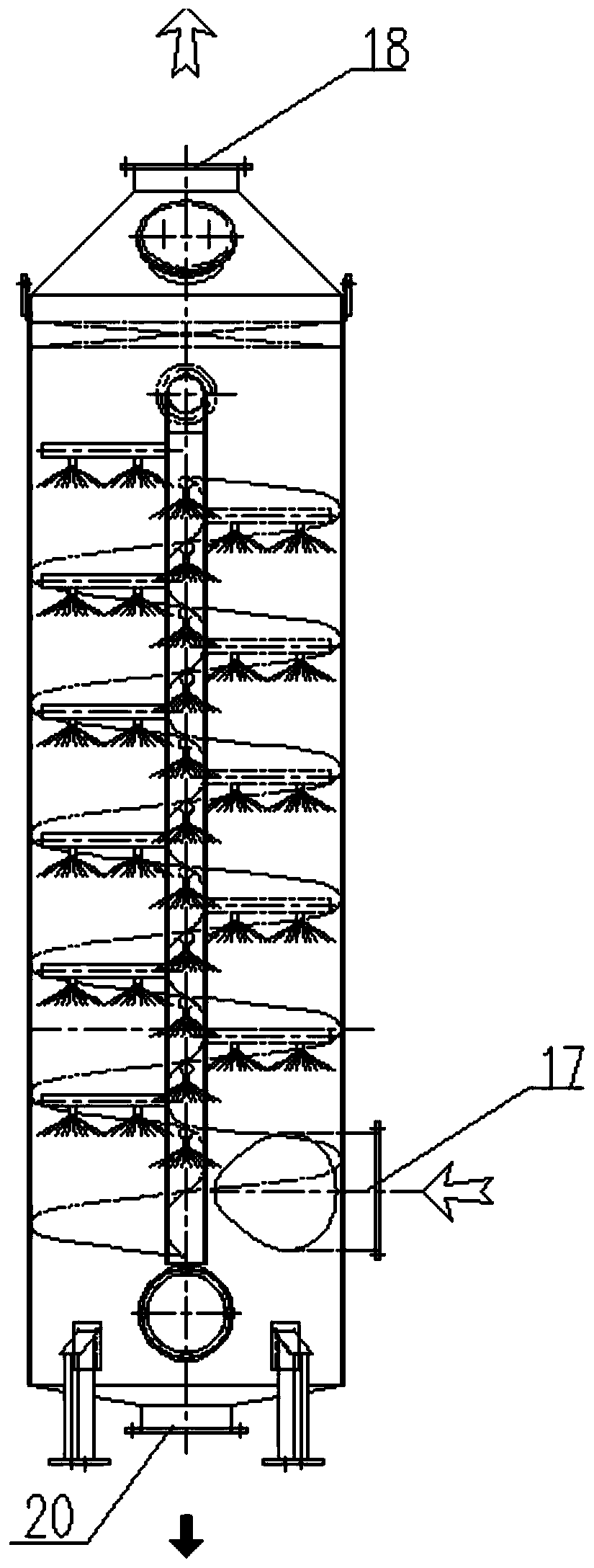

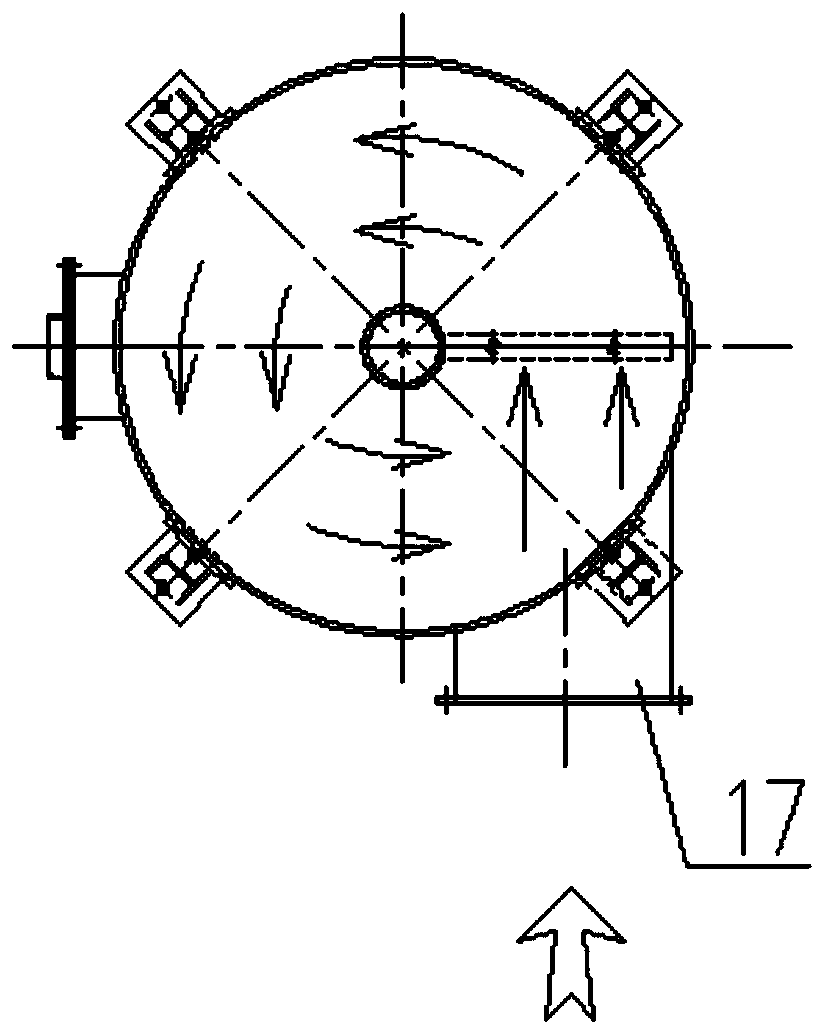

[0027] like Figure 1 to Figure 8 As shown, a scrubber for ship exhaust gas treatment includes a lower head 2, a cylinder body 3 and an upper head 5 welded to each other in sequence, and the outside of the cylinder body 3 is provided with several lugs 6 and fixed pullers. Ears 7 are respectively used for hoisting of the equipment and fixed braces after the equipment is installed in place. The lower head 2 is a conical head with a half top angle of 60°-80°. The cone angle is designed to quickly drain the bottom of the tower For washing wastewater, the lower part of the lower head 2 is provided with a support 1 for supporting the cylinder body 3. The support 1 is a vertical structure. According to the size of the washing tower and the structure of the installation place of the hull, the support 1 can be connected with the lower The head 2 or the cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com