Claus tail gas condensing treatment process

A Claus tail gas and treatment process technology, applied in the field of Claus tail gas condensation treatment process, can solve problems such as increased energy consumption, and achieve the effects of increasing gas volume, reducing steam consumption and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

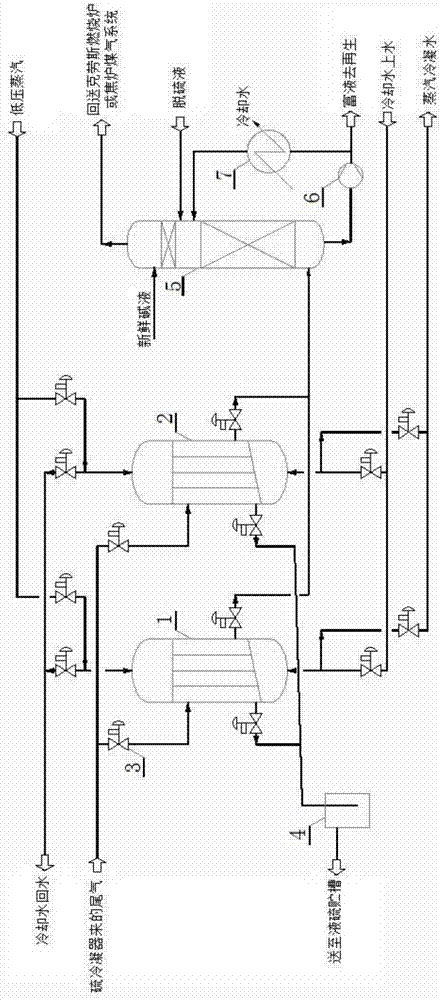

[0031] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0032] like figure 1 Shown, a kind of Claus tail gas condensation treatment process of the present invention comprises the steps:

[0033] 1) The temperature of the Claus tail gas coming out of the Claus process sulfur condenser is 130-160°C, controlled by the program-controlled valve 3, firstly enters the shell side of the heat exchanger-1, and passes into the tube side of the heat exchanger-1 for cooling Water cooling, the gaseous sulfur in the Claus tail gas is condensed on the outer surface of the heat exchange tube to be removed;

[0034] 2) The Claus tail gas from which gaseous sulfur has been removed is sent to the desulfurization absorption tower 5, and the desulfurization absorption tower 5 is sprayed with the desulfurization liquid from the gas purification device; most of the H in the Claus tail gas 2 S, SO 2 , CO 2 Absorbed by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com