Heating and steam dual-purpose boiler

A steam and boiler technology, applied in the direction of steam generation, steam generation methods, fluid heaters, etc., can solve the problems that water cannot be decomposed into hydrogen and carbon monoxide to support combustion, renewable energy cannot be developed and utilized, and additional combustible sources cannot be added. Achieve the effects of enhancing compression resistance, reducing power consumption, and improving mechanical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

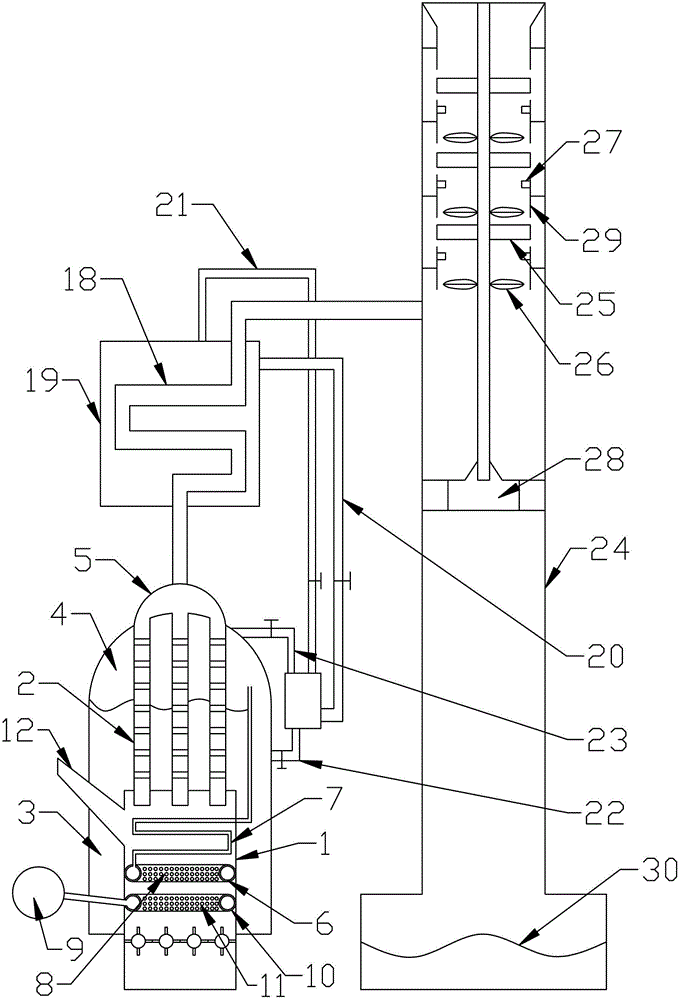

[0045] The present invention will be further described below in conjunction with the accompanying drawings.

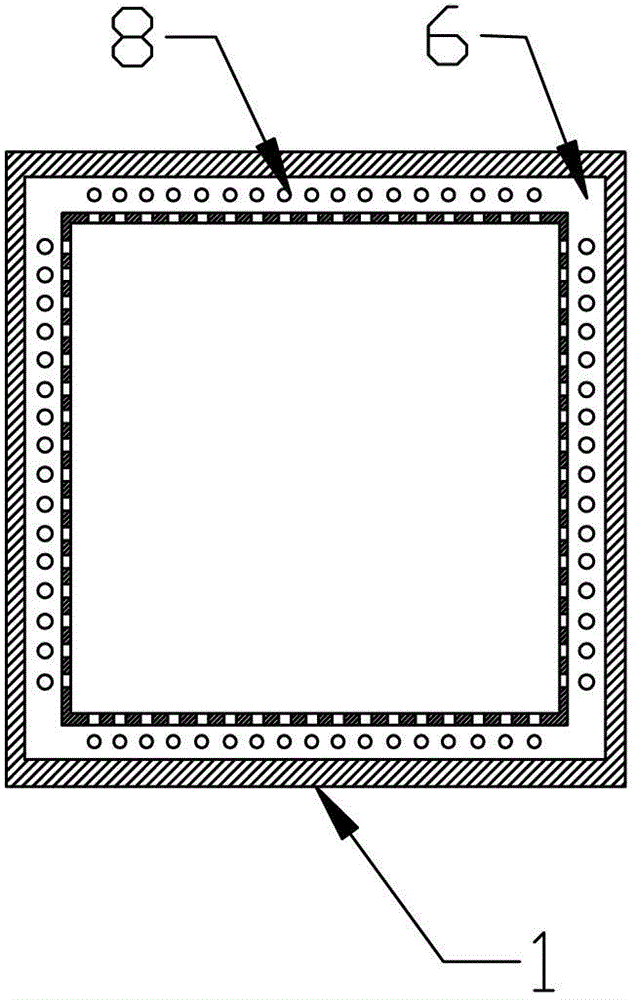

[0046] Such as Figure 1-Figure 7 As shown, a dual-purpose boiler for heating and steam described in the embodiment of the present invention at least includes a furnace 1, a water tank, a heating core 2, a flue gas secondary utilization device, a flue gas purification device, and a positioning grate device, wherein;

[0047] The hearth 1 is a rectangular cylinder with a water tank on its outer side and top, and a positioning fire grate device at the bottom of the hearth;

[0048] The water tank is composed of a water chamber 3 and a steam chamber 4;

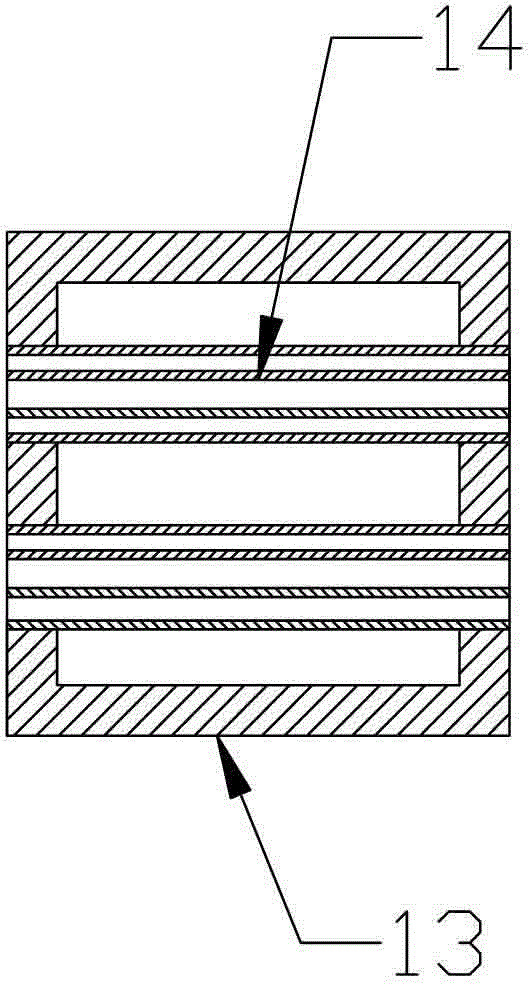

[0049] The at least one heating core 2 is sealed on the top of the water tank, one end of which is in communication with the furnace 1, and the other end is connected with the smoke cavity 5, and the smoke cavity 5 is connected with the flue gas secondary utilization device, and the flue gas secondary utilization device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com