Energy-saving type range tray

An energy-saving, stove technology, applied in the direction of stove/stove top, etc., can solve the problems of oxygen-deficient combustion, hindered fire, no flame energy release, etc., to achieve the effect of full combustion, convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

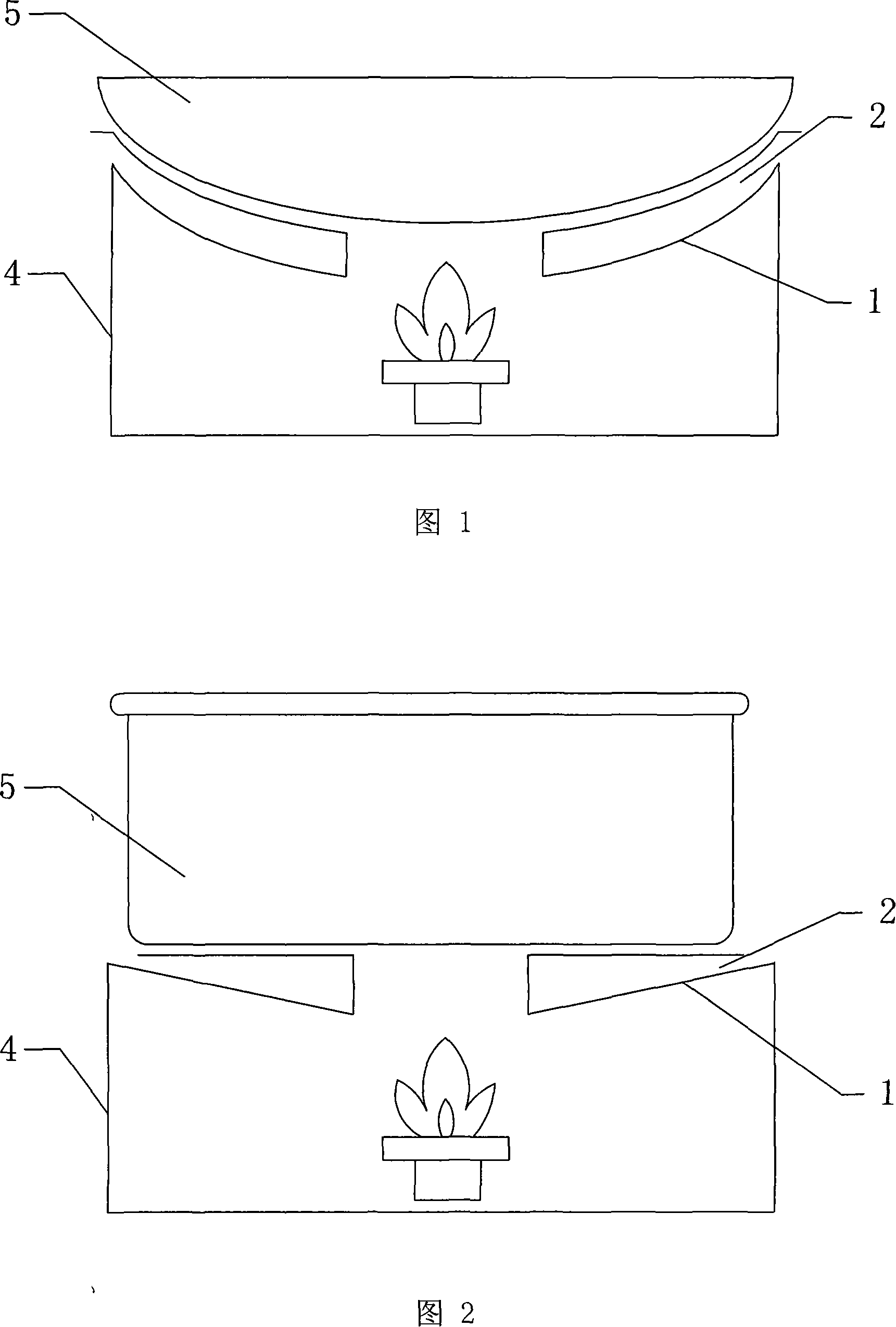

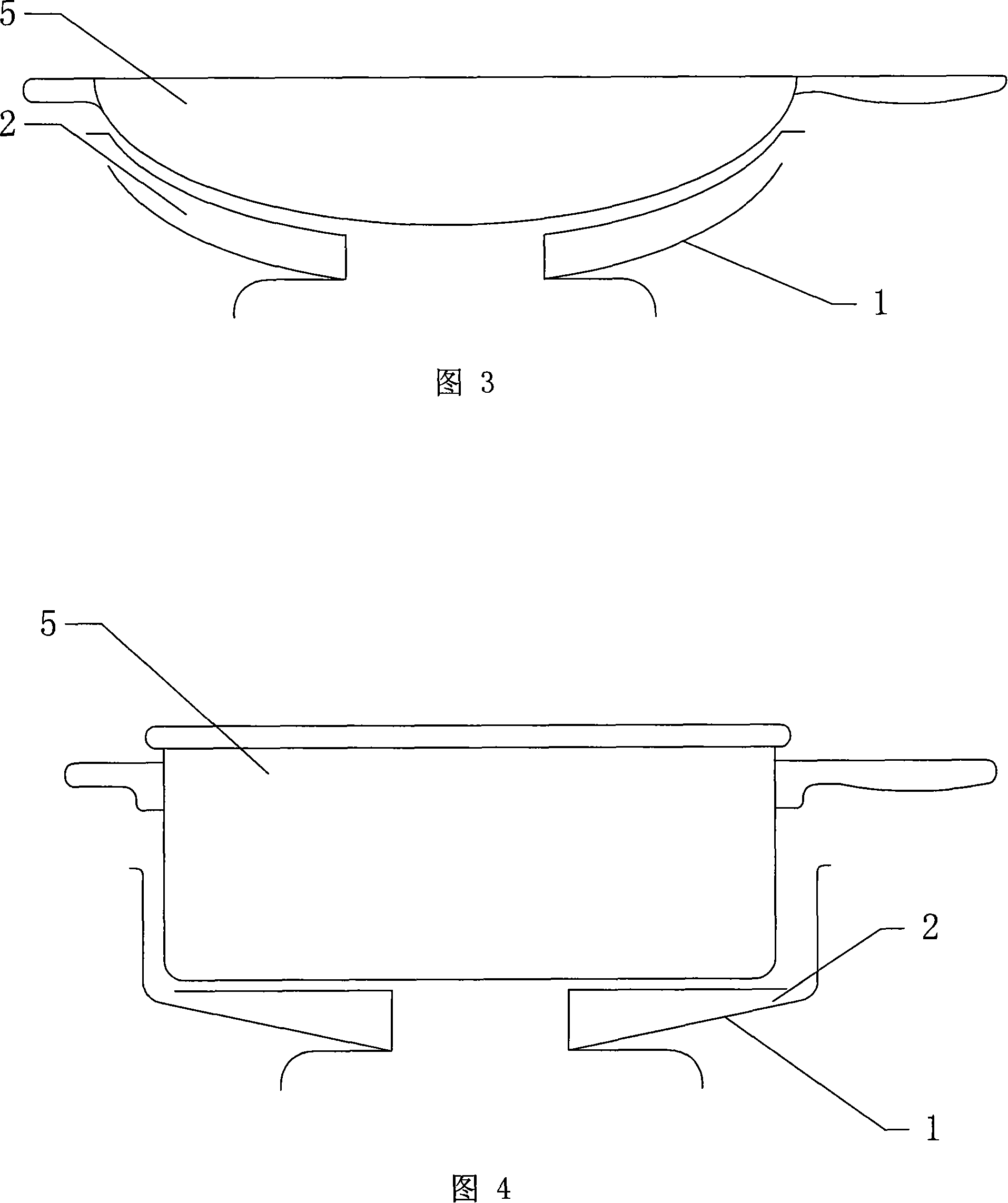

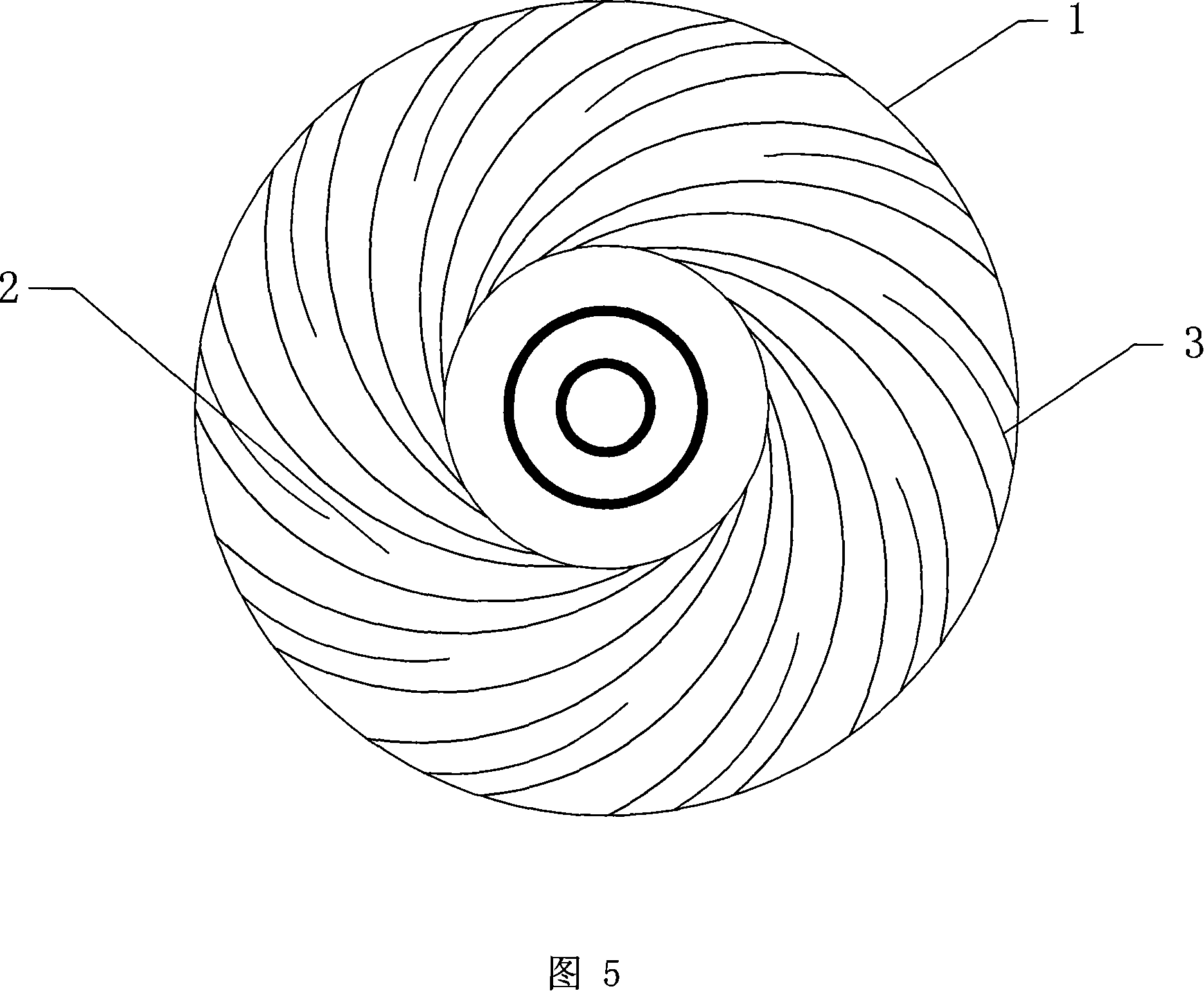

[0027] In the embodiment shown in Fig. 1, the energy-saving stove tray of the present invention includes an annular disk body 1, and the surface of the annular disk body 1 is provided with spiral grooves 2 with the same rotation direction and closely arranged, and the flame inlet of the spiral groove 2 is located in the ring The inner diameter edge of the disk body 1 and the flame outlet of the spiral groove 2 are located at the outer diameter edge of the annular disk body 1, as shown in FIG. 5 . The width of the spiral groove 2 gradually increases from the flame entrance to the flame exit, the flame exit width of the spiral groove 2 is equal to twice the flame entrance width of the spiral groove 2, and the depth of the spiral groove 2 is from the flame entrance to the flame exit Decreases gradually, the flame outlet depth of the spiral groove 2 is equal to 1 / 2 the flame inlet depth, and the phase angle difference between the flame inlet and outlet of the spiral groove 2 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com