Patents

Literature

46results about How to "Prevent decomposition reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

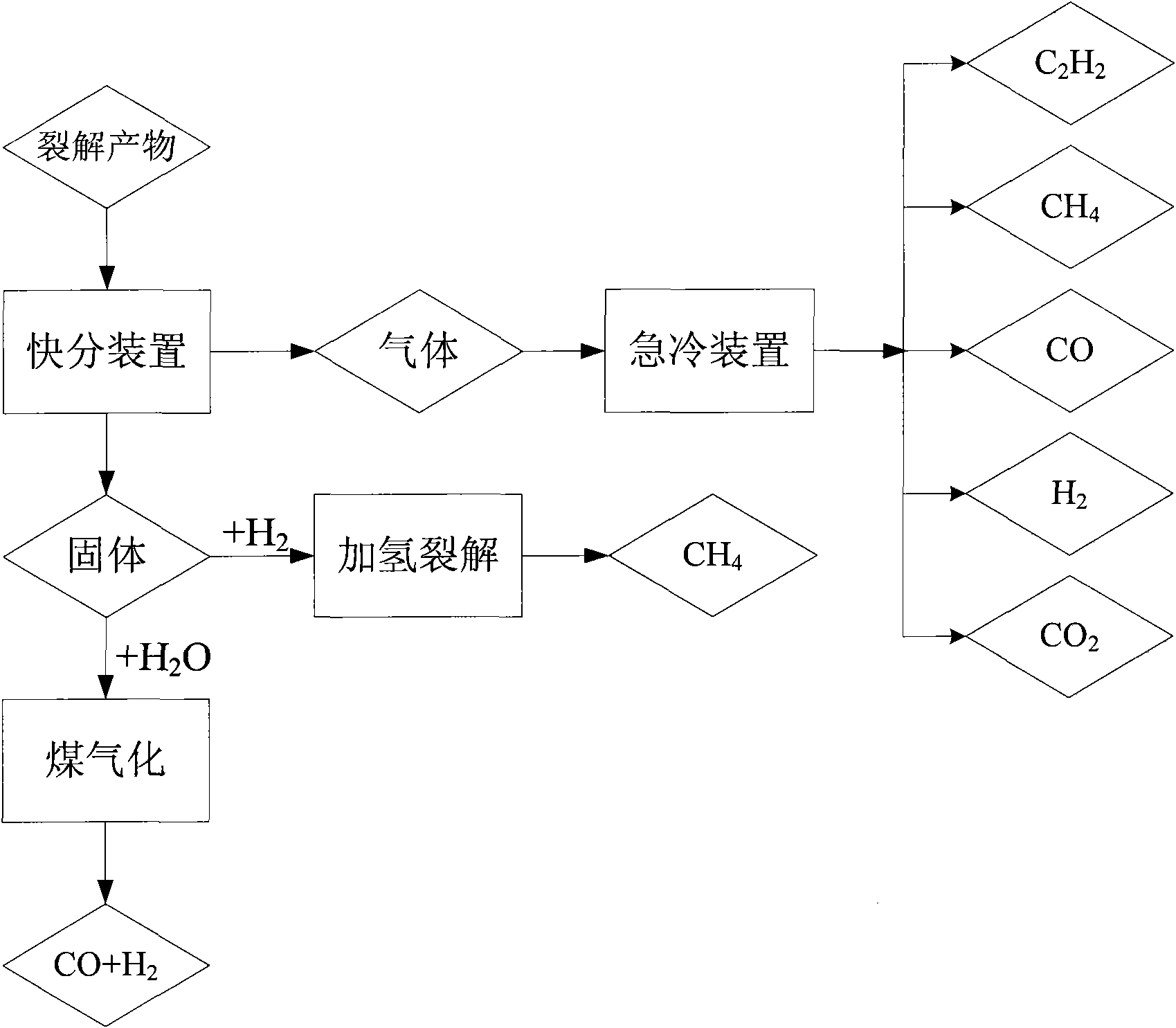

A post treatment process containing a fast gas-solid separation structure after plasma coal cracking

ActiveCN101550055AAvoid simultaneous coolingImprove cooling efficiencyOrganic chemistryChemical industryThermal energyGas phase

The present invention discloses a post treatment process containing a fast gas-solid separation structure after plasma coal cracking, which pertains to the technical field of coal chemical industry. This process includes: a) through a fast gas-solid separation device, gas-phase intermediate and solid-phase intermediate are obtained from the reaction products of plasma coal cracking; b) the gas-phase intermediate enters a quenching unit to obtain acetylene-containing cracking gas; c) the solid-phase intermediate enters another reactor to further react with water or hydrogen; d) the heat obtained from the reaction of the solid-phase intermediate provides partial electricity for plasma generator. The present invention may raise the acetylene content of cracking gas product, the overall coal conversion rate and the comprehensive value of the process and is applicable to the post treatment of high-temperature, high-flowrate gas-solid mixture.

Owner:TSINGHUA UNIV

Lithium ion battery and its preparing method

ActiveCN1988241AImprove high temperature stabilityImprove securityFinal product manufactureCell component detailsLithium-ion batteryCeramic membrane

This invention relates to Li ioninc cells including a pole set and non-solution electrolyte sealed in a shell, and the pole includes a positive, a negative pole and ceramic membranes, which is stable under high temperature and safe.

Owner:江苏永茂普隆汽车配件制造有限公司

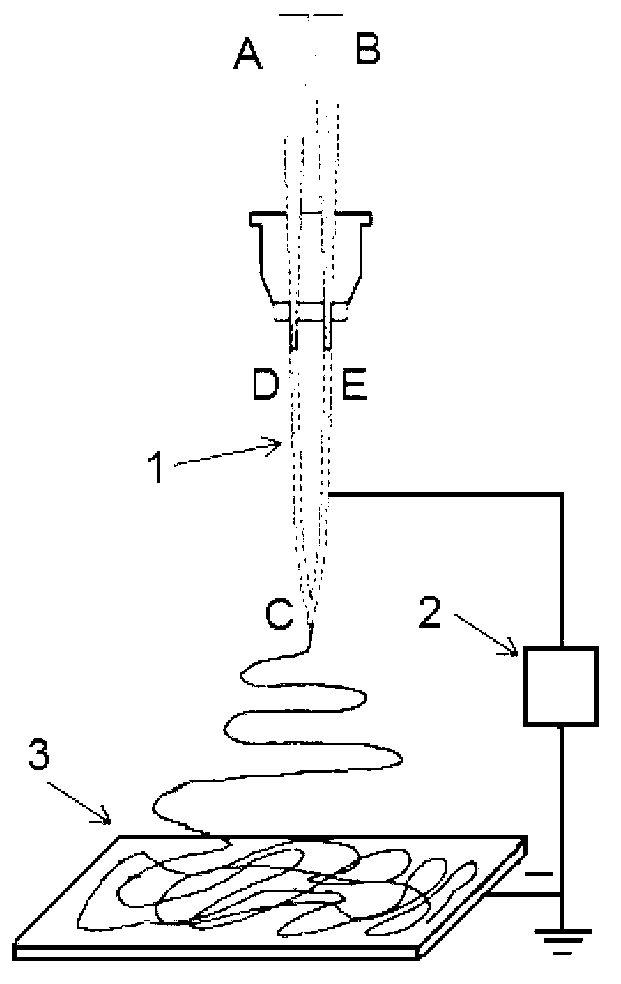

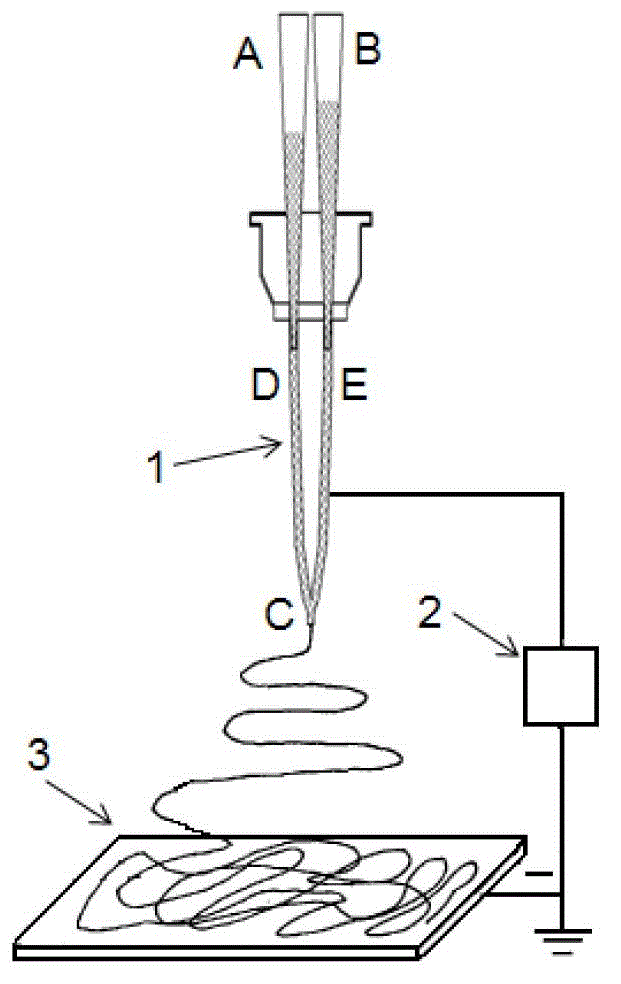

Method for preparing polyvinyl alcohol nano fibrous membrane containing nano silver and amino acid

The invention relates to a method for preparing a polyvinyl alcohol nano fibrous membrane containing nano silver and amino acid, which comprises the following steps: dissolving polyvinyl alcohol in a mixed solution of formic acid and deionized water, adding into a two-fluid beaming electrostatic spinning pouring pipe A, adding a complex solution generated from amino acid and silver ion into a two-fluid beaming electrostatic spinning pouring pipe B, gathering the two solutions in a sprayer C under the action of gravity, connecting a high-voltage generator to carry out electrostatic spinning while controlling the voltage at 15-20 KV, and receiving fibers with a metal flat plate; and crosslinking the received fibers in formaldehyde and concentrated acetic acid gas phase, and meanwhile, reducing the silver ion in silver histidine to obtain the nano silver, wherein the obtained nano fiber is hydrophilic, but can be easily dissolved in water. The preparation method provided by the invention is simple and high in yield; and the nano fibrous membrane has the advantages of high stability, high mechanical properties and favorable antimicrobial property, and can be used in the fields of medical treatment, cosmetics, food and the like.

Owner:JILIN AGRICULTURAL UNIV

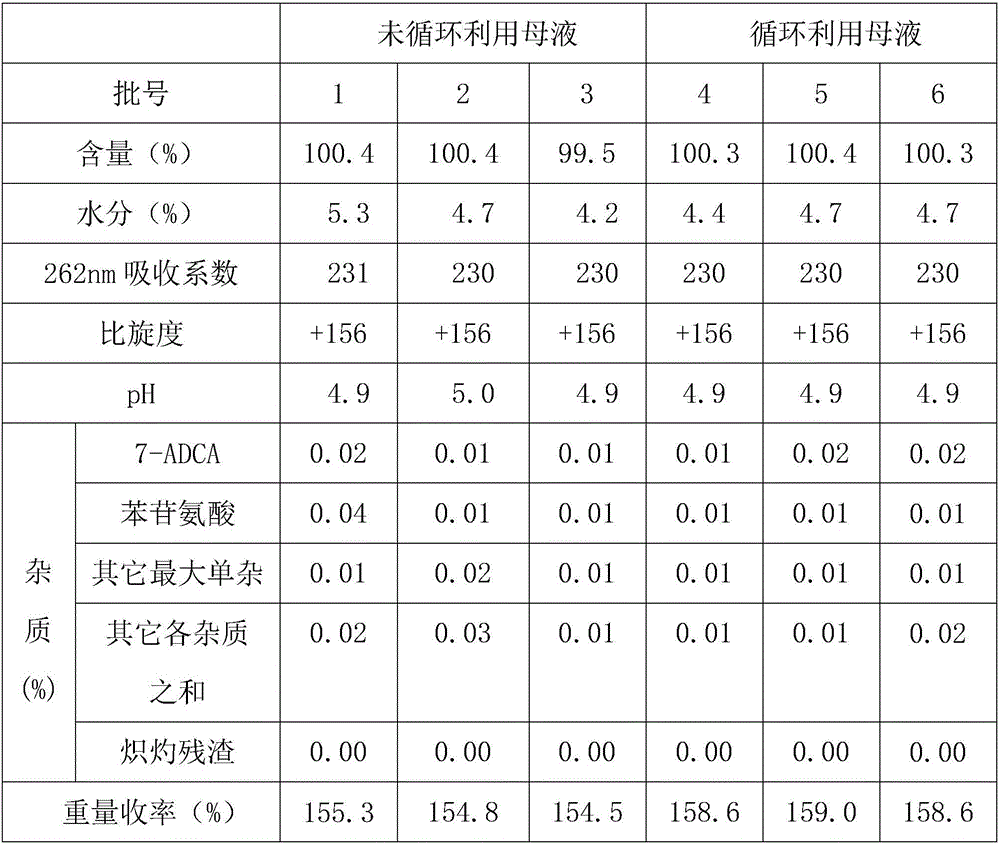

Method for recycling mother liquid of cefalexin synthesized by enzymatic method

The invention discloses a method for recycling mother liquid of cefalexin synthesized by an enzymatic method. The method provided by the invention comprises the following steps: 1) adjusting the pH value of the mother liquid of the cefalexin to 2.0 to 3.0 by using acid liquid at a certain temperature; 2) adsorbing, washing and desorbing the mother liquid to obtain a desorbed solution; 3) crystallizing the desorbed solution by ammonia water, filtering, washing and drying to obtain the finished product of the cefalexin; 4) distilling the filtrate in the step 3) under reduced pressure; 5) recycling ethanol obtained by distillation and the mother liquid after distillation for preparation of a desorbing agent next time and dissolution of 7-ADCA before synthesis. The preparation method provided by the invention is simple to operate, low in cost, energy-saving and environmentally friendly; meanwhile, the yield of the cefalexin prepared by the method is higher than that of the cefalexin prepared by a method without recycling the mother liquid.

Owner:NORTH CHINA PHARMA COMPANY

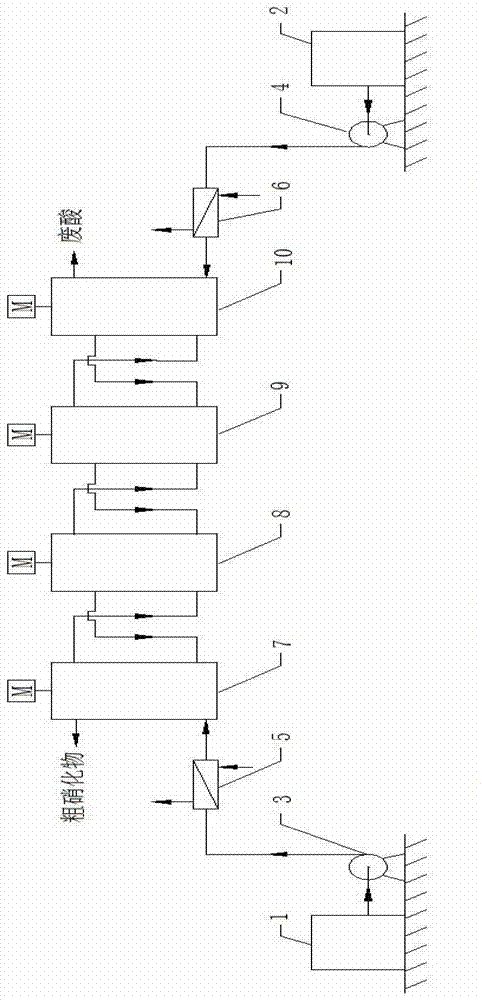

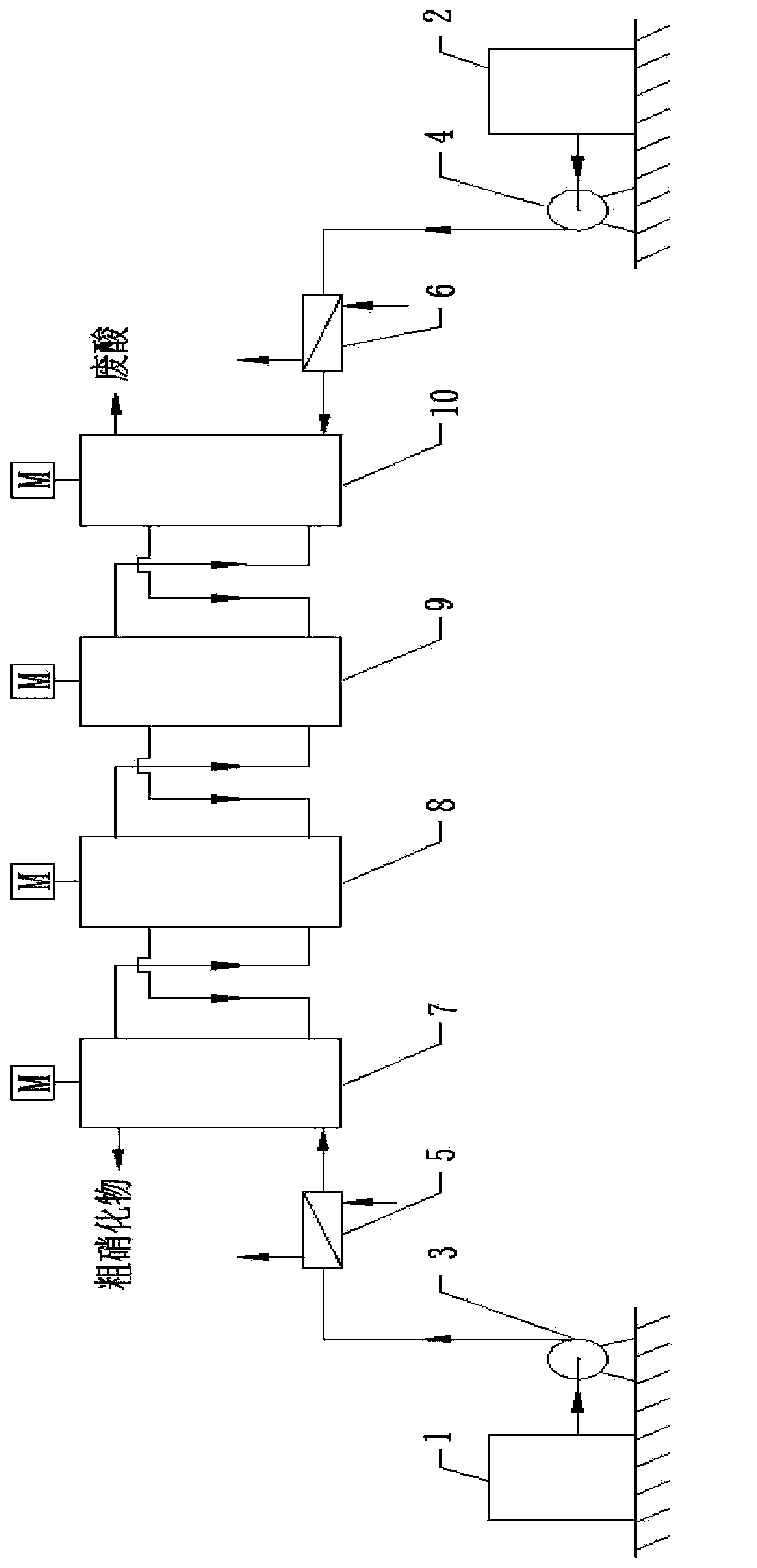

Safe production method of nitro-compound

ActiveCN103044261AHigh yieldLow costNitric acid ester preparationNitro compound preparationNitro compoundAutomatic control

The invention provides a production method of nitro-compound. The production method comprises the steps of: continuously feeding a mixed acid solution from a heavy-phase inlet of a first centrifugal extraction separation device of a nitration separation system disclosed by the invention, and continuously feeding a raw material to be nitrified from a light-phase inlet of a final centrifugal extraction separation device at the same time, wherein the reaction temperature inside each centrifugal extraction separation device is controlled at 10-160 DEG C, and the rotating speed of each centrifugal extraction separation device is controlled at 800-2000 r / min; after multi-stage continuous nitration reaction, discharging final coarse nitride from a light-phase outlet of the first centrifugal extraction separation device, and discharging final waste acid from a heavy-phase outlet of the final centrifugal extraction separation device; and carrying out common alkali washing and water washing on the coarse nitride, and distilling the coarse nitride to obtain the refined nitro-compound product. According to the method disclosed by the invention, the nitration reaction is continuously carried out; the device is compact, easy to achieve automatic control, large in operation elasticity, and high in production efficiency; and as the reaction product and the waste acid are separated from each other at the same time inside the same reactor, the contact time of the reaction product and the waste acid is greatly shortened, side reaction is effectively avoided, energy consumption and material consumption are greatly reduced, and the security of the nitration reaction process is fundamentally ensured.

Owner:徐德良 +1

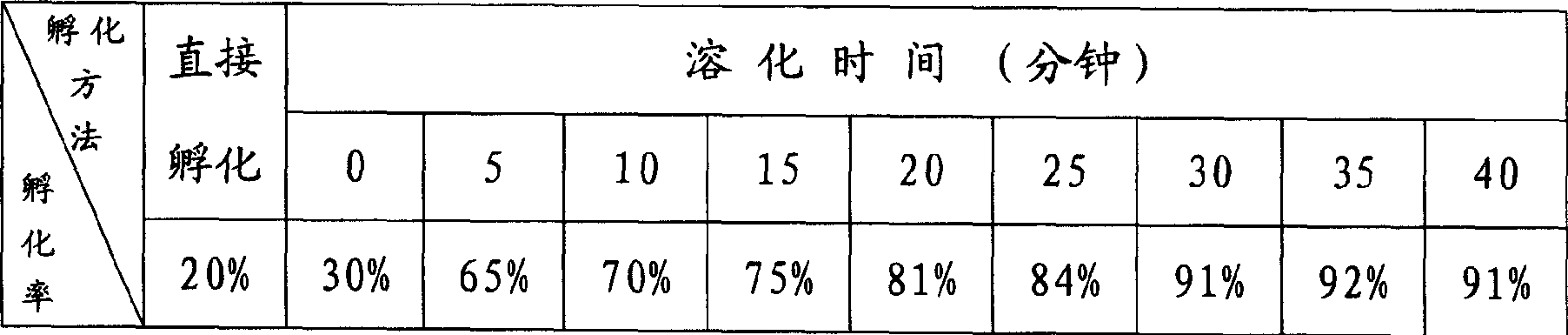

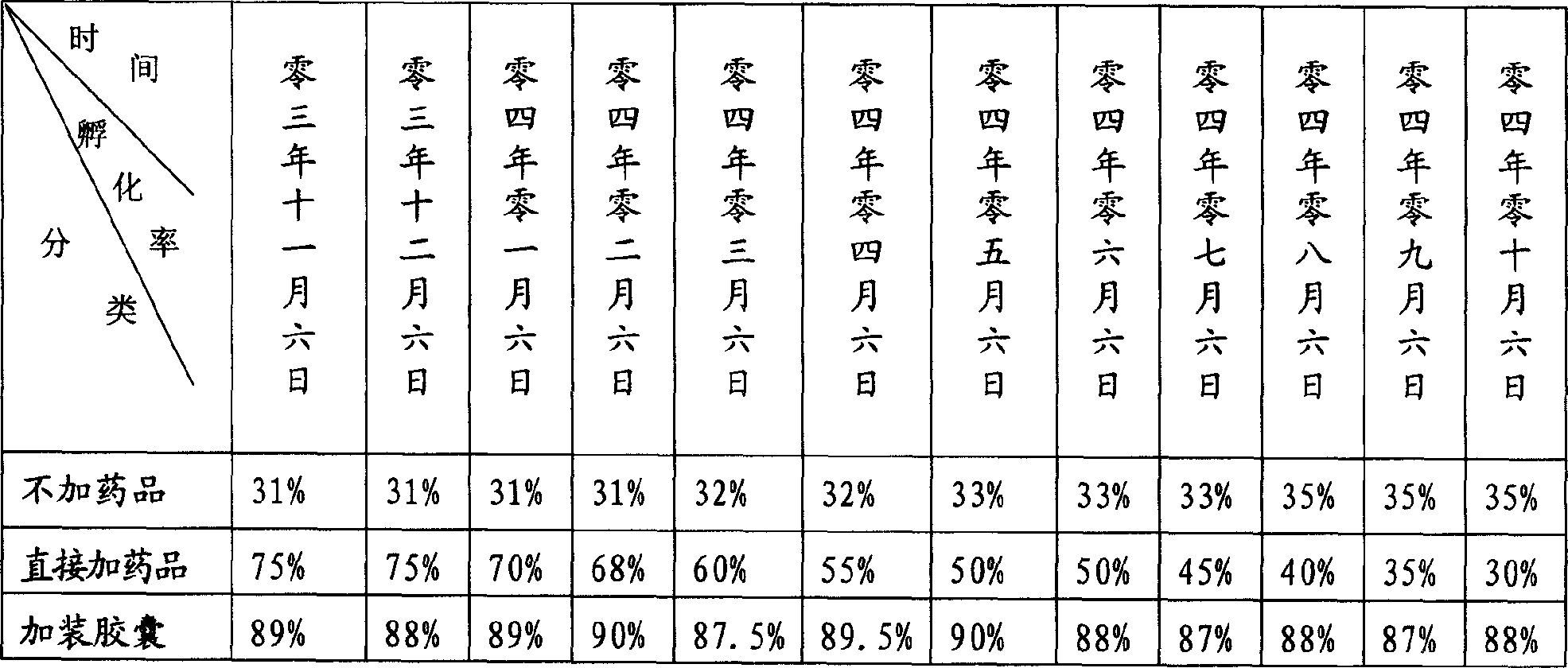

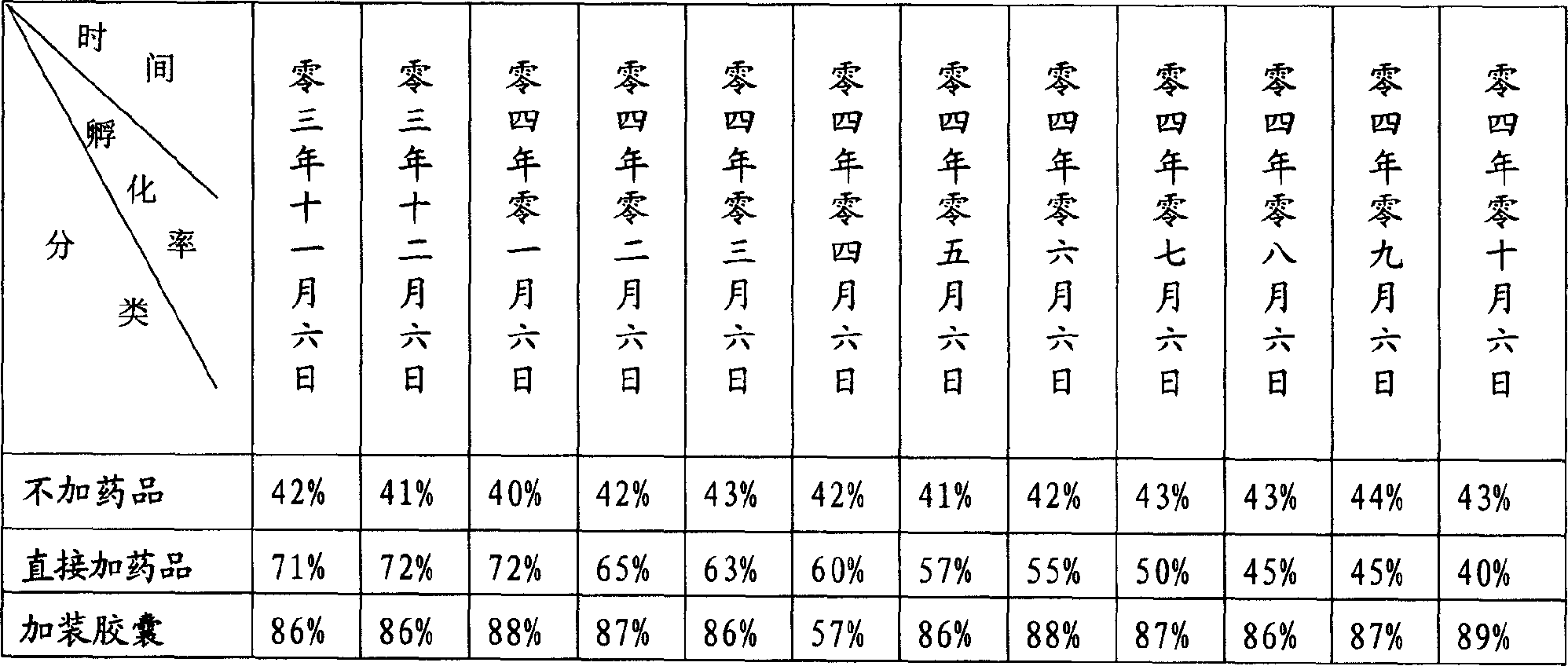

Artemia ovum hatching method with high hatchability rate

InactiveCN1631131AImprove hatchabilityAvoid deathClimate change adaptationOther angling devicesPackaging TankHatching

The invention discloses an Artemia ovum hatching method with high hatchability rate which comprises the steps of, freezing the collected insect ovum, drying directly, charging capsule with chemicals into the packaging tank, packaging together with the insect ovum, the chemicals include solids capable of generating hydrogen peroxide, during the using process, the insect ovum and capsule are poured into the hatching pool for hatching. The method can substantially increase hatching rate, the quality period can be extended for over 6 months.

Owner:付瑞岭

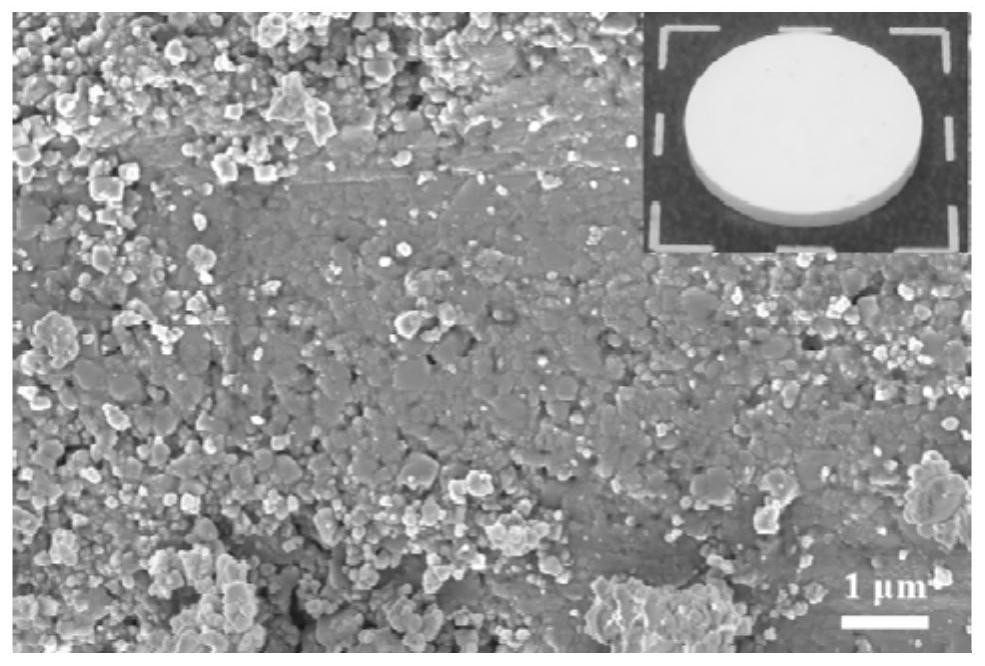

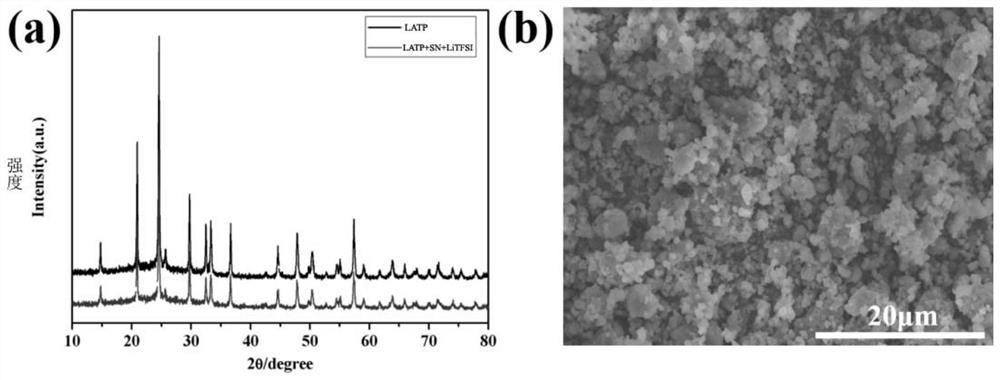

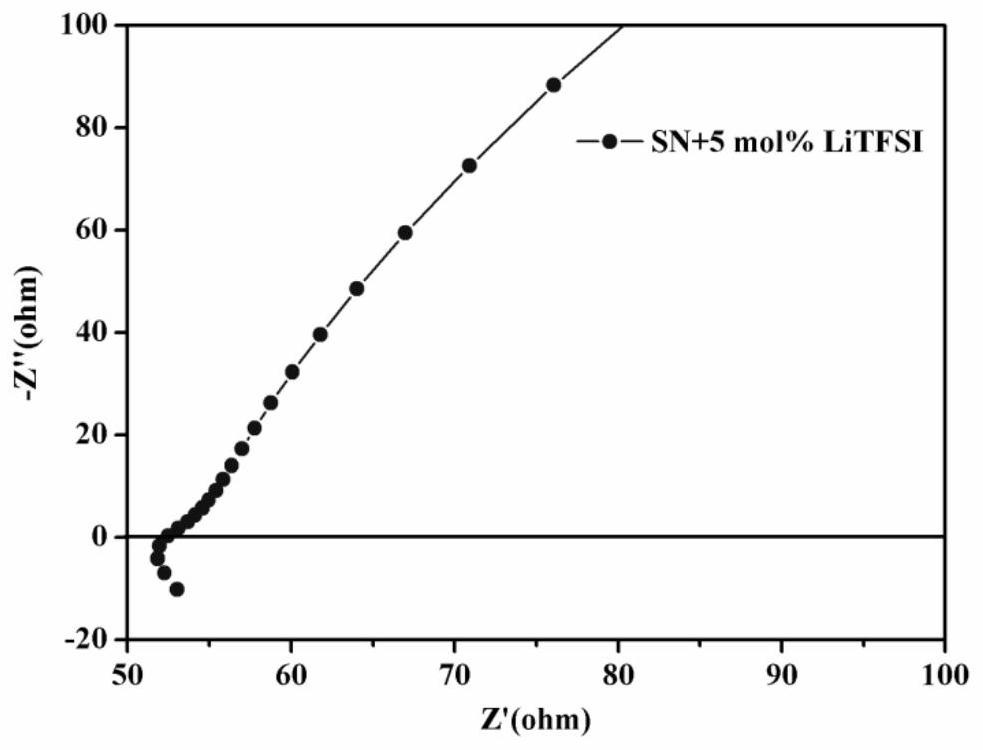

Plastic crystal-ceramic composite solid electrolyte and low-temperature hot-pressing preparation method thereof

InactiveCN112531204APrevent decomposition reactionHigh mechanical strengthFinal product manufactureLi-accumulatorsOxide ceramicPlastic crystal

The invention discloses a plastic crystal ceramic composite solid electrolyte and a low-temperature hot-pressing preparation method thereof. The method comprises the following steps of step 1, weighing oxide ceramic powder and the plastic crystal solid electrolyte, and uniformly mixing to obtain mixed powder; the plastic crystal solid electrolyte comprising a plastic crystal and a lithium salt, step 2, putting the mixed powder into a mold, and flattening the mixed powder; 3, the mixed powder being subjected to compression molding, meanwhile, the mixed powder being subjected to heat treatment,the heating temperature being lower than 600 DEG C, and the plastic crystal solid electrolyte absorbing heat to be molten; and then reducing the temperature to solidify and mold the plastic crystal solid electrolyte to obtain the plastic crystal ceramic composite solid electrolyte. According to the method, densification of the solid electrolyte can be realized at a relatively low temperature, thesolid electrolyte has relatively high ionic conductivity, and the processing time, energy loss and volatilization of a lithium element at a high temperature are greatly reduced.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

Continuous production method for triethyl phosphite

InactiveCN105503942APrevent decomposition reactionHigh purityGroup 5/15 element organic compoundsDimethylaniline N-oxideTriethylphosphite

The invention discloses a continuous production method for triethyl phosphite. The method comprises the steps that absolute ethyl alcohol and phosphorus trichloride are taken as reaction raw materials, dimethylaniline and o-dichlorobenzene are taken as reaction solvent, ammonia is introduced while reacting is performed, and after reacting is finished, a product is directly delivered into a continuous distillation column to be processed through reduced pressure distillation to obtain crude triethyl phosphite; the rest materials are delivered into a washing column to be washed by adding hot water and then layered, an organic layer is delivered into a distillation column to be processed through distillation dewatering to be recycled by serving as solvent, a water layer is delivered into a cooling kettle to be cooled, ammonium chloride solids are crystallized out, and mother liquor is continuously used for washing the rest materials of distillation. After the obtained triethyl phosphite is rectified through a rectifying column, the purity is 99.5%-99.9%, and the obtained ammonium chloride can serve as an ammonium fertilizer raw material. The continuous production method has the advantages that a decomposition reaction can be prevented from occurring in the process that the triethyl phosphite participates washing, dewatering can be achieved only by simply distilling the mother liquor, a salt column does not need to be introduced for dewatering, generation of secondary solid waste can be avoided, pollution to the environment is greatly reduced, the labor intensity is low, and the production cost is low.

Owner:JIANGSU SUYUANHUIPU CHEM

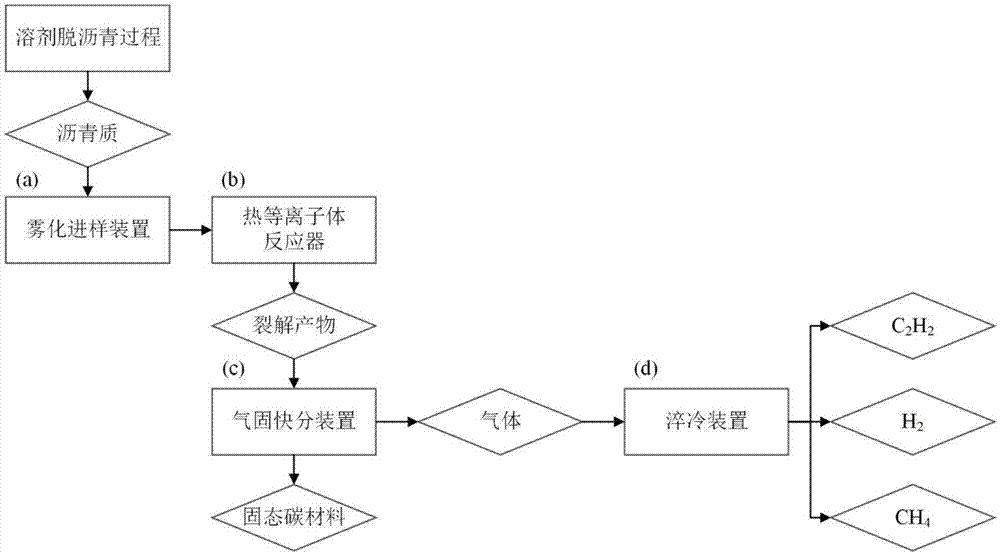

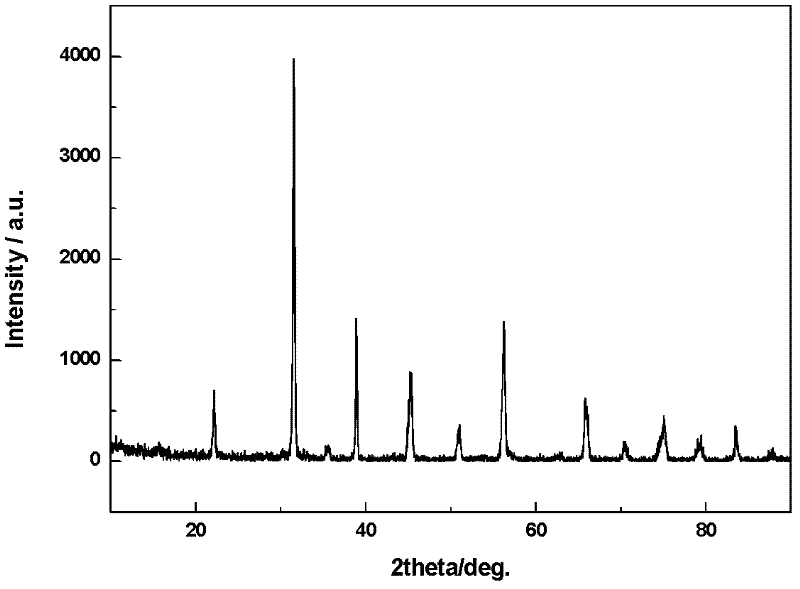

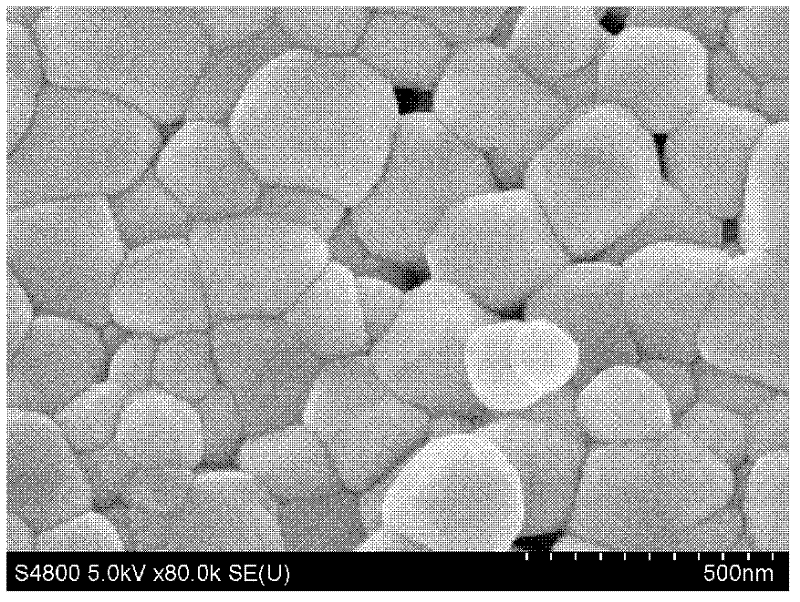

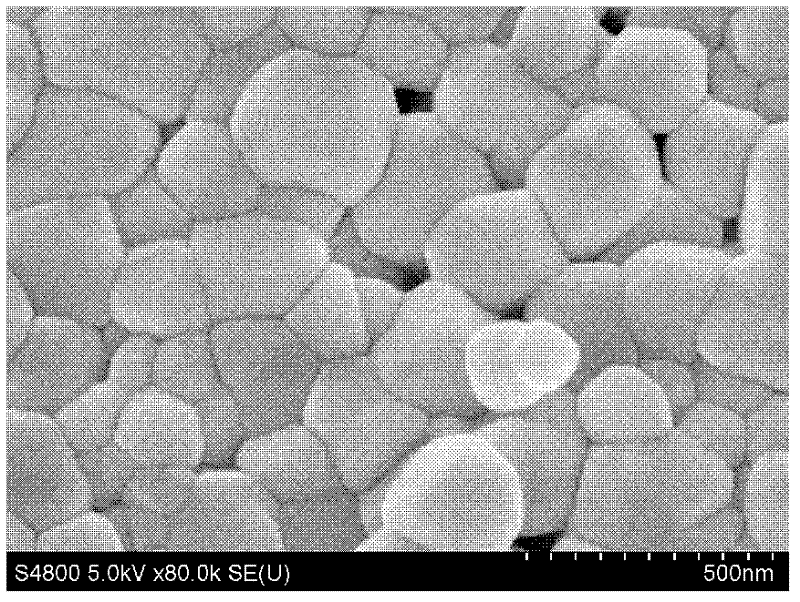

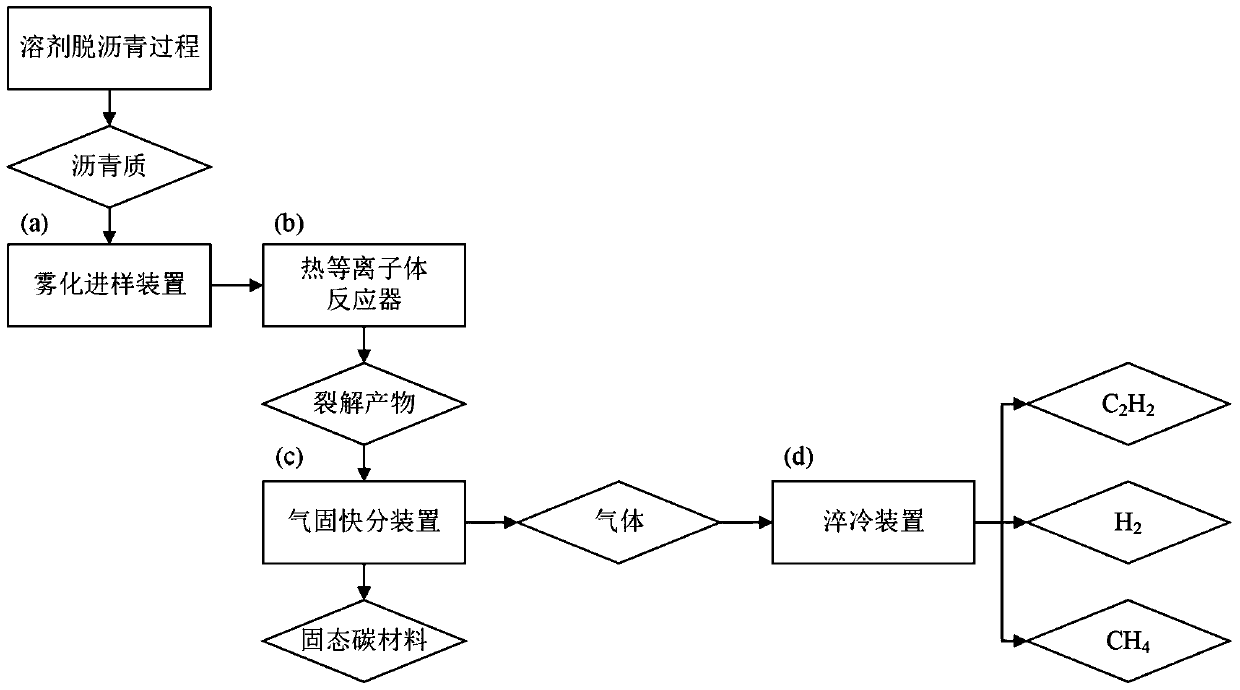

Asphaltene thermal plasma cracking processing method

ActiveCN106866334AAvoid simultaneous coolingImprove cooling efficiencyHydrogenHydrogen/synthetic gas productionPlasma jetGas phase

An asphaltene thermal plasma cracking processing method comprises the following steps: a) asphaltene produced by an inferior heavy oil solvent deasphalting process is sprayed into a thermal plasma reactor through an atomization device; b) in the thermal plasma reactor, the asphaltene undergoes a mixed reaction with a hydrogen thermal plasma jet flow, and a crackate is obtained from the reaction; c) the crackate passes through a gas-solid fast separation device, and a solid phase product and a gas phase product with the temperature of 1600-2000 K are obtained, wherein the solid phase product is a solid carbon material; and d) the gas phase product enters a quenching device, and cracked gas containing acetylene, hydrogen gas and methane is obtained. The method is suitable for processing the asphaltene produced by the inferior heavy oil solvent deasphalting process, can realize high efficiency conversion of the asphaltene, and produces high-added-value products such as the solid carbon material, acetylene, hydrogen gas and the like.

Owner:PETROCHINA CO LTD

Method for preparing BaTiO3 conductive ceramic powder by taking water as medium through rare earth phase-phase permeation

The invention discloses a method for preparing BaTiO3 conductive ceramic powder by taking water as a medium through rare earth phase-phase permeation, which relates to a synthesis method of an inorganic nanometer functional material and is used for overcoming the defects of high cost and non-environmental-friendliness existing in the conventional rare earth permeation method. In the method, waterinstead of an alcohol or amide organic solvent is taken as a permeation medium, so that cost is reduced, environmental pollution is prevented, the purity of a product is increased simultaneously, andthe repeatability of modification is enhanced. The method comprises the following specific steps of: raising the temperature of a furnace to be permeated to a set temperature of 750-900 DEG C; dripping distilled water into the furnace to exhaust air in the furnace; putting BaTiO3 ceramic powder into a permeated furnace; and dripping a permeation liquid containing rare earth elements into the furnace to obtain BaTiO3 conductive ceramic powder. The room temperature resistivity of a produced prepared with the method can be 10<-2> ohm.m, and the particle size of powder is 120-300 nanometers.

Owner:HARBIN INST OF TECH

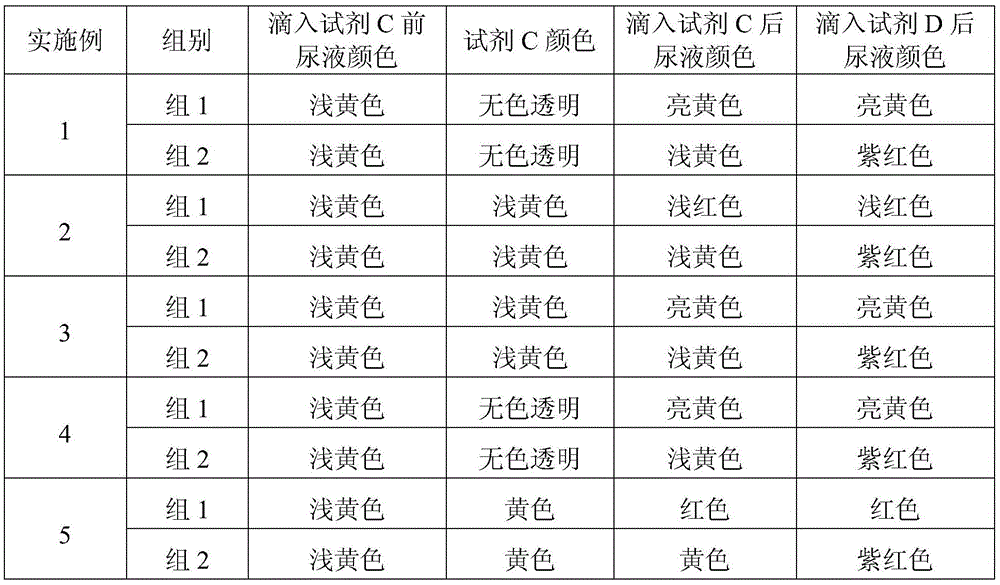

Para hydroxybenzene alanine urine detection kit and preparation method thereof

ActiveCN105606605AImprove stabilityHigh sensitivityMaterial analysis by observing effect on chemical indicatorETHYLENEDIAMINE DIHYDROCHLORIDEN-(1-Naphthyl)ethylenediamine

The invention provides a para hydroxybenzene alanine urine detection kit. The para hydroxybenzene alanine urine detection kit comprises a reagent A, a reagent B, a reagent C and a reagent D which are stored in four containers respectively. The reagent A is an inorganic acid water solution with the concentration of 0.01-0.5 mol / L. The reagent B is a sodium nitrite water solution with the concentration of 0.01-0.5 mol / L. The reagent C is an inorganic acid water solution of an aniline derivative with the concentration of 0.005-0.1 mol / L, the concentration of inorganic acid ranges from 0.01-0.5 mol / L, and a benzene ring of the aniline derivative at least comprises a sulfo group or a nitro group or a cyano group or a fluorine group. The reagent D is a water solution of N-1-naphthyl ethylenediamine dihydrochloride, and the concentration of N-1-naphthyl ethylenediamine dihydrochloride is 0.01-0.3 mol / L. The concentration of the aniline derivative in the reagent C is not higher than that of inorganic acid in the reagent A and that of sodium nitrite in the reagent B. Inorganic acid is selected from hydrochloric acid or sulfuric acid or tetrafluoroboric acid or hexafluorophosphoric acid. The invention further provides a preparation method of the kit. The detection kit has the good stability, reliability and broad spectrum.

Owner:张凤华

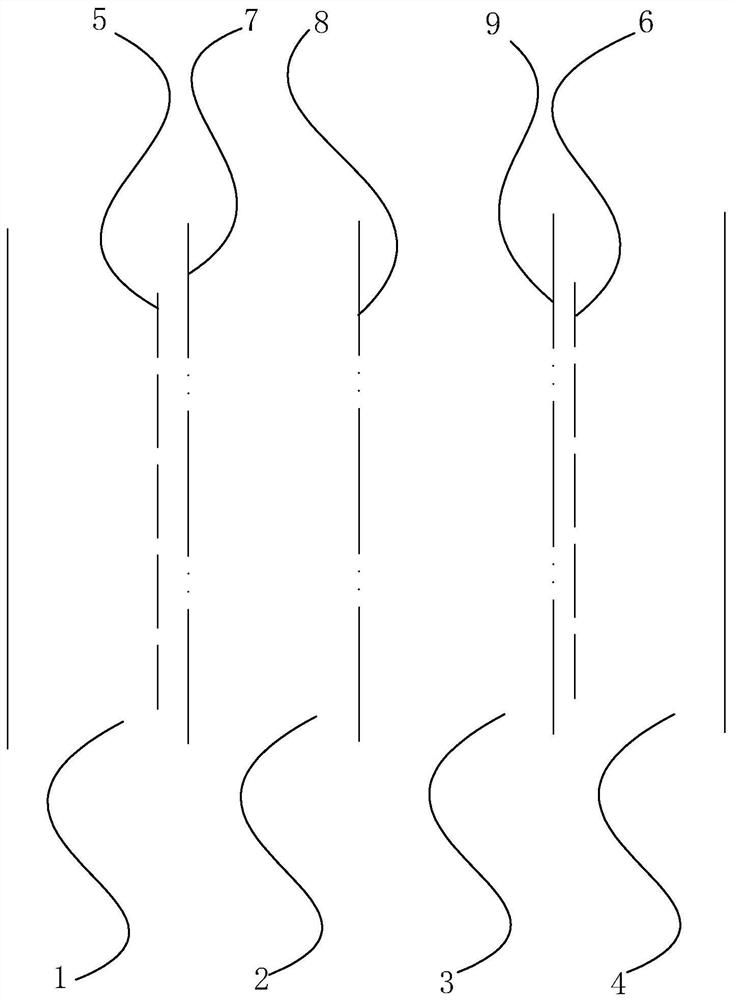

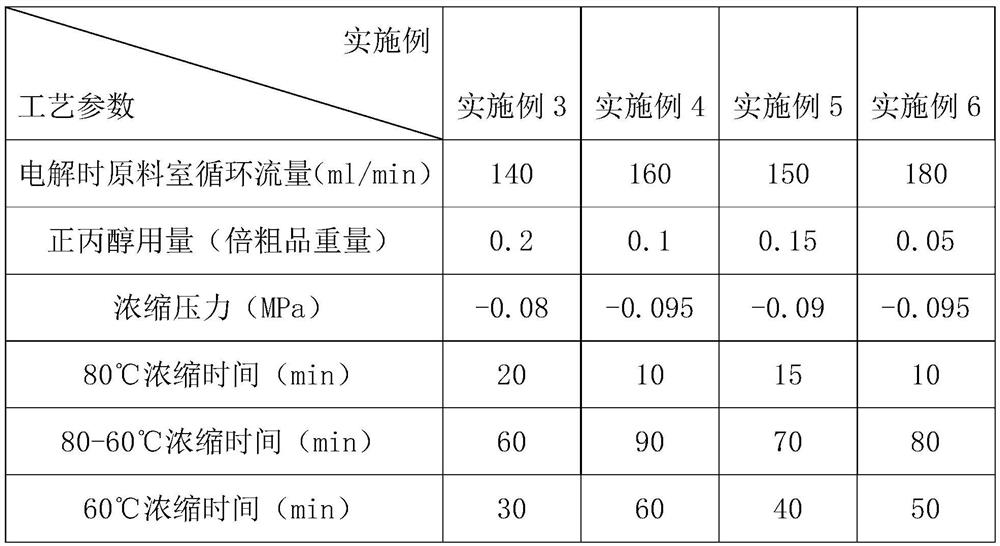

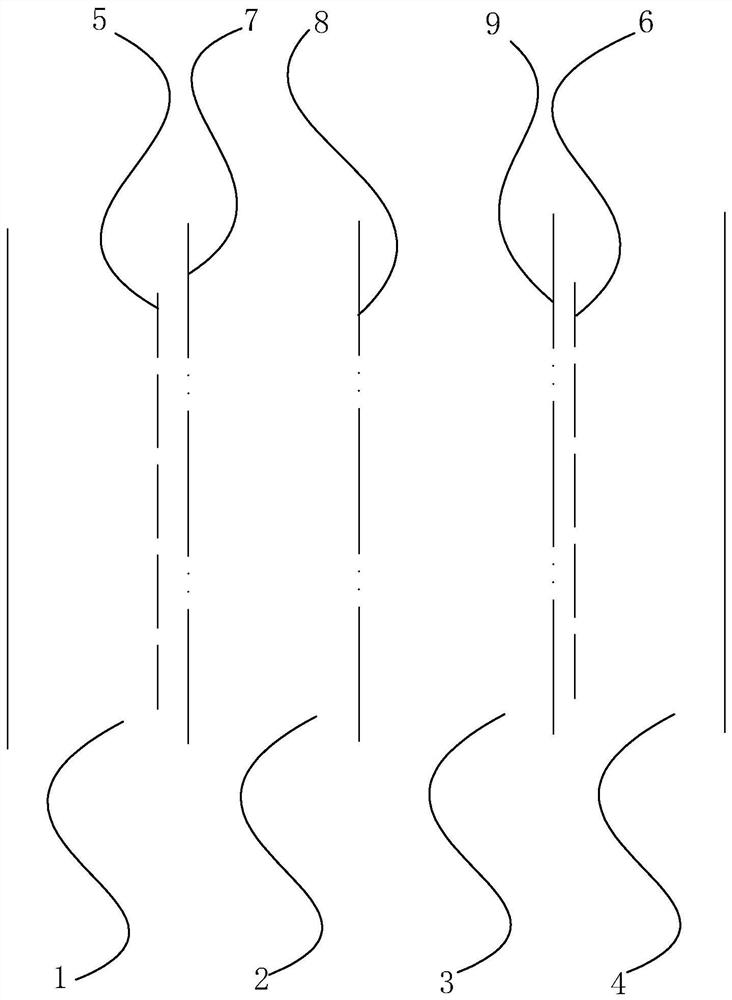

High-concentration tetrapropylammonium hydroxide production process and high-concentration tetrapropylammonium hydroxide prepared by production process

ActiveCN113235117APrevent decomposition reactionRaise the concentration temperatureCellsElectrolytic organic productionProcess engineeringAmmonium hydroxide

The invention discloses a high-concentration tetrapropylammonium hydroxide production process and high-concentration tetrapropylammonium hydroxide prepared by the production process, and relates to the technical field of quaternary ammonium base production. The high-concentration tetrapropylammonium hydroxide production process comprises the following steps: S1, electrolysis: taking tetrapropylammonium salt, adding water to prepare a tetrapropylammonium salt aqueous solution, combining tetrapropylammonium cations with hydroxyl ions generated by electrolysis through an electrolytic method to form tetrapropylammonium hydroxide, and preparing a crude product; and S2, concentration: adding n-propyl alcohol which is 0.05-0.2 time of the weight of the crude product into the crude product, uniformly mixing to obtain a mixed solution, heating the mixed solution to 60-80 DEG C, and concentrating for not less than 60 minutes to obtain the high-concentration tetrapropylammonium hydroxide. The high-concentration tetrapropylammonium hydroxide production process has the advantage of high production efficiency.

Owner:KENTE CATALYSTS INC

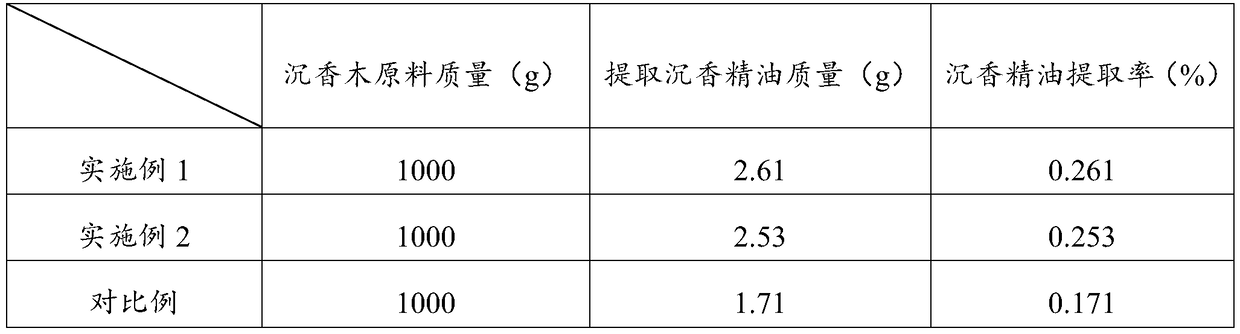

Agilawood essential oil extraction method

PendingCN109504541AEfficient separationPrevent decomposition reactionEssential-oils/perfumesThermal instabilityAgarwood

The invention discloses an agilawood essential oil extraction method. According to the technical scheme, agilawood is extracted according to a microwave extraction method, and microwave extraction refers to that the extraction efficiency of a solvent is enhanced by using microwaves, and certain organic components in a solid or a semi-solid test sample are effectively separated from substrate substances; the microwave heating time is short, and thermal unstable substances can be prevented from decomposition reactions; due to microwave extraction, rapidness and energy conservation can be achieved, the solvent can be saved, the pollution is low, and multiple test samples can be simultaneously treated; according to the technical scheme, two times of microwave extraction are implemented, so that volatile oil components in the agilawood can be well extracted, waste of raw materials is reduced, and the extraction efficiency can be improved.

Owner:FOSHAN UNIVERSITY

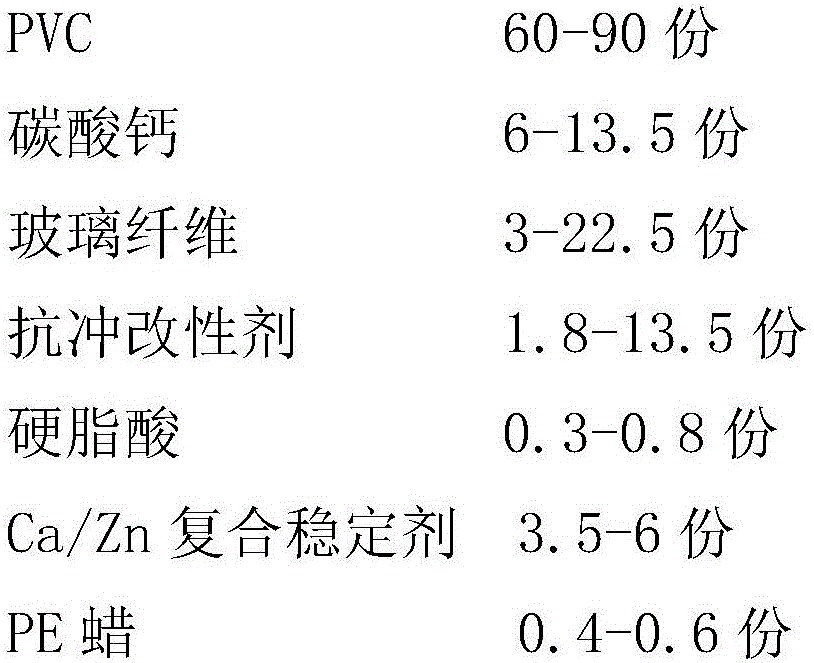

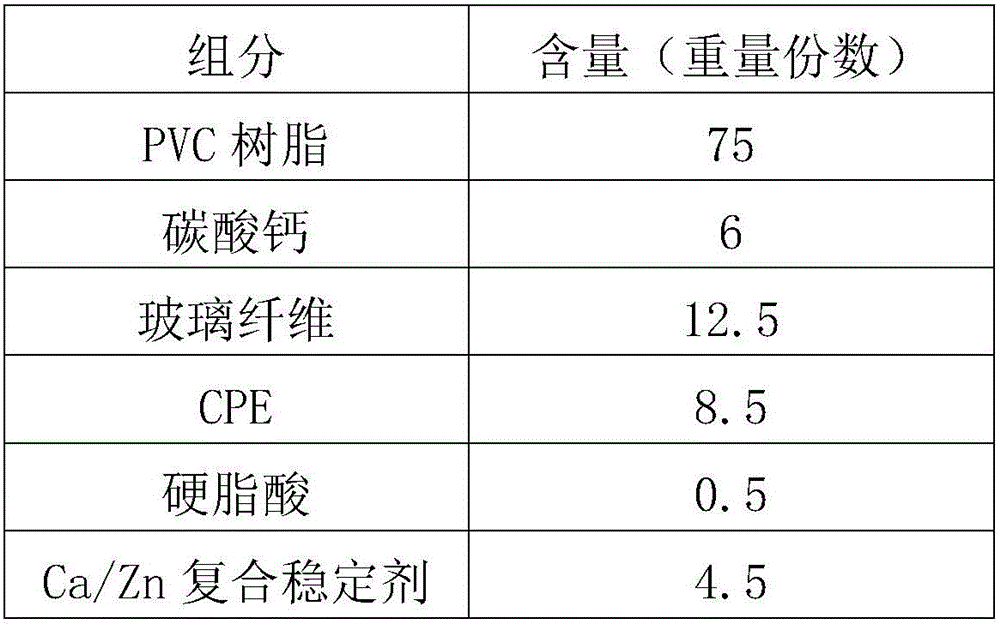

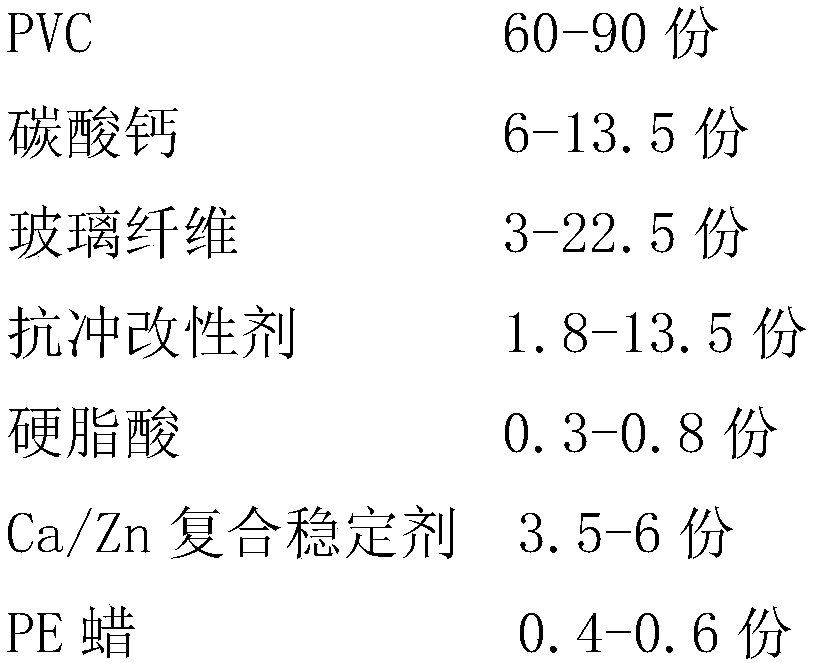

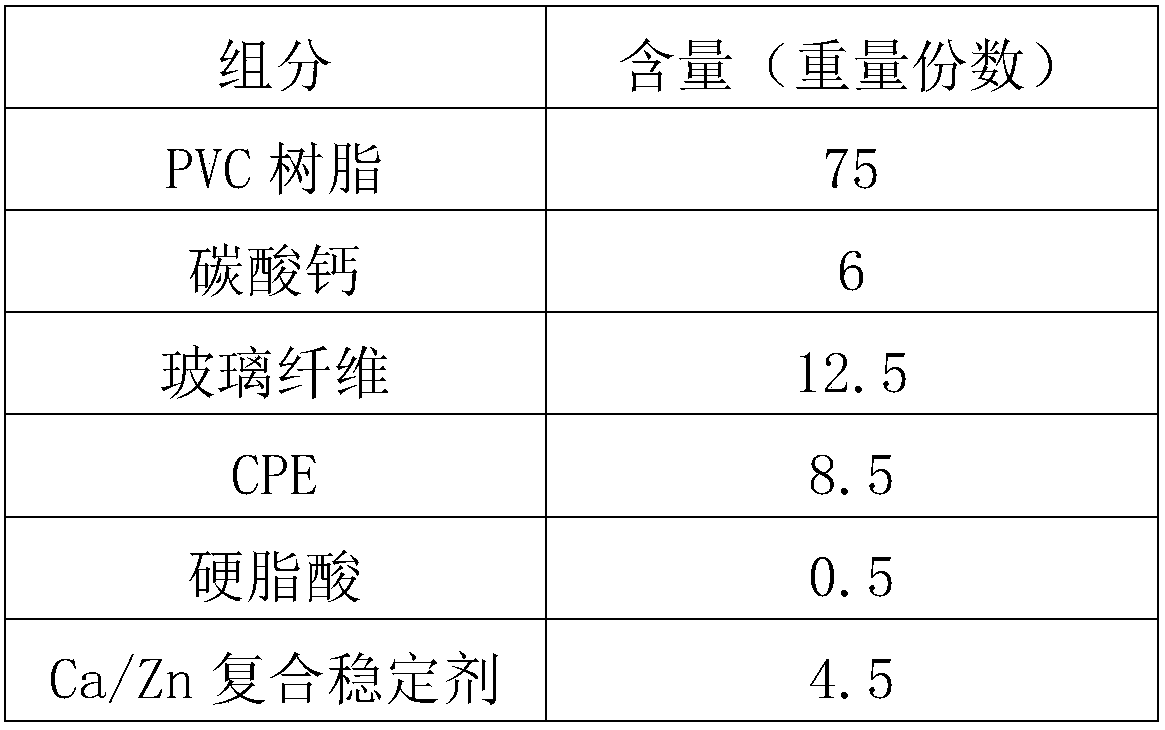

Wearproof glass fiber communication tube product and preparation method thereof

The invention discloses a wearproof glass fiber communication tube product. The wearproof glass fiber communication tube product comprises the raw materials shown in the specification in parts by weight in the formula of the communication tube product. An impact modifier is added in the formula of the glass fiber communication tube product, so that the toughness of the glass fiber communication tube product is improved, and the glass fiber communication tube product has the properties of compression resistance, impact resistance, high temperature resistance, and friction resistance.

Owner:WUJIANG JIATONG OPTICAL FIBER CO LTD

Safe production method of nitro-compound

ActiveCN103044261BEasy to separateEfficient separationNitric acid ester preparationNitro compound preparationNitro compoundAutomatic control

The invention provides a production method of nitro-compound. The production method comprises the steps of: continuously feeding a mixed acid solution from a heavy-phase inlet of a first centrifugal extraction separation device of a nitration separation system disclosed by the invention, and continuously feeding a raw material to be nitrified from a light-phase inlet of a final centrifugal extraction separation device at the same time, wherein the reaction temperature inside each centrifugal extraction separation device is controlled at 10-160 DEG C, and the rotating speed of each centrifugal extraction separation device is controlled at 800-2000 r / min; after multi-stage continuous nitration reaction, discharging final coarse nitride from a light-phase outlet of the first centrifugal extraction separation device, and discharging final waste acid from a heavy-phase outlet of the final centrifugal extraction separation device; and carrying out common alkali washing and water washing on the coarse nitride, and distilling the coarse nitride to obtain the refined nitro-compound product. According to the method disclosed by the invention, the nitration reaction is continuously carried out; the device is compact, easy to achieve automatic control, large in operation elasticity, and high in production efficiency; and as the reaction product and the waste acid are separated from each other at the same time inside the same reactor, the contact time of the reaction product and the waste acid is greatly shortened, side reaction is effectively avoided, energy consumption and material consumption are greatly reduced, and the security of the nitration reaction process is fundamentally ensured.

Owner:徐德良 +1

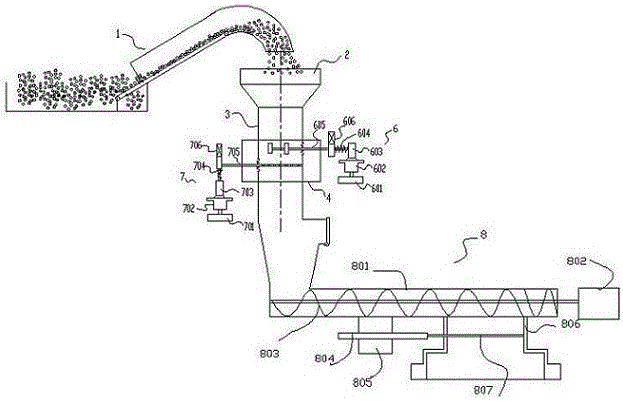

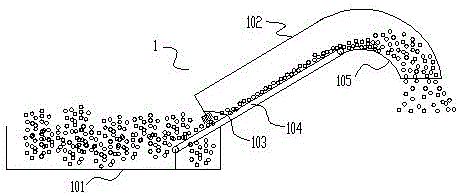

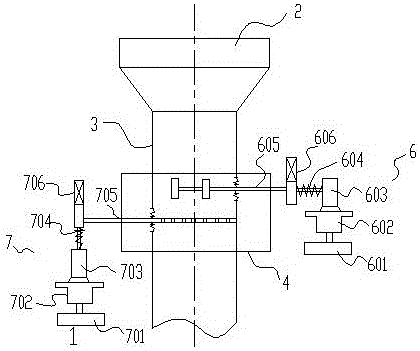

Front-end automatic feeding and screening iron removal device in the three-state decomposition process of rice husk

ActiveCN104741361BAvoid fireControl in and out speedGas current separationSolid waste disposalHuskDecomposition

Owner:HUNAN GULI NEW ENERGY TECH &SCI

Processing method of 13C urea

InactiveCN106631905AIncrease abundancePrevent decomposition reactionUrea derivatives preparationOrganic compound preparationDistillationNitrogen gas

The invention discloses a processing method of 13C urea. The processing method comprises the following steps: under conditions of moderate pressure and moderate temperature, carrying out five paths of procedures including synthesis, distillation, refining, crystallization and drying on production raw materials including sulfur, alcohols, hydrogen sulfide, nitrogen gas, ammonia gas and 13CO to obtain the 13C urea. The production of the13C urea produced by the processing method does not need a special synthesis tower; reaction only needs to be carried out in a common reaction kettle and an expensive catalyst is not added; a carbamoylurea impurity is often generated in a common urea reaction process,but the processing method does not generate related impurities.

Owner:JIANGSU HUAGEN TAILAI BIOTECH +1

Lithium ion battery and its preparing method

ActiveCN100505407CImprove high temperature stabilityImprove securityFinal product manufactureCell component detailsEngineeringLithium-ion battery

A lithium ion battery, the battery includes an electrode group and a non-aqueous electrolyte, the electrode group and the non-aqueous electrolyte are sealed in a battery case, the electrode group includes a positive electrode, a negative electrode and a diaphragm, wherein the diaphragm is a ceramic diaphragm. The lithium ion battery provided by the invention has good high temperature stability and safety performance.

Owner:江苏永茂普隆汽车配件制造有限公司

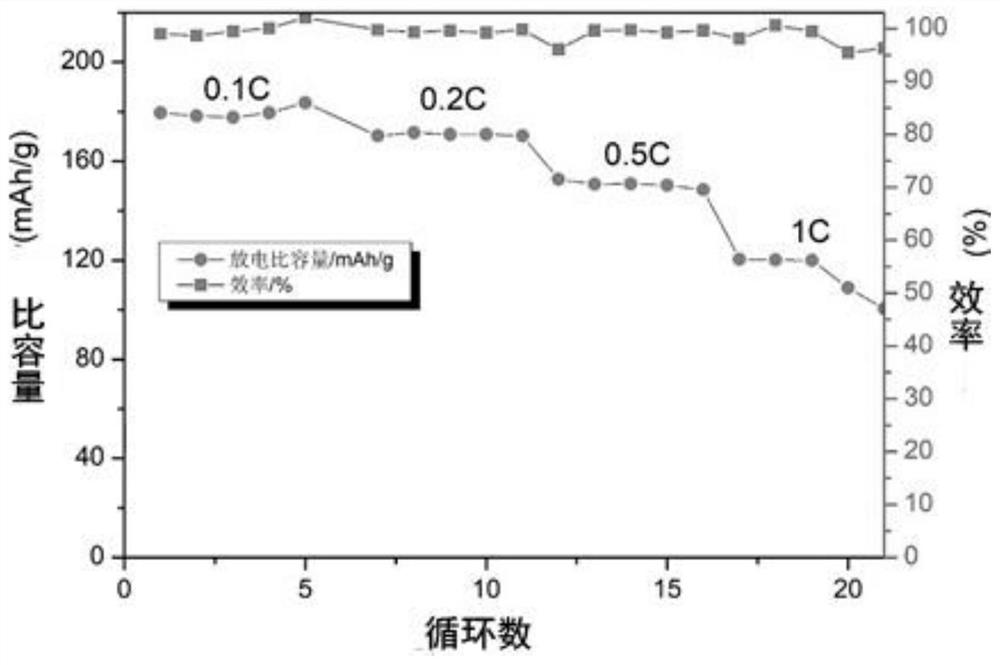

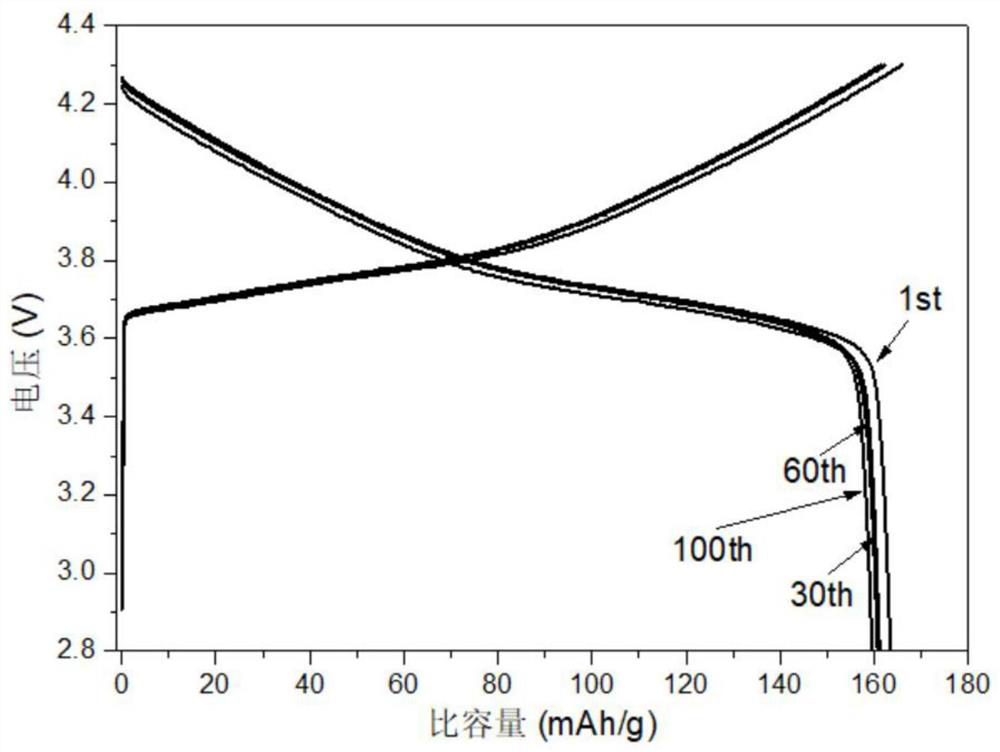

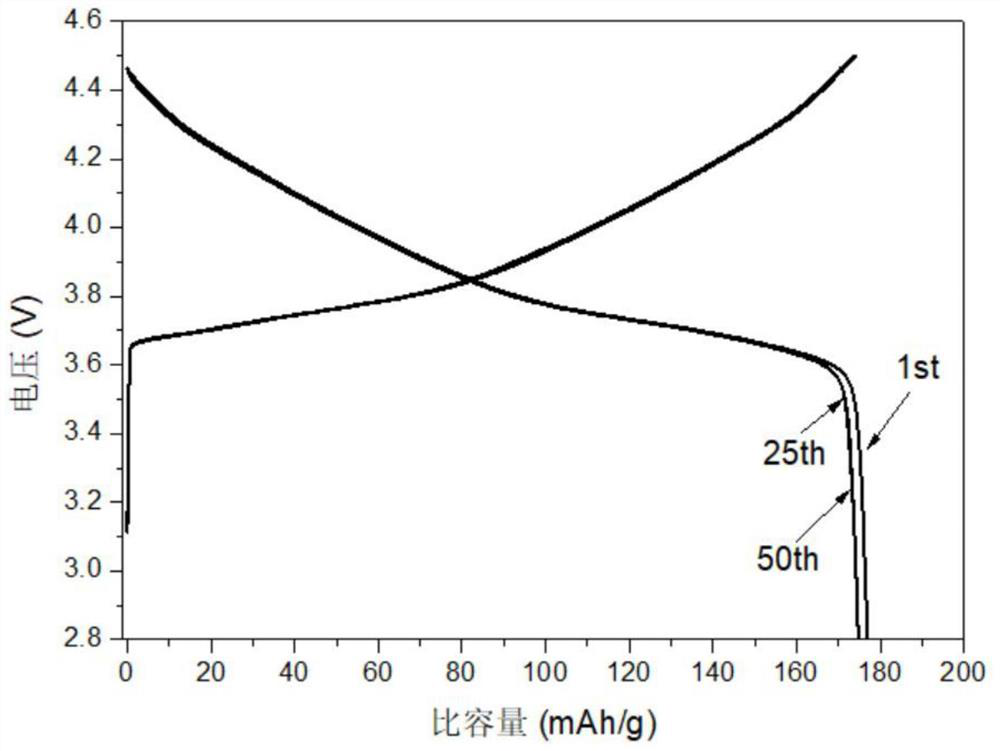

Electrolyte, application thereof and lithium ion battery

ActiveCN112838273AEnsuring High Pressure Chemical StabilityHas perfluorinated propertiesSecondary cellsElectrolytesElectrolytic agentElectrical battery

The invention belongs to the technical field of lithium ion batteries, and particularly relates to an electrolyte, application thereof and a lithium ion battery. The electrolyte provided by the invention comprises a solvent and a lithium salt, wherein the solvent is perfluoropolyether ester and a halogenated amide compound. According to the invention, the perfluoropolyether ester contains high-content fluorine atom substitution, so that the perfluoropolyether ester is not easy to oxidize and decompose under a high-voltage condition, and an assembled battery can maintain a relatively high capacity retention rate; the halogenated amide compound is used as a cosolvent of the electrolyte, is preferentially decomposed under a high-voltage condition, and reacts on the surface of the positive electrode to form a layer of stable protective film to coat the surface of the high-voltage positive electrode in situ, so that direct contact between the electrode and the electrolyte is avoided, and the cycle stability of the lithium ion battery under high voltage is further improved; the halogenated amide compound has a high dielectric constant, can dissociate a large amount of lithium salt, promotes rapid conduction of ions, and is beneficial to improving the electrochemical performance of the electrolyte.

Owner:吉林省东驰新能源科技有限公司

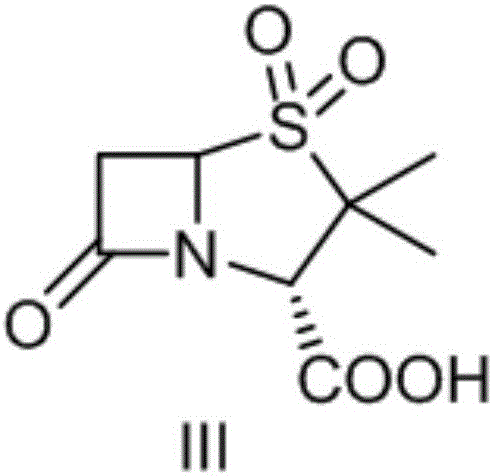

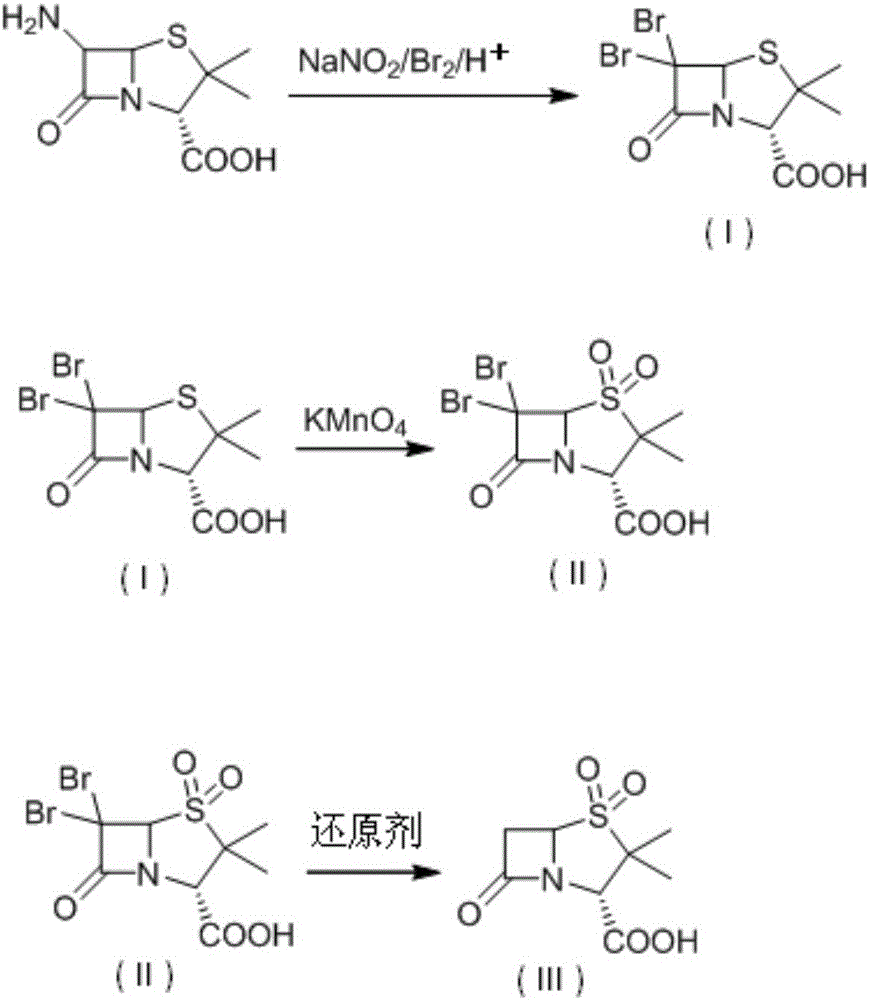

A kind of synthetic method of sulbactamic acid

ActiveCN104262359BPrevent decomposition reactionAvoid self-decomposition reactionsOrganic chemistrySulbactamAqueous solution

The invention discloses a synthetic method of salbactam acid. The synthetic method comprises the following steps: carrying out diazotized bromination reaction on 6-aminopenicillanic acid to form bromopenicillanic acid; and then, carrying out oxidation reaction and reduction reaction to obtain salbactam acid, wherein in the diazotized bromination reaction, 6-aminopenicillanic acid is continuously added in form of an acidic solution, the acidic solution of 6-aminopenicillanic acid is 5-8% sulfuric acid aqueous solution, 13-15% hydrobromic acid aqueous solution or 5-8% hydrochloric acid aqueous solution. 6-aminopenicillanic acid is dropwise added in form of the acidic solution, so that dust pollution is avoided and the work environment of field personnel is improved. Meanwhile, 6-aminopenicillanic acid exists in form of stable salt, decomposition reaction is avoided, and the reaction quality is improved. The three-step yield of the method is over 70%, the HPCL purity is over 99.7%, the individual impurity content is less than 0.1% and the total impurity content is less than 0.5%.

Owner:JIANGXI FUSHINE PHARMA CO LTD

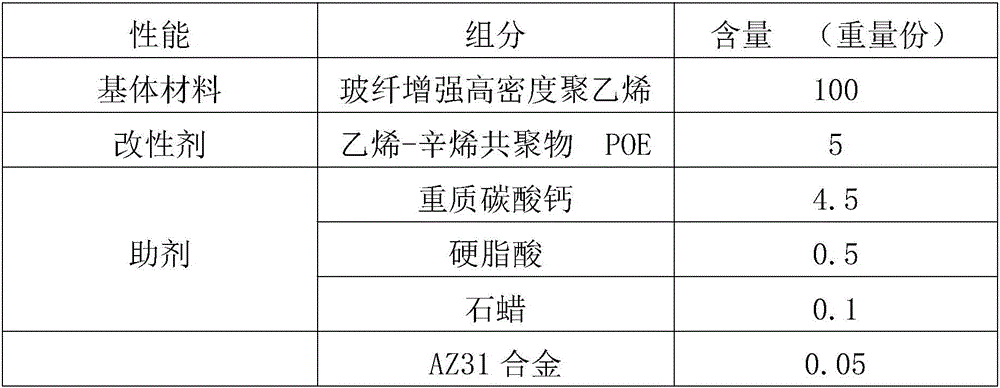

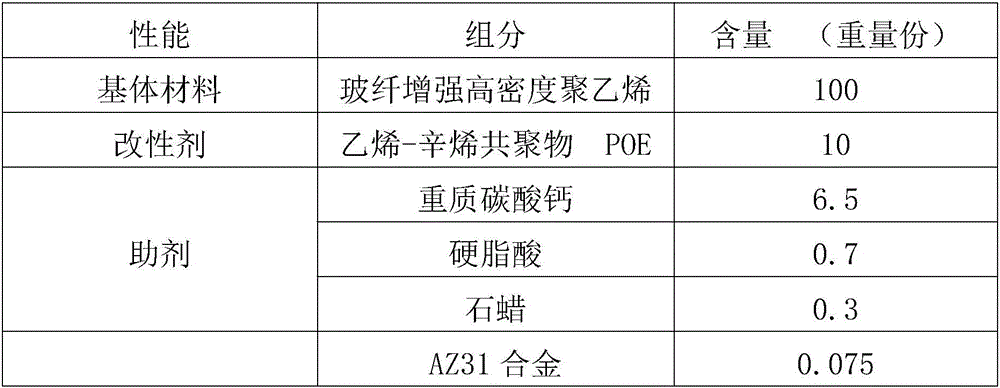

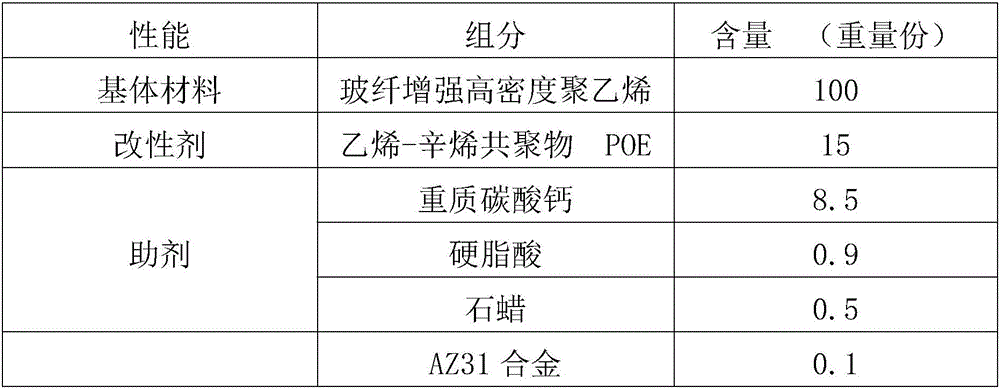

Preparation method of radiation-resistant communication pipe

The invention discloses a preparation method of a radiation-resistant communication pipe. The method comprises the following steps: (1) preparing glass fiber reinforced high-density polyethylene; (2) modifying the glass fiber reinforced high-density polyethylene; (3) carrying out drying; (4) feeding the material to a twin-screw extruder for extruding and granulating; (5) feeding aggregates prepared in the step (4) into an injection molding machine after drying, and carrying out injection molding to prepare a molded communication pipe; and (6) carrying out performance analysis on the communication pipe prepared in the step (5). Through improvement of the material formula of the communication pipe and control on the preparation technology, the tenacity of the communication pipe is improved; and the communication pipe has high specific strength and specific stiffness and relatively good electromagnetic shielding performance.

Owner:WUJIANG JIATONG OPTICAL FIBER CO LTD

A kind of preparation method of modified limestone powder

ActiveCN107349920BHigh surface energyAvoid condensationGas treatmentOther chemical processesMicrocrystalline waxNon toxicity

The invention provides a preparation method of modified limestone powder. The method comprises the following operation steps that (1) after big blocks of limestone are subjected to crushing treatment by a jaw type crushing machine, the limestone is sieved by a sieve being 20 to 30 meshes; (2) the sieved limestone is mixed with microcrystalline wax, then, an obtained mixture is conveyed to a material storage hopper by an elevator; next, the materials are uniformly, quantitatively and continuously conveyed into a host grinding chamber of an European style powder grinding machine to be ground through a vibration feeding machine; the ground limestone powder is blown up by wind and is graded by a powder selection machine; 325-mesh modified limestone powder is prepared. The preparation method of the modified limestone powder provided by the invention has the advantages that the operation is simple; the raw materials can be easily obtained; the manufacturing cost is low; the performance is stable; non-toxicity and harmlessness are realized; environment is protected; no pollution is caused; the preparation method is suitable for large-scale industrial production.

Owner:阳泉元丰建材有限公司

A wear-resistant glass fiber communication pipe and its preparation method

The invention discloses a wearproof glass fiber communication tube product. The wearproof glass fiber communication tube product comprises the raw materials shown in the specification in parts by weight in the formula of the communication tube product. An impact modifier is added in the formula of the glass fiber communication tube product, so that the toughness of the glass fiber communication tube product is improved, and the glass fiber communication tube product has the properties of compression resistance, impact resistance, high temperature resistance, and friction resistance.

Owner:WUJIANG JIATONG OPTICAL FIBER CO LTD

A kind of high-concentration tetrapropyl ammonium hydroxide production process and the high-concentration tetrapropyl ammonium hydroxide prepared therefrom

ActiveCN113235117BPrevent decomposition reactionRaise the concentration temperatureCellsElectrolytic organic productionPropanolHigh concentration

Owner:KENTE CATALYSTS INC

Method for preparing polyvinyl alcohol nano fibrous membrane containing nano silver and amino acid

The invention relates to a method for preparing a polyvinyl alcohol nano fibrous membrane containing nano silver and amino acid, which comprises the following steps: dissolving polyvinyl alcohol in a mixed solution of formic acid and deionized water, adding into a two-fluid beaming electrostatic spinning pouring pipe A, adding a complex solution generated from amino acid and silver ion into a two-fluid beaming electrostatic spinning pouring pipe B, gathering the two solutions in a sprayer C under the action of gravity, connecting a high-voltage generator to carry out electrostatic spinning while controlling the voltage at 15-20 KV, and receiving fibers with a metal flat plate; and crosslinking the received fibers in formaldehyde and concentrated acetic acid gas phase, and meanwhile, reducing the silver ion in silver histidine to obtain the nano silver, wherein the obtained nano fiber is hydrophilic, but can be easily dissolved in water. The preparation method provided by the invention is simple and high in yield; and the nano fibrous membrane has the advantages of high stability, high mechanical properties and favorable antimicrobial property, and can be used in the fields of medical treatment, cosmetics, food and the like.

Owner:JILIN AGRICULTURAL UNIV

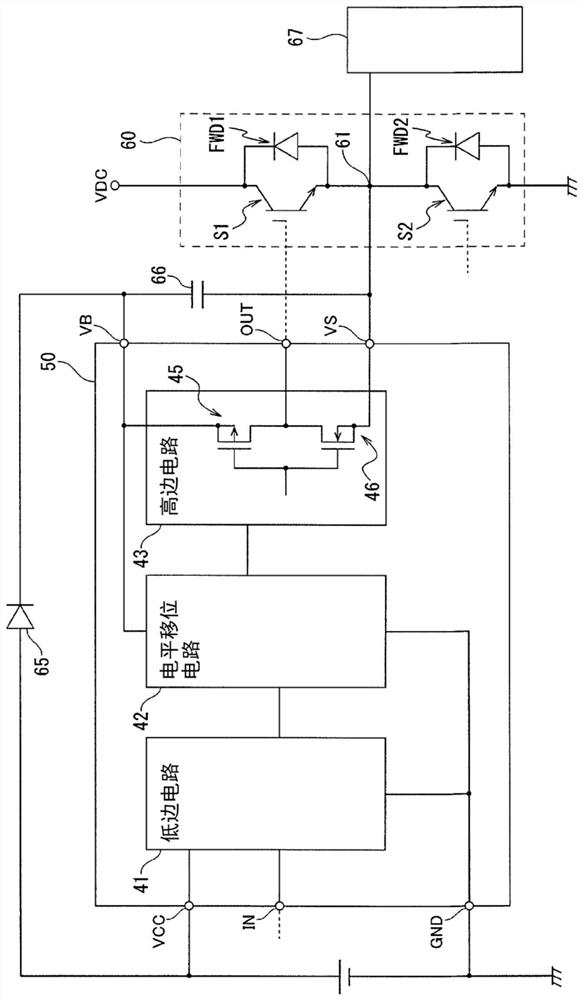

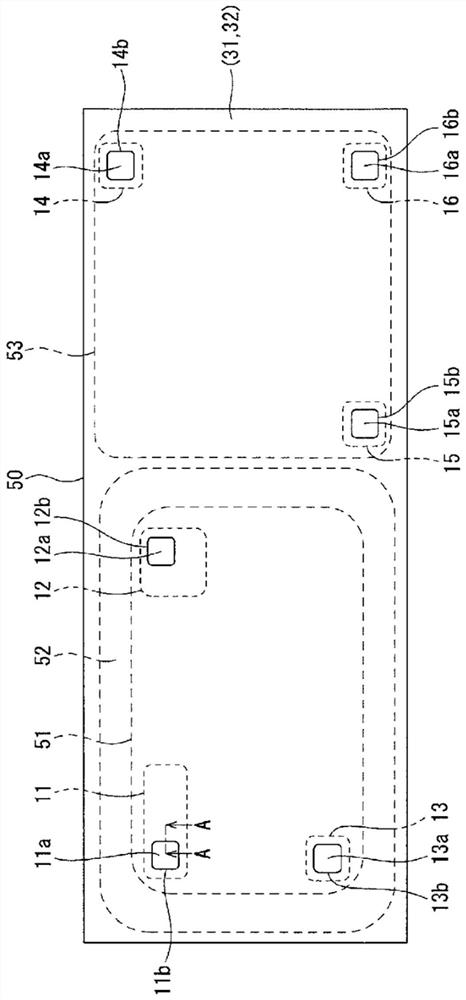

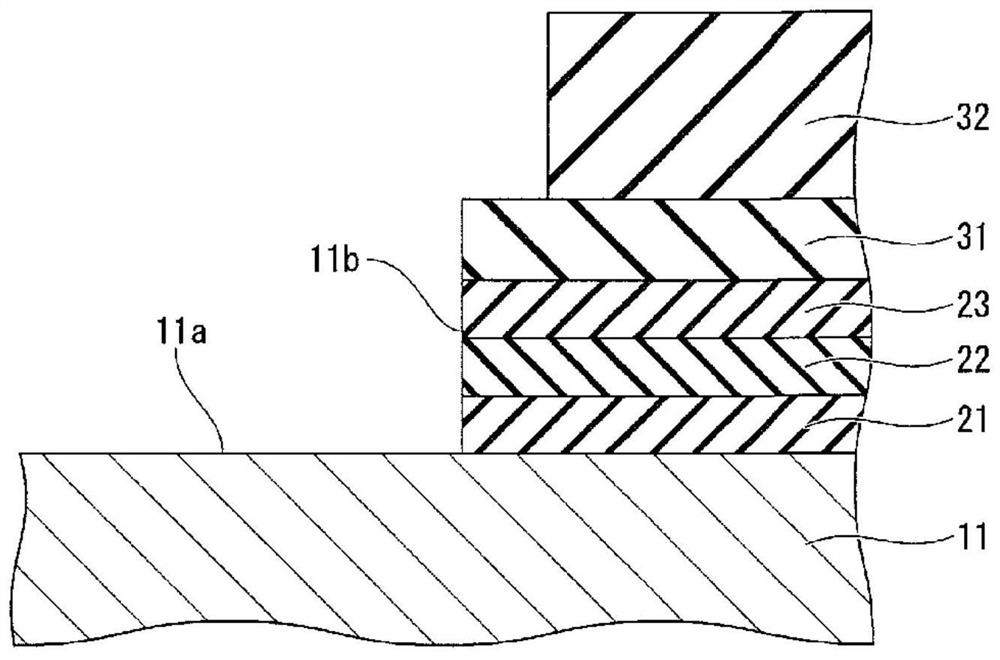

Semiconductor device, and manufacturing method for same

PendingCN113661571APrevent decomposition reactionAvoid corrosionConversion constructional detailsSemiconductor/solid-state device detailsDevice materialTitanium nitride

Provided is a semiconductor device capable of preventing, inter alia, the decomposition reaction of an antireflection film provided on a semiconductor substrate and the corrosion of a wiring layer, and capable of improving reliability. The semiconductor device comprises: a wiring layer (11); a titanium nitride layer (21) provided on the wiring layer (11); a titanium oxynitride layer (22) provided on the titanium nitride layer (21); a titanium oxide layer (23) provided on the titanium oxynitride layer (22); and surface protective films (31, 32) provided on the titanium oxide layer (23). The semiconductor device also has an opening (11b) that passes through the titanium nitride layer (21), the titanium oxynitride layer (22), the titanium oxide layer (23), and the surface protective films (31, 32) to expose a part of the wiring layer (11), and the exposed part of the wiring layer (11) constitutes a pad (11a).

Owner:FUJI ELECTRIC CO LTD

Method of using cotton linter to directly prepare microcrystalline cellulose

ActiveCN106400567AIntegrity guaranteedInhibit side effectsWashing/displacing pulp-treating liquorsPulp bleachingAmylaseCellulase

The invention discloses a method of using cotton linter to directly prepare microcrystalline cellulose and belongs to the technical field of biology. The method includes: using special protease and special normal-temperature amylase to successfully and efficiently remove protein and starch at normal temperature; using alkali liquid to remove hemicellulose, lignin, ash and greasy substance; adopting special cellulase to partly degrade cellulose molecules; maintaining pH to slightly alkaline to enable a cellulose molecule crystal area to be protected, wherein functions of a cellulase damaging crystal area are weakened under slightly alkaline conditions to retain a segment of the cellulose molecule crystal area, and the segment is the microcrystalline cellulose. Ingredients like protein, starch, grease, ash, hemicellulose and lignin in the cotton linter are successfully removed through a simple process, the segment of the cellulose molecule crystal area is retained effectively, and the microcrystalline cellulose having excellent quality is obtained. The method is simple in process and easy to operate and popularize.

Owner:JINAN MIDUOTAN NEW ENERGY TECH

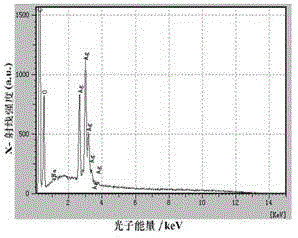

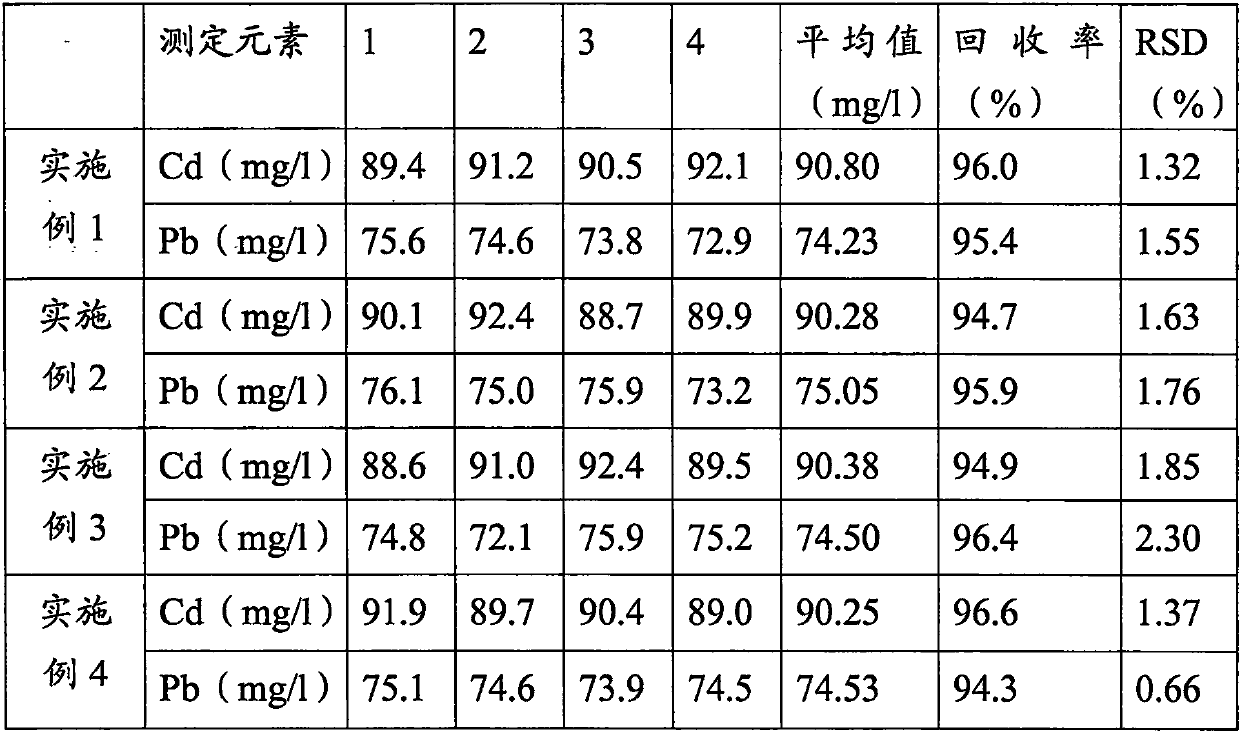

Method for determining heavy metal content in edible packaging material

InactiveCN109682764AAvoid circulationReduce usageColor/spectral properties measurementsFood safetyDigestion Treatment

The invention discloses a method for determining the heavy metal content in an edible packaging material. The method comprises the following steps: (1) sequentially pulverizing and drying the edible packaging material; (2) putting the dried edible packaging material after drying in a clean and dry polytetrafluoroethylene pressure digestion tank, then adding digestion solution for digestion treatment, and obtaining a solution to be determined; (3) conducting qualitative and quantitative analysis on heavy metals in the solution to be determined by adopting a flame atomic absorption spectrophotometer. The method utilizes the flame atomic absorption spectrophotometer to conduct trace detection on the heavy metals in the edible packaging material, can quickly, effectively and accurately determine the heavy metal content in the edible packaging material, accordingly effectively prevents heavy metal polluted edible packaging materials from being circulated on the market and improves food safety performance.

Owner:新疆出入境检验检疫局检验检疫技术中心 +1

Thermal plasma cracking treatment method of asphaltenes

ActiveCN106866334BAvoid simultaneous coolingImprove cooling efficiencyHydrogenHydrogen/synthetic gas productionSolid carbonPlasma jet

Owner:PETROCHINA CO LTD

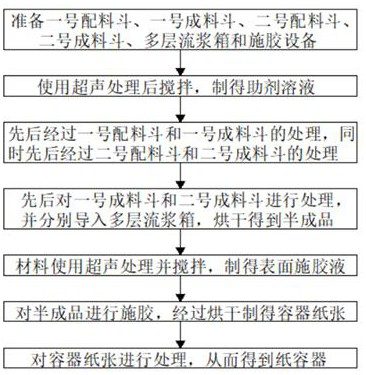

Preparation method of high-temperature-resistant, high-water-resistant and anti-deformation paper container

InactiveCN114411449ASmall apertureImprove compactnessFlexible coversWrappersProcess engineeringLactose

The invention belongs to the field of food packaging, particularly relates to a preparation method of a high-temperature-resistant, high-water-resistant and anti-deformation paper container, and provides the following scheme aiming at the problems that an existing paper container is not resistant to high temperature, poor in water resistance, poor in oil resistance and prone to deformation. The method comprises the following steps that a first batch hopper, a first forming hopper, a second batch hopper, a second forming hopper, a multi-layer headbox and sizing equipment are prepared, chitosan, microcrystalline cellulose and lactitol are used for improving the oil resistance of paper, high-temperature-resistant powder is used for improving the high-temperature-resistant capacity of a paper container, the paper is prevented from becoming brittle, and the paper container is made of paper. A waterproof film can be formed on the surface of the paper container through the surface sizing liquid, the waterproof capacity of the paper container is enhanced, the paper container has the advantages of high temperature resistance, water resistance and oil resistance, meanwhile, a double-layer structure is adopted, strength is high, toughness is good, impact resistance is achieved, stability is high, and the manufactured paper container is not prone to deformation.

Owner:福建益百利包装材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com