Front-end automatic feeding and screening iron removal device in the three-state decomposition process of rice husk

A technology of decomposition process and automatic feeding, which is applied in the removal of solid waste, separation of solids, and separation of solids from solids by air flow. , Avoid equipment blockage and ensure the effect of environmental sanitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

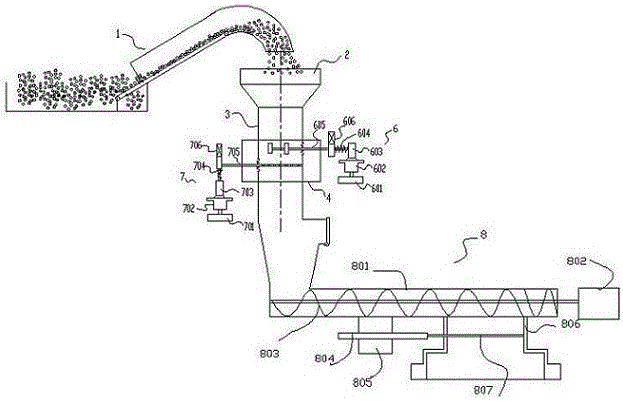

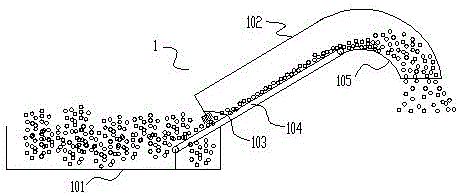

[0033] Such as figure 1 As shown, the structural relationship of the present invention is: it includes the outer conveying mechanism 1 that is connected in sequence, the screening deironing mechanism, and the feeding mechanism 8; The feed conveying pipe 102 connected above the bucket 101 is arranged on the conveyer belt 104 inside the feed conveying pipe 102; The corner of the feed elbow 105;

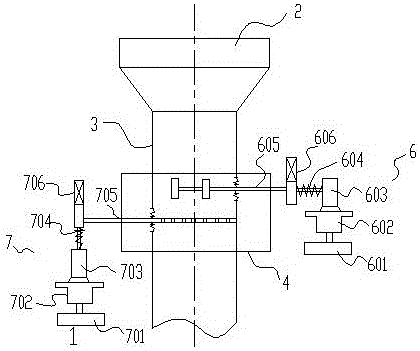

[0034] The screening and deironing mechanism includes: a hopper 2 arranged below the feeding elbow 105, a conveying pipe 3 is arranged below the hopper 2; a vibrating cover 4 is installed on the conveying pipe 3, and the inside of the vibrating cover 4 is sequentially arranged from top to bottom. The first vibrating device 6 and the second vibrating device 7 are connected; the first vibrating device 6 includes: a first vibrating rod 605 arranged in the vibrating cover 4, a first electromagnet arranged at the outer end of the first vibrating rod 605 606. The first vibration motor 603 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com