Preparation method of radiation-resistant communication pipe

A communication pipe and anti-radiation technology, which is applied in the field of preparation of radiation-resistant communication pipes, can solve the problems of PE pipes such as easy aging, low strength, and low service life, so as to avoid uneven mixing and distribution, avoid decomposition reactions, and reduce processing time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

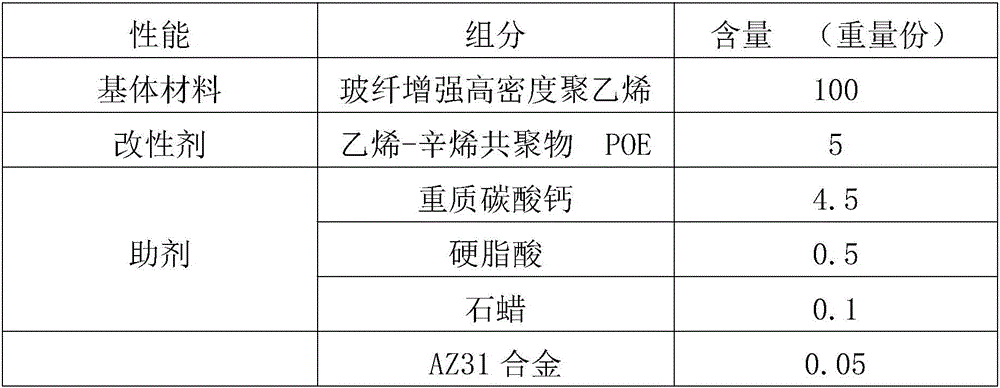

Embodiment 1

[0026] Embodiment 1 discloses a method for preparing a radiation-resistant communication pipe, which includes the following steps:

[0027] Step 1. Take 100 parts of high-density polyethylene and 15 parts of glass fiber for drying treatment, add a high-speed mixer, and mix for 1.5 minutes; put the mixture into a twin-screw extruder to extrude and granulate to obtain glass fiber reinforcement High-density polyethylene; the extrusion granulation process conditions are: the temperature of the first stage is 110°C, the temperature of the second stage is 120°C, the temperature of the third stage is 125°C, the temperature of the fourth stage is 130°C, the temperature of the fifth stage is The temperature of the sixth stage is 135°C, the temperature of the sixth stage is 140°C, the temperature of the head is 155°C, the temperature of the melt is 150°C, the feeding speed is 15.5r / min, the speed of the main engine is 36.5r / min, and the traction speed is 43.5r / min .

[0028] Step 2, th...

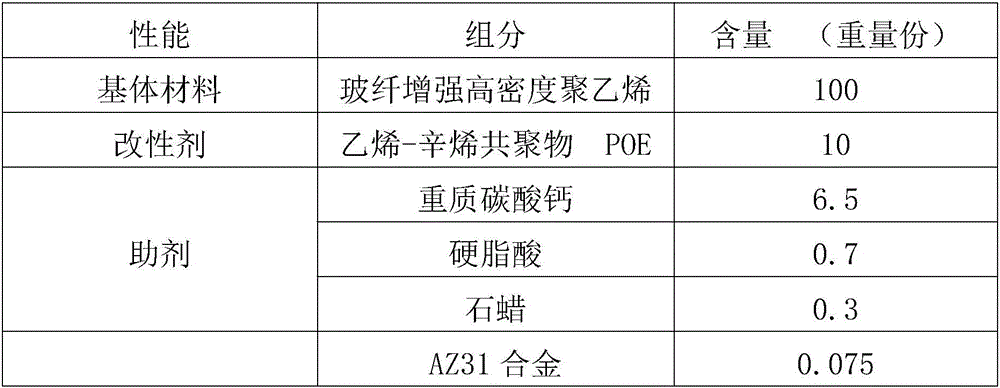

Embodiment 2

[0037] The preparation process in Example 2 is the same as that in Example 1, the difference lies in the formula of the pipe material, and the material formula in Step 2 is shown in Table 2.

[0038] Formulation table in table 2 embodiment 2

[0039]

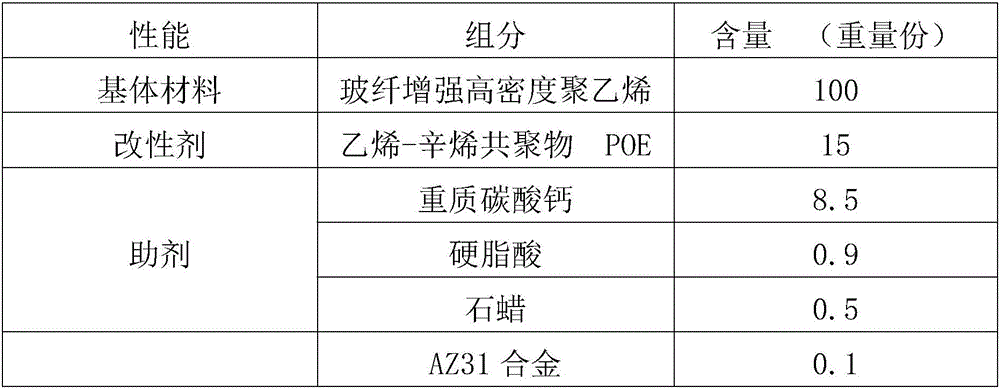

Embodiment 3

[0041] The preparation process in Example 3 is the same as that in Example 1, the difference lies in the formula of the pipe material, and the material formula in Step 2 is shown in Table 3.

[0042] Formulation table in the embodiment 3 of table 3

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com