Electrolyte, application thereof and lithium ion battery

A lithium-ion battery and electrolyte technology, applied in the field of lithium-ion batteries, can solve the problems of reducing the electrochemical performance of high-voltage lithium-ion batteries, the process of intercalating and removing lithium cannot be carried out normally, and the cycle performance of electrolyte is deteriorating, so as to improve cycle stability performance, ensure high voltage chemical stability, and excellent cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The preparation method of the electrolyte is not particularly limited in the present invention, and a preparation method well known to those skilled in the art can be adopted, specifically, such as directly mixing a lithium salt with a solvent.

[0050] The present invention also provides the application of the electrolyte solution described in the above technical solution in lithium-ion batteries.

[0051] The present invention has no special limitation on the application, and the application to the lithium ion electrolyte well known to those skilled in the art can be used.

[0052] The present invention also provides a lithium ion battery, comprising a positive electrode, an electrolyte, a diaphragm and a negative electrode, the electrolyte being the electrolyte described in the above technical solution.

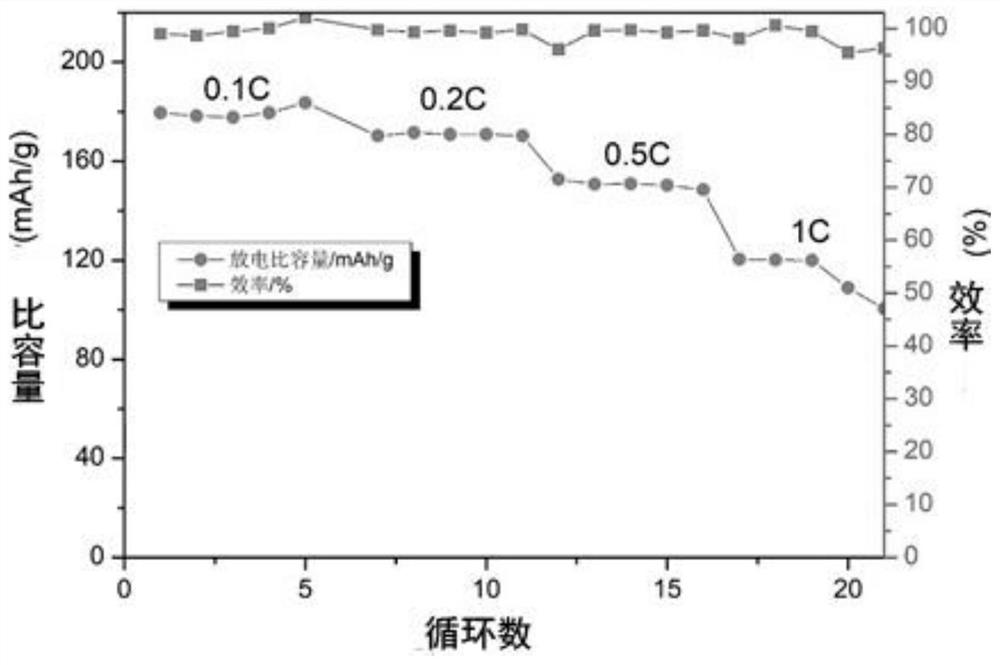

[0053] In the present invention, the working voltage of the lithium ion battery is preferably ≥4.3V.

[0054] In the present invention, the positive electrode pref...

Embodiment 1

[0061] In this embodiment, the perfluoropolyether ester is perfluoropolyether ethyl methyl carbonate, and the structural formula is Wherein, R is R4, and the n value is 2; the halogenated amide compound is trifluoropropionamide, and the structural formula is

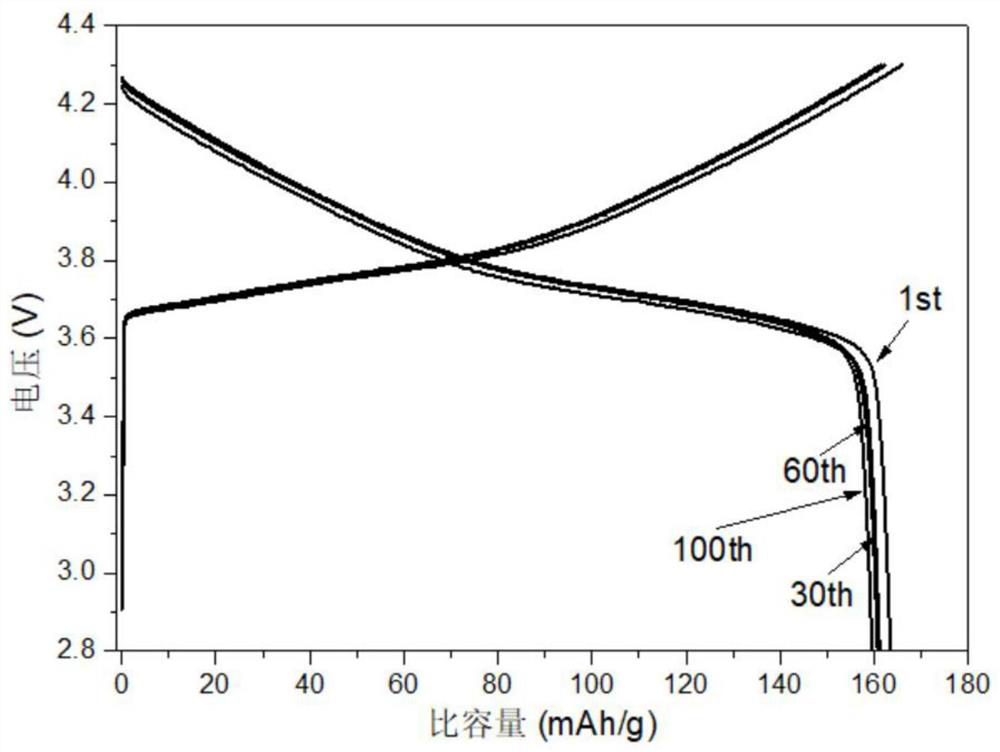

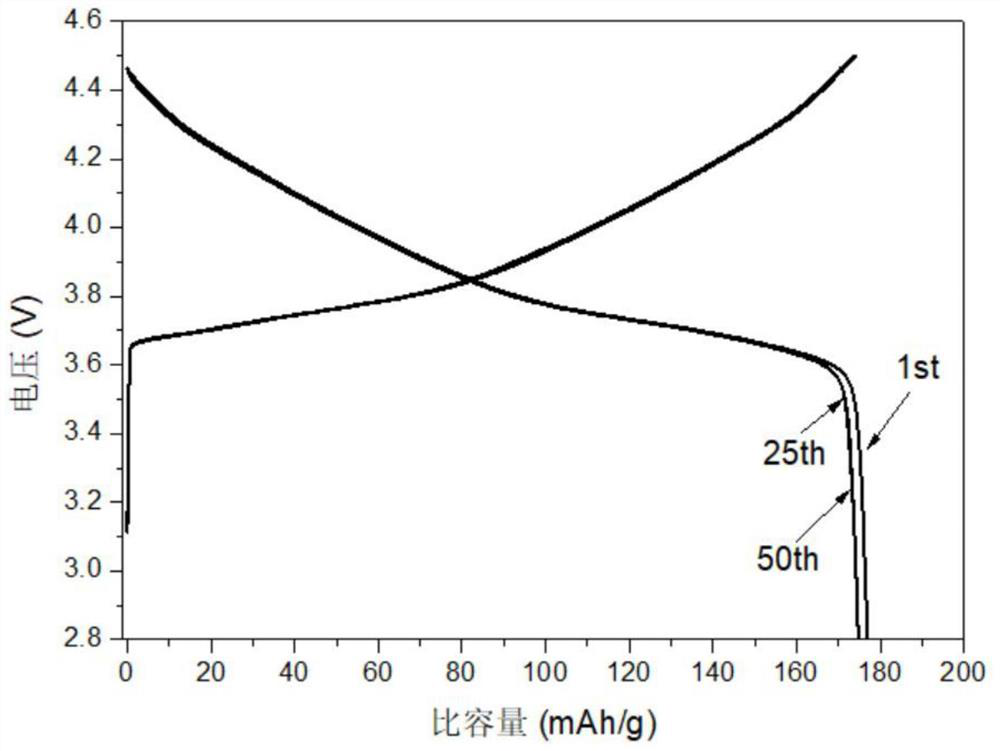

[0062] Perfluoropolyether ethyl methyl carbonate and trifluoropropionamide were prepared as the solvent of the electrolyte at a volume ratio of 4:1, and the obtained solvent was mixed with LiTFSI to obtain an electrolyte with a LiTFSI concentration of 2.5 mol / L.

Embodiment 2

[0067] In this embodiment, the perfluoropolyether ester is perfluoropolyether ethylene carbonate, and the structural formula is Wherein, R is R2, and the n value is 3; the halogenated amide compound is N,N-dimethyltrifluoroacetamide, and the structural formula is

[0068] Perfluoropolyether ethylene carbonate and N,N-dimethyltrifluoroacetamide are prepared as the solvent of the electrolyte according to the volume ratio of 3:1, and the obtained solvent is mixed with LiFSI to obtain an electrolyte with a LiFSI concentration of 2mol / L .

PUM

| Property | Measurement | Unit |

|---|---|---|

| molar mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com