Agilawood essential oil extraction method

A kind of agarwood essential oil, extraction technology, applied in the direction of essential oil/spice, fat production, etc., can solve the problems of raw material waste, the extraction efficiency of agarwood is not very high, and the agarwood is expensive, and achieves reduced waste, short heating time, and less pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

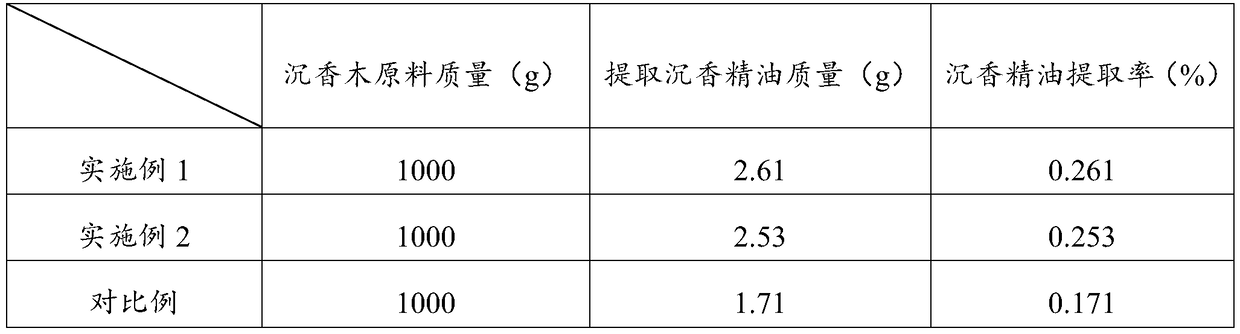

Examples

Embodiment 1

[0024] A method for extracting agarwood essential oil, comprising the following steps:

[0025] (1) raw material processing: crushing agarwood into agarwood powder, and spraying the agarwood powder so that the water content of the agarwood powder reaches 75%;

[0026] (2) The first microwave extraction: put the agarwood powder processed in step (1) into a physical bottle for solvent-free microwave extraction for the first microwave extraction, and the first microwave extraction method is intermittent The specific process of extraction is as follows: microwave output power is 400W, microwave extraction is 5 minutes, and the interval is 5 minutes, which is an extraction cycle, and this extraction cycle is repeated 6 times.

[0027] (3) The product obtained in step (2) was left to stand for 2 hours, and the oil layer was removed to obtain the first agarwood essential oil;

[0028] (4) The second microwave extraction: the agarwood powder after the first microwave extraction is pu...

Embodiment 2

[0034] A method for extracting agarwood essential oil, comprising the following steps:

[0035] (1) Raw material processing: crushing agarwood into agarwood powder, and spraying the agarwood powder so that the water content of the agarwood powder reaches 80%;

[0036] (2) The first microwave extraction: put the agarwood powder treated in step (1) into a physical bottle for solvent-free microwave extraction for the first microwave extraction, wherein the microwave output power is 200W, and the microwave extraction is 10min, and 10min is an extraction cycle, and this extraction cycle is repeated 6 times.

[0037] (3) The product obtained in step (2) was left to stand for 2 hours, and the oil layer was removed to obtain the first agarwood essential oil;

[0038] (4) The second microwave extraction: the agarwood powder after the first microwave extraction is put into an ethanol solution with a mass concentration of 90% and soaked for 3 to 5 hours. After the soaking is completed, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com