Semiconductor device, and manufacturing method for same

A manufacturing method and semiconductor technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve problems such as corrosion at the periphery of pads, and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0048]

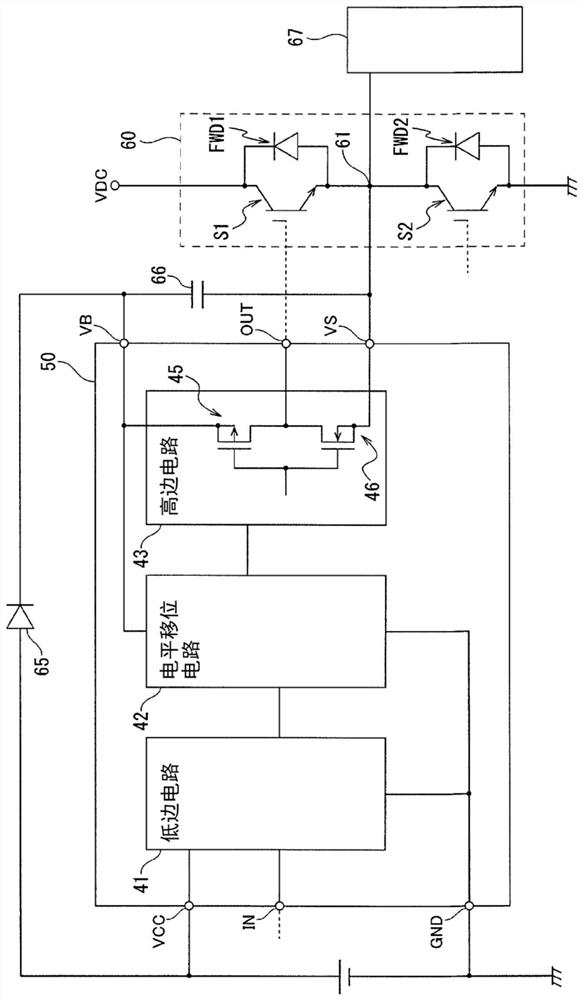

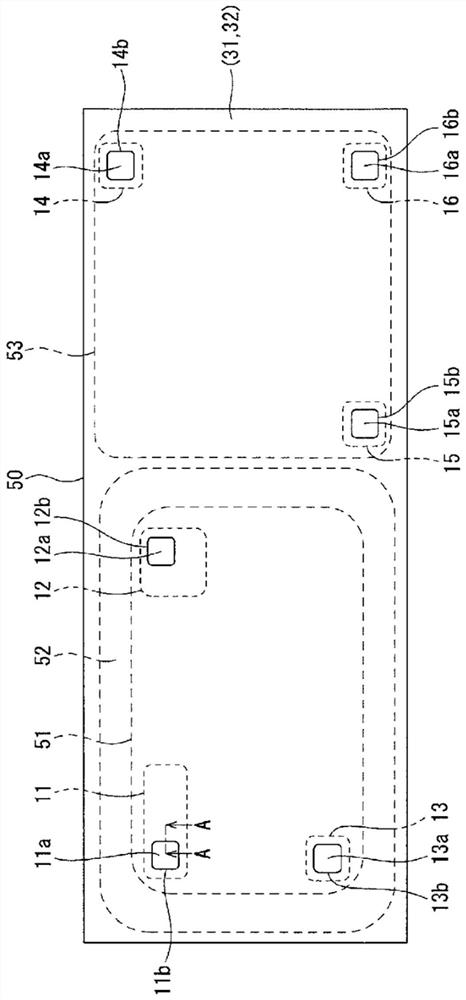

[0049] As the semiconductor device according to the first embodiment of the present invention, a high withstand voltage integrated circuit (hereinafter referred to as “HVIC”) that drives power switching elements constituting a bridge circuit for power conversion or the like is exemplified. Such as figure 1 As shown, the semiconductor device 50 according to the first embodiment of the present invention drives, for example, the power conversion unit 60 that is one phase of a bridge circuit for power conversion. In the power conversion unit 60 , the high-voltage side switching element S1 and the low-voltage side switching element S2 are connected in series to form an output circuit.

[0050]exist figure 1 In the above, the case where the high-voltage side switching element S1 and the low-voltage side switching element S2 are respectively IGBTs is exemplified, but the high-voltage side switching element S1 and the low-voltage side switching element S2 are not limited t...

no. 2 approach

[0098]

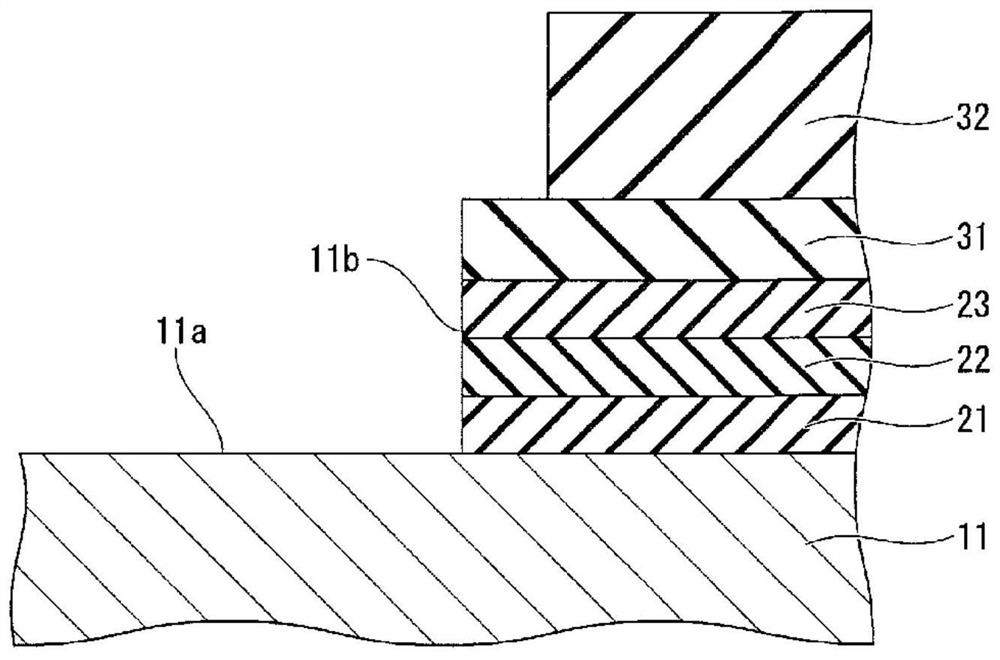

[0099] As the semiconductor device according to the second embodiment of the present invention, an HVIC is exemplified similarly to the semiconductor device according to the first embodiment of the present invention. Such as Figure 12 As shown, the semiconductor device according to the second embodiment of the present invention has wiring layers (high potential side wiring layers) 81 , 82 , and 83 in the uppermost layer of the multilayer wiring structure on the semiconductor substrate. Parts of the high-potential-side wiring layers 81 and 82 constitute pads (high-potential-side pads) 81a and 82a. The high potential side pads 81a, 82a are partitioned by openings 81b, 82b of a surface protection film (not shown). exist Figure 12 In , the openings 81b and 82b of the surface protection film are shown by dashed-dotted lines. The high-potential-side wiring layer 83 constitutes a meandering wiring pattern.

[0100] exist Figure 13 The left and right are shown side ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com