Preparation method of high-temperature-resistant, high-water-resistant and anti-deformation paper container

A technology for anti-deformation and paper containers, which is applied in papermaking, paper, wrapping paper, etc., can solve the problems of low temperature resistance, poor water resistance, poor oil resistance, etc., and achieve the effects of preventing moisture infiltration, increasing compactness, and improving oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further explained below in conjunction with specific embodiments.

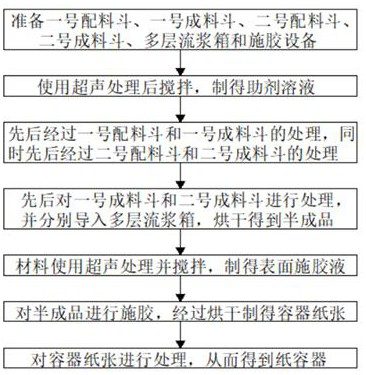

[0027] refer to figure 1 , embodiment one

[0028] In this example, a method for preparing a high-temperature-resistant, high-water-resistant, anti-deformation paper container is proposed, and base paper and modified materials are prepared, and the following steps are adopted:

[0029] S1: Prepare No. 1 batching hopper, No. 1 finishing hopper, No. 2 batching hopper, No. 2 finishing hopper, multi-layer headbox and sizing equipment;

[0030] S2: According to the mass percentage, 56 parts of polylactic acid are obtained and heated to 50 ℃ ~ 80 ℃, add 4 parts of chitosan, 3 parts of microcrystalline cellulose and 2 parts of sodium pyrophosphate dispersant, and use ultrasonic equipment Stir after treatment to prepare an additive solution. First prepare the polylactic acid into a 5% to 10% aqueous solution before heating, then heat the polylactic acid solution to 50°C to 80°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com