Method for determining heavy metal content in edible packaging material

A technology for packaging materials and heavy metals, applied in measuring devices, analytical materials, color/spectral characteristics measurement, etc., can solve problems such as detection of heavy metal content in edible packaging materials, liver and bone hazards, visceral toxicity, etc., to improve food safety Performance, improvement of drying effect, effect of accelerating drying rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

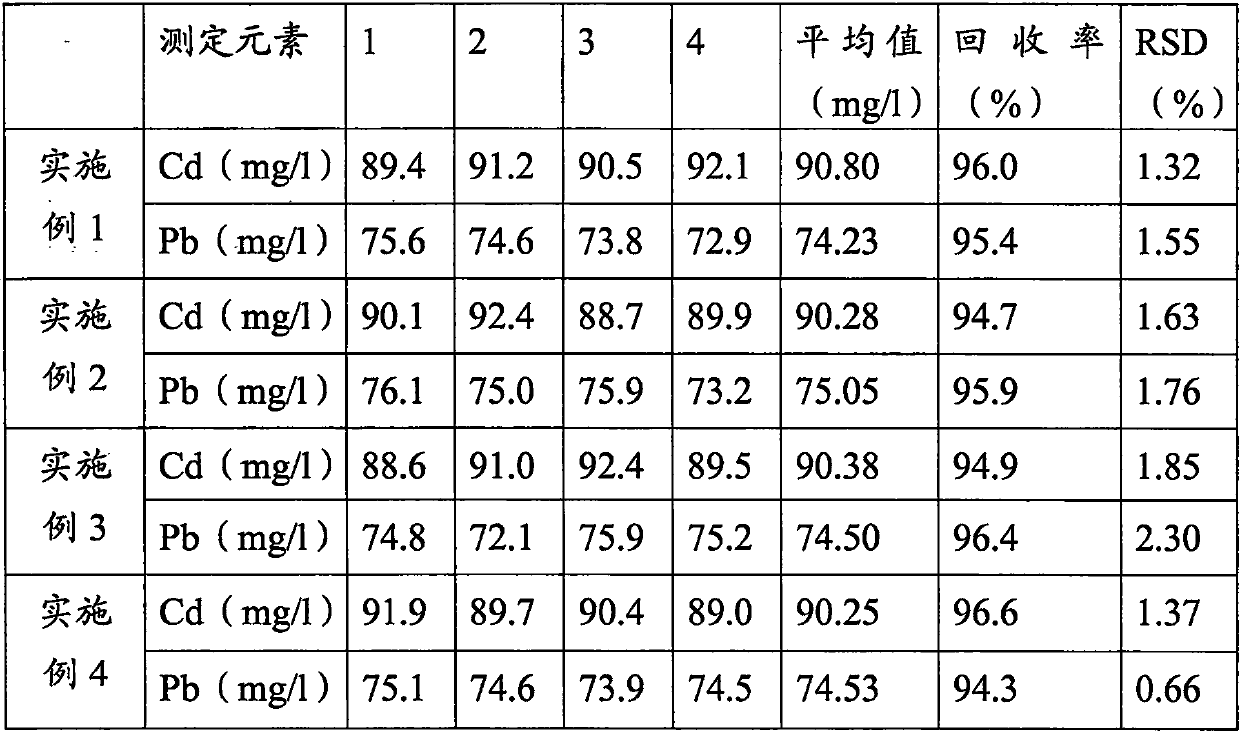

Examples

Embodiment 1

[0038] Embodiment 1 of the present invention discloses a method for measuring the content of heavy metals in edible packaging materials, which specifically includes the following steps:

[0039] (1) First crush the edible packaging material until the particle size is less than 100 mesh, and then dry it at 75°C for 5 hours;

[0040] (2) First mix the nitric acid solution with a mass concentration of 65% and the hydrogen peroxide with a mass concentration of 25% according to a volume ratio of 1:2 to obtain a digestion solution; then place the dried edible packaging material in a clean and dry place Add the digestion solution to the polytetrafluoroethylene pressure digestion tank for digestion treatment to obtain the solution to be tested; the conditions of the digestion treatment process are: first raise the temperature to 90 °C at a heating rate of 20 °C / min, and keep it warm for 4 minutes; then Continue to heat up to 115°C at a heating rate of 20°C / min, and keep warm for 3 min...

Embodiment 2

[0048] Embodiment 2 of the present invention discloses a method for measuring the content of heavy metals in edible packaging materials, which specifically includes the following steps:

[0049] (1) First crush the edible packaging material until the particle size is less than 100 mesh, and then dry it at 90°C for 3 hours;

[0050] (2) First, the nitric acid solution with a mass concentration of 65 to 75% and the hydrogen peroxide with a mass concentration of 25 to 35% are mixed according to a volume ratio of 2:3 to obtain a digestion solution; then the dried edible packaging material is placed In a clean and dry polytetrafluoroethylene pressure digestion tank, add digestion solution for digestion to obtain the solution to be tested; the conditions for the digestion process are: first raise the temperature to 100°C at a heating rate of 20°C / min, and keep it warm 4min; then 125°C, and keep warm for 5min; then continue to heat up to 175°C at a heating rate of 30°C / min, and keep ...

Embodiment 3

[0058] Embodiment 3 of the present invention discloses a method for measuring the content of heavy metals in edible packaging materials, which specifically includes the following steps:

[0059] (1) First crush the edible packaging material until the particle size is less than 100 mesh, and then dry it at 85°C for 4 hours;

[0060] (2) First mix the nitric acid solution with a mass concentration of 70% and the hydrogen peroxide with a mass concentration of 30% according to a volume ratio of 1:3 to obtain a digestion solution; then place the dried edible packaging material in a clean and dry place In the PTFE pressure digestion tank, add digestion solution for digestion treatment to obtain the solution to be tested; the conditions of the digestion treatment process are: first raise the temperature to 95 °C at a heating rate of 20 °C / min, and keep it for 5 minutes; then 120 °C ℃, and keep warm for 4min; then continue to heat up to 173℃ at a heating rate of 30℃ / min, and keep warm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com