Method for preparing polyvinyl alcohol nano fibrous membrane containing nano silver and amino acid

A nanofiber membrane, polyvinyl alcohol technology, used in textiles, papermaking, non-woven fabrics, etc., can solve the problems of unstable silver nitrate solution, unstable silver nitrate, graying, etc., to promote wound healing, accelerate healing, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

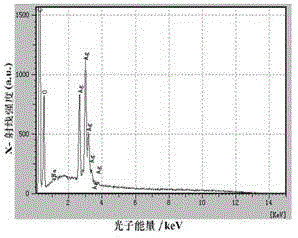

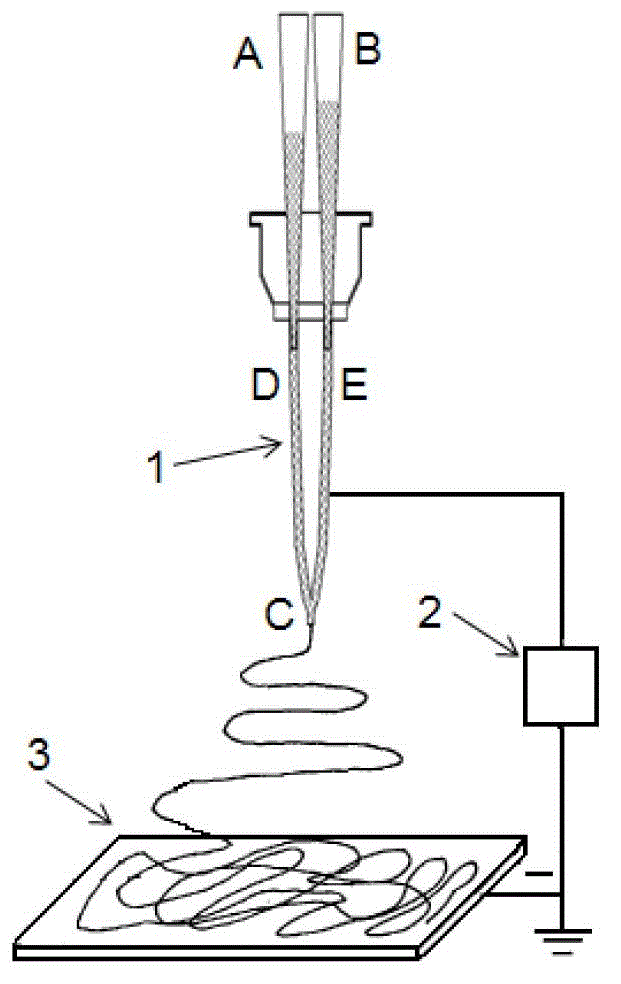

[0029] 1. Take 5ml of anhydrous formic acid and 16ml of deionized water to prepare an aqueous formic acid solution with a volume ratio of 1:3.2, dissolve 2.86g of polyvinyl alcohol with the solution, and prepare formic acid and polyvinyl alcohol with a mass percentage concentration of 12% of polyvinyl alcohol. solution, fully stirred for 2-3 hours to dissolve evenly, and packed into the liquid filling pipe A of the double-fluid parallel-axis electrospinning device 1 (such as figure 1 shown);

[0030] 2. Weigh 0.47g of silver nitrate, and dissolve it in 10ml of saturated L-histidine solution (4.3g / 100ml, 25°C) under dark conditions, that is, the amount of silver nitrate and L-histidine The ratio is 1:1, react at room temperature for 1 hour, and then put this solution into the liquid filling tube B of the double-fluid parallel-axis electrospinning device 1 (such as figure 1 shown);

[0031] 3. The solution in the liquid filling pipe A and the solution in the liquid filling pip...

Embodiment 2

[0036] By the way of Example 1, the difference is that the polyvinyl alcohol of 3.42g is added in step 1, and the mass percent concentration of the prepared polyvinyl alcohol solution is 14%; the silver nitrate quality 1.16g added in step 2 is dissolved in 5ml In the L-lysine saturated solution (40g / 100ml, 35 ℃), the ratio of the amount of silver nitrate and L-lysine is 0.5:1; Use mass percentage concentration in step 5 and be 40% formaldehyde and 36 % Concentrated acetic acid was used to carry out cross-linking reaction on the prepared nanofibrous membrane under the condition of gas phase, and the cross-linking time was 2 hours. Other processing conditions are all with embodiment 1.

[0037] The prepared nano-silver particles are attached to the surface of nanofibers of L-lysine polyvinyl alcohol, the average diameter of nano-silver particles is 22nm, the average diameter of nanofibers is 208nm, and the average diameter of fibers after crosslinking is 610nm.

Embodiment 3

[0039] According to the method of Example 1, the difference is that in step 1, 4ml of anhydrous formic acid and 16ml of deionized water are added, that is, the volume ratio is 1:4 to dissolve 3.53g polyvinyl alcohol, and the mass concentration of the prepared polyvinyl alcohol solution is 15%, the quality of silver nitrate added in step 2 is 0.92g dissolved in 8ml of L-arginine saturated solution (14.8g / 100ml, 25 ℃), the amount of silver nitrate and L-arginine The ratio is 0.8:1, and other process conditions are the same as in Example 1.

[0040] Prepared nano silver particles attached to the surface of nanofibers of L-arginine polyvinyl alcohol, the average diameter of nano silver particles is 20nm, the average diameter of nanofibers is 210nm, and the average diameter of fibers after crosslinking is 625nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com