High-concentration tetrapropylammonium hydroxide production process and high-concentration tetrapropylammonium hydroxide prepared by production process

A technology of tetrapropylammonium hydroxide and tetrapropylammonium bromide, applied in the field of quaternary ammonium alkali production, can solve the problems of affecting the production efficiency of high-concentration tetrapropylammonium hydroxide products, affecting product quality, and low concentration temperature , to achieve the effect of shortening the electrolysis time, shortening the concentration time and increasing the concentration temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

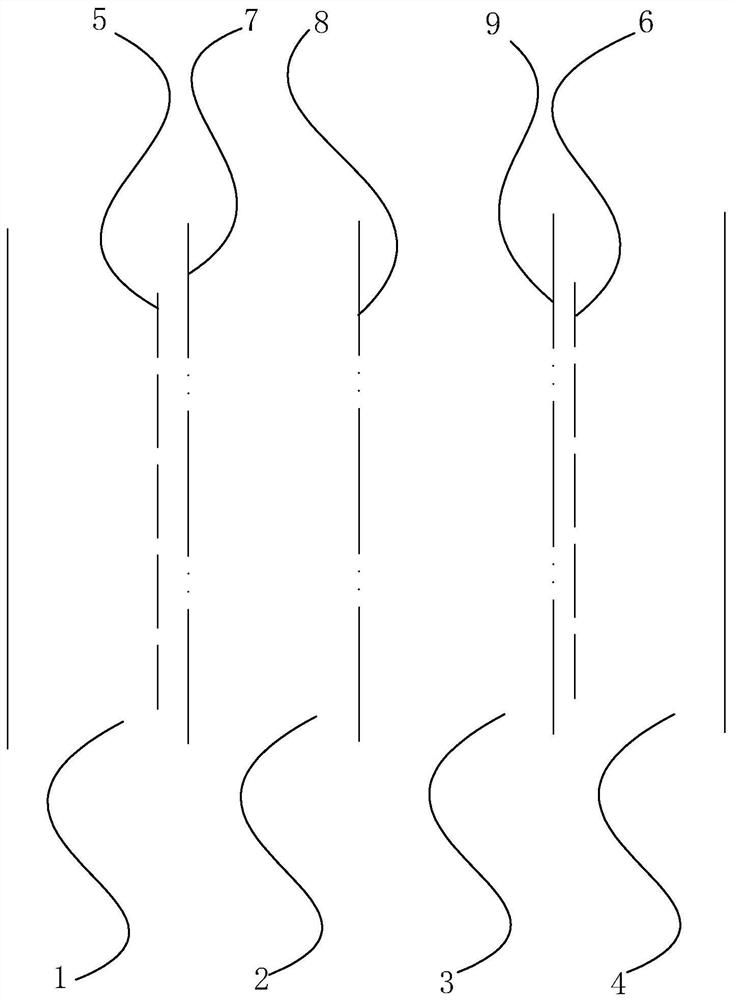

[0040] Embodiment 1: high-concentration tetrapropyl ammonium hydroxide production process, use electrolyzer to carry out electrolysis, as figure 1 As shown, the electrolytic cell includes an anode chamber 1, a by-product chamber 2, a raw material chamber 3 and a cathode chamber 4 which are successively adjacent at the same height; an anode plate 5 is installed in the anode chamber 1, and a cathode plate 6 is installed in the cathode chamber 4 , the anode plate 5 is connected to the cathode plate 6 through a power supply; the anode chamber 1 communicates with the by-product chamber 2 through the first cationic membrane 7, the by-product chamber 2 communicates with the raw material chamber 3 through the anion membrane 8, and the raw material chamber 3 and The cathode chambers 4 are communicated through the second cationic membrane 9; the production process includes the following steps:

[0041] S1 electrolysis: take tetrapropylammonium bromide, add water to prepare tetrapropylam...

Embodiment 2

[0044] The difference between Example 2 and Example 1 is that step S2 of Example 2 was concentrated in a water bath at 80° C. for 125 minutes without cooling down the concentration process, and the others were consistent with Example 1.

Embodiment 3-6

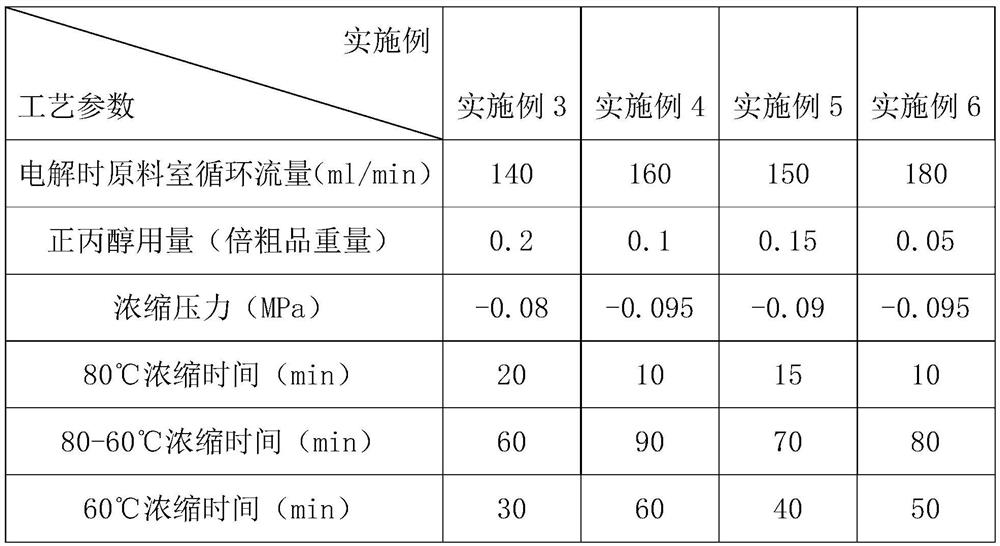

[0046] The difference between embodiment 3-6 and embodiment 1 is that the process parameters of each step of embodiment 3-6 are different, the circulation flow rate of material in the anode chamber, by-product chamber and cathode chamber is 120ml / min, and others are all kept with embodiment 1 Consistent, each step process parameter of embodiment 3-6 is shown in Table 1.

[0047] Each step technological parameter of table 1 embodiment 3-6

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com