Method for recycling mother liquid of cefalexin synthesized by enzymatic method

A technology of cephalexin mother liquor and enzymatic synthesis, which is applied in the field of resource recycling in the cephalexin mother liquor production industry, to achieve the effects of reducing costs, avoiding decomposition reactions, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

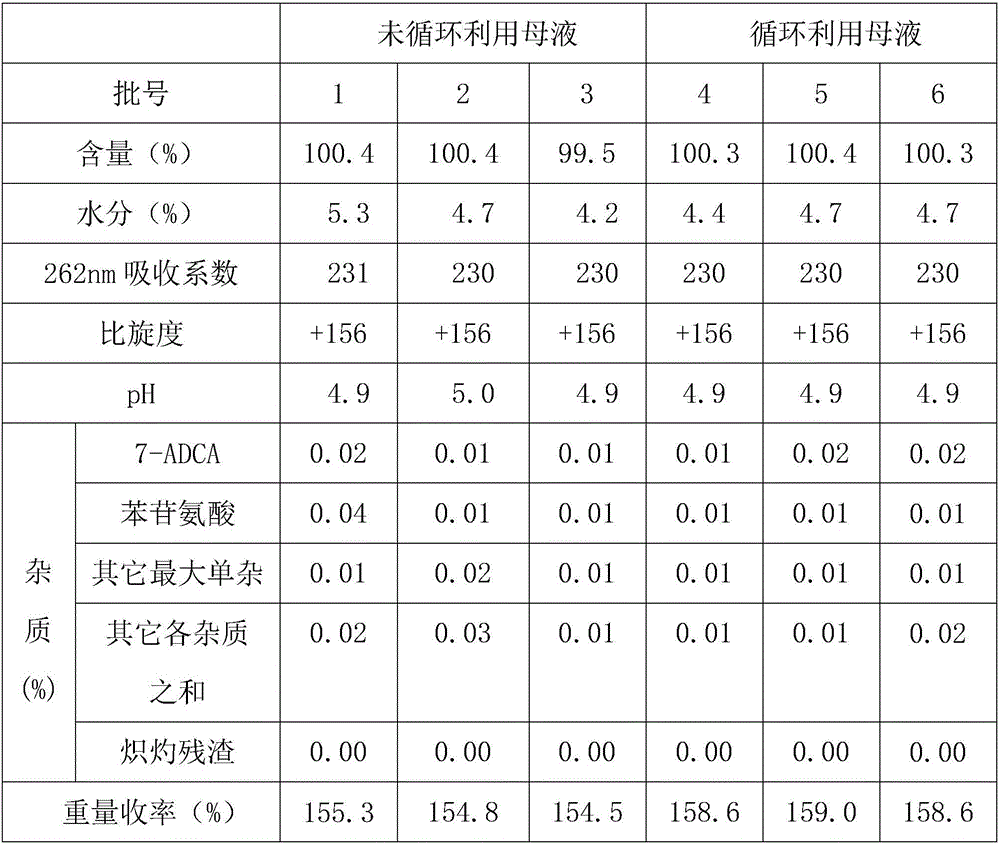

Examples

Embodiment 1

[0035] Take 2.6L of cephalexin mother liquor, adjust the pH to 2.52 with 25% sulfuric acid, and control the temperature at 21°C. Then, after resin adsorption, the adsorption flow rate is 1.5BV / h, the resin column capacity is 500mL, and a total of 2600mL is adsorbed, about 39g of cephalexin. After washing the resin column with 1BV of water, analyze it with 20% ethanol solution with pH=1.0 at a rate of 1BV / h, control the temperature at 21°C, and collect 0.75BV. Adjust the pH of 0.75 BV of the collected analytical solution (total 375 mL) with 15% ammonia water to crystal out, and grow the crystal for 30 minutes. Continue to add 15% ammonia water dropwise to pH=4.50, stop the dropwise addition, lower the temperature to 9.5° C., and grow the crystal for 30 minutes. Vacuum suction filtration, at a temperature of 40 ° C, dried for 2 hours to obtain cephalexin 38.0g, the recovery rate of cephalexin was 97.4%, (remarks: 1BV refers to 1 times the resin column volume) was detected by hi...

Embodiment 2

[0038] Take 2.6L of cephalexin mother liquor, adjust the pH to 2.60 with 25% sulfuric acid, and control the temperature at 21°C. Then, after resin adsorption, the adsorption flow rate is 1.5BV / h, the resin column capacity is 500mL, and a total of 2600mL is adsorbed, about 39g of cephalexin. After the resin column was washed with 1BV of water, it was analyzed with 20% ethanol solution with pH=1.0 at a rate of 1BV / h, and the temperature was controlled at 20°C. Collect 0.75BV to end. Adjust the pH of 0.75 BV of the collected analytical solution (total 375 mL) with 15% ammonia water to crystal out, and grow the crystal for 30 minutes. Continue to add 15% ammonia water dropwise to pH=4.50, stop the dropwise addition, lower the temperature to 8.5° C., and grow the crystal for 30 minutes. Vacuum suction filtration, at temperature 40 ℃, dry 2 hours, obtain cephalexin 37.8g, cephalexin recovery rate 96.9%, (1BV refers to the resin column volume of 1 times) through HPLC detection, cep...

Embodiment 3

[0041]Take 2.6L of cephalexin mother liquor, adjust the pH to 2.55 with 25% sulfuric acid, and control the temperature at 22°C. Then, after resin adsorption, the adsorption flow rate is 1.5BV / h, the resin column capacity is 500mL, and a total of 2600mL is adsorbed, about 39g of cephalexin. After washing the resin column with 1BV of water, analyze it with 20% ethanol solution with pH=1.0 at a rate of 1BV / h, control the temperature at 21°C, and collect 0.75BV. Adjust the pH of 0.75 BV of the collected analytical solution (total 375 mL) with 15% ammonia water to crystal out, and grow the crystal for 30 minutes. Continue to add 15% ammonia water dropwise to pH=4.50, stop the dropwise addition, lower the temperature to 9.0° C., and grow the crystal for 30 minutes. Vacuum suction filtration, at temperature 40 ℃, dry 2 hours, obtain cephalexin 38.0g, cephalexin recovery rate 97.4%, (remark: 1BV refers to the resin column volume of 1 times) detects through high-performance liquid chr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com