Fuse and exploder adopting same

A kind of technology of fuse lead and fuse wire, applied in the direction of detonation cord, blasting, etc., can solve the problems of easy generation of open flame, high risk, spark sputtering, etc., and achieve the effect of easy control, high safety, and less intense combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

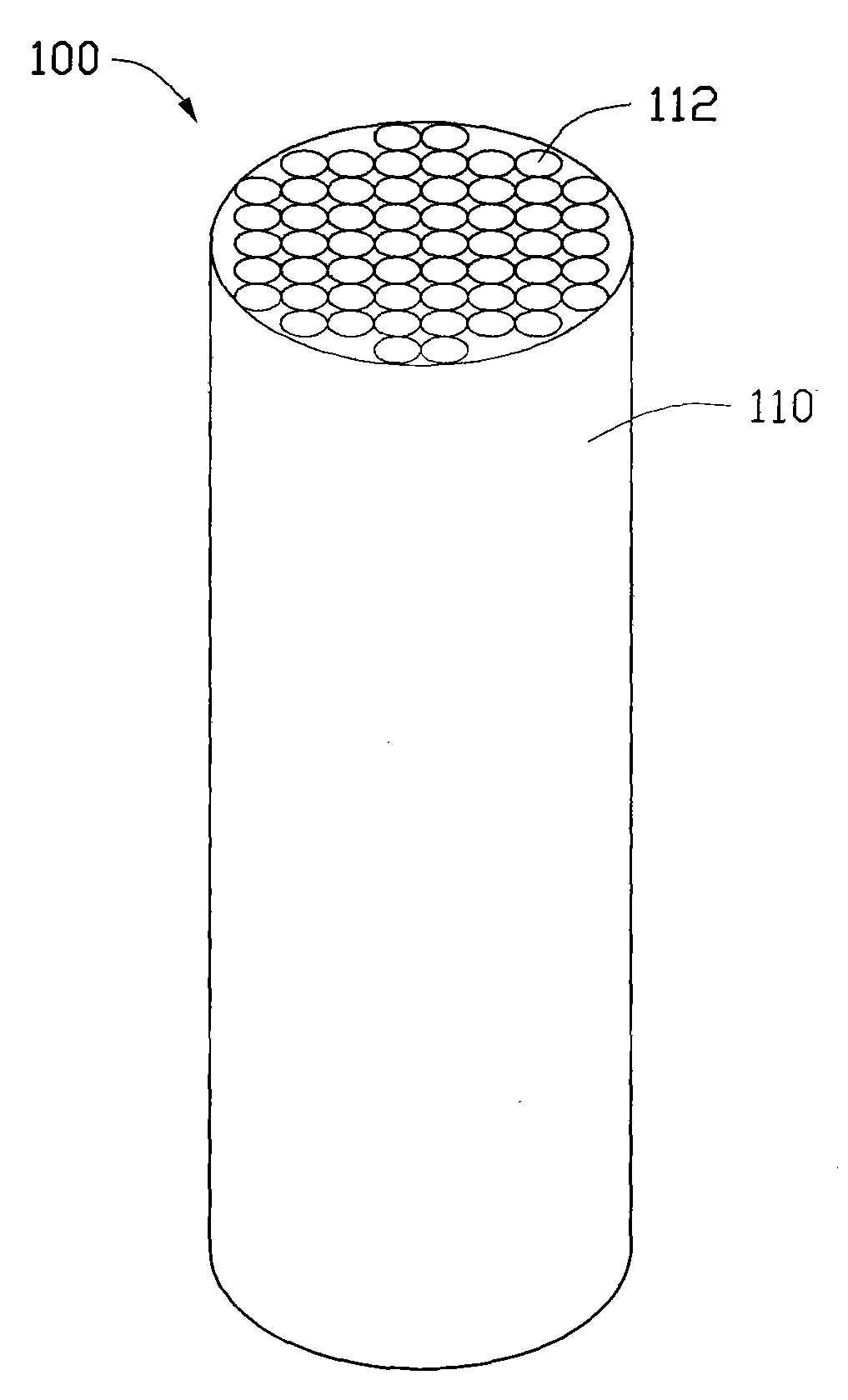

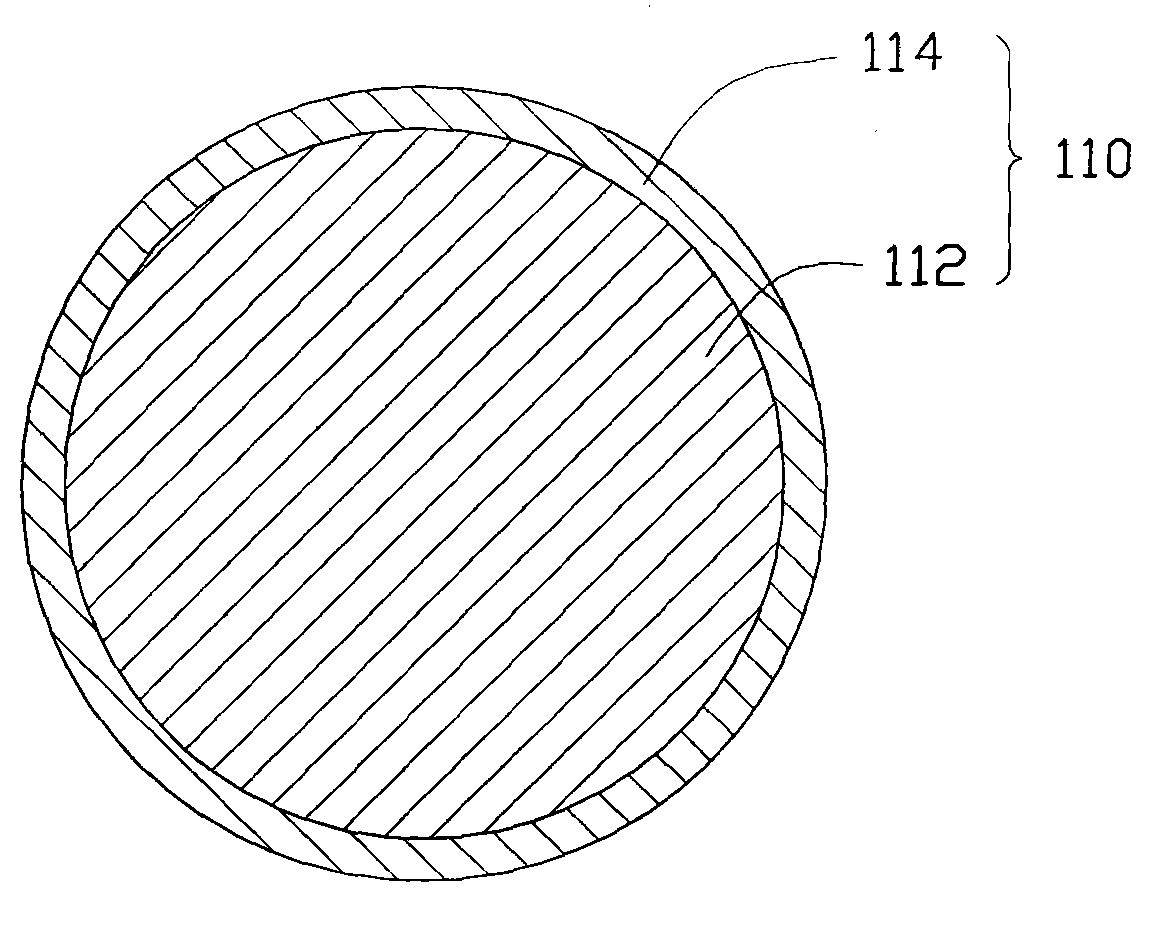

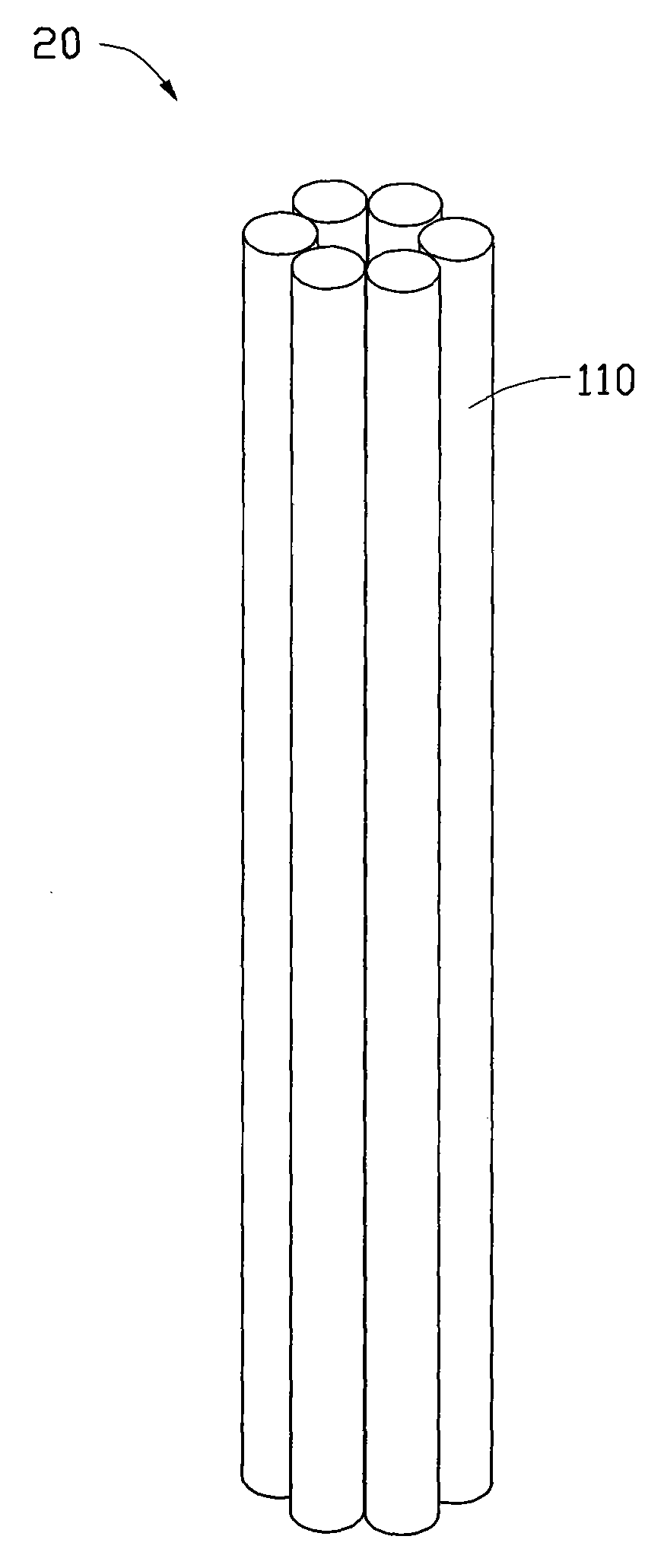

[0031] see image 3 and Figure 4, the method for preparing the carbon nanotube linear structure 110 in the embodiment of the present invention mainly includes the following steps:

[0032] Step 1: providing a carbon nanotube array 216 .

[0033] The carbon nanotube array 216 provided by the embodiment of the present invention is one or more of a single-walled carbon nanotube array, a double-walled carbon nanotube array, and a multi-walled carbon nanotube array. In this embodiment, the preparation method of the super-parallel carbon nanotube array adopts the chemical vapor deposition method, and its specific steps include: (a) providing a flat substrate, which can be a P-type or N-type silicon substrate, or can be formed There is the silicon substrate of oxide layer, and the present embodiment preferably adopts the silicon substrate of 4 inches; (b) uniformly forms a catalyst layer on the substrate surface, and this catalyst layer material can be selected iron (Fe), cobalt (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com