System and method for producing hydrogen fuel gas by low-energy nuclear reaction

A technology for fuel gas and hydrogen production, applied in the field of low-energy nuclear reactions, can solve problems such as increasing CO2 emissions, and achieve the effect of small safety scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

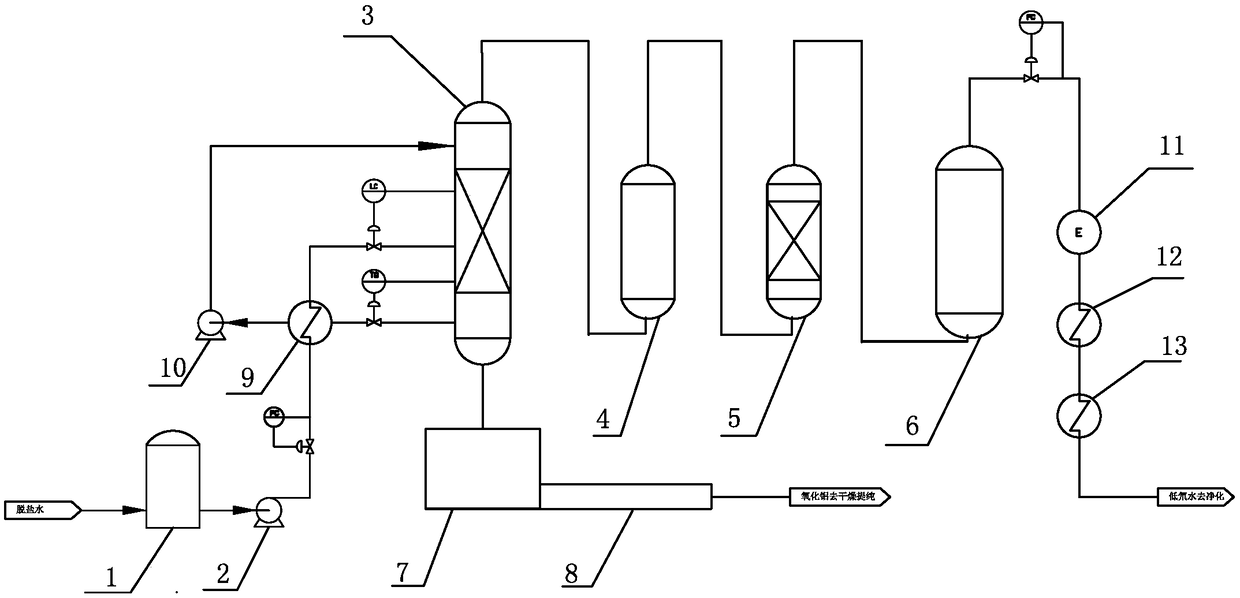

[0040] A low-energy nuclear reaction system to produce hydrogen fuel gas, such as figure 1 As shown, including desalinated water tank 1, reaction feed pump 2, low-energy nuclear reactor 3, buffer tank 4, filter 5, gas storage tank 6, precipitation tank 7, screw conveyor 8, water preheater 9, reaction circulation pump 10. Hydrogen internal combustion generator set 11, waste heat recovery heat exchanger 12 and deuterium-depleted water condenser 13, the desalinated water tank 1 is provided with a water inlet, and the bottom water outlet of the desalinated tank 1 is connected with the water inlet of the reaction feed pump 2, and the reaction inlet The water outlet of the feed pump 2 is connected with the cold water inlet of the water preheater 9, the hot water outlet of the water preheater 9 is connected with the middle water inlet of the low energy nuclear reactor 3, and the bottom water outlet of the low energy nuclear reactor 3 is connected with the water preheater The hot water...

specific Embodiment 2

[0042] A method for producing hydrogen fuel gas by low-energy nuclear reaction using the system of specific embodiment 2, such as figure 1 As shown, including the following steps:

[0043] (1) Feed the raw water (soft water, boiler deaerated water, distilled water and other clean water can be used as raw material water for production) into the desalinated water tank 1 for desalination, and then preheat the desalinated water to 85°C through the preheater. Enter the low-energy nuclear reactor 3;

[0044] (2) The metal catalyst aluminum is fed into the low-energy nuclear reactor 3 containing desalinated water at 85°C. After the metal catalyst aluminum is in contact with water for 5-30 minutes, there is no need for any external heat source or energy source. The metal catalyst aluminum reacts with water automatically to generate heat , The water temperature in the low-energy nuclear reactor 3 will gradually rise, and the pressure in the low-energy nuclear reactor 3 will gradually incre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com