Multiple-injection control method for fuel supply device of natural gas engine

A fuel supply device and multiple injection technology, applied in fuel injection control, engine control, electrical control, etc., can solve the problems of slow flame propagation speed, insufficient combustion, poor ignition stability of natural gas engines, etc., to improve flame propagation speed, ensuring stable ignition, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

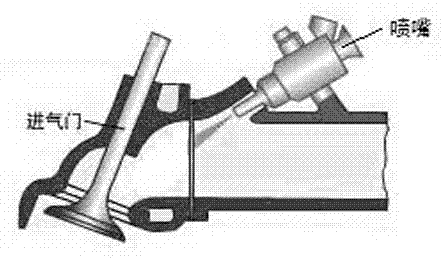

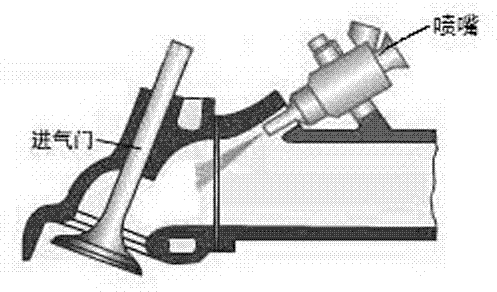

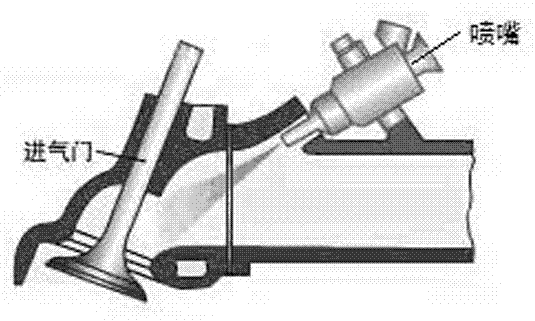

[0023] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the multiple injection control method of the fuel supply device of the natural gas engine is a four-stroke engine, and each working cycle of the natural gas engine is divided into four stages, including the intake stroke, the compression stroke, the combustion stroke and the exhaust stroke. The fuel supply device of the engine is arranged on the side of the intake valve, and natural gas and air are mixed and burned in the cylinder; the multiple injection control of the fuel supply device is 240 degrees before the top dead center of the engine piston compression stroke. 0 Crankshaft angle to compression stroke top dead center 240 0 Adjust the number of injections and the injection quantity of the natural gas supplied by the fuel supply device within the crank angle rang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com