Partial pre-mixing and pre-evaporation burning chamber with prefilm type nozzle

A combustor and pre-evaporation technology, which is applied in the field of aero-engines, can solve the problems of unstable combustion, long premixing section, prone to spontaneous combustion and backfire, etc., to prevent spontaneous combustion and backfire, reduce pollutant emissions, and ensure stable The effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

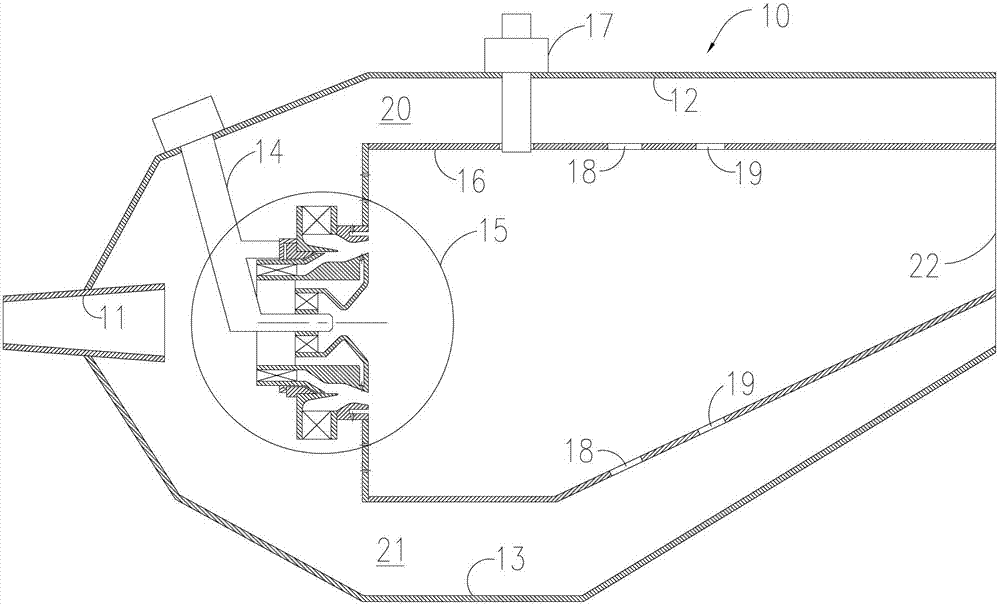

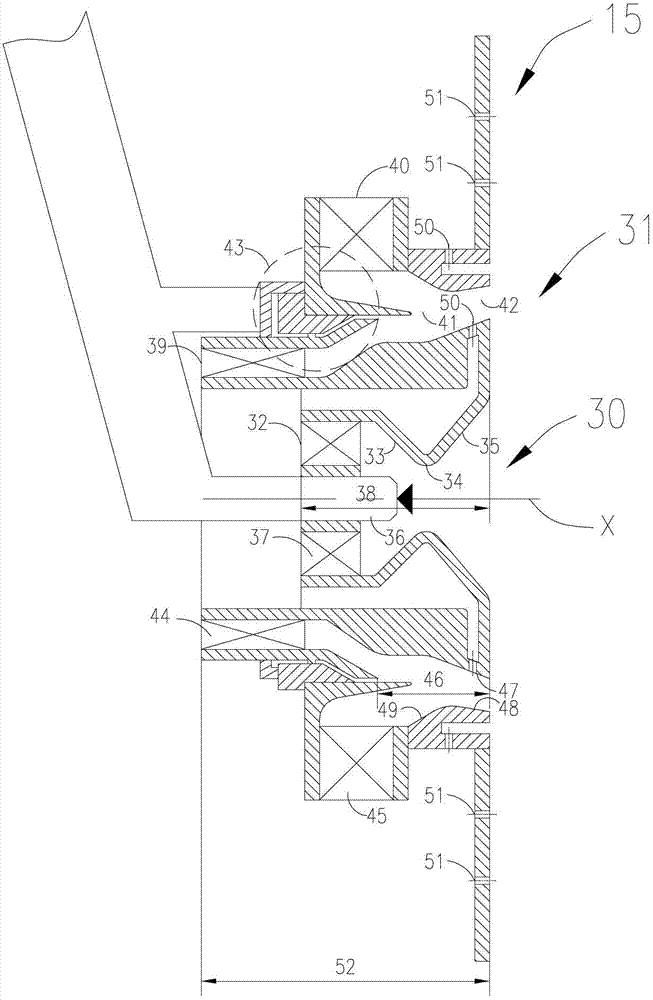

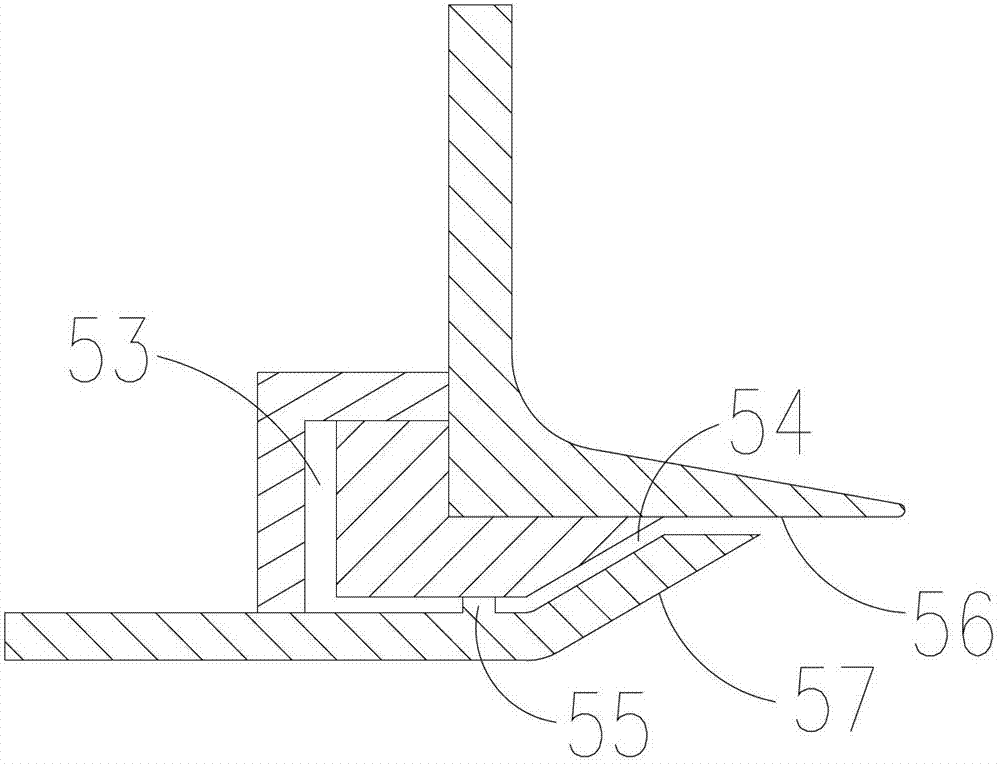

[0022] Introduce the present invention in detail below in conjunction with accompanying drawing and concrete implementation example, please refer to Figure 1 to Figure 3 . The head scheme of the patent of the present invention adopts the DIPME (Rich / Lean Direct Injection and Lean Partial Pre-Mixing&Pre-Evaporation) mixed combustion mode of the center stage, that is, in the start-up and small states, the secondary combustion stage adopts the Rich Direct Injection (Rich Direct Injection) ) combustion mode, the combustion mode is to achieve partial fuel enrichment through the auxiliary combustion stage composed of the auxiliary oil channel centrifugal nozzle (or air atomizing nozzle) and the auxiliary combustion stage axial vortex device. This organization combustion method is between premixed combustion and diffusion combustion; in large states (including take-off, cruise, etc.), the secondary combustion stage adopts the lean direct injection (Lean Direct Injection) combustion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com