Low-flow, high-mixing ratio and stepless regulation gas-liquid mixing gas generator

A gas generator, high mixing ratio technology, applied in the direction of regulating fuel supply, burner, gas fuel, etc., can solve the problem that it is difficult to meet the technical requirements and indicators of the gas generator, and achieve the problem that the flame is difficult to stabilize and the adjustment range is wide , Combustion stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

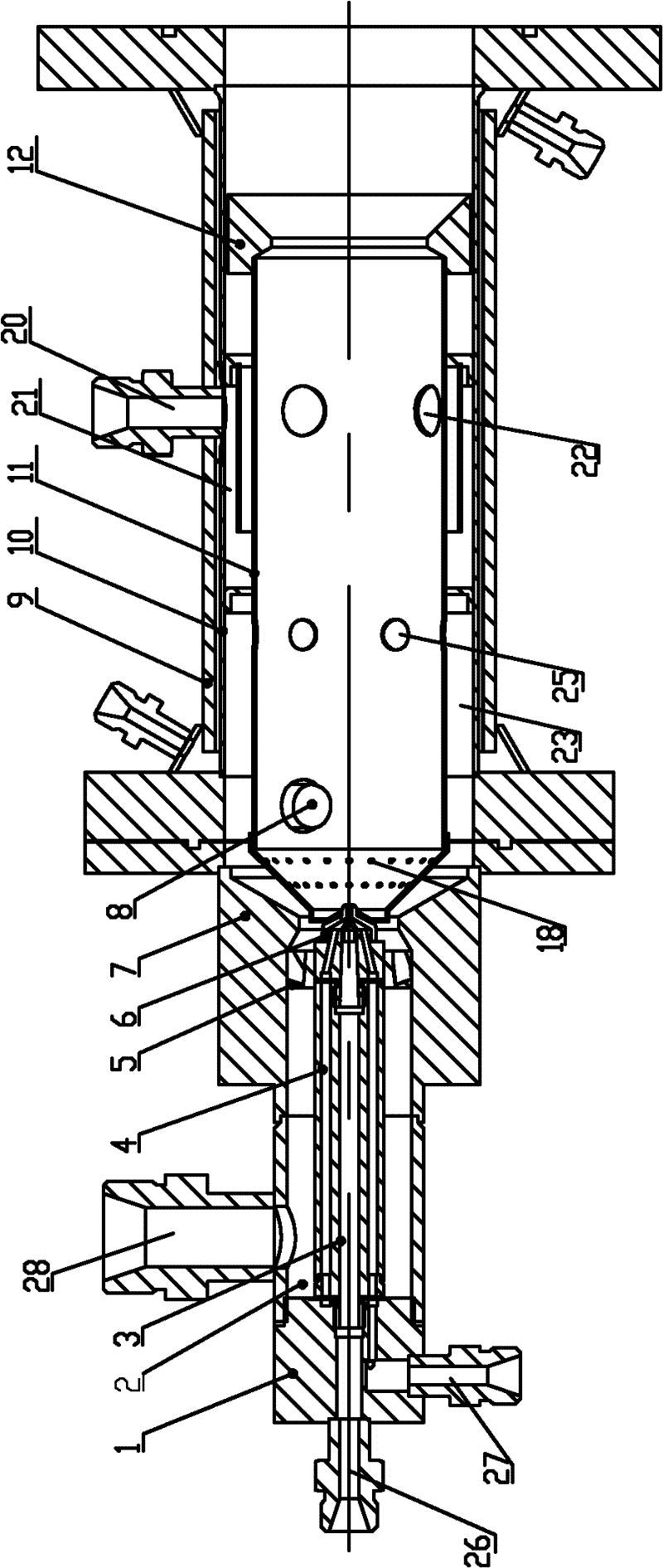

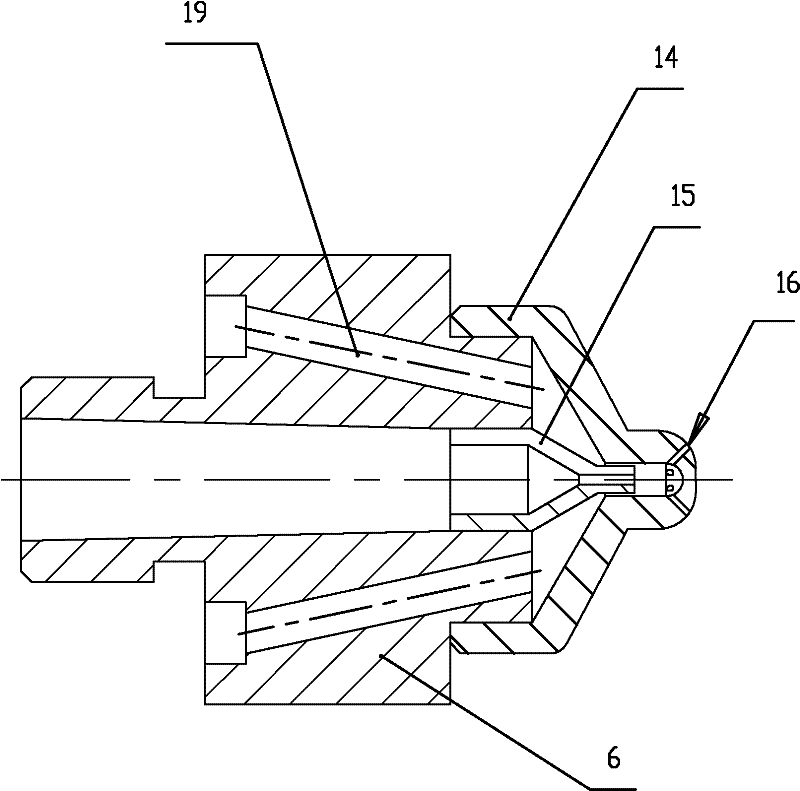

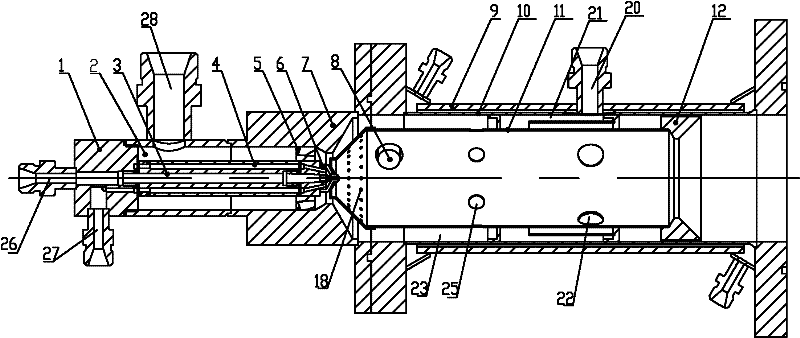

[0020] see figure 1 and figure 2 , the present invention provides a small flow rate, high mixing ratio, steplessly adjustable gas-liquid mixed gas generator, comprising a circular mixing channel, a nozzle 6, an igniter 8 and a body, the nozzle is arranged between the circular mixing channel and the body and The opening faces the body, and the igniter is arranged in the body; the circular mixing channel includes a fuel channel 3 communicated with the fuel joint 26, a main air channel 2 communicated with the main air joint 28, and an auxiliary air channel 4 communicated with the auxiliary air joint 27; The spray head includes a bubble nozzle and an air nozzle; the air nozzle includes a swirler 5 and a throat 7 communicating with the air passage 2; the bubble nozzle includes a conical head 15 communicating with the fuel passage 3, and an air through hole communicating with the auxiliary air passage 4 19 and the mixing chamber 14; one end face of the mixing chamber 14 communicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com