Catalytic ozonation system and method and application

A technology of ozone catalytic oxidation and ozone oxidation, applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, water/sewage treatment, etc., can solve the problems of toxic intermediate products, excessive intermediate products, bromate by-products, etc., and achieve Improve gas solubility, increase gas-liquid mixing ratio, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

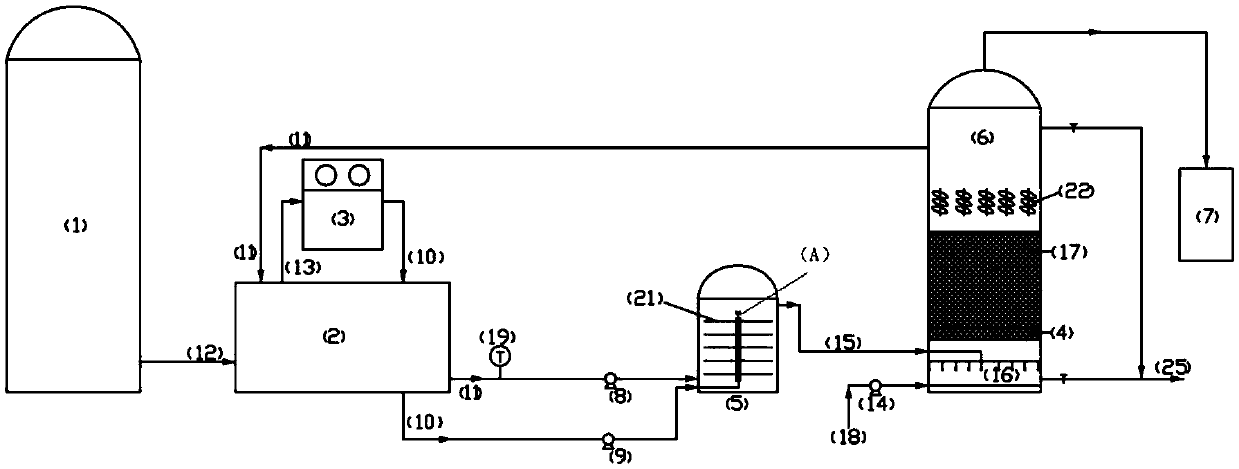

[0083] Example 1 see figure 1 , the liquid oxygen 12 in the liquid oxygen storage tank 1 is gasified into pure oxygen 3 by the low energy consumption refrigeration device 2 as the gas source of the ozone generator 3; After the low-energy refrigeration device 2 cools down, it reaches 0-10°C; part of the waste water treated by the catalytic ozonation reaction tank 6 is returned to the low-energy refrigeration device 2 for cooling through the upper outlet of the tank, and the temperature of the waste water is about 5-40°C. The cooling device 2 reaches 0-5°C after cooling; the cooled ozone-containing gas 10 and return water 11 are pressurized by the gas booster pump 9 and the liquid booster pump 8 respectively, and then enter the bubble-free high-concentration ozone water preparation device 5, Uniformly mix in the bubble-free high-concentration ozone water preparation device 5 to form high-concentration ozone water 15; high-concentration ozone water 15 enters the catalytic ozonati...

Embodiment 2

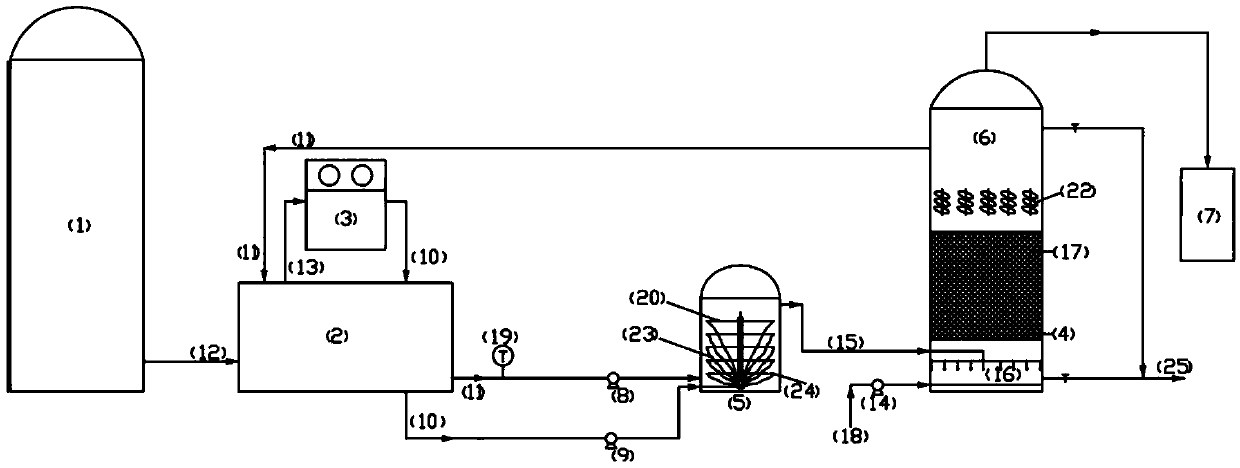

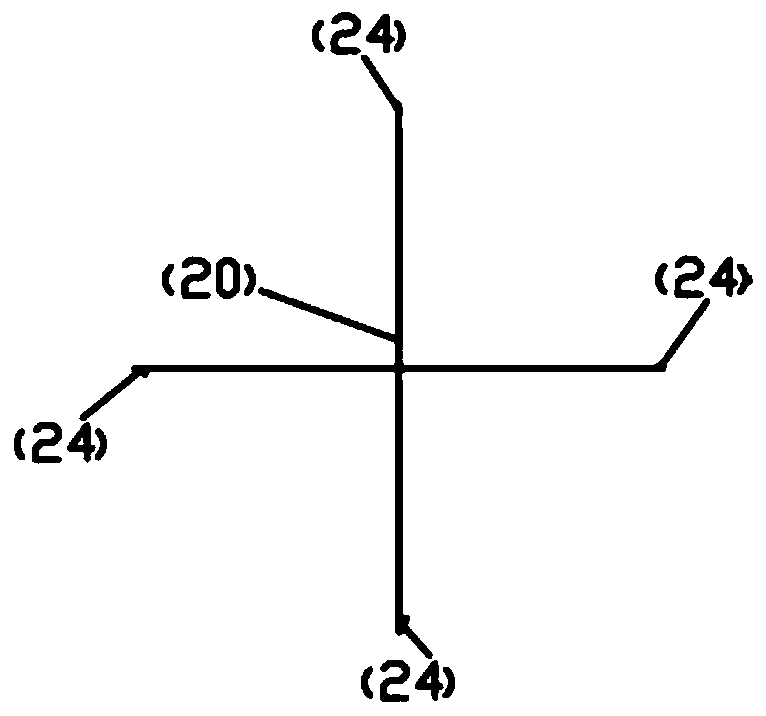

[0085] Example 2 see figure 2 , the liquid oxygen 12 in the liquid oxygen storage tank 1 is gasified into pure oxygen 3 by the low-energy refrigeration device 2 as the gas source of the ozone generator 3; After the low-energy refrigeration device 2 cools down, it reaches 0-8°C; part of the wastewater treated by the catalytic ozonation reaction tank 6 is returned to the low-energy refrigeration device 2 through the upper outlet of the tank for cooling, and the temperature of the waste water is about 5-35°C. The cooling device 2 reaches 0-5°C after cooling; the cooled ozone-containing gas 10 and return water 11 are pressurized by the gas booster pump 9 and the liquid booster pump 8 respectively, and then enter the bubble-free high-concentration ozone water preparation device 5, Mix uniformly in the bubble-free high-concentration ozone water preparation device 5, and the aeration head 24 at the end of the capillary is set and fixed on the aeration head fixing device 20 at each h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com