Input type automatic PH glass electrode adjusting device and method

A glass electrode and automatic adjustment technology, which is applied in the direction of control/regulation system, instrument, computer control, etc., can solve the problems of measurement medium liquid level change uncertainty, large maintenance amount, high frequency of electrode cleaning, etc., so as to reduce manual maintenance cost, ensure the quality of water treatment, and ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

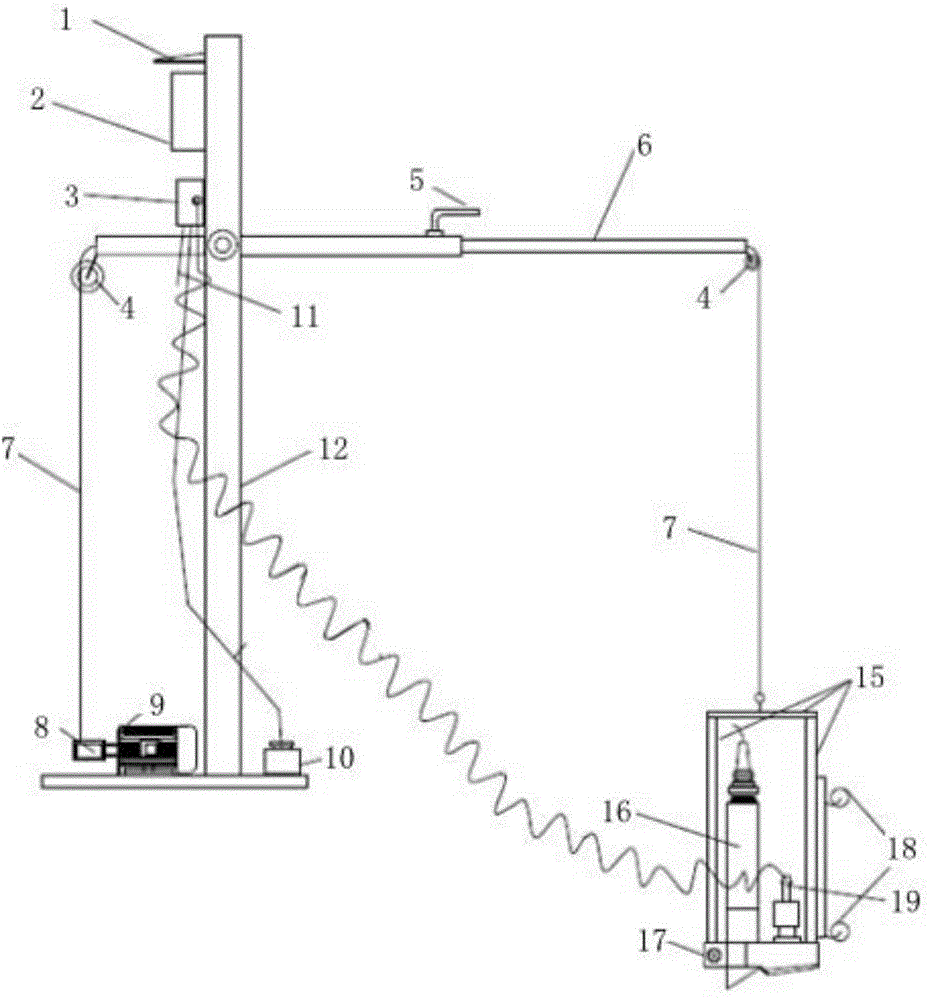

Embodiment 1

[0033] 1. Data collection: Determine the electrode insertion level according to the level switch on the electrode mount.

[0034] 2. Parameter setting: Set the cleaning cycle, rinse time, cleaning time, and stability time parameters of the electrode automatic cleaning unit through the man-machine dialogue operation keyboard connected with the micro-processing. The cleaning mode can be selected between automatic and manual modes. In manual mode, press the start button to enter the cleaning program; in automatic mode, set the cleaning cycle, and the cycle time is up, and the cleaning program will automatically enter.

[0035] 3. Analysis and calculation: Analysis of the lifting action of the electrode automatic lifting device: operating condition 1, insert the liquid level alarm value through the electrode, when the liquid level is low, it is concluded that the electrode is exposed to the air, and the electrode automatic lifting device needs to be lowered Instruction, when the liquid...

Embodiment 2

[0039] On the basis of method embodiment 1, set the electrode cleaning judgment program after the step analysis and calculation. In the electrode cleaning program, set the electrode running cleaning cycle value, water rinse value time value, cleaning time value, and stable time value in advance, according to the water quality In case of cleaning effect, the operator corrects the set parameter value.

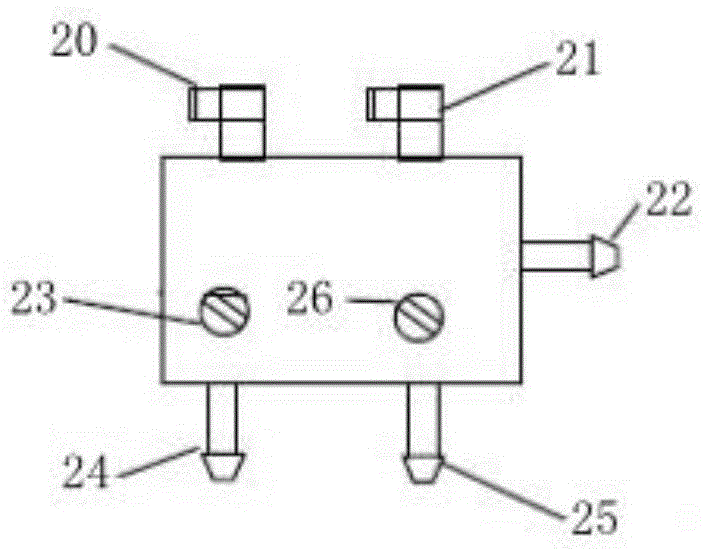

[0040] The microprocessor of the present invention adopts the 32-bit ARM main control chip LPC1752. The LPC1752 chip has fast operation speed, high cost performance, and provides abundant common peripheral interfaces, which can provide good system device functions. The storage unit of the microprocessor includes an EEPROM data memory, which is mainly composed of a piece of CAT24C256, which is used to store historical data of the control system, store status data and process alarm information. Liquid level switch, used to measure the high and low switching signal of the medium liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com