Patents

Literature

41results about How to "Save research funds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Device for testing powder combustion characteristics in vacuum condition

InactiveCN101382533ARealize measurementEfficient use ofChemical analysis using combustionFuel testingCombustion chamberHeating time

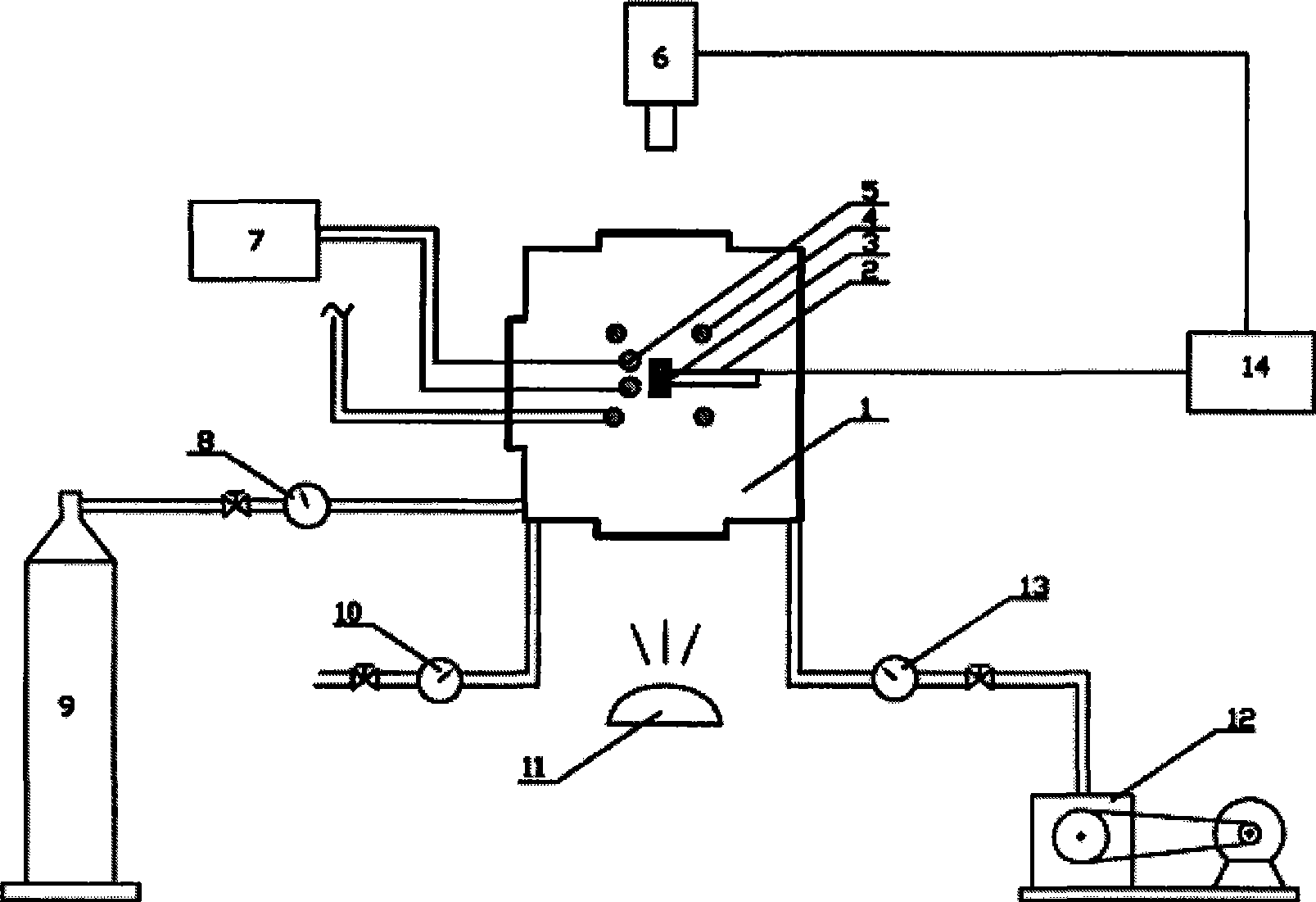

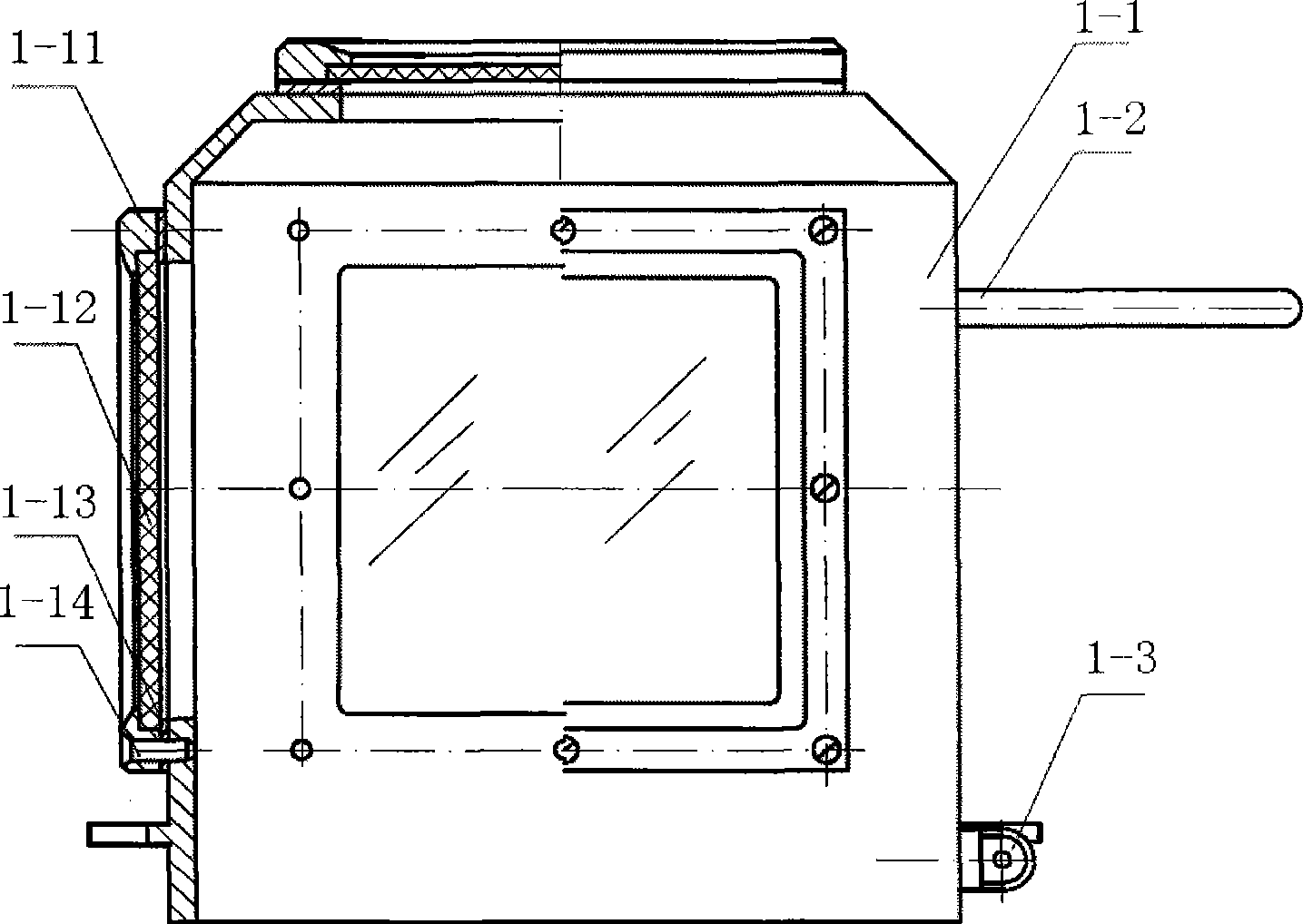

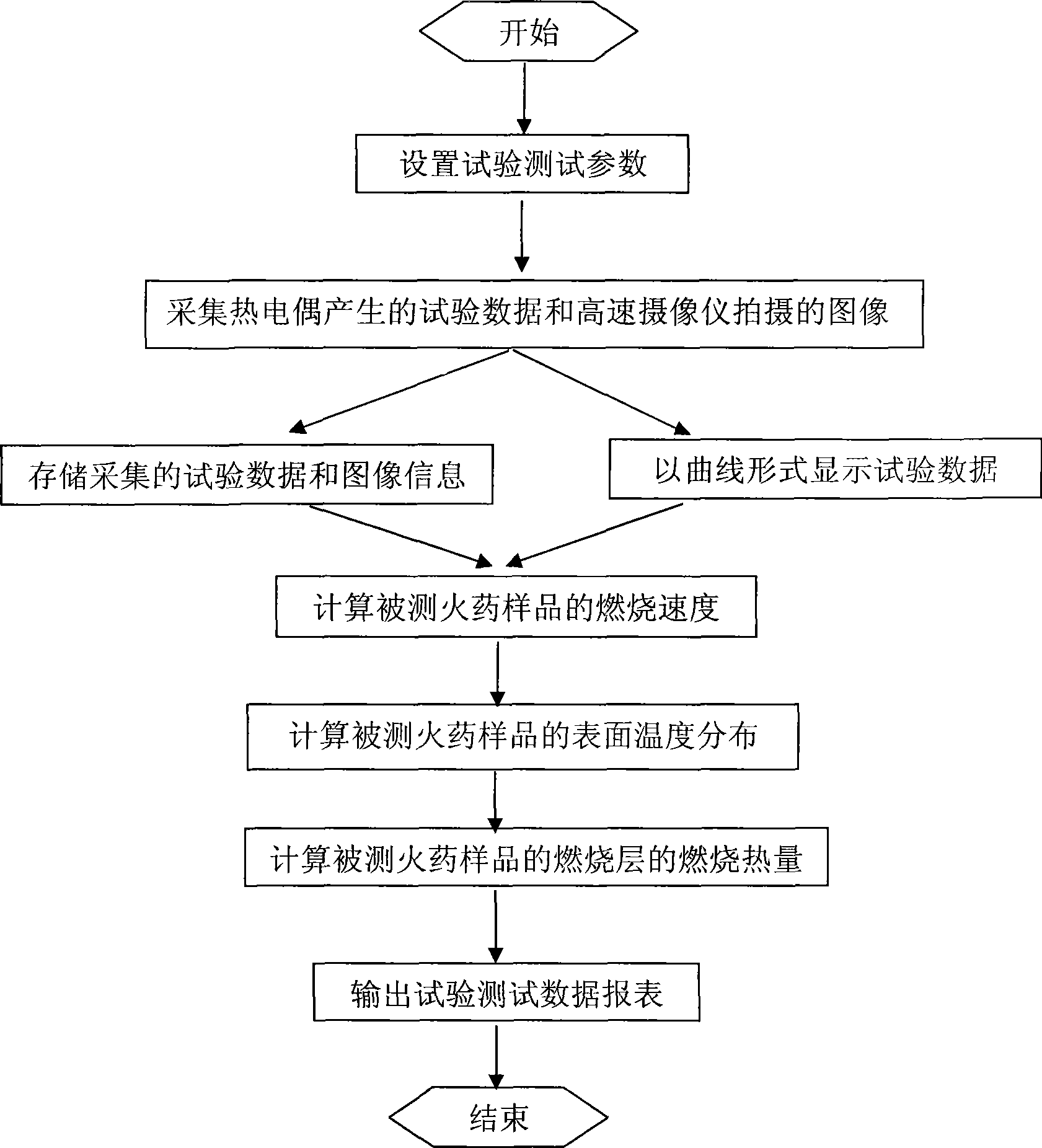

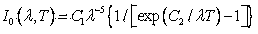

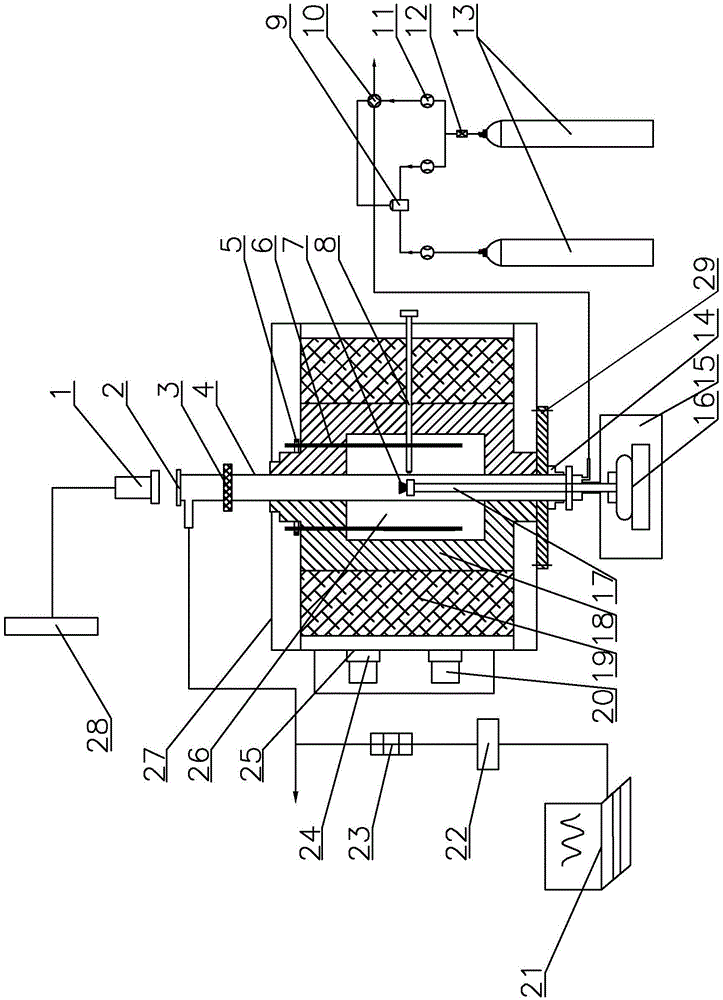

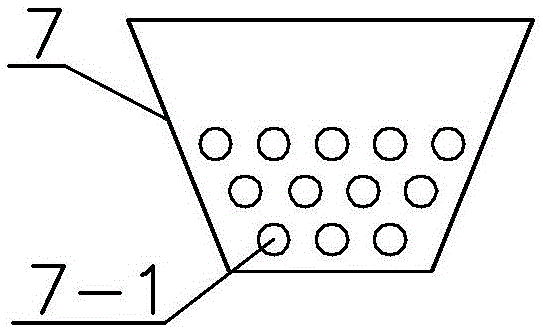

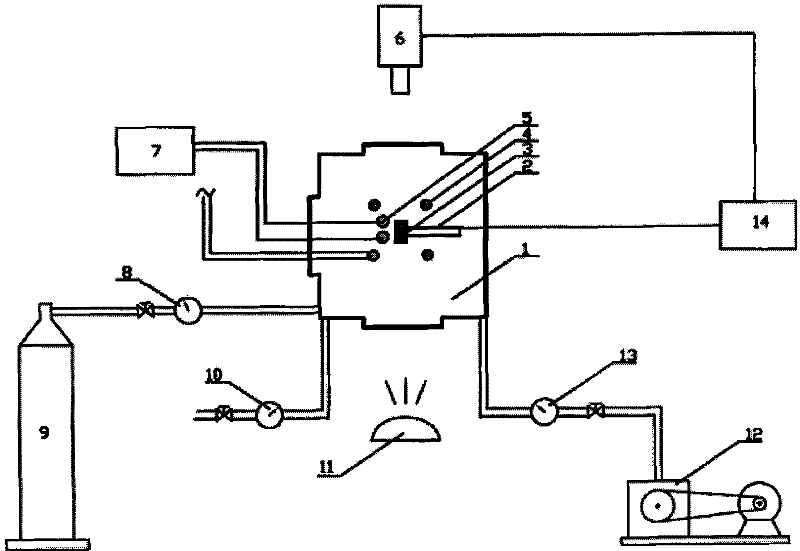

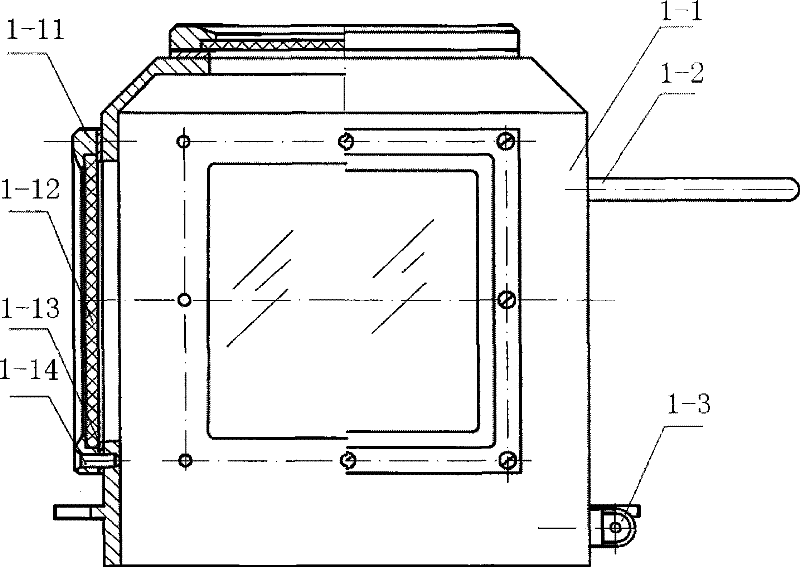

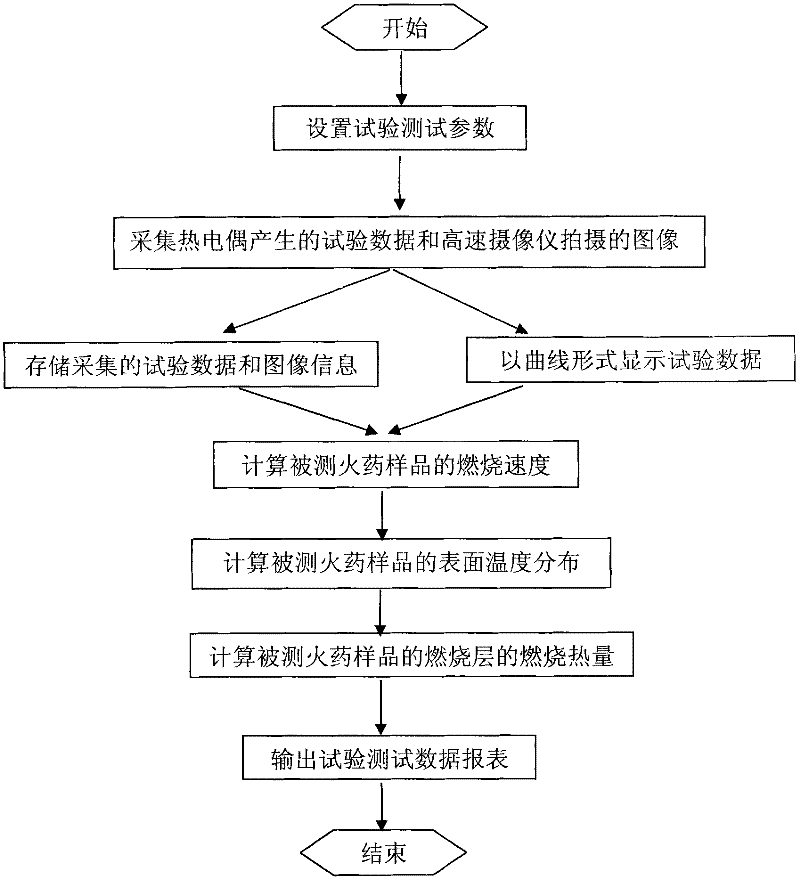

The invention discloses a testing device of gunpowder combustion characteristics in vacuum, which mainly comprises a combustion chamber, a vacuum pump, an electric heater, a thermoelectric couple, a high speed camera and a data acquisition and processing system; wherein, the vacuum pump provides vacuum environment for the combustion chamber; by controlling the heating current and the heating time of the electric heater, different ignition isoperibols can be provided for tested gunpowder samples in the combustion chamber; and the data acquisition and processing system collects the test data generated by the thermoelectric couple and the gunpowder combustion images shot by the high speed camera when the tested gunpowder samples combust, and finally obtains the combustion characteristics of the tested gunpowder samples through corresponding processing and calculation. The invention not only can be used for testing the parameters such as combustion speed, combustion surface temperature and combustion heat and the like of the gunpowder in vacuum, but also can be used for the generation and collection of the combustion products of the gunpowder under different vacuum conditions. The invention has the overriding advantages of high integration level, obtaining various parameters by one testing and low testing expenses.

Owner:XIAN MODERN CHEM RES INST

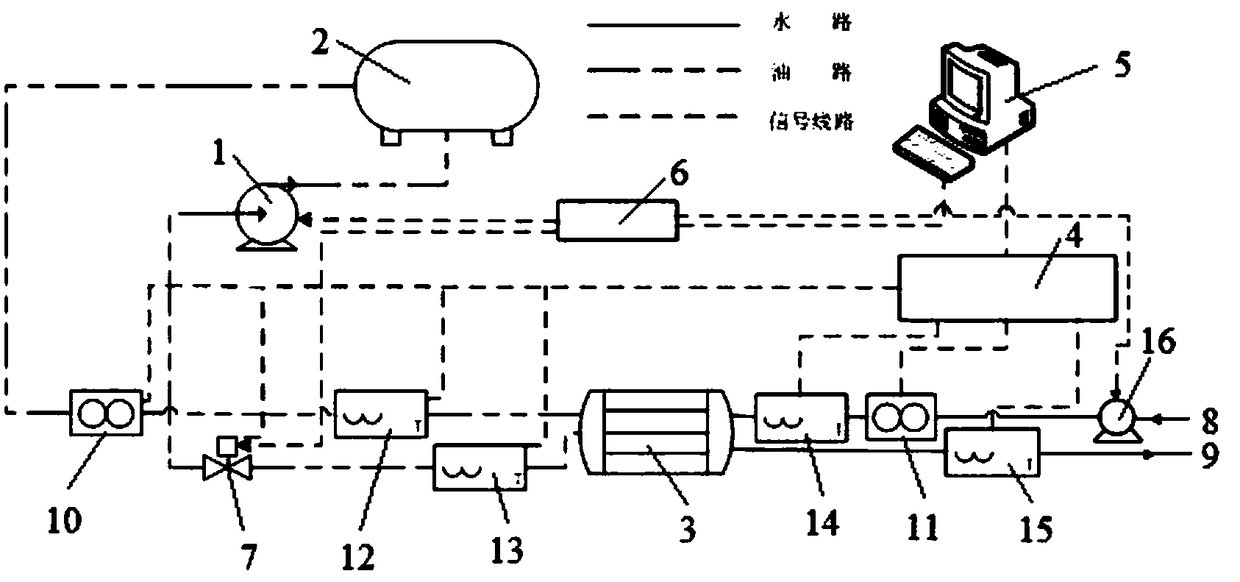

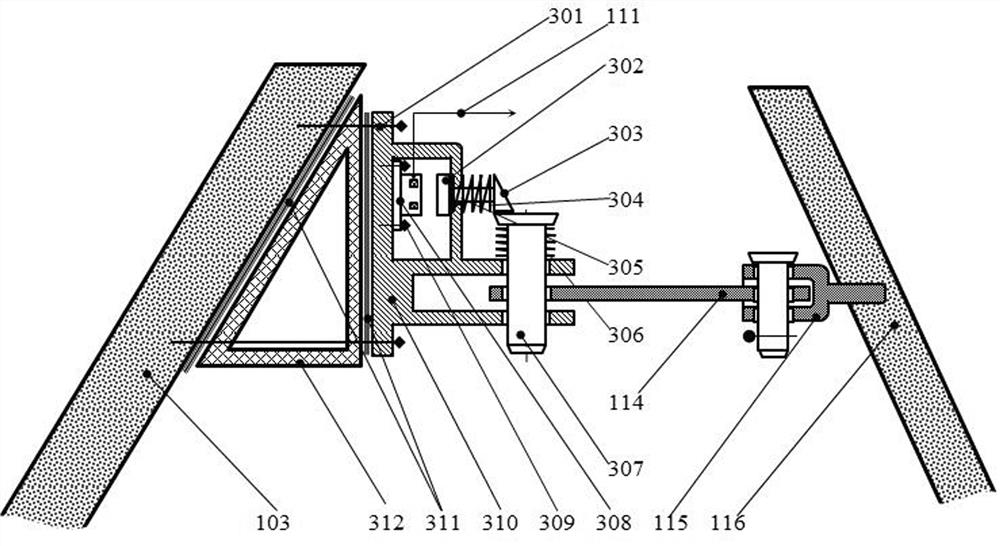

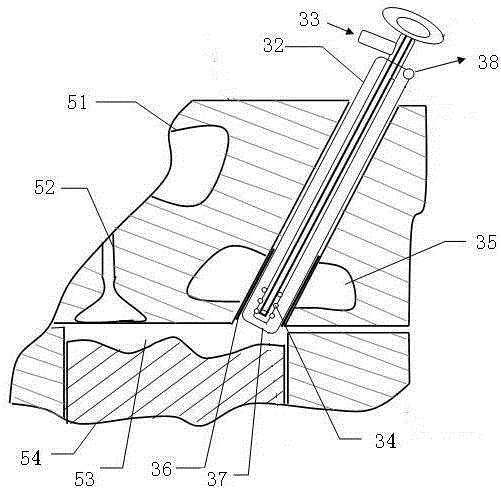

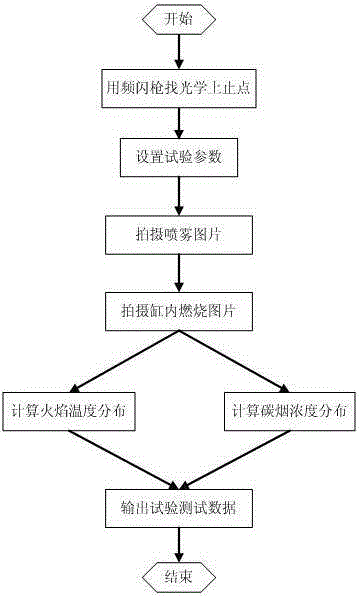

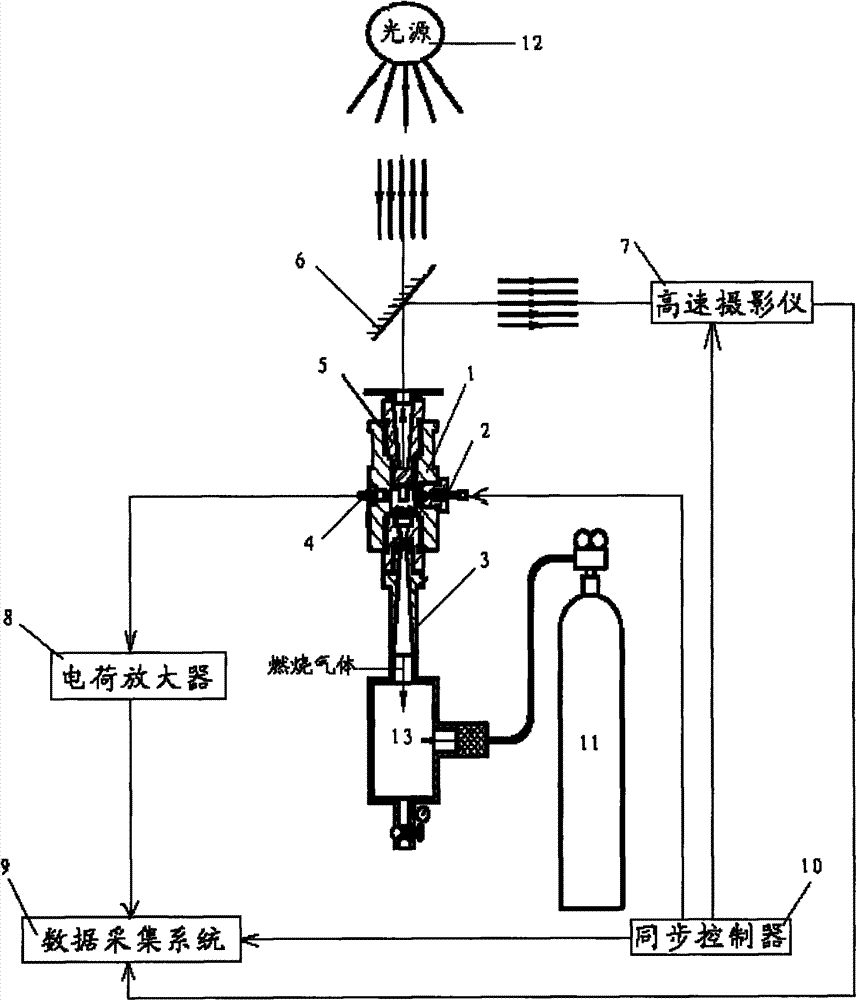

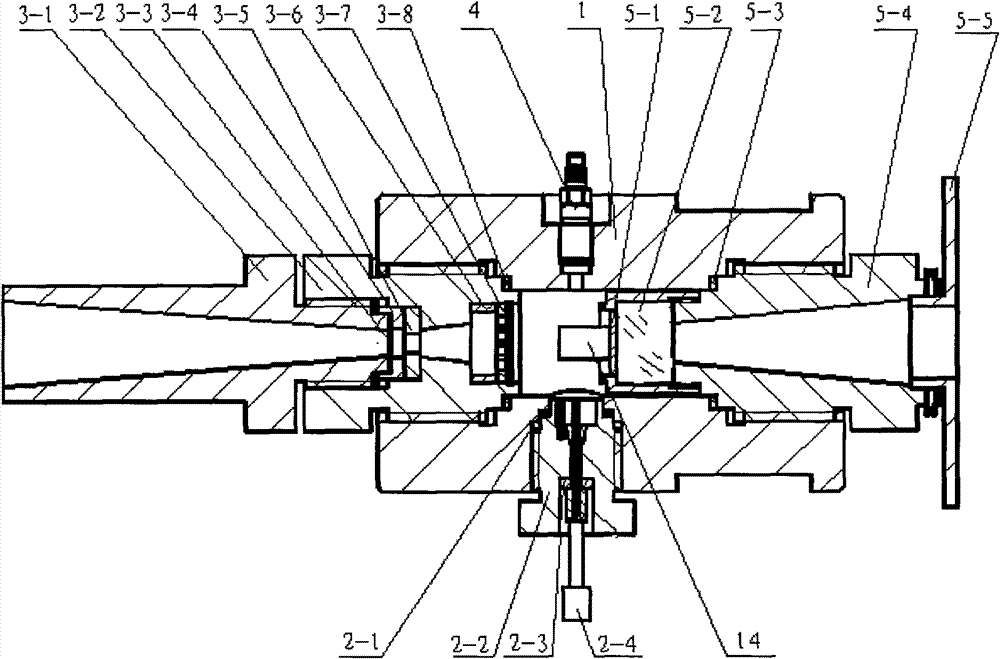

Diesel engine in-cylinder spraying and combustion visualization testing apparatus and testing method

InactiveCN103792090ARealize resource sharingSave research fundsInternal-combustion engine testingCcd cameraTop dead center

The invention relates to a diesel engine in-cylinder spraying and combustion visualization testing apparatus and testing method. The testing apparatus is mainly composed of a digital CCD camera, a computer image acquisition and processing system, a nitrogen cylinder, a pressure stabilizing barrel, a compressed air bottle, a pressure reducing valve, a light-emitting unit, an angle marking instrument, a frequency multiplier, a stroboscopic gun, a diesel engine test cylinder, an endoscope and a stroboscope. During testing, an optical system top head center corresponding to a mechanical top head center of a diesel engine is found out; initialization parameter setting is carried out; dynamic spraying image collection and in-cylinder combustion dynamic shooting are carried out; collected image processing is carried out by using system software of the computer image acquisition and processing system; and then the collected image is processed by using the system software of the computer image acquisition and processing system. According to the invention, with the visualization testing apparatus and testing method, the basis can be provided for the research of improvement of diesel engine air-intake organization, spraying and combustion chamber structure; the accuracy of the apparatus is high; and the operation is convenient.

Owner:JIANGSU UNIV

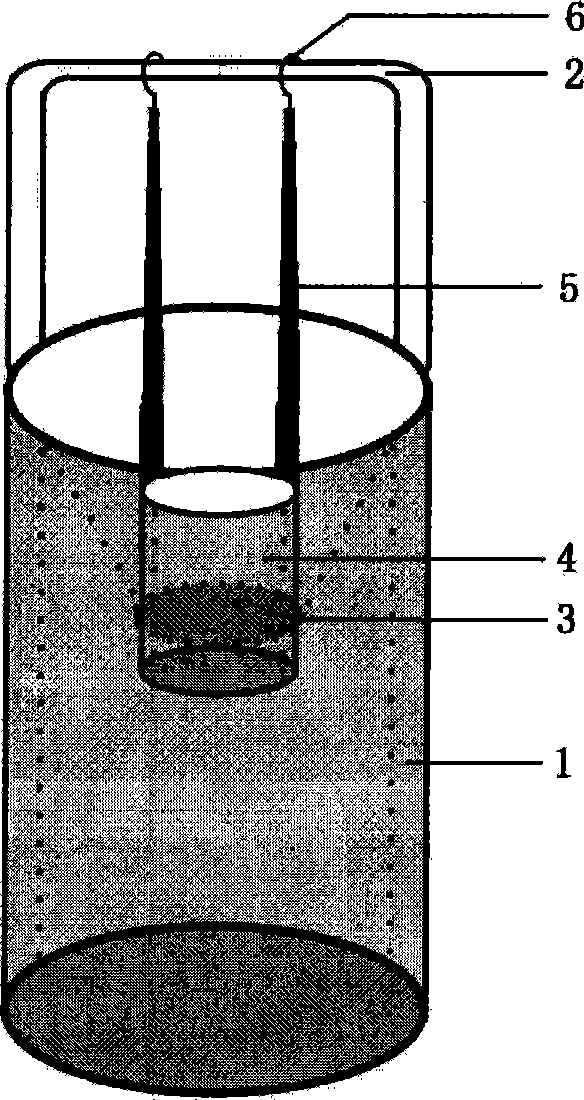

Reaction thermogravimetric analysis system for synergistic heating process of electrical heating and microwave heating

The invention provides a reaction thermogravimetric analysis system for a synergistic heating process of electrical heating and microwave heating and relates to a reaction thermogravimetric analysis system. The system solves the problems in the prior art that the temperature field of each part within an entire region cannot be well reflected through the temperature measurement of either a thermocouple or an infrared thermometer and no reaction thermogravimetric equipment for realizing the synergistic heating process of electrical heating and microwave heating is available. According to the technical scheme of the invention, the outer wall of a reaction tank is provided with a microwave heating system. A furnace tube successively passes through the reaction tank and a furnace lining from top to bottom. At least two silicon carbide rods are arranged in a hearth and are positioned closer to the furnace tube. A sample bracket is arranged in the furnace tube in the penetrated manner. The top end of the sample bracket is provided with a sample crucible. The bottom end of the sample bracket is provided with an electronic balance. The bottom end of the furnace tube is communicated with an atmosphere adjustment system. One end of a filter vat is communicated with the top of the furnace tube. The other end of the filter vat is connected with a computer via a flue gas analyzer. The temperature measurement terminal of a thermocouple is placed in the hearth. The system is applied to reactions during the synergistic heating process of electrical heating and microwave heating.

Owner:HARBIN INST OF TECH

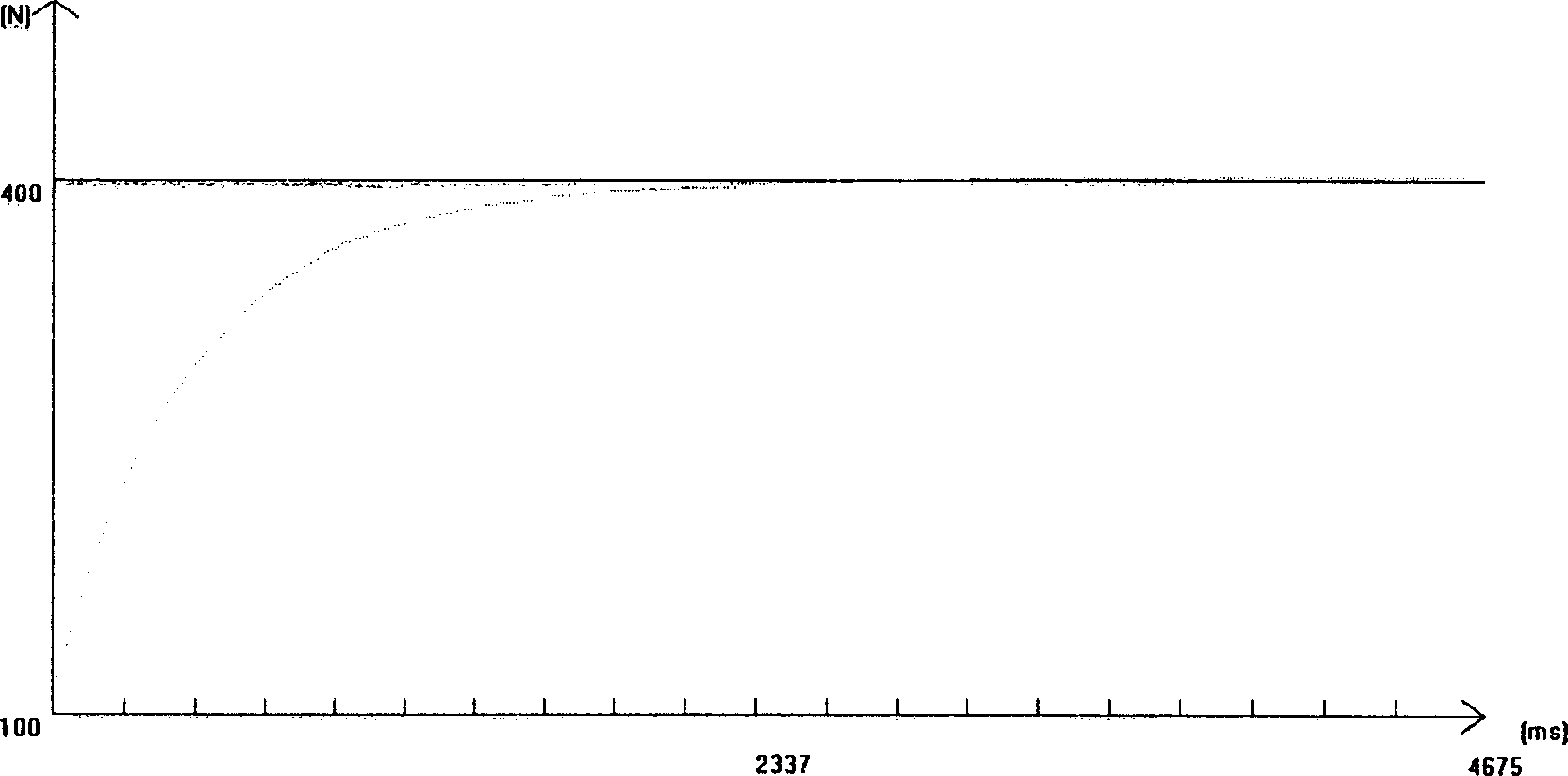

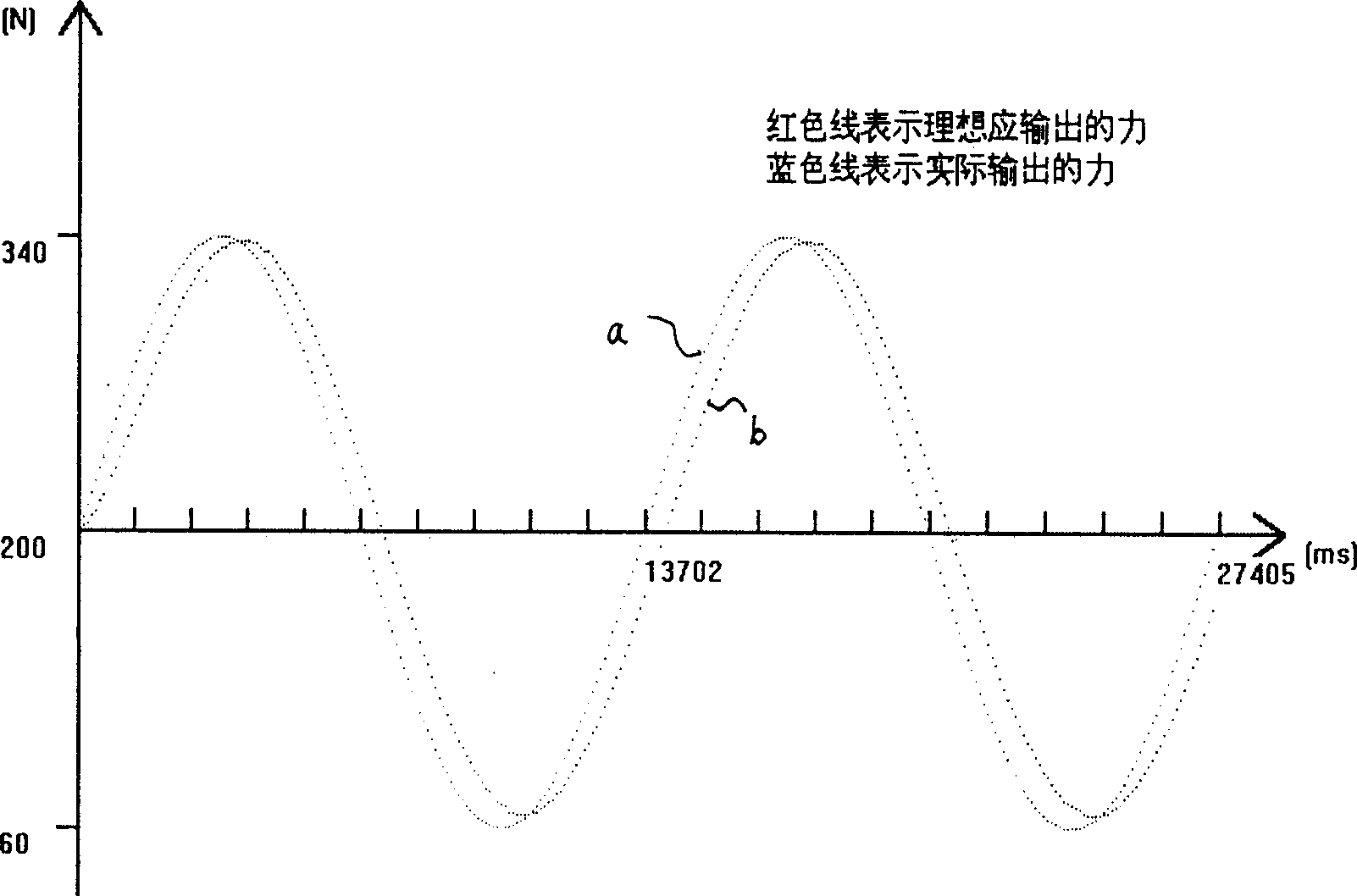

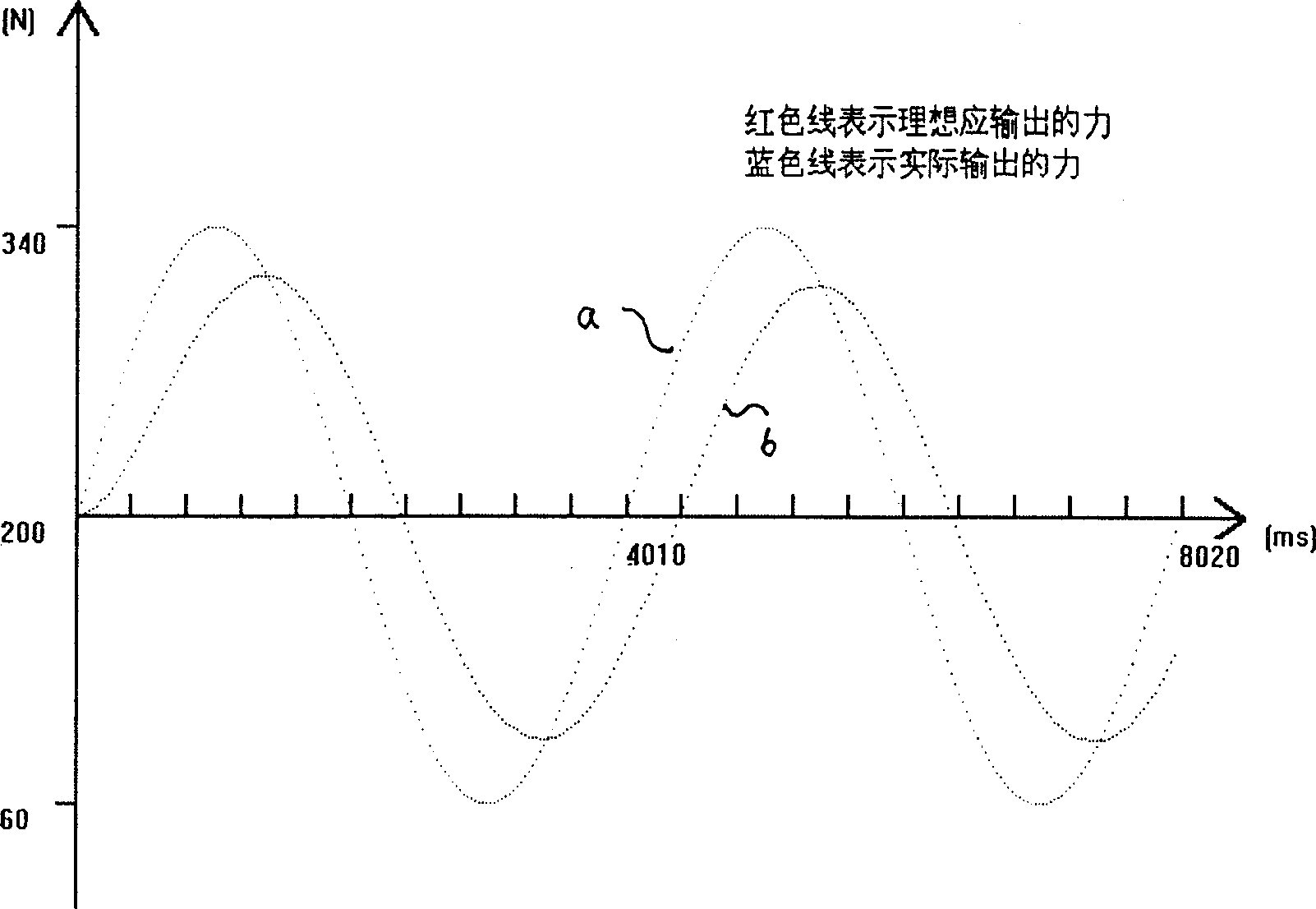

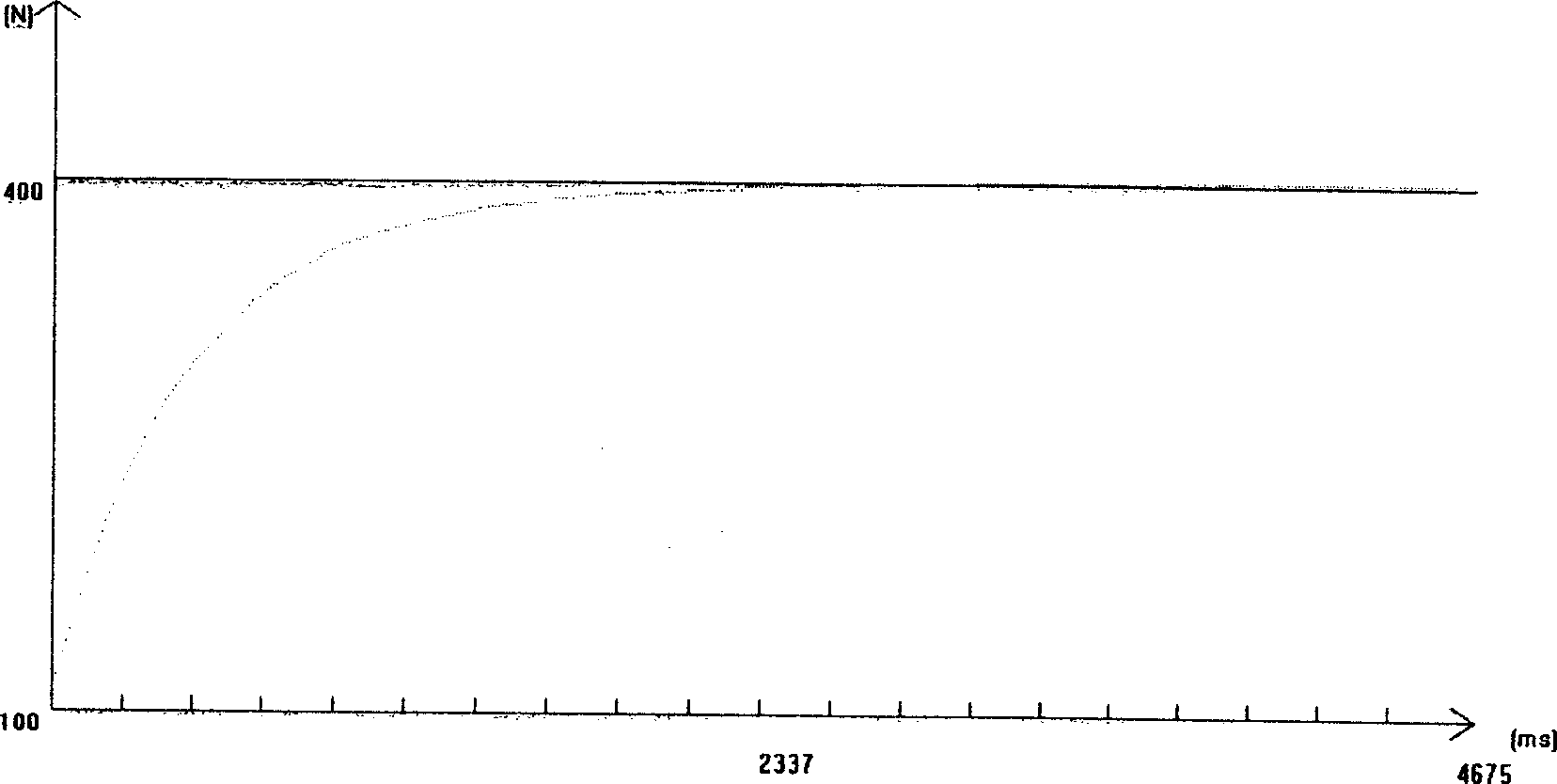

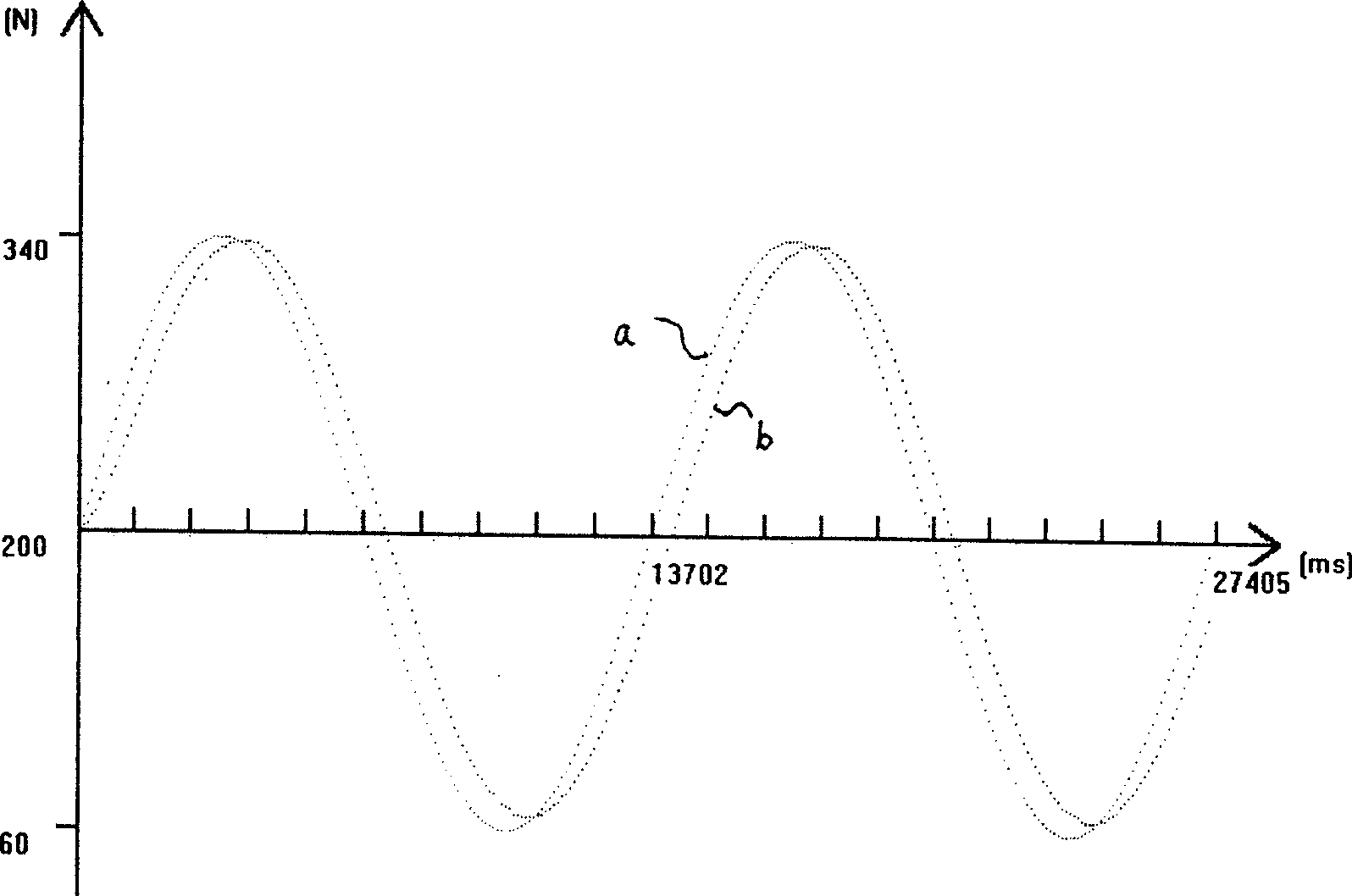

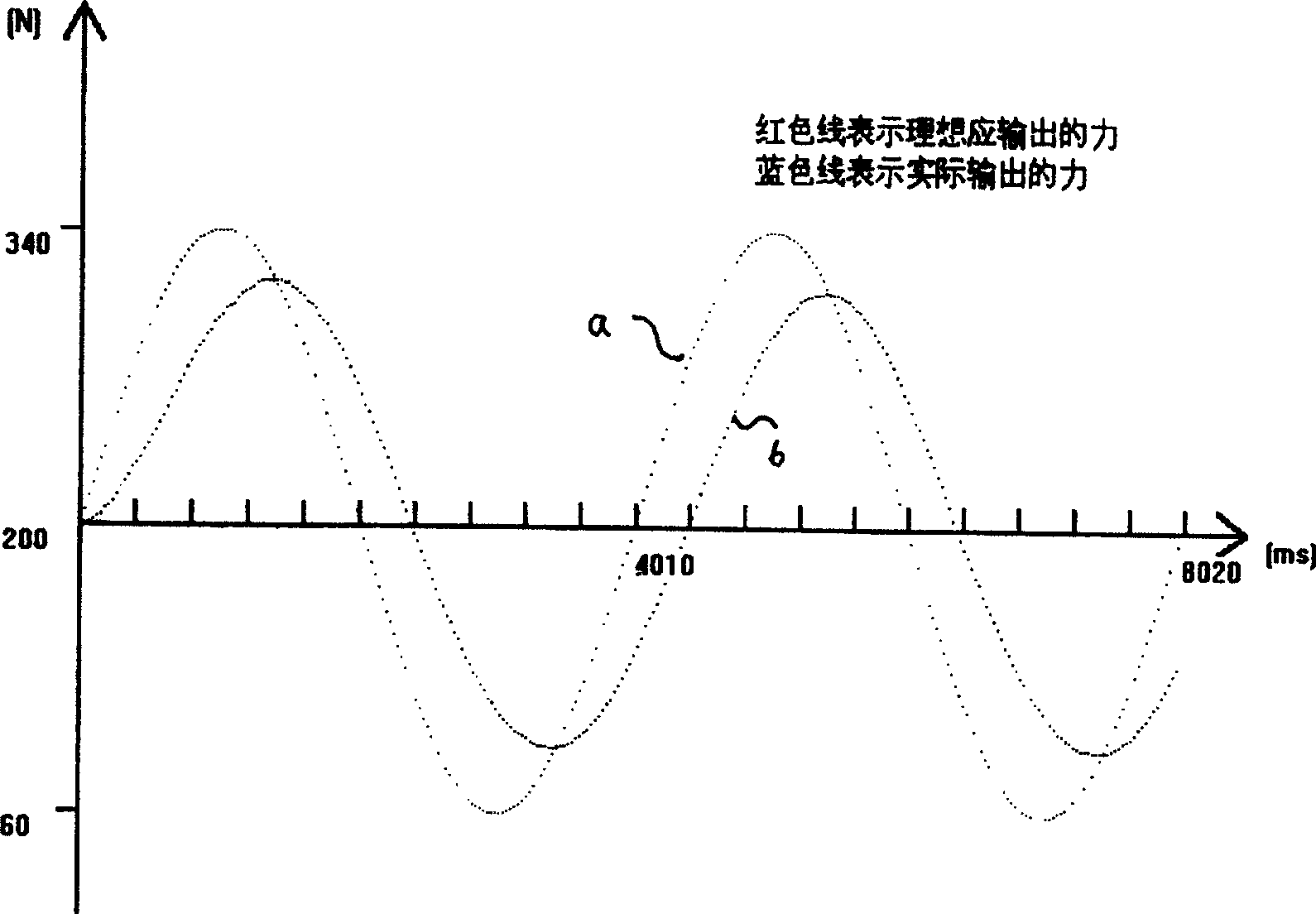

Force control method for lap surface control of stressed lap and equipment thereof

InactiveCN1799769AReduce weightSimple mechanical structureOptical surface grinding machinesLensMicrocontrollerPower flow

The invention relates to a method for controlling the force when actively burnishing the disc. It comprises that: the computer transfers the data and control instruction to the single chip; the single chip control the drawing motor to rotate the ball lead screw and the nut pushes the lever to frap steel wire; the pull sensor measures the tension force of steel wire; the measured result is transferred to single chip; at the same time, the current signal of control motor is feedback to the single chip; the single chip processes PID calculation via power amplifier to be transferred to control motor to regulate rotation speed to adjust the pull of steel wire. Since said steel wire can continuously change the shape of active burnishing surface to keep the same with adhesive part of burnished optical mirror face. The invention also provides a relative device. Since it uses a pull ring-current ring control system while integrates the computer signal process, motor driving, and the process of pull sensor into one circuit to simplify the circuit structure, the invention has small volume, lighter load and quick dynamic response.

Owner:NANJING INST OF ASTRONOMICAL OPTICS & TECH NAT ASTRONOMICAL OBSE

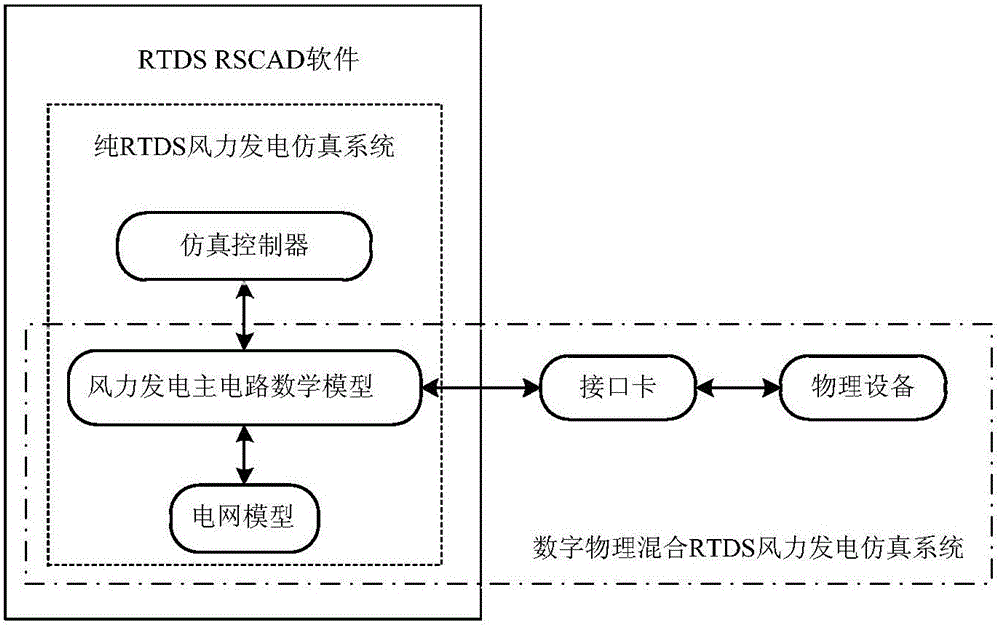

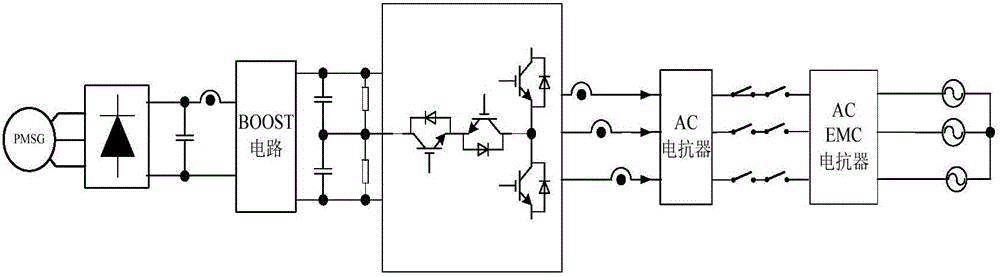

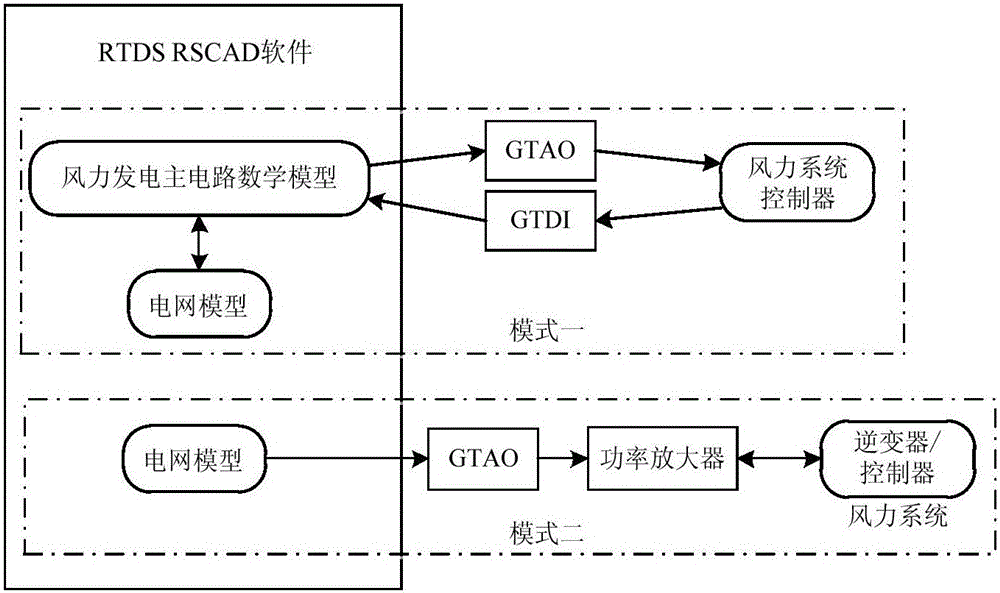

Wind-power-generation digital physical hybrid simulation system based on RTDS and method thereof

InactiveCN105867161AShorten the research cycleSave research fundsSimulator controlMathematical modelPower grid

The invention discloses a wind-power-generation digital physical hybrid simulation system based on an RTDS and a method thereof. The simulation system can realize pure RTDS wind power generation system simulation and can realize digital physical hybrid RTDS wind power generation system simulation. The system is formed by a pure RTDS wind power generation simulation system and a digital physical hybrid RTDS wind power generation system. The pure RTDS wind power generation simulation system is realized in RTDS RSCAD software. A simulation controller, a main-circuit mathematical model of a wind power generation system and a simulation power grid model are included. The digital physical hybrid RTDS wind power generation simulation system is formed by the RTDS RSCAD software, an interface card and physical equipment. In the invention, through a variety of modes of simulation, the wind power generation system is integrally analyzed; and in a physical platform, performance of a control strategy is tested and debugged, and a control parameter and the control strategy can be corrected in real time so that an important practice basis is provided for a practical engineering design.

Owner:SOUTH CHINA UNIV OF TECH

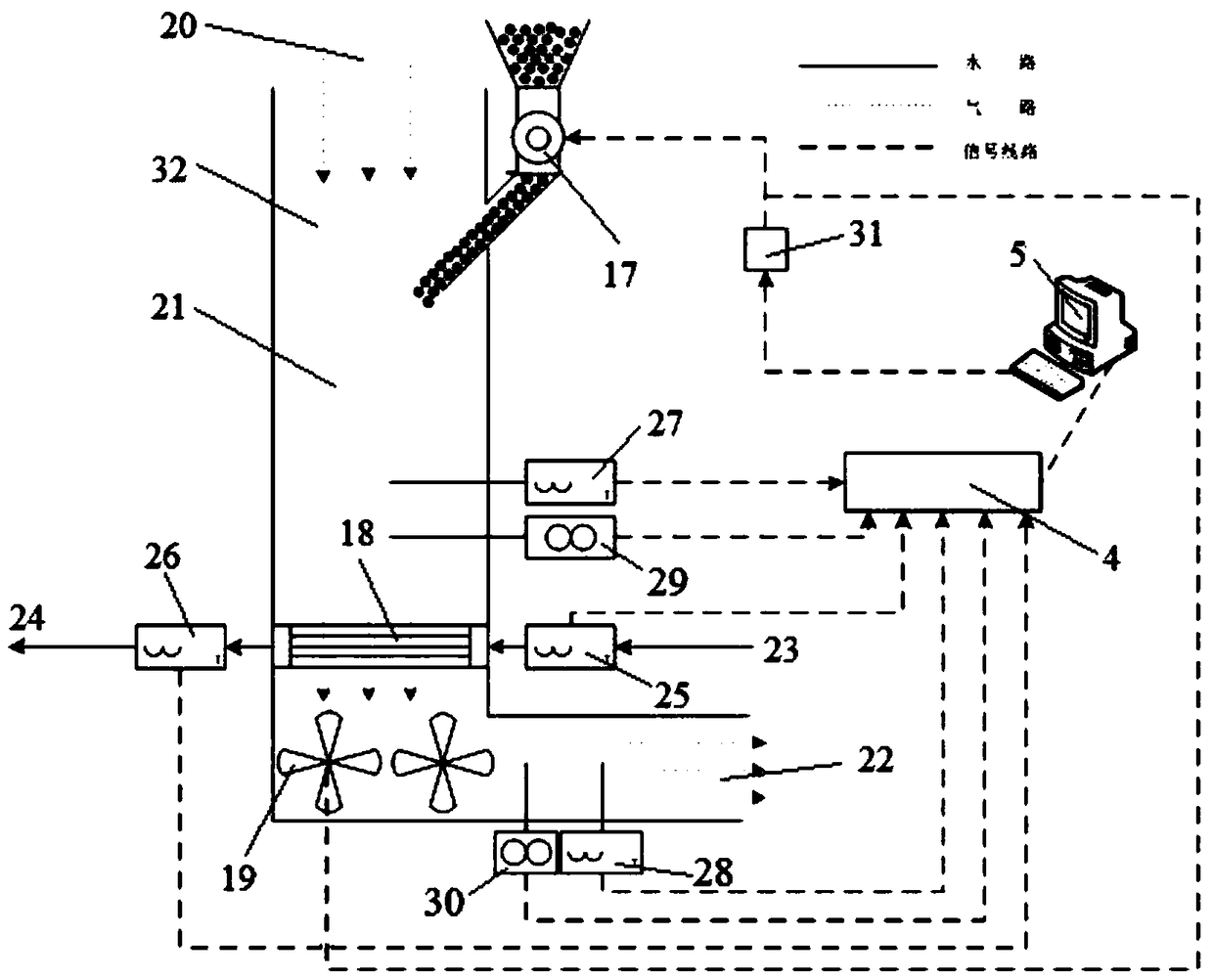

Device for simulating radiating capacity of armored vehicle radiator in sand-dust environment

InactiveCN109030046AImprove environmental adaptabilityImprove battlefield survivabilityStructural/machines measurementEngineeringFlue

The invention discloses a device for simulating radiating capacity of an armored vehicle radiator in sand-dust environment. The device comprises a heating device and a radiator radiating capacity simulating device; a first cooling water inlet and a second cooling water outlet are formed on the heating device; the radiator radiating capacity simulating device comprises a radiator, an air flue, a feeder and a fan; the feeder, the radiator and the fan are orderly arranged in the air flue from top to bottom; a second cooling water inlet and a second cooling water outlet are respectively arranged at two sides of the radiator; the first cooling water outlet is communicated with the second cooling water inlet, and the second water cooling outlet is communicated with the first cooling water inlet.The radiating performance of the armored vehicle radiator in the sand-dust condition is researched by using the device for simulating radiating capacity of the armored vehicle radiator in the sand-dust environment, thereby providing a test condition for the design and optimization of the armored vehicle radiator, and enhancing the environment adaptability and battlefield survival ability of the armored vehicle.

Owner:ARMOR ACADEMY OF CHINESE PEOPLES LIBERATION ARMY

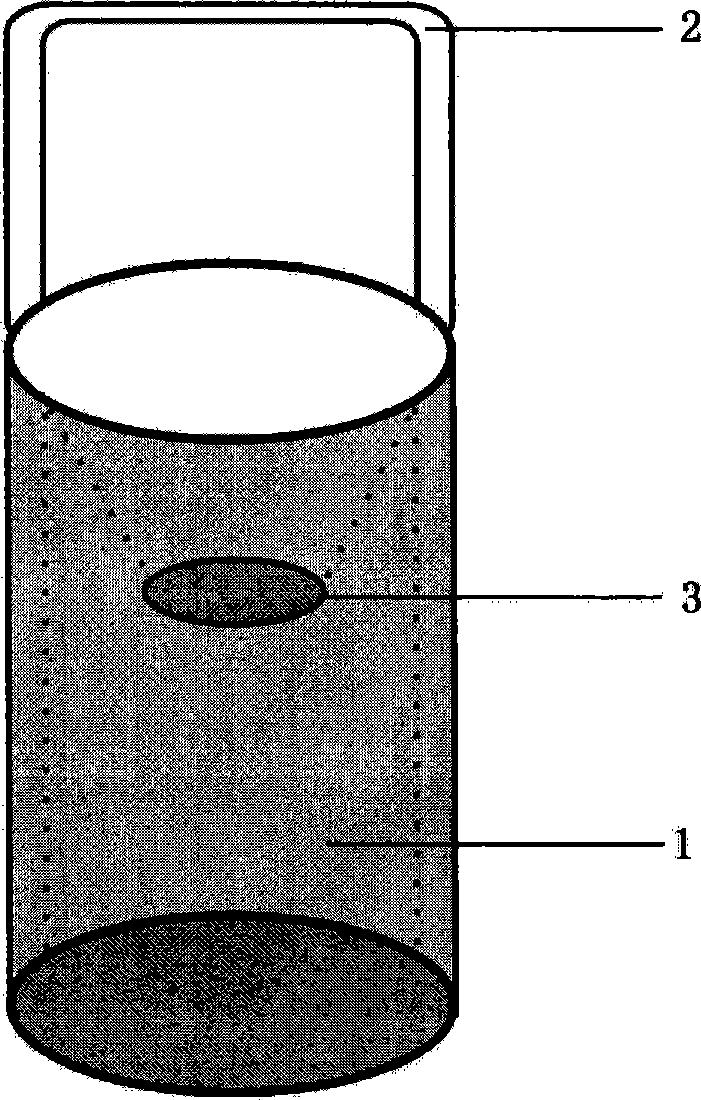

Multifunction organization embedding and refrigerating plant

InactiveCN101451928AReduce volatilityEasy to carryLighting and heating apparatusWithdrawing sample devicesFrozen tissueEmbryo

This invention is a tissue embed-freeze apparatus for frozen tissue section used for life science experiment and medical pathological tissue examination, comprised of a multifunctional liquid nitrogen storage thermostatic bottle and an adjustable suspending water tank. The multifunctional liquid nitrogen storage thermostatic bottle is internally designed with a conical baffle for the adjustable suspending water tank to enter, used for freezing the embedded tissue and reducing volatilization of liquid nitrogen therein. The adjustable suspending water tank is disposed with two freely operable pull rods on two sides thereof, in order to adjust immerging depth and position of the water tank into the liquid nitrogen in the thermostatic bottle within 0 to 30cm according to actual need. With utilization, this invention can rapidly and conveniently carry out high quality freezing process can be carried out on embedded tissue and embryo as a special tissue embed-freeze apparatus, especially suitable for life science, pathology and anatomy, etc., which simultaneously bring new improvement for existing tissue embed-freeze module.

Owner:INST OF ANIMAL SCI OF CHINESE ACAD OF AGRI SCI

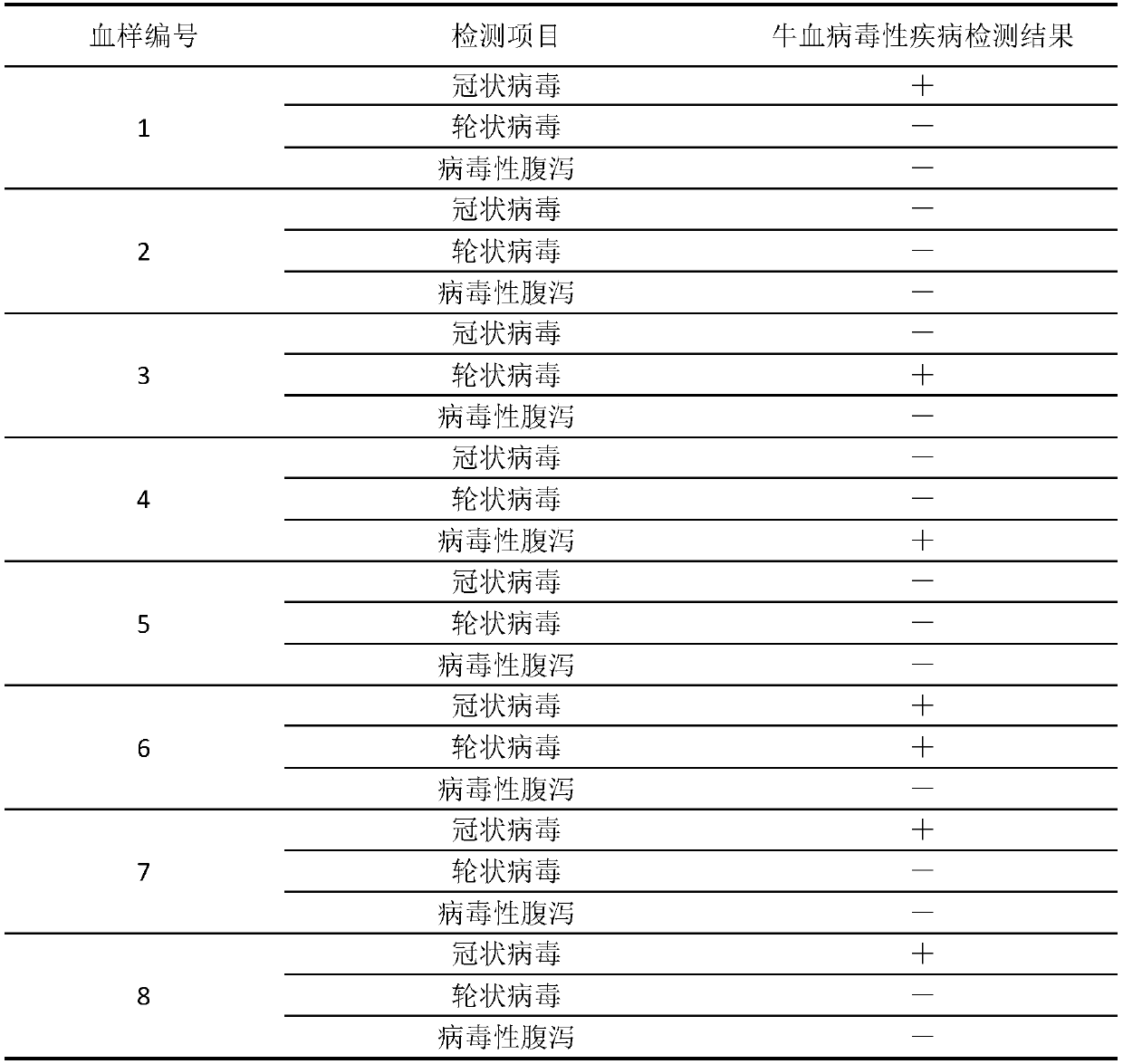

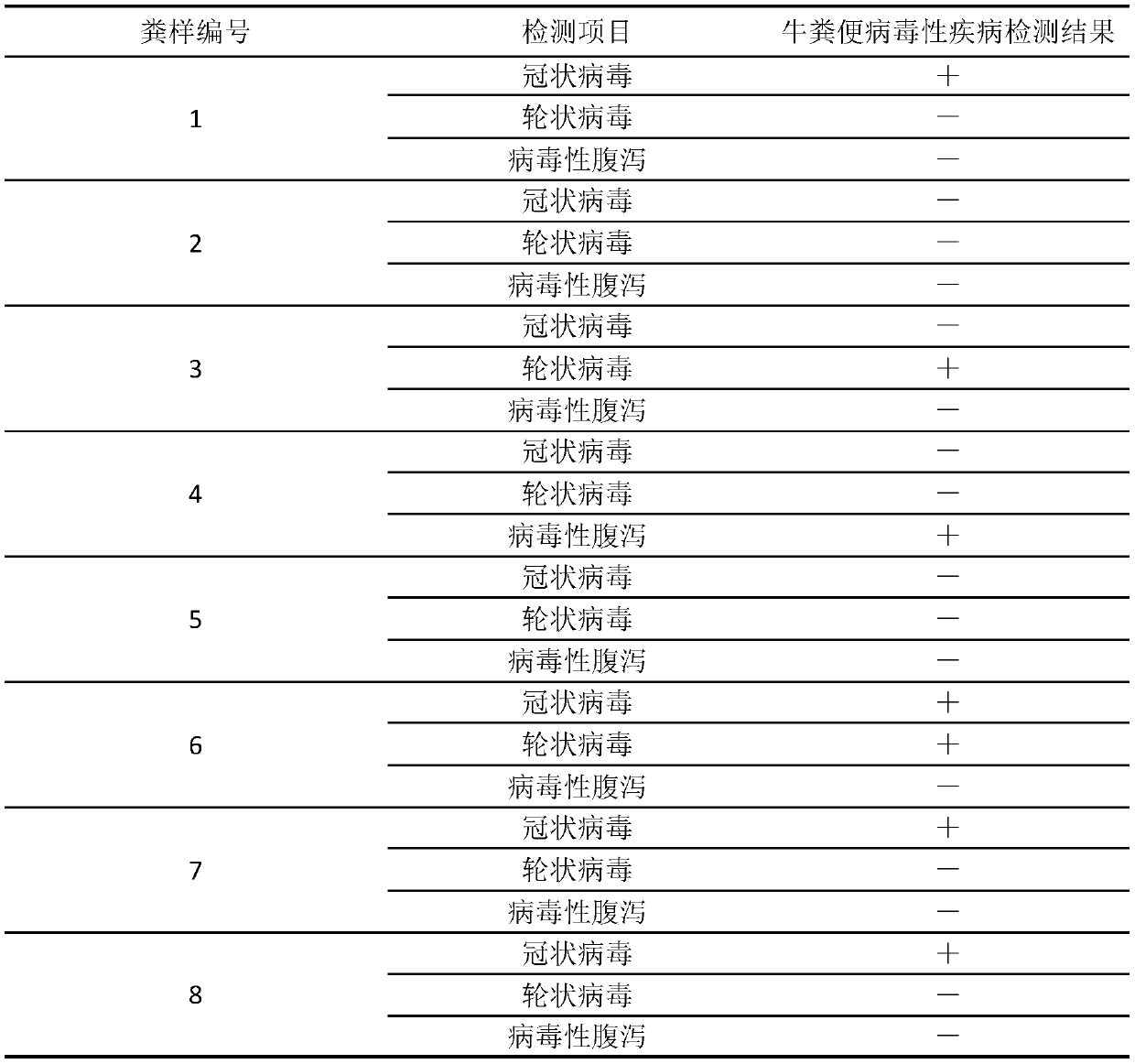

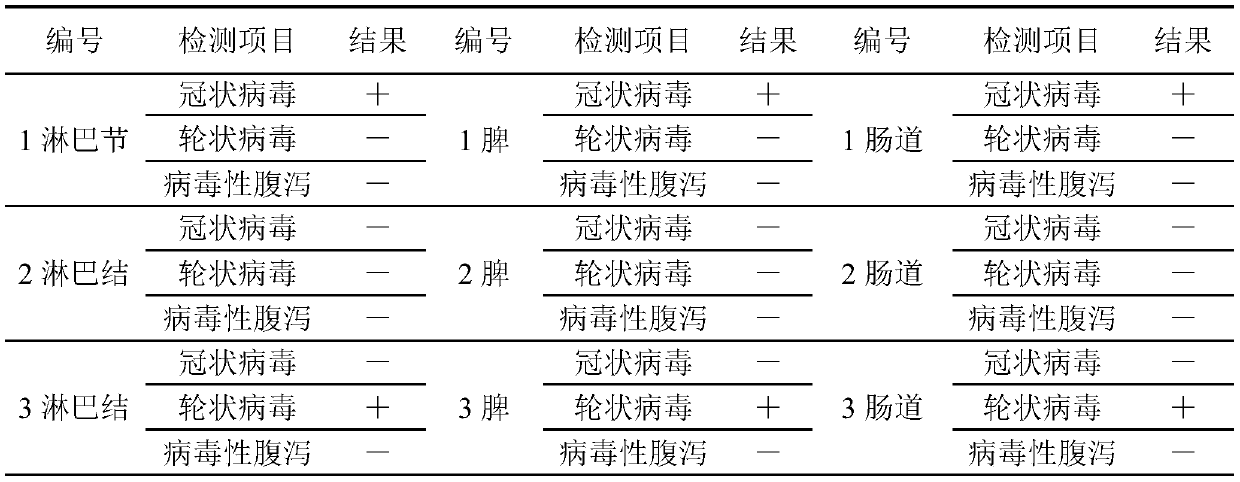

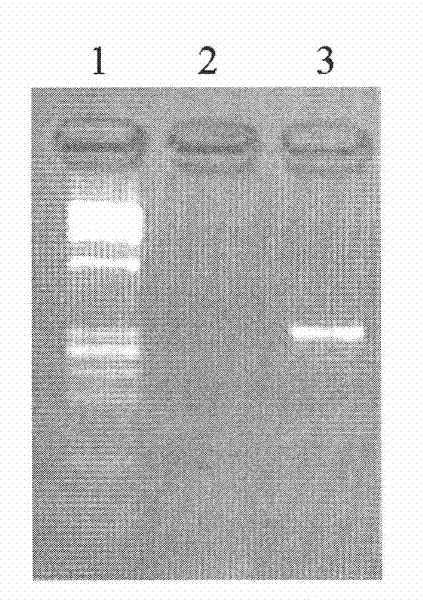

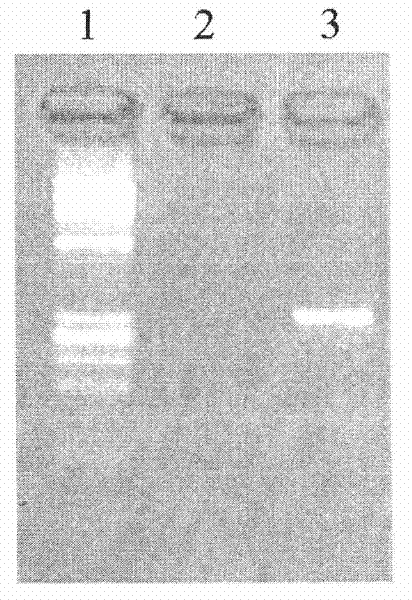

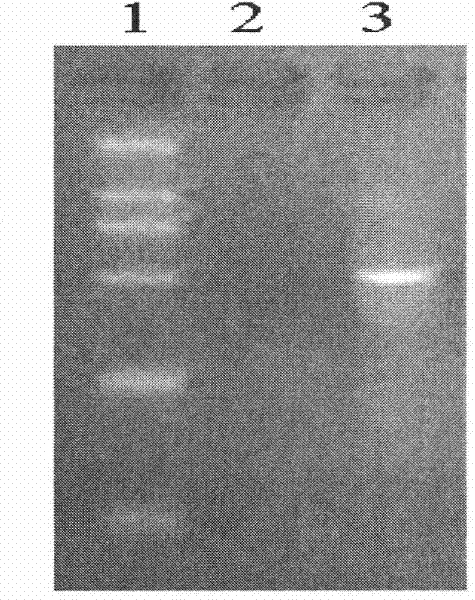

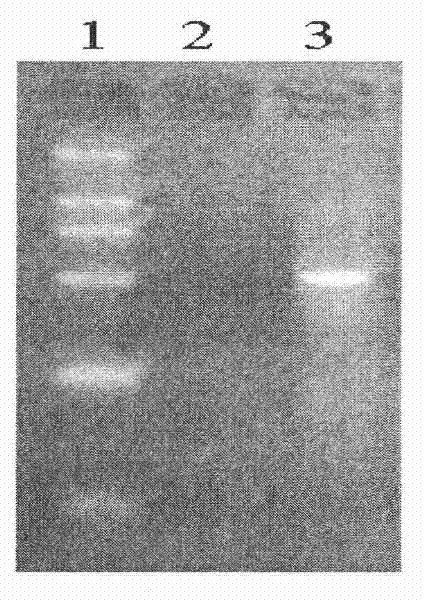

Bovine rotavirus, coronavirus, and viral diarrhea virus multi-connected RT-PCR detection method

ActiveCN110079637AShorten the timeReagent savingMicrobiological testing/measurementAgainst vector-borne diseasesBovine rotavirusElectrophoresis

The invention discloses a bovine rotavirus, coronavirus, and viral diarrhea virus multi-connected RT-PCR detection method, which is characterized in that according to the detection method, RNA of a to-be-detected sample is taken as an RNA template, and a specificity upstream primer and a specificity downstream primer designed according to hereditary characteristics of the bovine rotavirus, coronavirus, and viral diarrhea virus are taken as a primer to perform RT-PCR proliferation to obtain a proliferation product. Then, electrophoresis detection is performed on the proliferation product with 1.5% agarose gel, and a result is recorded; according to the results of the electrophoresis detection, whether the to-be-detected sample contains the bovine rotavirus, coronavirus, and viral diarrhea virus is determined. The bovine rotavirus, coronavirus, and viral diarrhea virus detection method achieves has the beneficial effect of accurately, rapidly and efficiently distinguishing and diagnosingthe three viral disease with RT-PCR.

Owner:INNER MONGOLIA UNIV FOR THE NATITIES

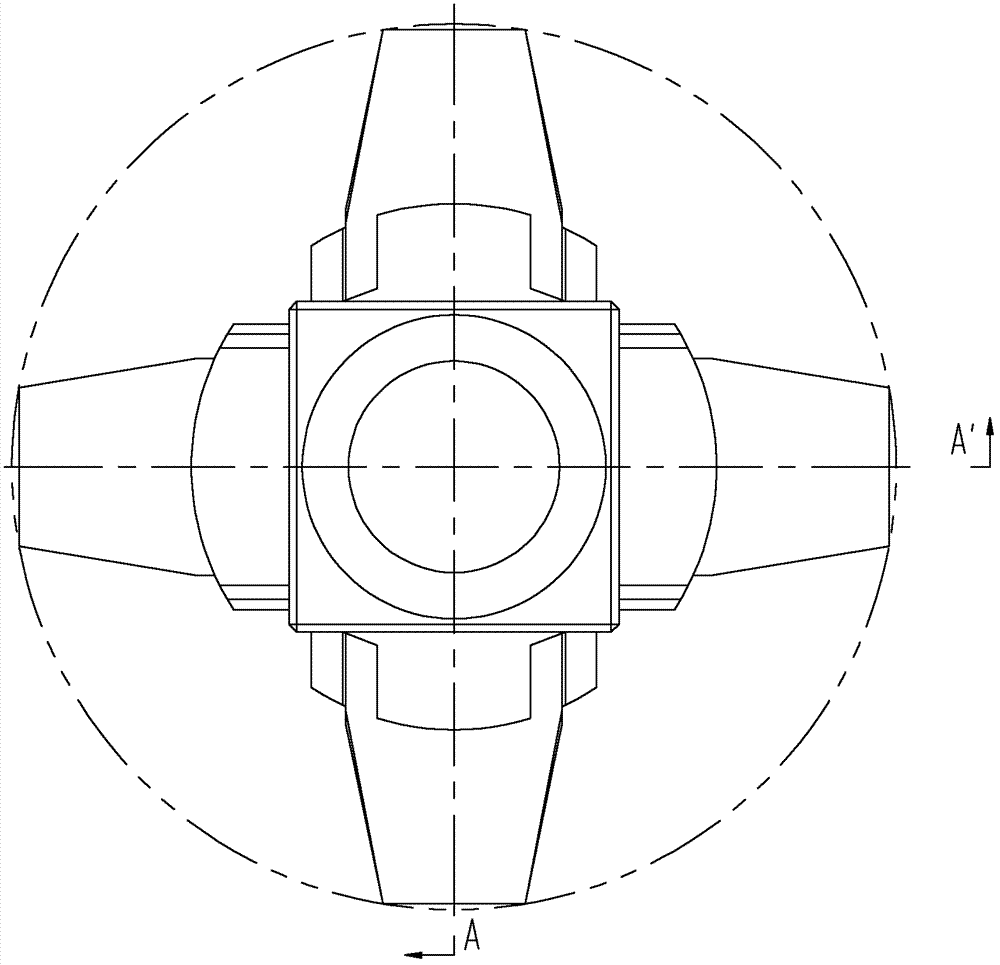

Angle-adjustable stirring machine

InactiveCN102895908ASave research fundsShort experiment cycleMixer accessoriesExperimental DevicesEngineering

The invention relates to a stirring machine, and especially relates to an angle-adjustable stirring machine. The angle-adjustable stirring machine comprises a wheel hub and stirring blades. A shaft sleeve is arranged outside the wheel hub. A connection plate which can rotate by 360 DEG is connected on the shaft sleeve. The connection plate is connected to a blade seat through a hexagon socket bolt. The blade seat comprises bevel-angle blade seats and straight-angle blade seats. The bevel-angle blade seats are connected with bevel-angle blades through blade connection screws. The straight-angle blade seats are connected with straight-angle blades through blade connection screws. The bevel-angle blades and the straight-angle blades are distributed adjacently. According to the invention, a newly manufactured wheel hub is not needed. Simply the blades and the shaft sleeve of the wheel hub are adjusted, and a purpose for changing a stirring effect can be achieved, wherein an adjustment angle can reach 360 DEG. The stirring machine provided by the invention is especially suitable to be popularized in small experimental devices. With the machine, research funds are greatly reduced, experiment period is shortened, and working efficiency is improved.

Owner:江苏华东明茂机械有限公司

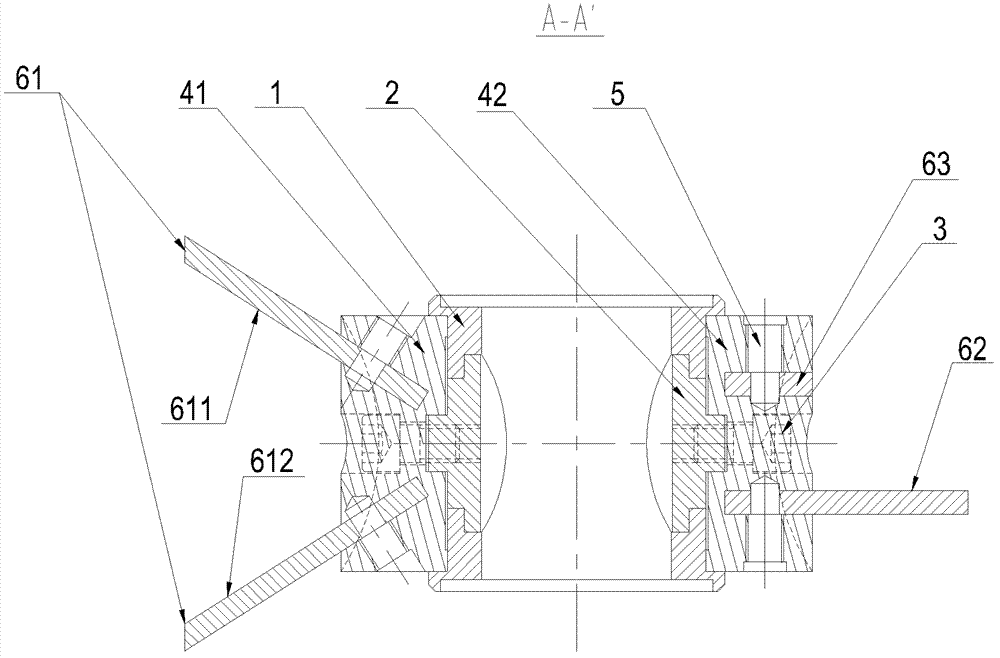

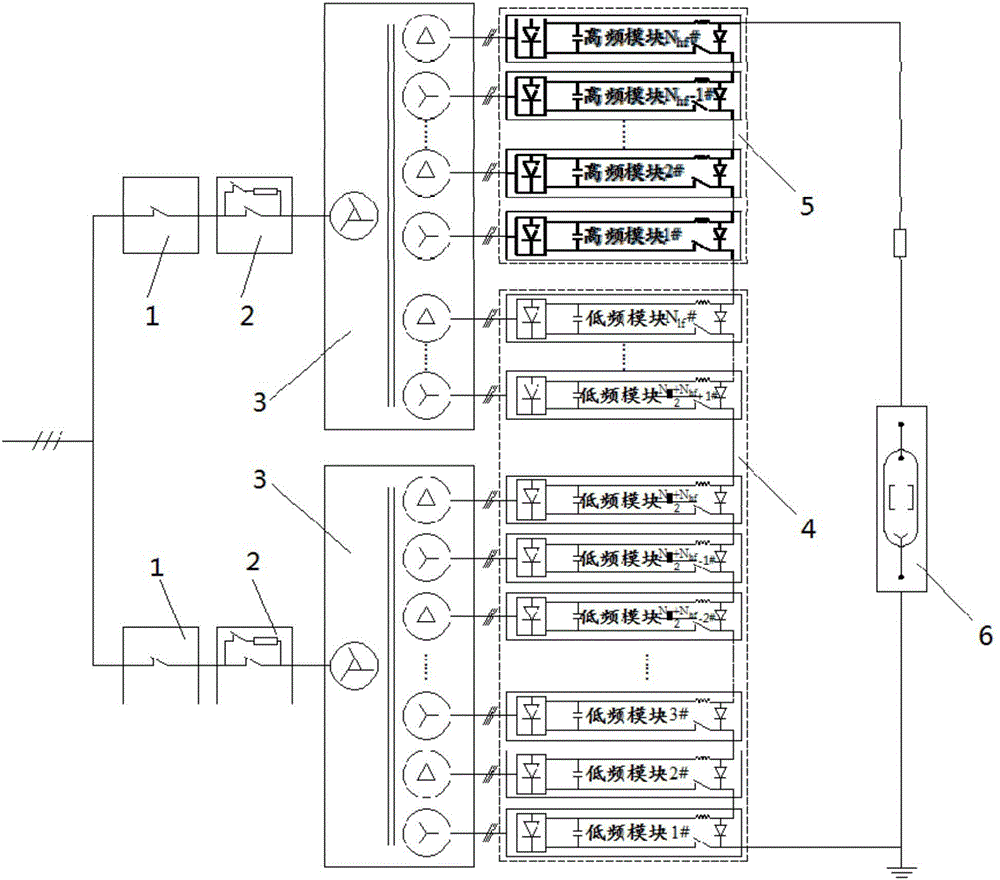

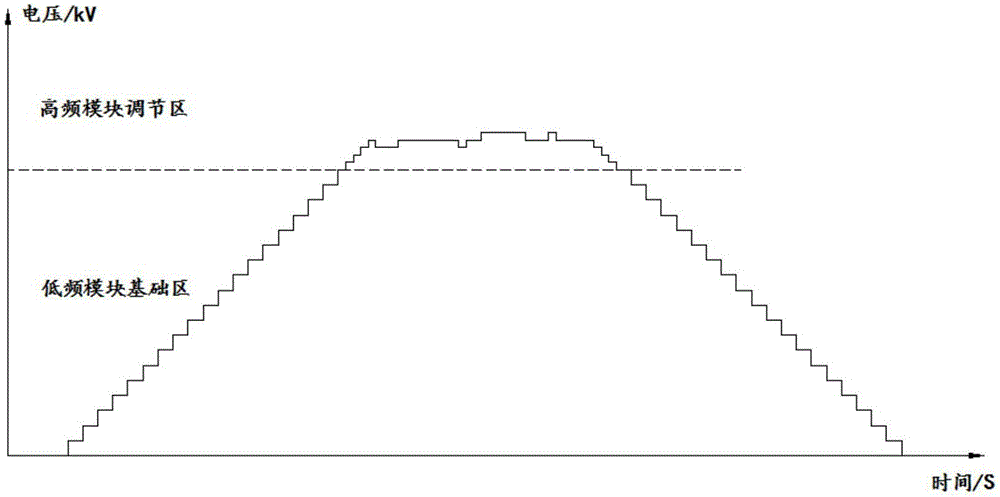

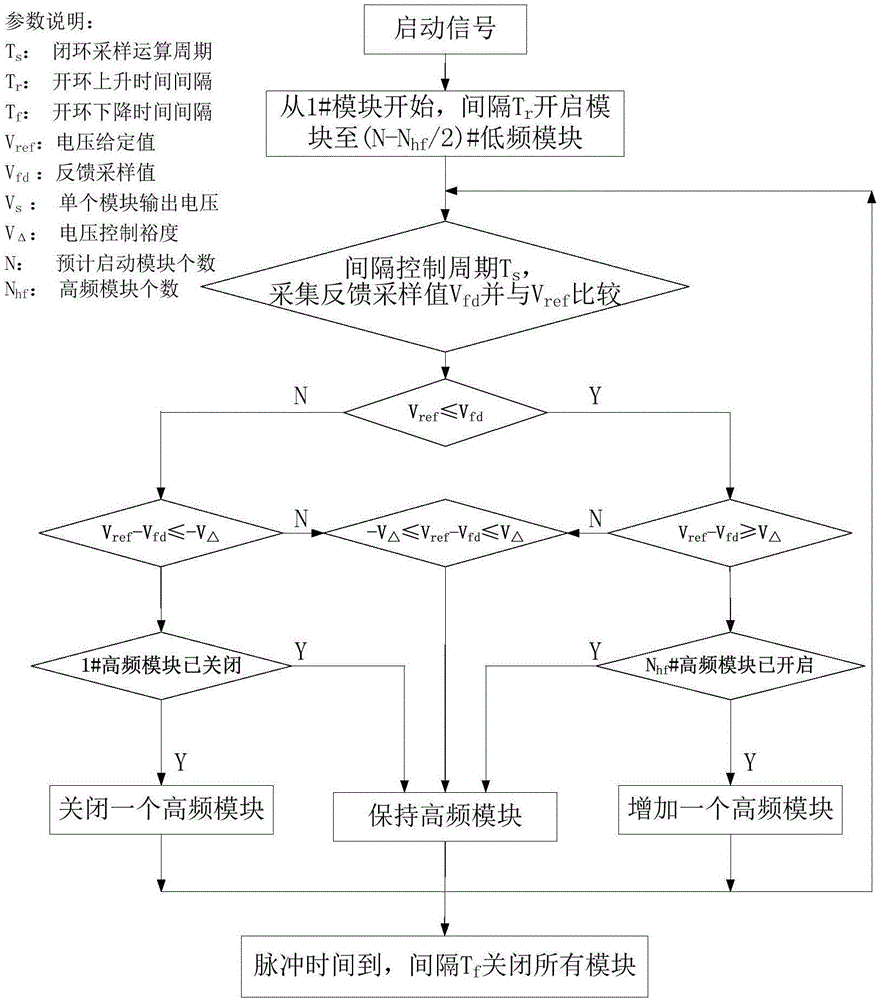

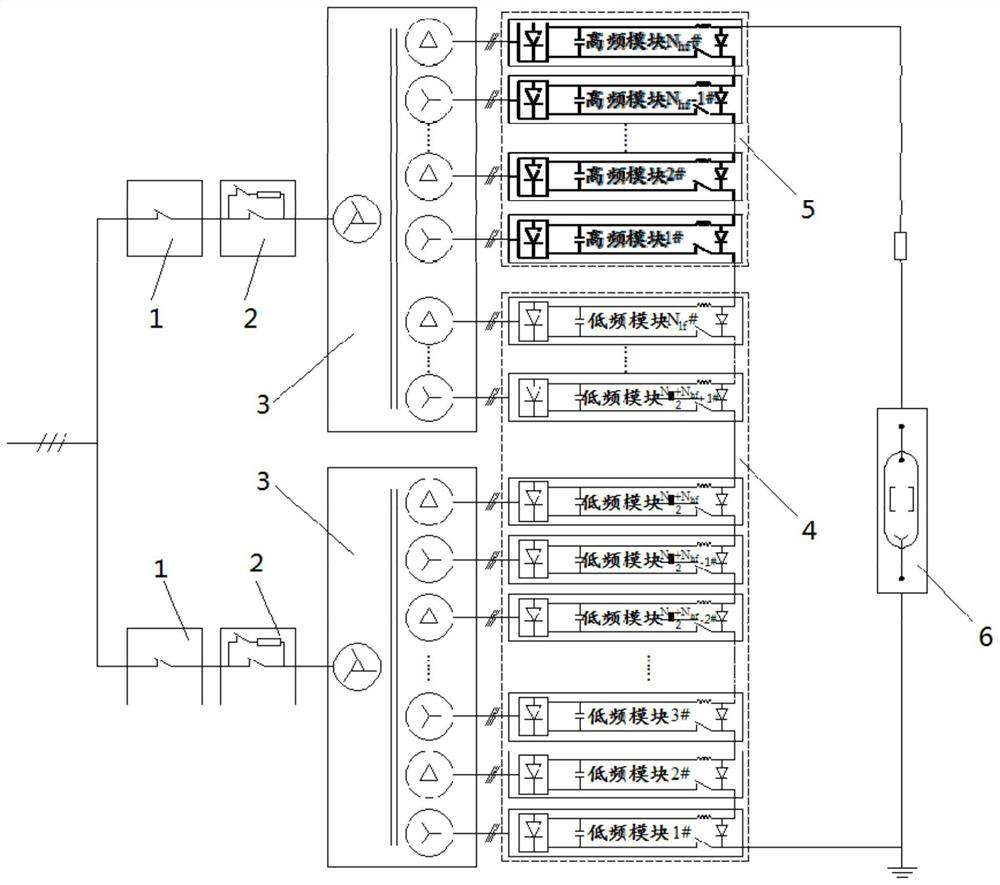

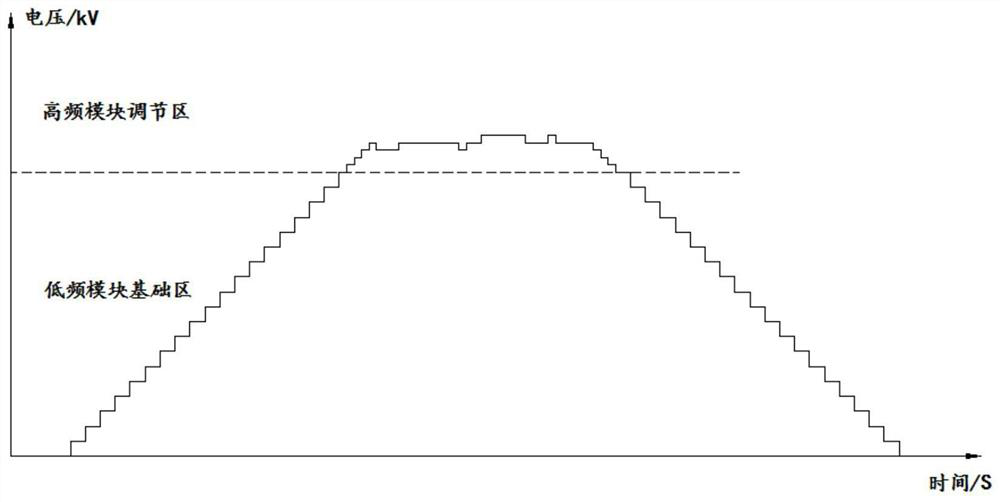

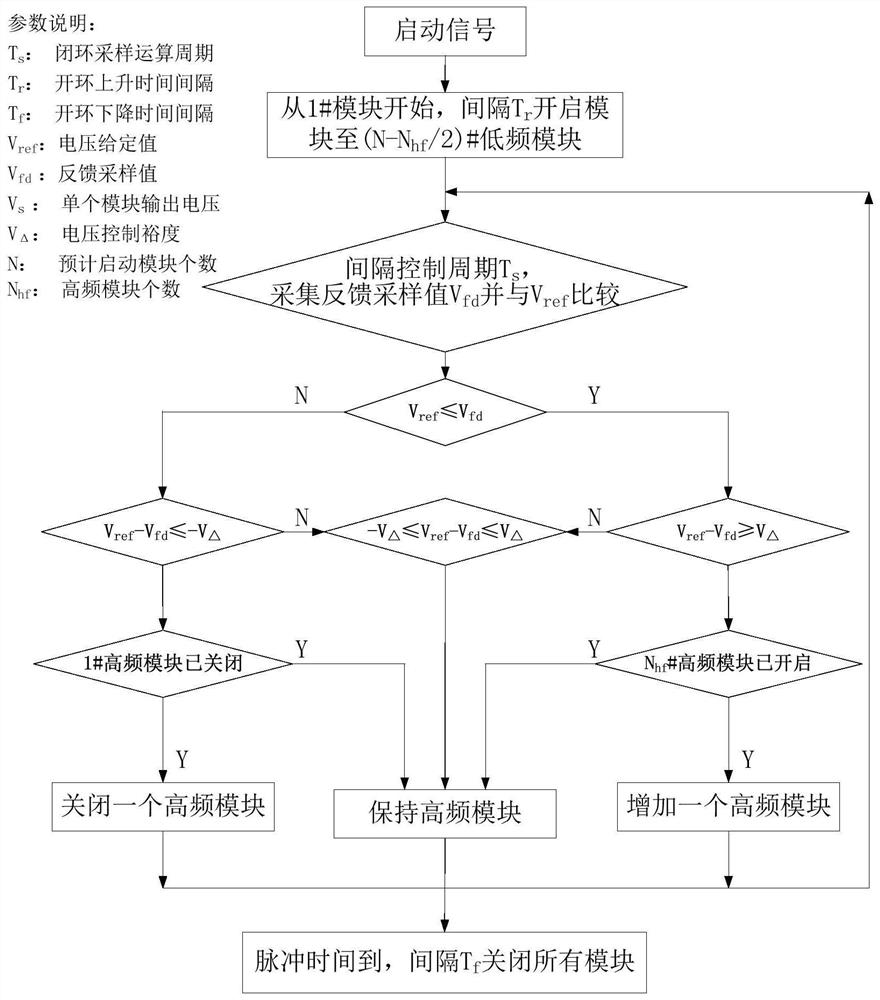

PSM high-voltage power supply system and feedback control realization method therefor

ActiveCN106533222AGuaranteed uptimeMeet control requirementsAc-dc conversion without reversalKlystronEngineering

The invention discloses a PSM high-voltage power supply system and a feedback control realization method therefor. The PSM high-voltage power supply system comprises a high-voltage wire-inlet part, wherein the high-voltage wire-inlet part is formed by two high-voltage circuit breaker cabinets which are connected with a high-voltage contactor cabinet in series separately; two high-voltage contactor cabinets are connected with a multi-winding high-voltage isolation transformer separately; the multi-winding high-voltage isolation transformer is connected with low-frequency rectifying power supply modules and high-frequency rectifying power supply modules separately; and the low-frequency rectifying power supply modules and the high-frequency rectifying power supply modules are all connected in series and then connected to a load. By adoption of the PSM high-voltage power supply system and the feedback control realization method therefor, the problem of severe fluctuation on high-voltage output caused by power grid disturbance in a discharging period of an EAST apparatus is well solved, so that the control requirement of a klystron on voltage precision is satisfied, thereby satisfying requirements of various physical experiments.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

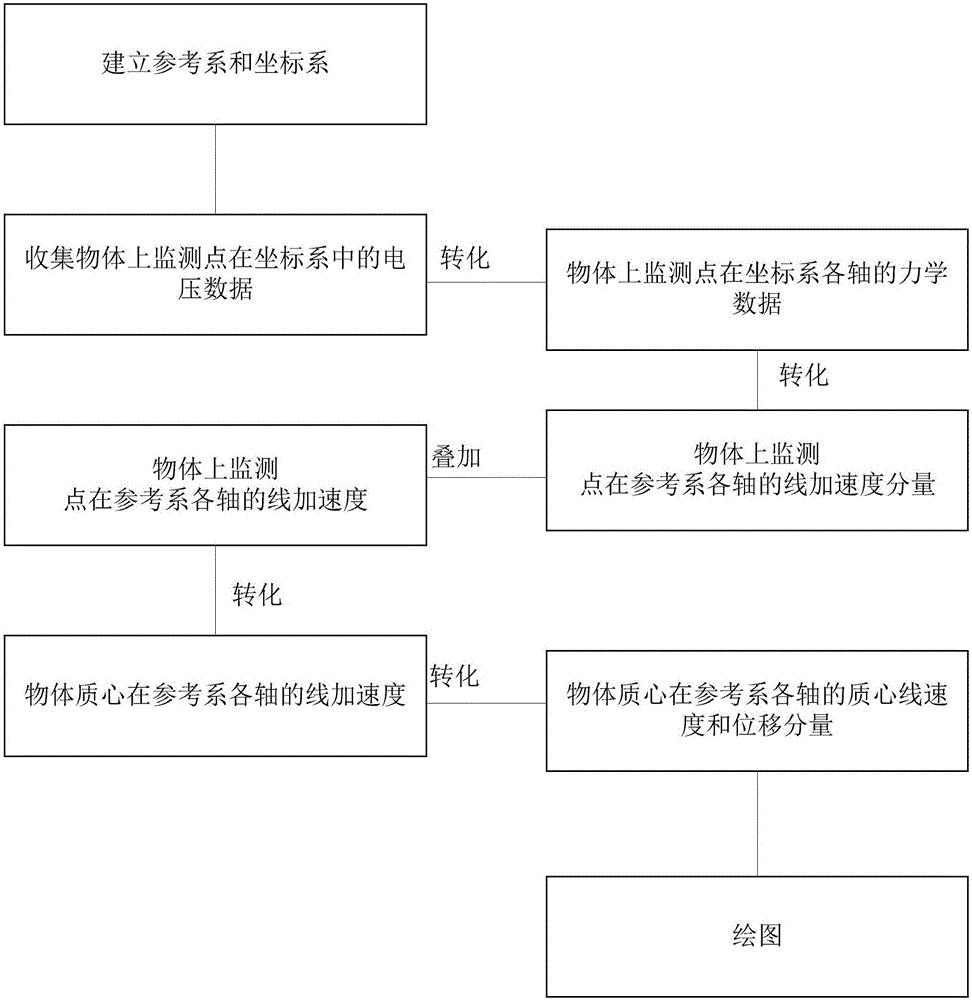

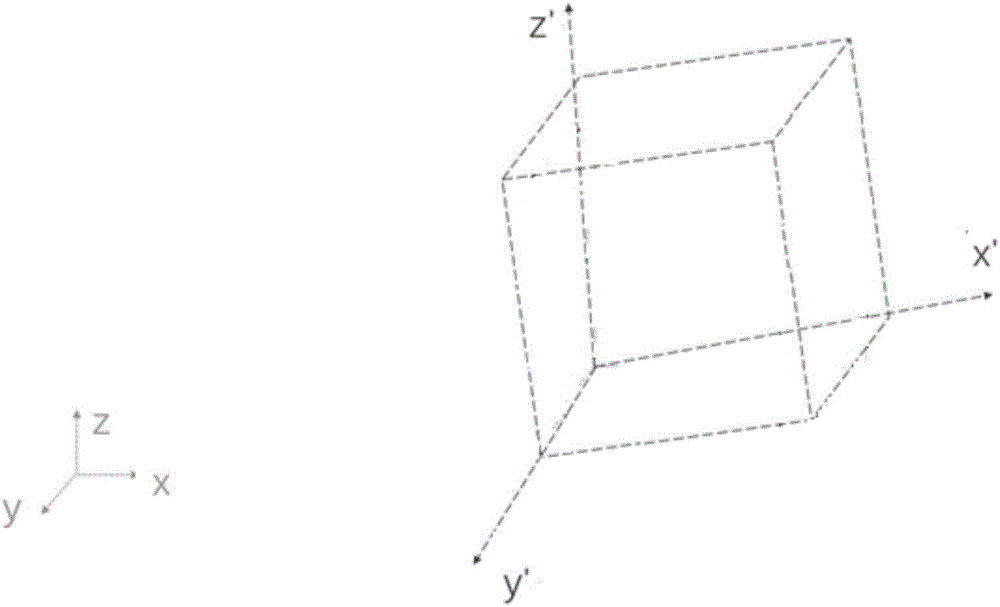

Six-degree-of-freedom motion track data processing method of drop test pre-embedded sensor

InactiveCN106767781APromote technological developmentSolve the problem that the movement state of falling rocks cannot be fully obtainedSpeed measurement using accelerationNavigation by speed/acceleration measurementsObject motionDrop tests

The invention discloses a six-degree-of-freedom motion track data processing method of a drop test pre-embedded sensor. The method comprises building a reference system corresponding to object motion based on the ground, building a coordinate system corresponding to object motion based on a drop test pre-embedded sensor, collecting voltage data of monitoring points on the object in the coordinate system in object motion, transforming the voltage data into mechanical data, respectively transforming linear acceleration values of the object monitoring points on all axes of the coordinate system into linear acceleration components of the object monitoring points on all the axes of the reference system, calculating the sum of the linear acceleration components of the object monitoring points on all the axes in the reference system to obtain linear acceleration values of the object monitoring points on all the axes in the reference system, transforming the linear acceleration values into linear acceleration values of the object centroid on all the axes of the reference system, carrying out time integration to obtain centroid linear acceleration values and displacement components of the object centroid on all the axes of the reference system, and drawing a time-history function and a displacement function in object motion. The method has scientific universality and can be widely used in rockfall disaster research.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

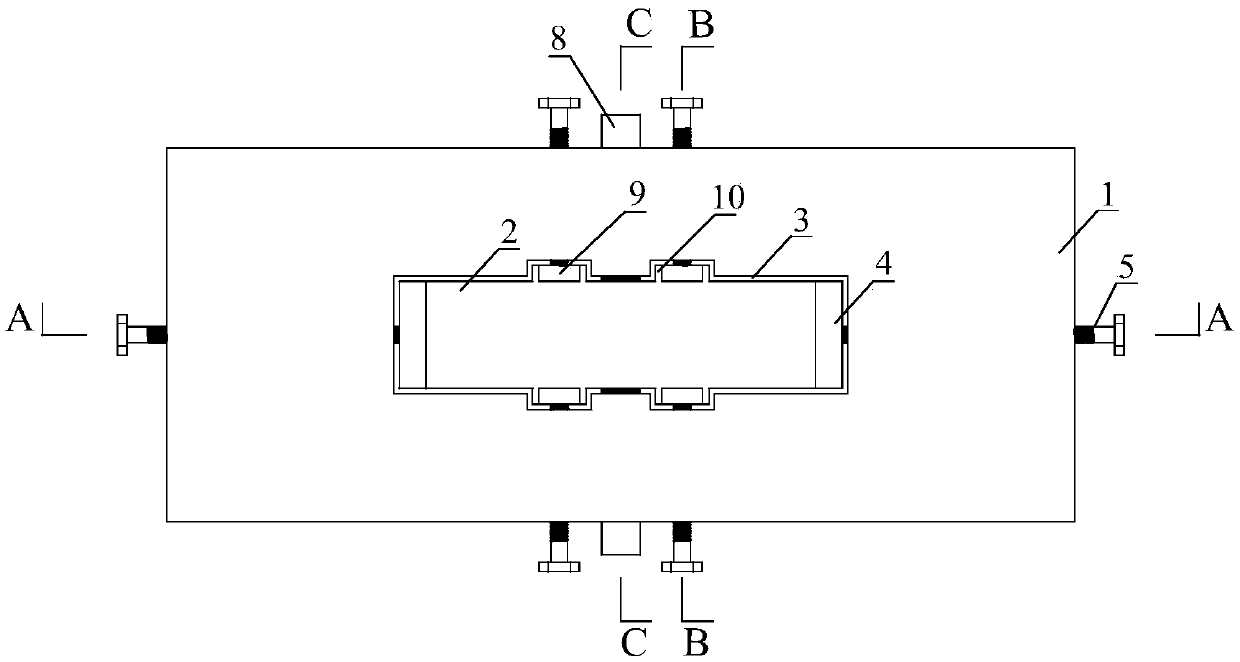

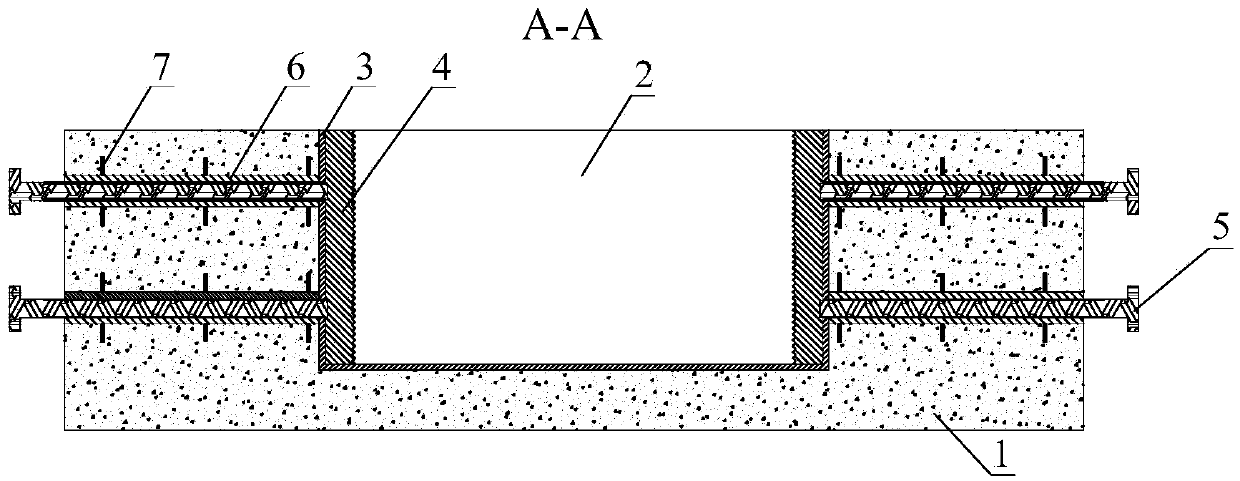

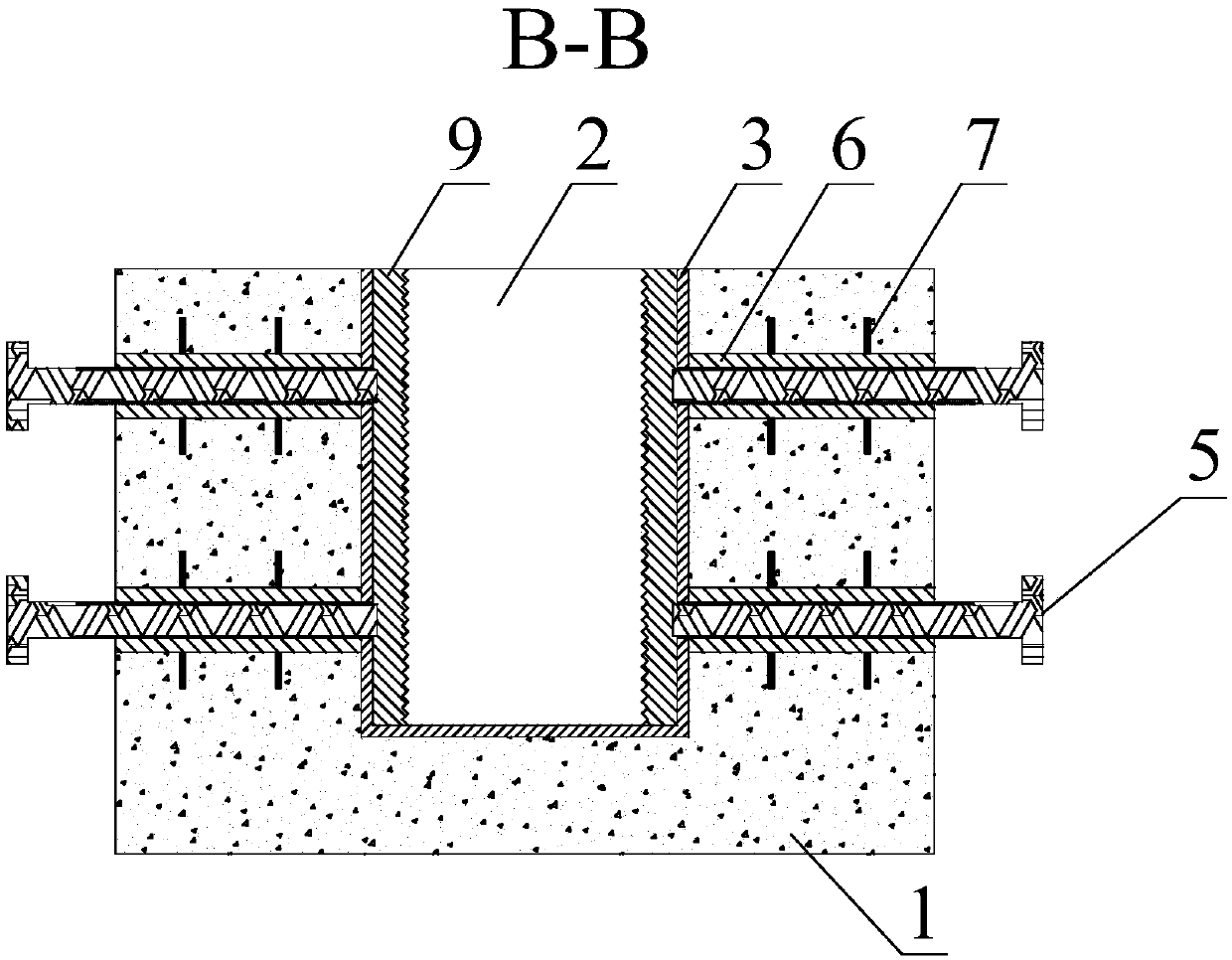

Reusable wall low-cycle repeated loading test foundation

The invention discloses a reusable wall low-cycle repeated loading test foundation, which comprises a base. A rectangular groove is formed in the top surface of the base. A plurality of horizontally arranged casing pipes are embedded in the side walls of the base. One end of each casing pipe is communicated externally and the other end of each casing pipe is communicated with the inner cavity of the groove through the side walls of the base. Fastening bolts are screwed into the casing pipes. According to the invention, solid round steel rods pass through the casing pipes and connecting holes reserved in a wall test piece to fix the wall test piece with the base preliminarily; the fastening bolts are screwed and a first anchoring plate and a second anchoring plate are supported tightly on the wall test piece, so that the wall test piece is fixed in the groove firmly. The base can be reused to avoid repeated making of a reinforced concrete base, so that the test materials and the scientific research cost are saved; the test cycle is reduced; and concrete wastes after the test completion are reduced.

Owner:INNER MONGOLIA UNIV OF TECH

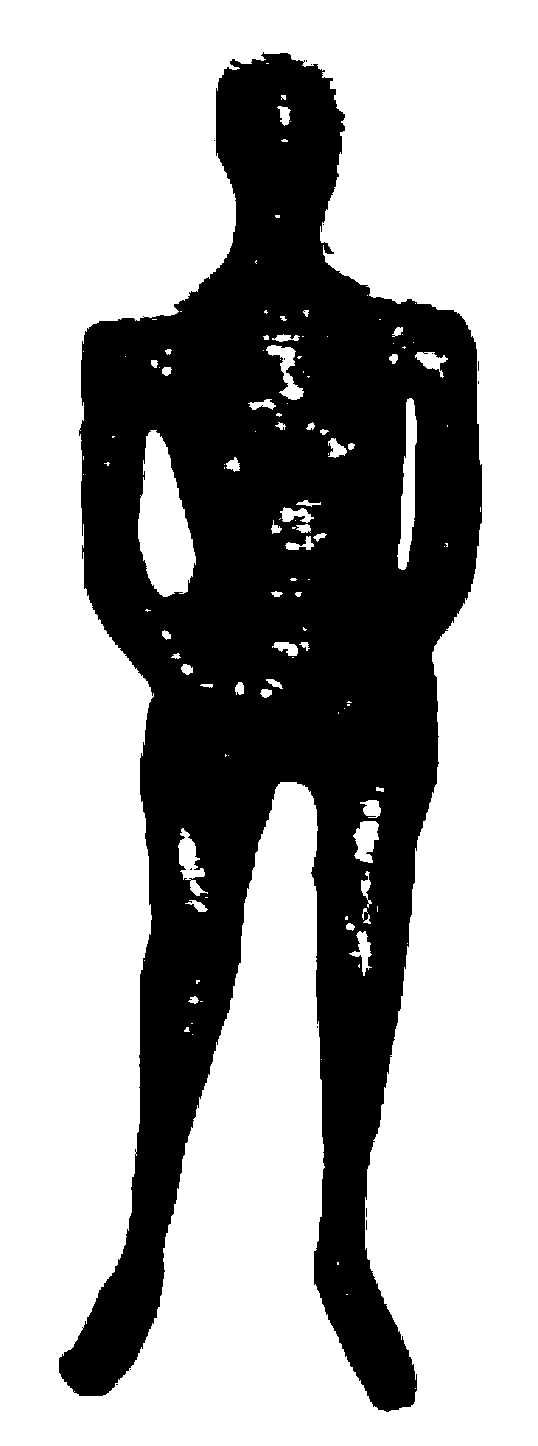

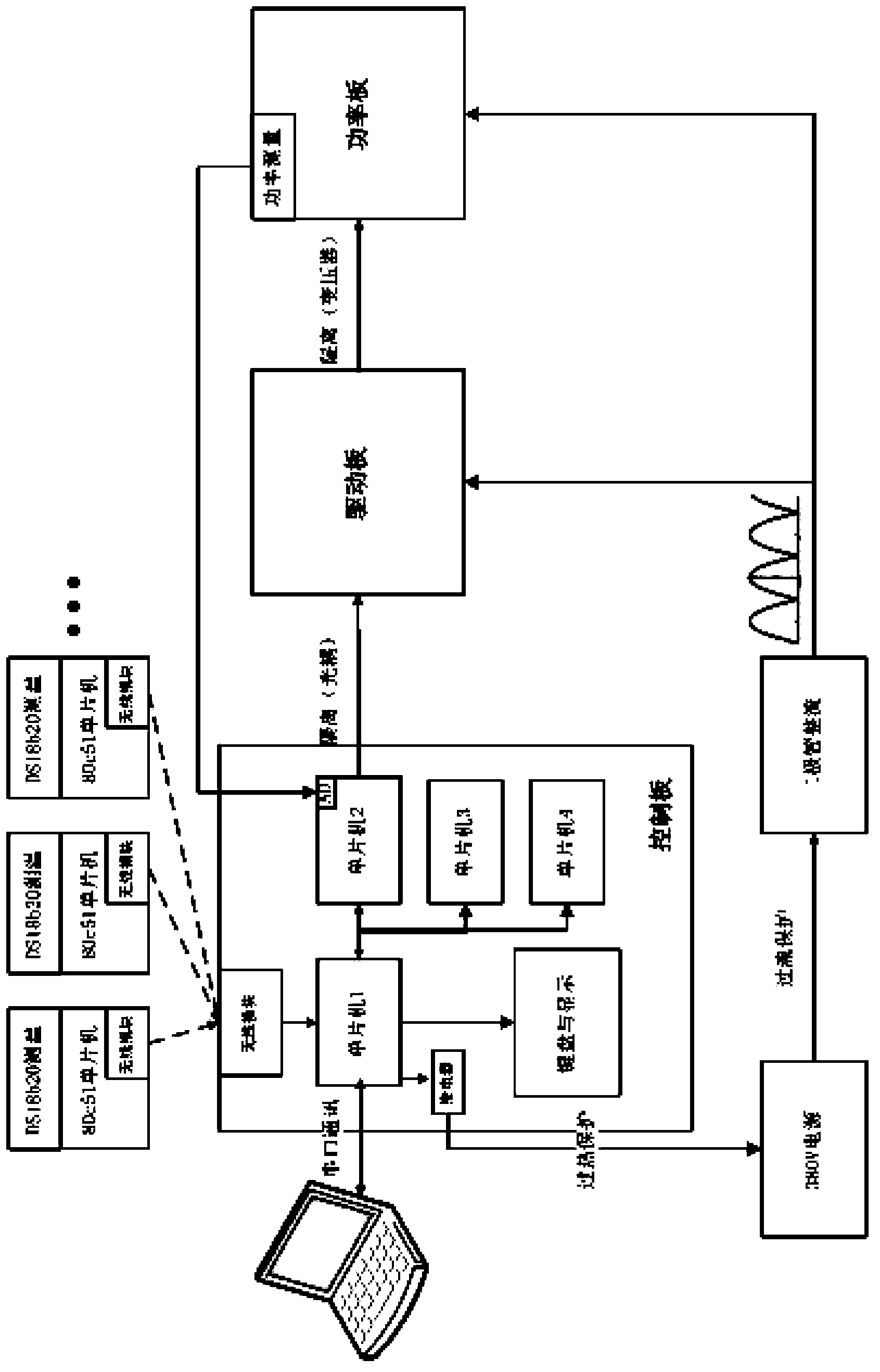

Cluster system of heating dummy model

ActiveCN103365319ACalorific value stableReasonable designAuxillary controllers with auxillary heating devicesMaterial thermal analysisHuman bodyElectrical resistance and conductance

The invention discloses a cluster system of a heating dummy model. The cluster system comprises the heating dummy model and a power control system. The heating dummy model is composed of a head, a trunk, two arms and two legs. The surfaces of the heating dummy model are all wound with heating resistance wires, each arm is wound with four heating resistance wires which are connected in parallel, and other portions are provided with two heating resistance wires which are connected in parallel. The heating resistance wires cover the surface area of the heating dummy model by 97 percent to 97.5 percent, the total resistance of the heating resistance wires after the heating resistance wires are connected in series is 1600 omega to 1699 omega, and the heating amount is 75W. The power control system comprises a 380V power supply, a control panel, a drive board, a power amplifier board, a temperature-measuring sensor and a voltage regulator. The cluster system of the heating dummy model achieves automatic control, is convenient and fast to operate, stable in heating amount and capable of achieving simulation of different human bodies with different dummies working with different power, and has the advantage of being wide in range of application. Meanwhile, the heating dummy model can adjust the heating amount under the control of the voltage regulator.

Owner:TIANJIN UNIV

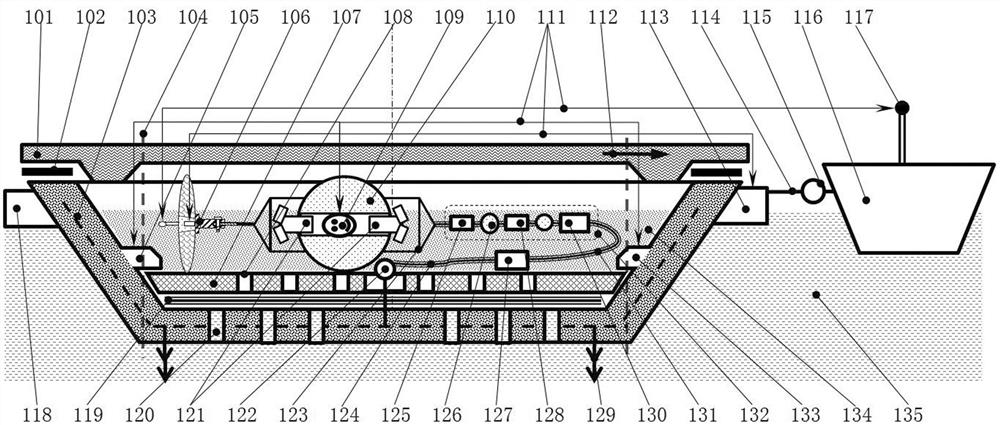

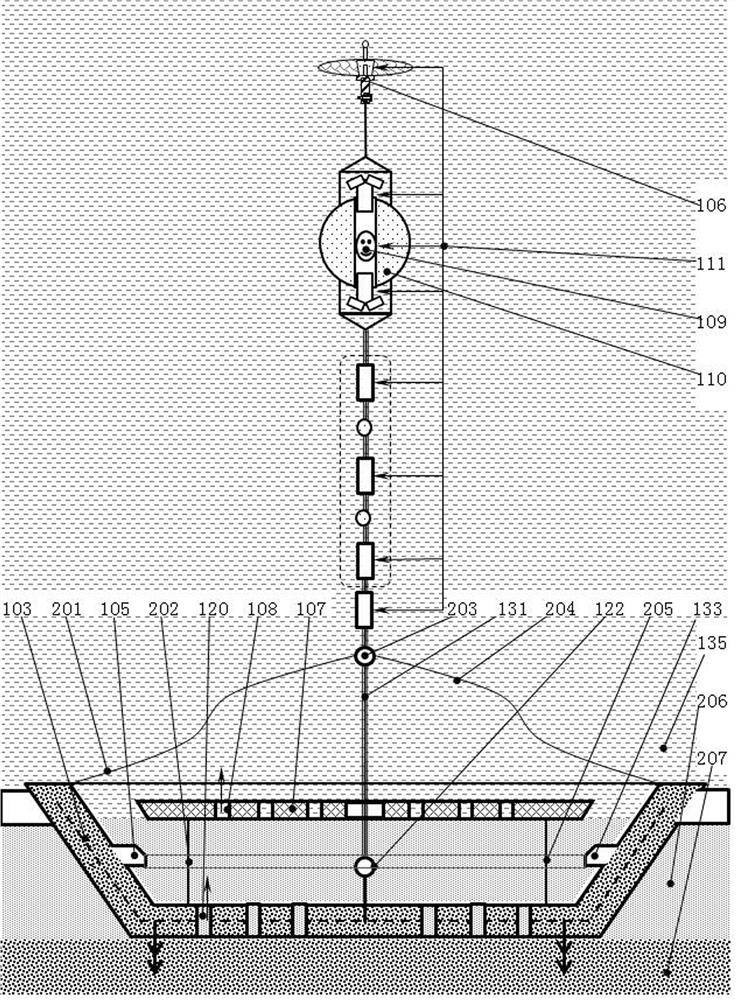

Remote laying intelligent subsurface buoy dragged by unmanned ship

ActiveCN113120167AExpand accurate knowledgeAvoid safety accidentsWaterborne vesselsUnmanned surface vesselsOcean observationsOcean observation

The invention relates to the technical field of ocean observation high-end equipment, and in particular relates to a remote laying intelligent subsurface buoy dragged by an unmanned ship. The remote laying intelligent subsurface buoy comprises a main floating ball, a stainless steel support, a flow velocity profiler, an instrument chain, an acoustic releaser, an anchor chain, a satellite communication device, a controller and a ship-shaped balance weight, and the acoustic releaser is connected with the ship-shaped balance weight through the anchor chain; the unmanned ship drags the ship-shaped balance weight by using the release device; the controller is in electric signal connection with the satellite communication device, the release device and a water inlet device through a signal cable; the controller receives a laying instruction sent by a remote laying person through the satellite communication device, and controls the release device to disconnect traction of the unmanned ship to the ship-shaped balance weight and control the water inlet device to inject water into the ship-shaped balance weight according to the instruction so as to achieve remote laying. In the transportation process, the ship-shaped balance weight serves as a container for containing the subsurface buoy and serves as an anchor for fixing the subsurface buoy after being laid, the ship time cost is saved, the laying quality is improved, and the situation that safety accidents of equipment and personnel are possibly caused by ocean observation with life dangers under the high sea condition is avoided.

Owner:GUANGDONG OCEAN UNIVERSITY

Peony underground bud bare-handed slicing method and application thereof

InactiveCN107688021AEasy to observe differentiationQuality improvementInvestigation of vegetal materialPreparing sample for investigationRoom temperatureEngineering

The invention relates to the field of biological slicing, in particular to a peony underground bud bare-handed slicing method and application thereof. The bare-handed slicing method comprises the following steps of (1) flatly cutting the bud base part of the peony underground bud in a direction vertical to the growth direction; cutting the bud base part into a cuboid shape; (2) transversely putting the underground bud treated by the step (1) onto a tabletop; vertically cutting the middle of the bud base part in the growth direction by a cutter blade, and performing advancing towards the growthpoint of the underground bud until the underground bud is completely cut into two halves. According to the application of the bare-handed slicing method, the cutting surfaces of the two halves of budslices face the upward direction and are dried for 4 to 6 min at the room temperature; then, the bud slices are put under an anatomical lens to be observed. The slicing method has the advantages thatthe operation is simple; the research funding is reduced; in addition, the use of chemical reagents is not needed; green and environment-friendly effects are achieved; convenience is provided for thepeony blossom bud differentiation study; the reference basis is also provided for the flower bud differentiation study of other plants with the similar flower buds.

Owner:BEIJING FORESTRY UNIVERSITY

A visual test device and test method for spray and combustion in a diesel engine cylinder

InactiveCN103792090BReal-time recording of real spray conditionsNo change in formInternal-combustion engine testingPresent methodCombustion chamber

The invention relates to a diesel engine in-cylinder spraying and combustion visualization testing apparatus and testing method. The testing apparatus is mainly composed of a digital CCD camera, a computer image acquisition and processing system, a nitrogen cylinder, a pressure stabilizing barrel, a compressed air bottle, a pressure reducing valve, a light-emitting unit, an angle marking instrument, a frequency multiplier, a stroboscopic gun, a diesel engine test cylinder, an endoscope and a stroboscope. During testing, an optical system top head center corresponding to a mechanical top head center of a diesel engine is found out; initialization parameter setting is carried out; dynamic spraying image collection and in-cylinder combustion dynamic shooting are carried out; collected image processing is carried out by using system software of the computer image acquisition and processing system; and then the collected image is processed by using the system software of the computer image acquisition and processing system. According to the invention, with the visualization testing apparatus and testing method, the basis can be provided for the research of improvement of diesel engine air-intake organization, spraying and combustion chamber structure; the accuracy of the apparatus is high; and the operation is convenient.

Owner:JIANGSU UNIV

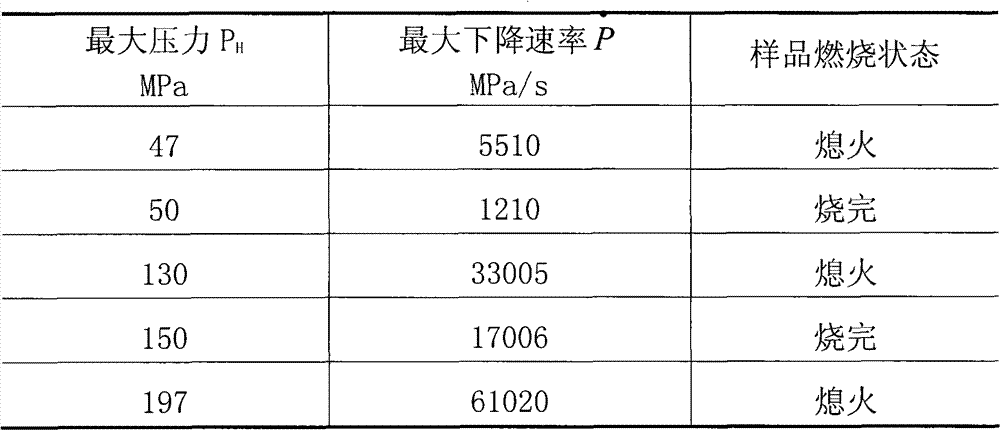

Gunpowder combustion property test device under pressure reduction condition

The invention discloses a gunpowder combustion property test device under pressure reduction condition, wherein, a watch window, a pressure discharge component, a pressure sensor and an igniting component are arranged on a combustion chamber of the device; the pressure discharge component is communicated with a pressure gas buffer tank which is filled with certain-pressure nitrogen and a high-speed camera can shoot combustion process of gunpowder sample through optical lens and the watch window; when the gas pressure in the combustion chamber reaches the pressure-proof critical value of the pressure discharge component by the combustion of gunpowder sample, the pressure discharge component discharges the gas in the combustion chamber into the pressure gas buffer tank; a data collection system collects and records the data output by the pressure sensor and the high-speed camera; and an operator can obtain related property parameters of the gunpowder sample based on analysis and calculation of recorded data. The invention can measure the combustion speed, flameout state and parameters of gunpowder under different pressures and pressure reduction rates and has the outstanding advantages of high measurement pressure, large regulating range of pressure reduction rate, low test cost and wide application scope.

Owner:XIAN MODERN CHEM RES INST

Device for testing powder combustion characteristics in vacuum condition

InactiveCN101382533BRealize measurementEfficient use ofChemical analysis using combustionFuel testingHeating timeCombustion chamber

The invention discloses a testing device of gunpowder combustion characteristics in vacuum, which mainly comprises a combustion chamber, a vacuum pump, an electric heater, a thermoelectric couple, a high speed camera and a data acquisition and processing system; wherein, the vacuum pump provides vacuum environment for the combustion chamber; by controlling the heating current and the heating timeof the electric heater, different ignition isoperibols can be provided for tested gunpowder samples in the combustion chamber; and the data acquisition and processing system collects the test data generated by the thermoelectric couple and the gunpowder combustion images shot by the high speed camera when the tested gunpowder samples combust, and finally obtains the combustion characteristics of the tested gunpowder samples through corresponding processing and calculation. The invention not only can be used for testing the parameters such as combustion speed, combustion surface temperature and combustion heat and the like of the gunpowder in vacuum, but also can be used for the generation and collection of the combustion products of the gunpowder under different vacuum conditions. The invention has the overriding advantages of high integration level, obtaining various parameters by one testing and low testing expenses.

Owner:XIAN MODERN CHEM RES INST

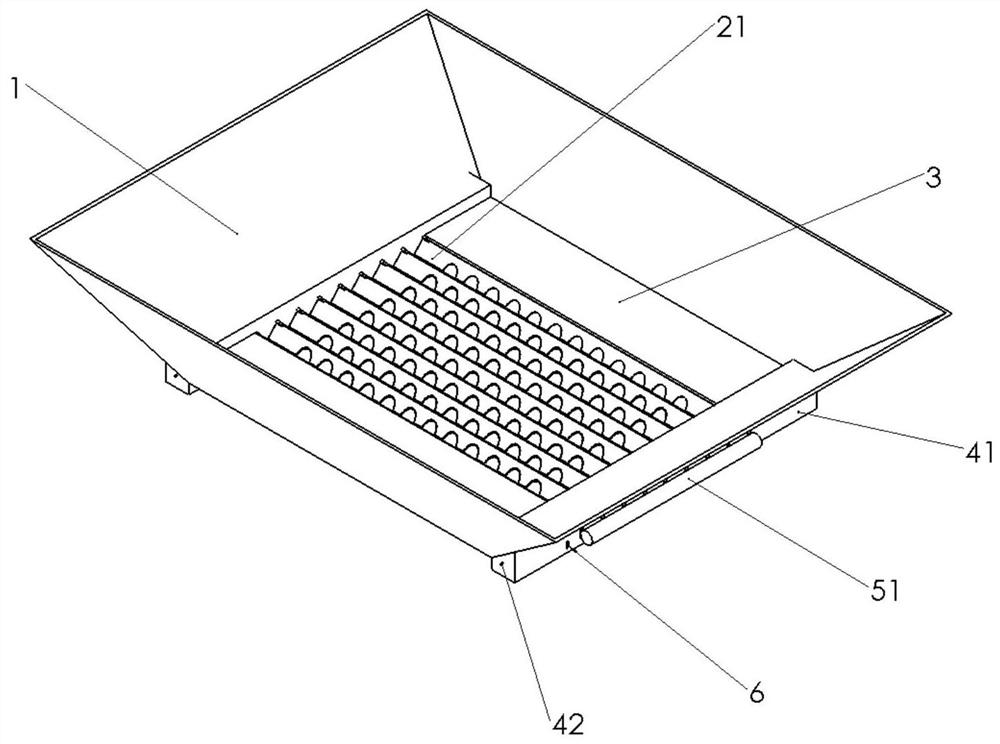

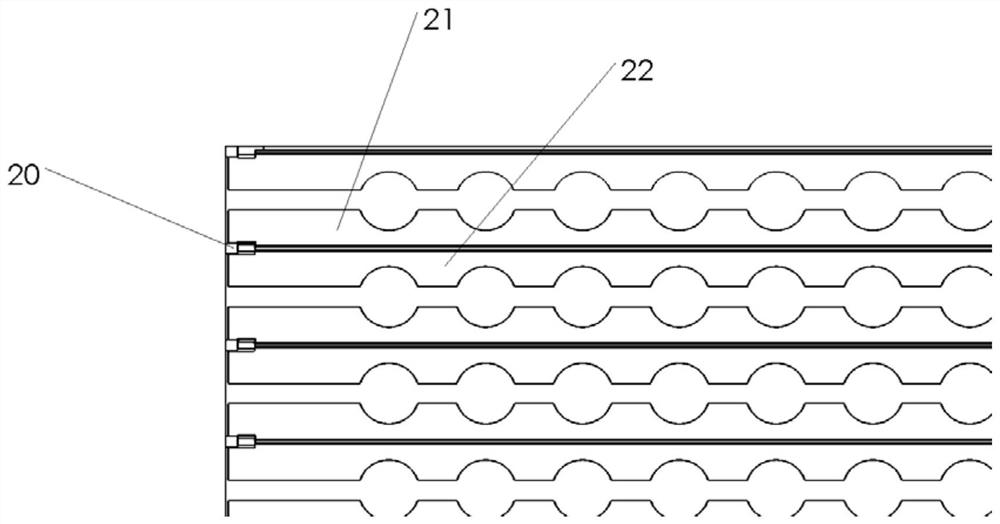

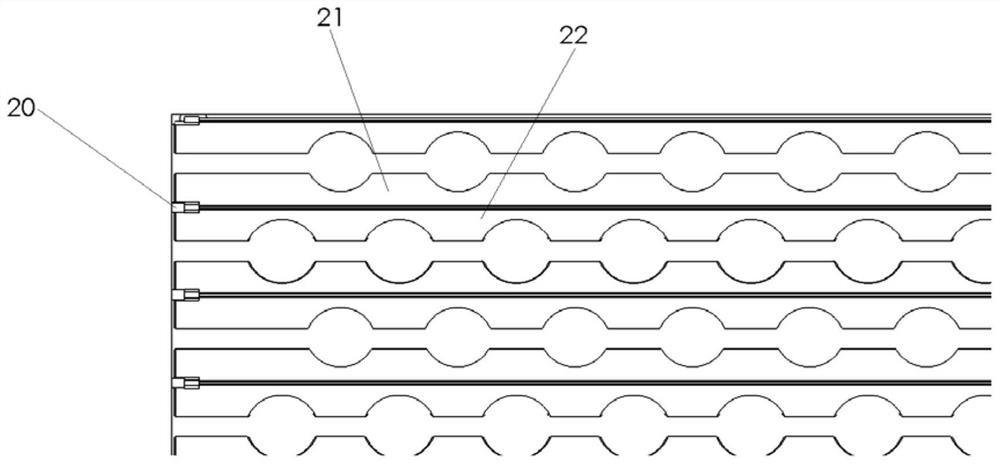

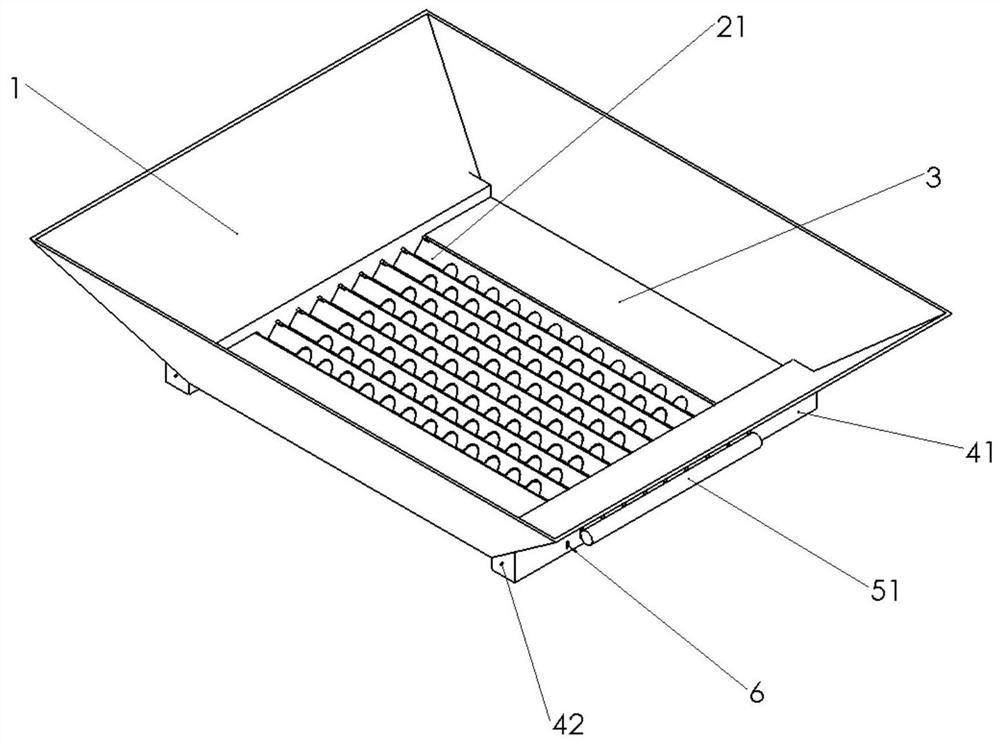

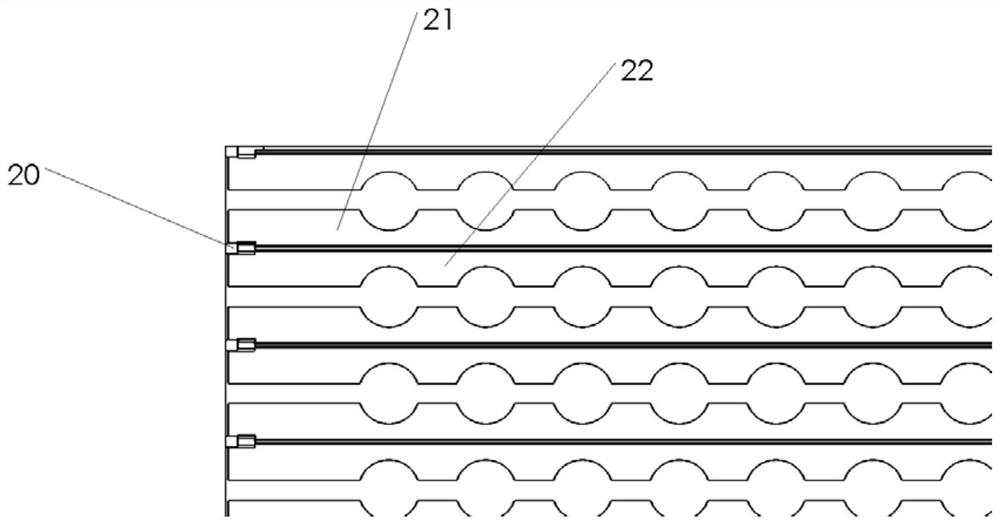

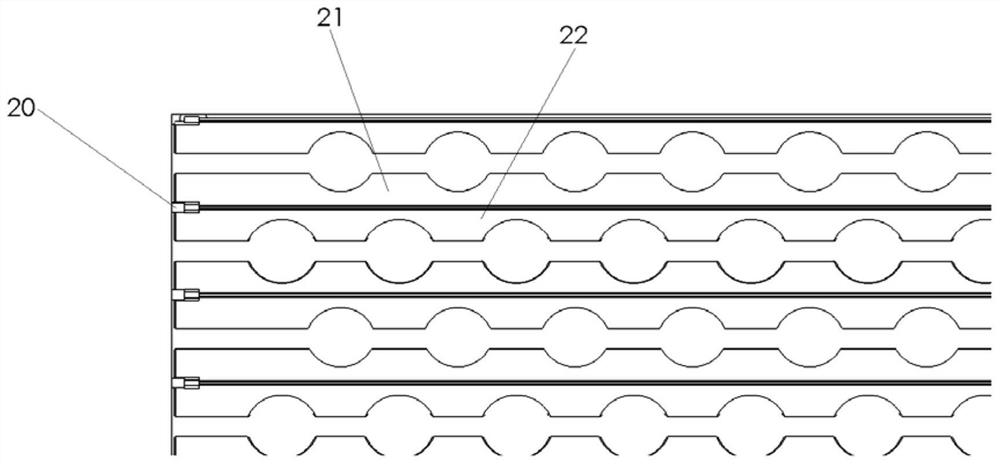

A rapid packing device for laboratory pipette tips

ActiveCN112246294BShorten the timeEasy to operateBurettes/pipettesSupporting apparatusPipetteEngineering

Owner:上海昂朴生物科技有限公司

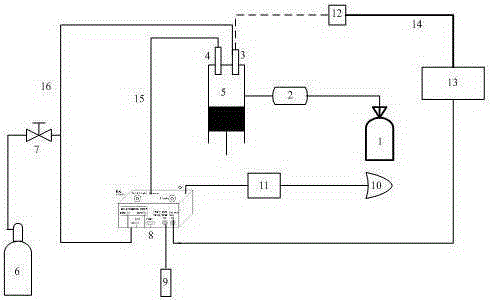

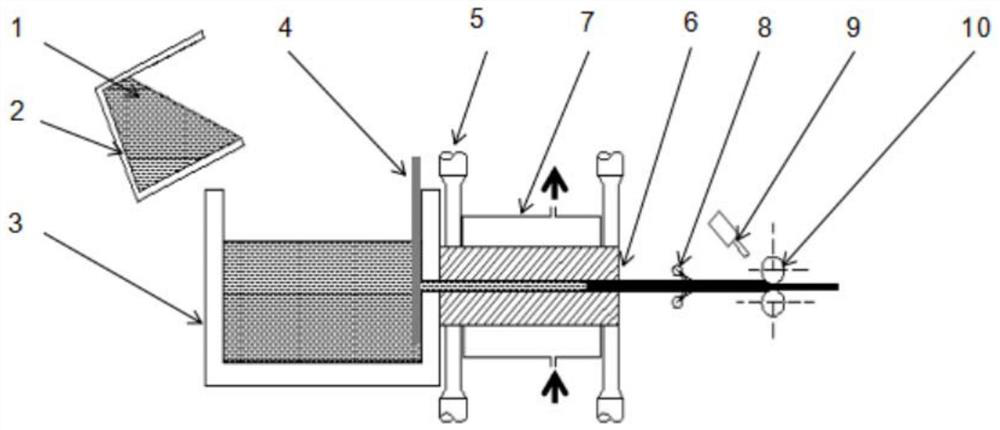

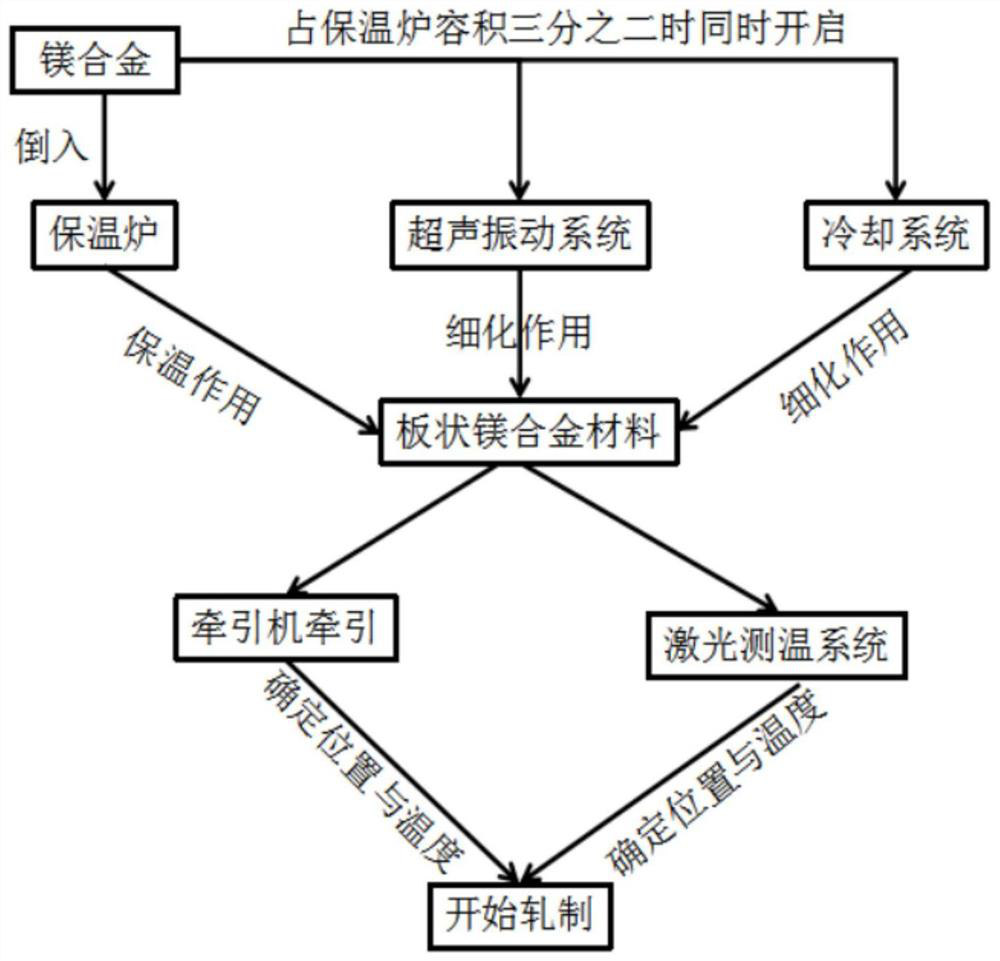

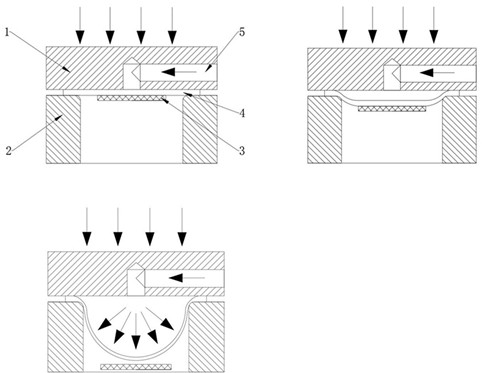

A preparation method and equipment for continuous casting and rolling of magnesium alloy materials assisted by ultrasonic waves

ActiveCN108405616BHigh strengthGrain refinementMetal rolling arrangementsMetal alloyTemperature monitoring

The invention relates to a method and equipment for ultrasonic-assisted continuous casting and rolling of magnesium alloys, belonging to the field of ultrasonic composite preparation of high-strength metal alloys. The technical features of the patent of the present invention are: the ultrasonic emitting device acts on the upper and lower parts of the metal sleeve to form a composite device integrating cooling and refinement; the cooled and refined magnesium alloy moves towards the rolling mill through the action of the tractor, and is monitored by temperature The device measures the temperature of the alloy surface, determines the position of the rolling mill, and finally achieves the purpose of being able to control the rolling of the alloy at different temperatures. The present invention mainly includes a heat preservation device, a cooling device, a temperature measuring device, an ultrasonic emitting device, and a continuous casting and rolling device; Cover 6, cooling device 7, tractor 8, laser temperature detector 9, rolling mill 10.

Owner:HEILONGJIANG INST OF TECH +1

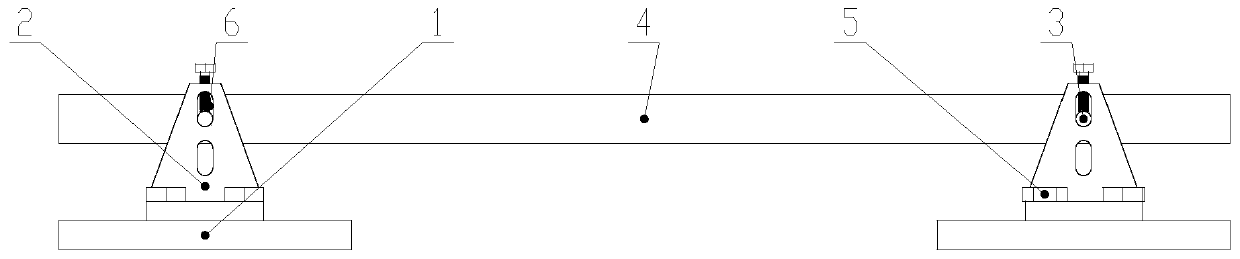

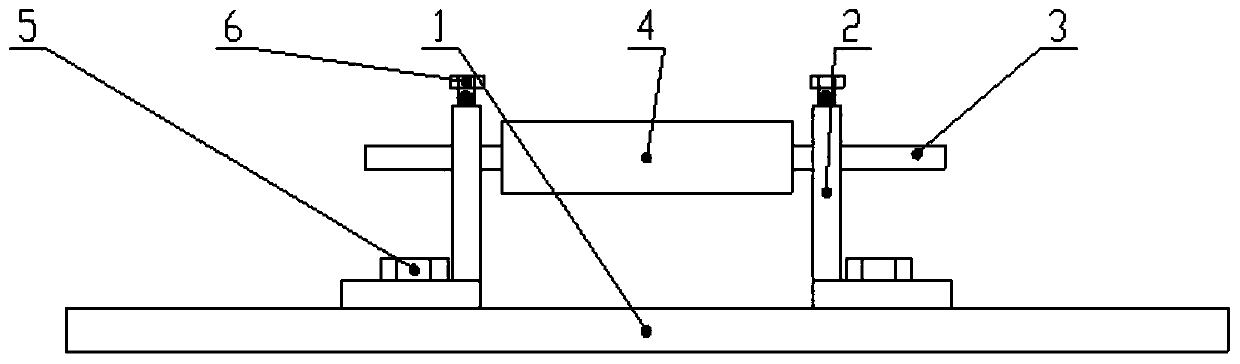

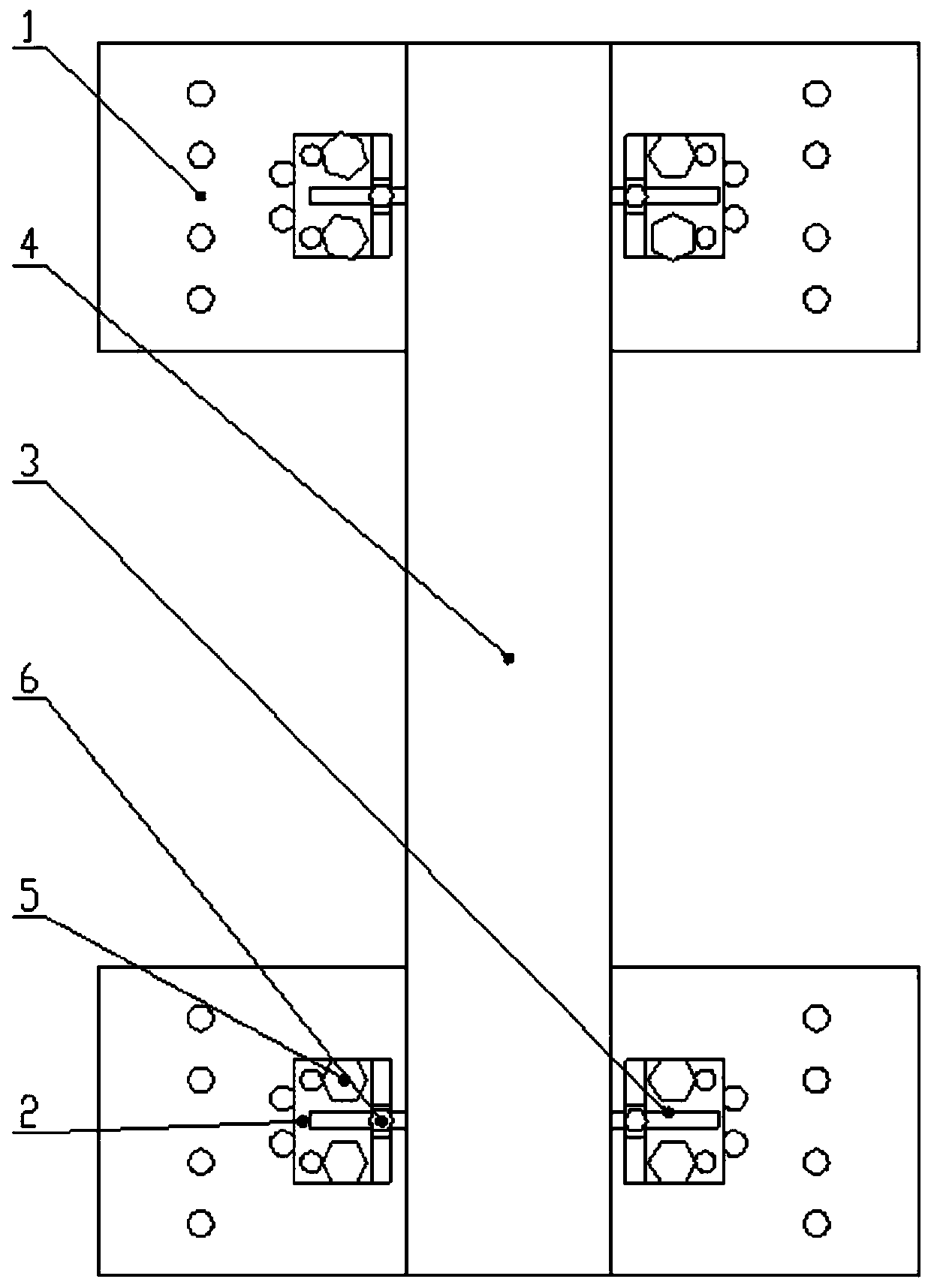

Multi-span simply-supported boundary condition test device

InactiveCN111366348ASimply supportedImplement simply supported boundary conditionsMachine part testingTest beamClassical mechanics

The invention discloses a multi-span simply-supported boundary condition test device, relates to a supporting test device and aims to solve problems that the support position of an existing beam and plate simple support boundary condition experiment device cannot be adjusted, and that beams (plates) with different sizes cannot be simply supported in the prior art. The device comprises a pluralityof bottom plates, a cross beam and a plurality of supporting assemblies, wherein the bottom plates are arranged side by side along a straight line, one supporting assembly is installed on each bottomplate, and a test beam is horizontally installed on the supporting assemblies. The invention belongs to the technical field of mechanical test devices. The device is advantaged in that simple supporting of beams (plates) with different widths and lengths can be achieved, cost is low, universality is high, and the scientific research expenditure of related experiments can be saved.

Owner:HARBIN ENG UNIV

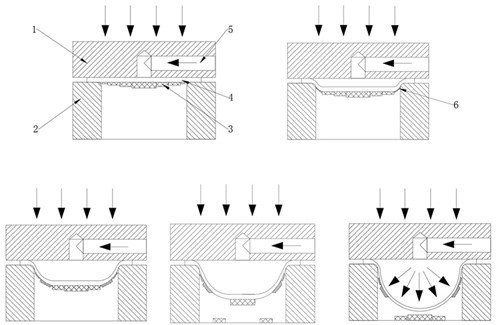

A Method of Using Inorganic Glue to Improve the Uniformity of Wall Thickness of Magnesium Alloy Superplastic Inflatable Forming

InactiveCN109675997BPlay a fixed roleEasy to processMetal-working feeding devicesPositioning devicesAdhesive cementAluminium oxides

The invention relates to a method of improving the uniformity of the wall thickness of a magnesium alloy superplastic gas bulging formed piece by utilizing an inorganic adhesive. The method concretelycomprises the following step of utilizing multiple inorganic adhesives with different viscosities, or coating different deformation areas of a magnesium alloy bulged piece with the inorganic adhesivewith different thicknesses and same viscosity, wherein the deformation rates of different deformation regions are homogenized through the "adhesion" effect of the inorganic adhesive, so that the improvement effect to different wall thicknesses of magnesium alloy is achieved; a selected type of the inorganic adhesive is a double-component adhesive, a component A is water glass, and a component B is formed by mixing and sintering silica, alumina and the like; and by changing the content of the water glass, the adhesives with different viscosities can be obtained. By adopting the method of the invention, the problem of unevenness in wall thickness of a magnesium alloy plate caused by factors including plate instability, unevenness in stress, different thinning rate and poor die adhering effect in the magnesium alloy high temperature gas bulging forming process can be solved, the formation effect of the process is further improved, operation is simple, realization is easy, the cost is lowered, and the production efficiency is improved.

Owner:HARBIN UNIV OF SCI & TECH

Method for washing and recycling membranate glass slide for microdissection

ActiveCN101576653BFull protection adhesionIncrease stickinessAnionic surface-active compoundsDetergent solventsAlcoholDistilled water

The invention discloses technology for washing and recycling a membranate glass slide for microdissection. The technology can be implemented according to the following steps: (1) dipping and shaking the membranate glass slide in mixed solution A of boric acid, alcohol and EDTA; (2) washing the membranate by using double distilled water, and transferring the membranate glass slide into prolease K solution to incubate; (3) placing the glass slide into clean water; slightly touching a sample on the membrane by a finger; and washing the membranate glass slide by the double distilled water; (4) dipping the glass slide in mixed solution B of hydrochloric acid, the alcohol and the EDTA; washing the membranate glass slide by using the double distilled water and absolute ethyl alcohol; and finishing the last washing in the absolute ethyl alcohol; and (5) quickly transferring the membranate glass slide onto a super-clean bench; quickly drying the absolute ethyl alcohol; and carrying out ultraviolet radiation at the same time. The technology removes tissues, nucleic acid, albumen and other micromolecular substances remained on the surface of a consumptive material, and can sufficiently maintain the completeness and adhering effect of the membranate glass slide for microdissection.

Owner:THE FIRST HOSPITAL OF CHINA MEDICIAL UNIV

A psm high-voltage power supply system and its feedback control implementation method

ActiveCN106533222BGuaranteed uptimeMeet control requirementsAc-dc conversion without reversalKlystronPower grid

The invention discloses a PSM high-voltage power supply system and a feedback control realization method therefor. The PSM high-voltage power supply system comprises a high-voltage wire-inlet part, wherein the high-voltage wire-inlet part is formed by two high-voltage circuit breaker cabinets which are connected with a high-voltage contactor cabinet in series separately; two high-voltage contactor cabinets are connected with a multi-winding high-voltage isolation transformer separately; the multi-winding high-voltage isolation transformer is connected with low-frequency rectifying power supply modules and high-frequency rectifying power supply modules separately; and the low-frequency rectifying power supply modules and the high-frequency rectifying power supply modules are all connected in series and then connected to a load. By adoption of the PSM high-voltage power supply system and the feedback control realization method therefor, the problem of severe fluctuation on high-voltage output caused by power grid disturbance in a discharging period of an EAST apparatus is well solved, so that the control requirement of a klystron on voltage precision is satisfied, thereby satisfying requirements of various physical experiments.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Quick boxing device for pipettor gun heads for laboratory

ActiveCN112246294AShorten the timeEasy to operateBurettes/pipettesSupporting apparatusTip positionStructural engineering

The invention discloses a rapid pipettor tip boxing device for a laboratory, which is characterized by comprising a tip positioning device, the outer side of the tip positioning device is connected with a baffle bottom bracket, and a baffle is arranged on the baffle bottom bracket; the gun head positioning device is composed of a plurality of sets of metal sheets, each set of metal sheets is composed of two rotatable metal sheets, the two metal sheets are connected through a middle shaft, the end of the middle shaft is connected with a support at the bottom of the baffle, and a plurality of grooves are distributed in each metal sheet; gun head holes corresponding to the gun heads are formed by the grooves of any two adjacent and different groups of metal sheets; a boxing control rod for controlling the opening and closing of the two adjacent and different groups of metal sheets is arranged on the bracket at the bottom of the baffle. By means of the rapid boxing device for the pipettorgun heads, the gun heads can be boxed at a time, operation is easy and convenient, the structure is exquisite, and therefore the experiment preparation time is saved, the scientific research expenditure is saved, and the experiment efficiency is improved.

Owner:上海昂朴生物科技有限公司

Method for cleaning and reusing microdissection sample-collecting tubes

ActiveCN101587237BFully cleanedProtective AdhesionWithdrawing sample devicesNon-surface-active detergent compositionsSilica particleDistilled water

The invention discloses a method for cleaning and reusing microdissection sample-collecting tubes. The method can be implemented according to the following steps in turn: (1) adding xylene to a collecting tube, capping and oscillating the collecting tube and discarding the xylene; (2) adding suspension A to the collecting tube, oscillating and then emptying the collecting tube; (3) adding double-distilled water to the collecting tube while adding silica particles, oscillating and then emptying the collecting tube; (4) repeating the step (2) and the step (3) twice in turn; (5) adopting the double-distilled water to wash the collecting tube; (6) uncapping the collecting tube and placing the collecting tube in a refrigerator till liquid completely evaporates; (7) taking the collecting tube out, smearing polylysine on the surface of a viscous module on the inner surface of a tube cap, putting the collecting tube back into the refrigerator and keeping the collecting tube standing; and (8) repeating the step (7). The method can effectively maintain and repair the adhesion property of the viscous module on the inner surface of the tube cap of the collecting tube, and can effectively remove superfluous substances remaining in the collecting tube so as to repeatedly recycle the collecting tube and save a large amount of experiment funding.

Owner:THE FIRST HOSPITAL OF CHINA MEDICIAL UNIV

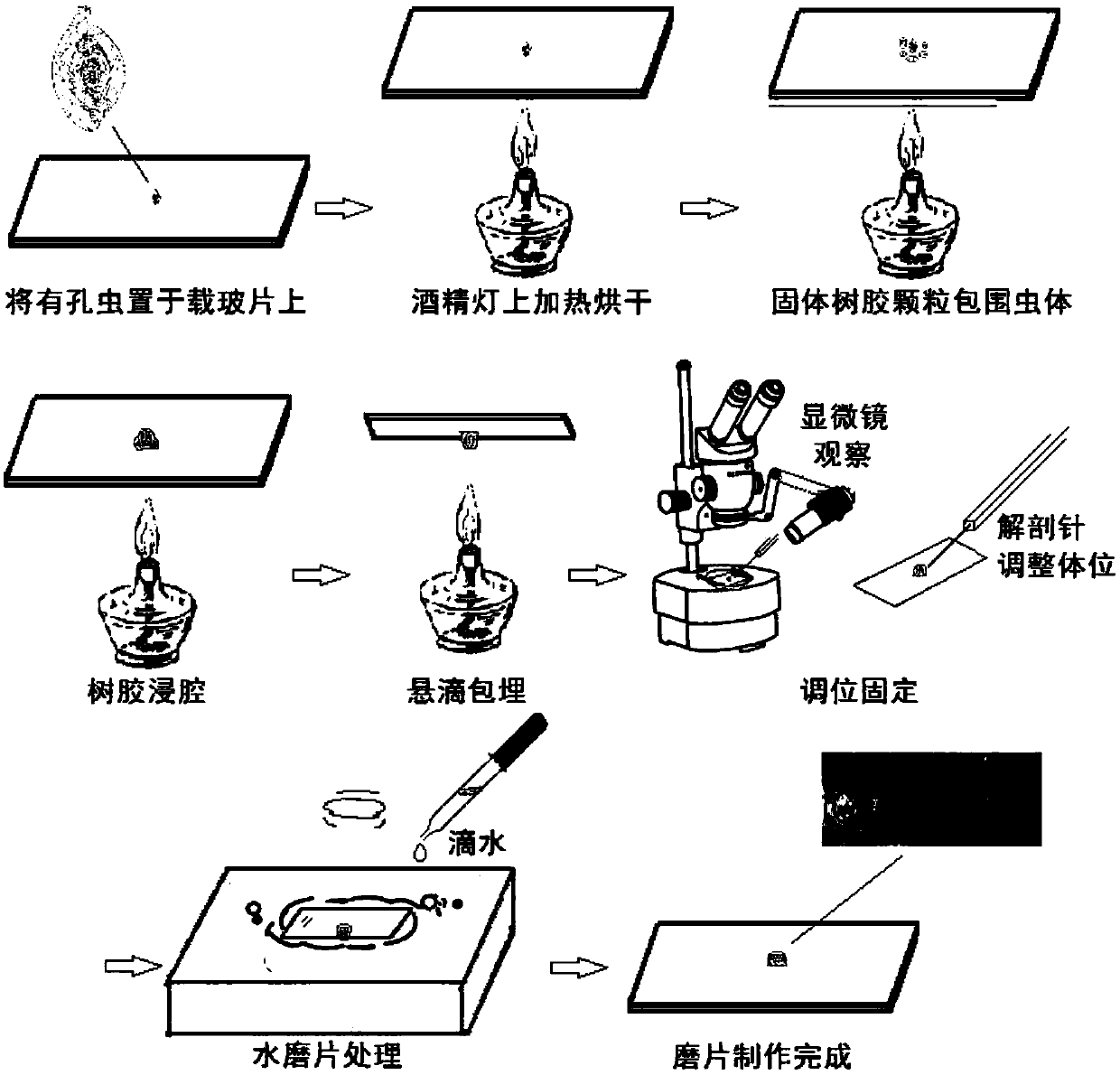

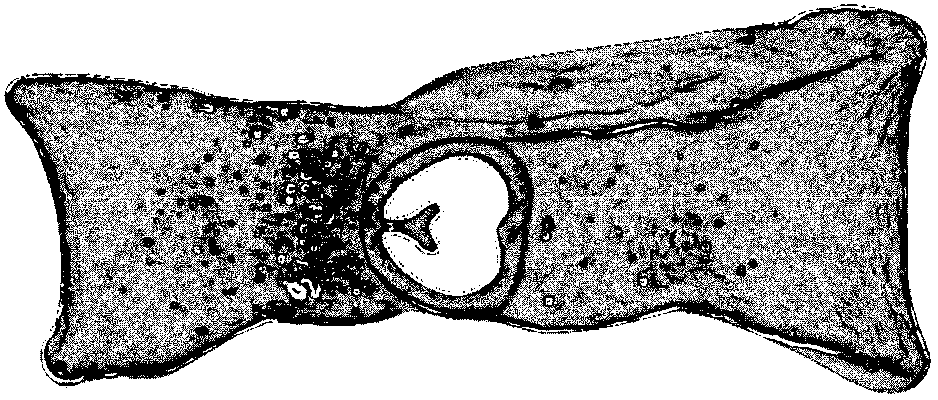

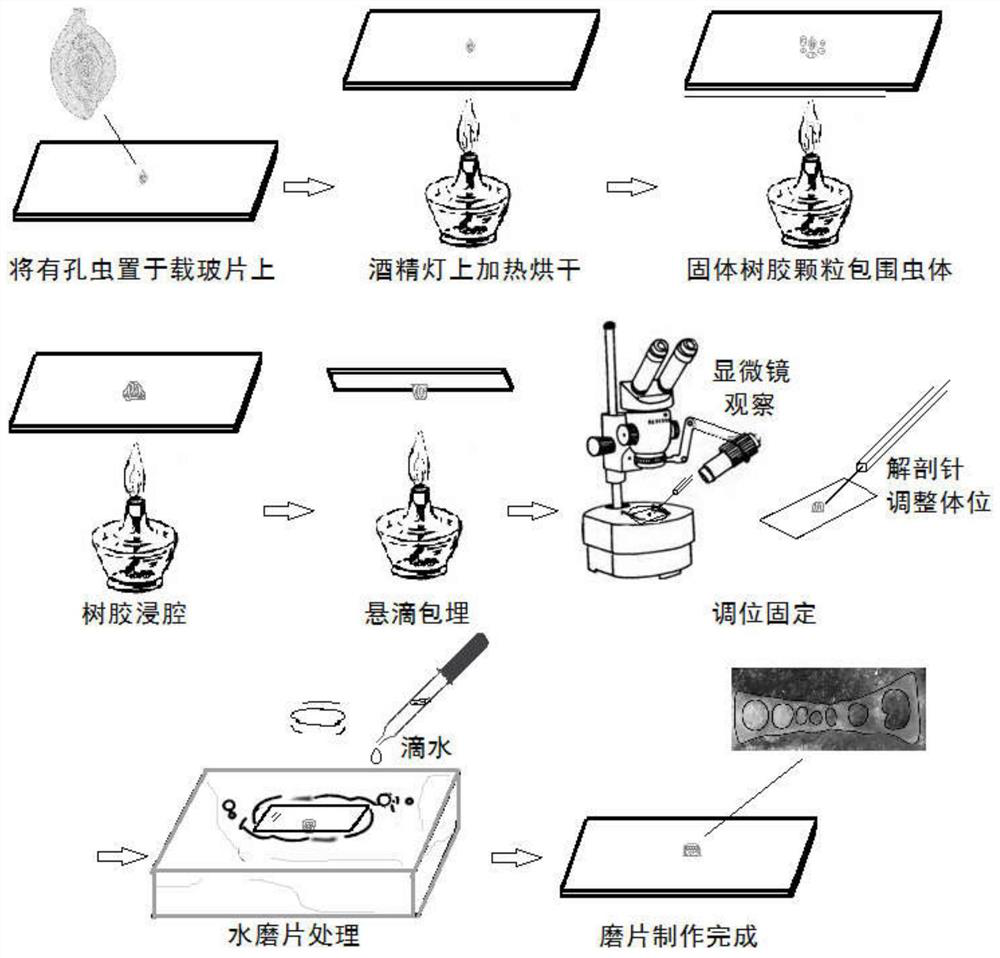

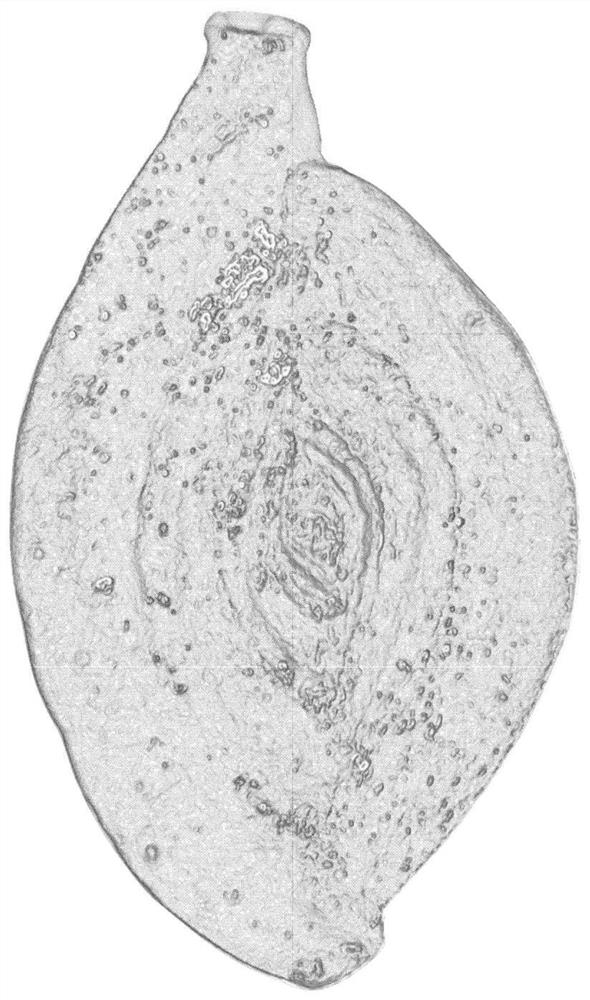

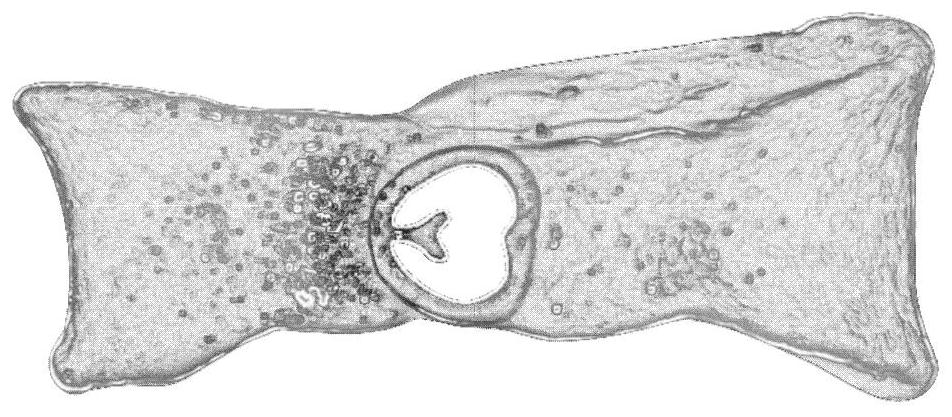

Rapid preparation method for lumen grinding disc of deep-sea foraminifera

ActiveCN110243640AIncrease success rateClear imagingPreparing sample for investigationPaleoceanographyEnvironment of Albania

The invention relates to the disciplines of marine biology, paleoceanography and sedimentary geology, can be applied to the field of the identification research of the species of foraminifera, the research of marine environment indication, the research of paleoenvironmental reconstruction and global change, and the like, and in particular provides a rapid preparation method for a lumen structure grinding disc of deep-sea foraminifera. The foraminifera obtained from the separation of deep-sea sediments are subjected to gum dipping lumen, hanging drop embedding, positioning fixation and water-grinding disc processing, that is, a complete grinding disc of the lumen structure of the deep-sea foraminifera is quickly obtained. The method provided by the invention, through the layer information obtained by the grinding disc, can more accurately identify the species of foraminifera, avoids scientific confusion such as identification errors caused by external morphological variations such as the shape, texture and number of compartments of the worm body, and provides accurate scientific basis and quick problem solving solutions for the disciplines of accurate identification of the species of deep-sea foraminifera, the research thereof of marine environment indication, the research of paleoenvironmental reconstruction, the research of global change, and the like.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI +1

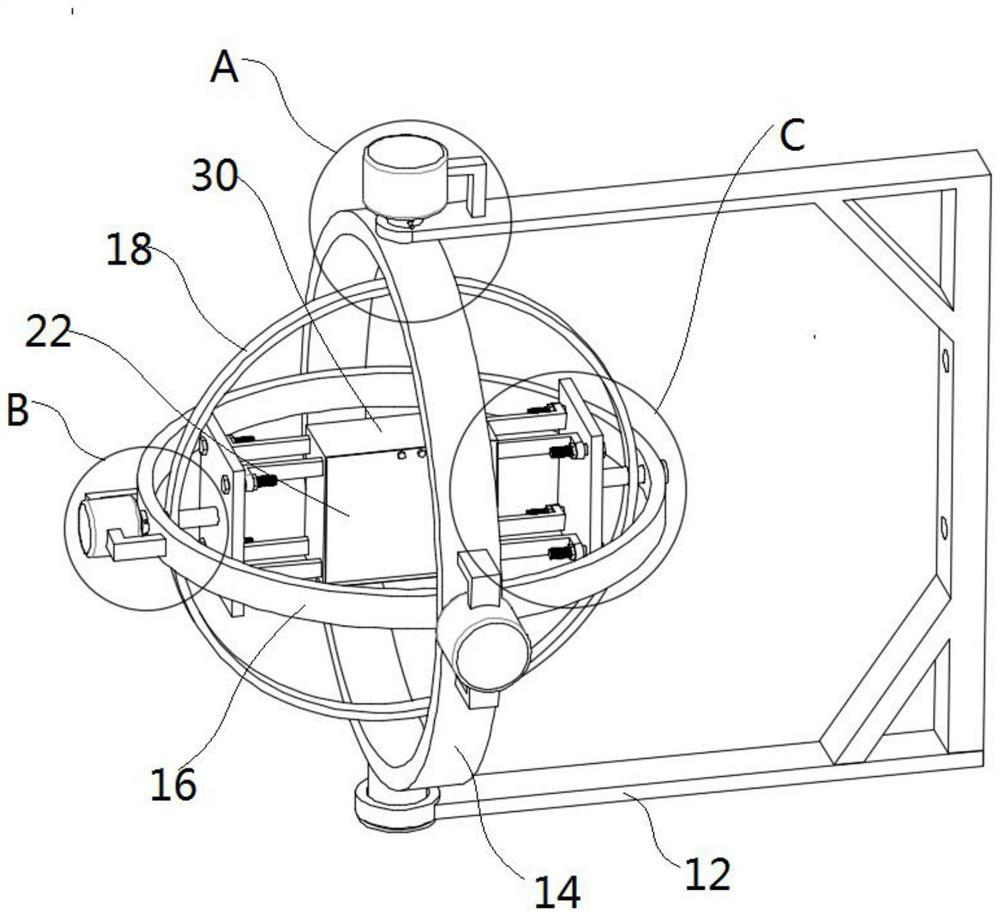

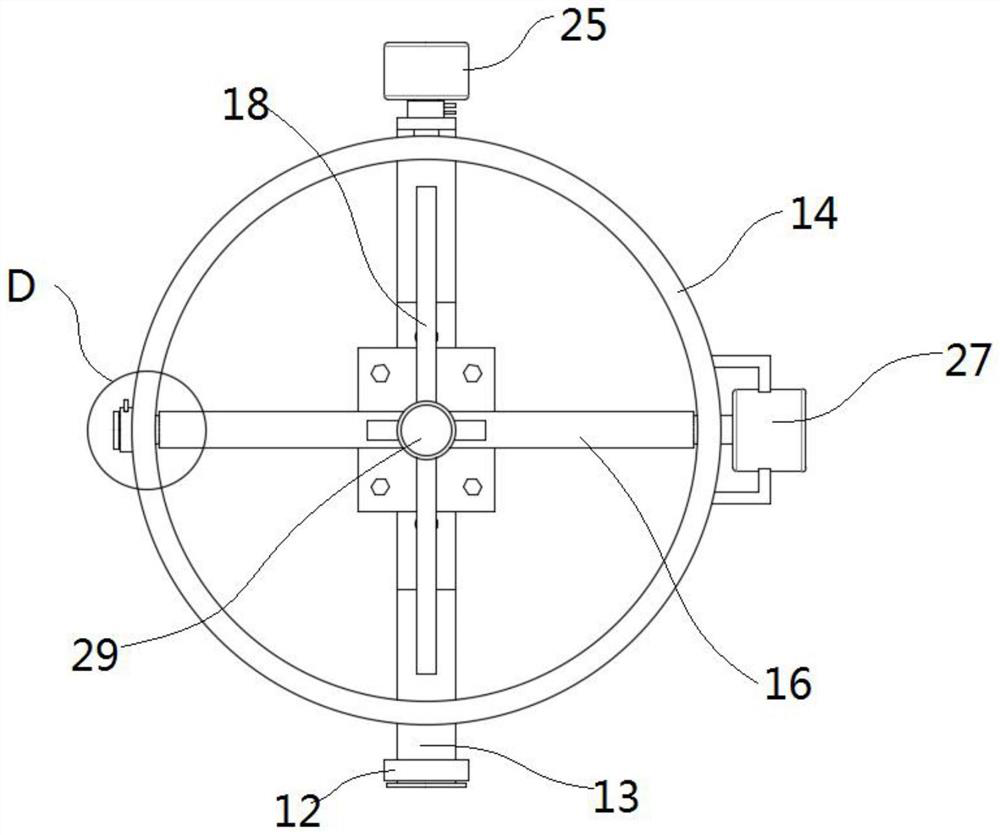

Program-controlled dual-channel amplitude-phase controller

InactiveCN114488890ALow costSave research fundsProgramme controlComputer controlNumerical controlMicrowave

The invention, which relates to the technical field of amplitude-phase controller manufacturing, discloses a program-controlled dual-channel amplitude-phase controller comprising a housing arranged on a three-axis simulation rotating table mechanism and an amplitude-phase controller assembly arranged in the housing. Comprising a first chip, a second chip, a microwave unit, a first power divider, a second power divider, an amplitude measurement and phase discrimination module, a third power divider, a fourth power divider and a single chip microcomputer, one side of a shell is provided with I / O interfaces, a main circuit board is arranged in the shell, and the other ends of the I / O interfaces are connected with the main circuit board; the microwave unit comprises a microwave circuit board arranged on the main circuit board, and a frequency conversion local oscillator, a switch filter bank, a total amplitude control attenuator, a first amplitude control attenuator, a second amplitude control attenuator, a first numerical control shifter and a second numerical control shifter which are arranged on the microwave circuit board. The invention discloses a program-controlled dual-channel amplitude-phase controller which has the advantages of low price, high test efficiency and high precision.

Owner:YANGZHOU YUAN ELECTRONICS TECH CO LTD

Rapid Preparation Method of Internal Cavity Polishing of Deep-sea Foraminifera

ActiveCN110243640BIncrease success rateClear imagingPreparing sample for investigationMicroporaSediment

The present invention relates to marine biology, paleoceanography, sedimentary geology and other disciplines, and can be applied in the fields of foraminifer species identification research, marine environment indication research, paleoenvironment reconstruction and global change research, etc. Specifically, it is a A rapid preparation method for deep-sea foraminifera lumen structure grinding plate. Foraminifera isolated from deep-sea sediments were treated with gum immersion, hanging drop embedding, position adjustment and water grinding, that is, complete grinding of the inner cavity structure of deep-sea foraminifera was quickly obtained. The invention can more accurately identify the species of the foraminifera through the level information obtained by grinding, and avoid scientific confusion such as identification errors caused by external morphological variations such as the shape, texture, and number of chambers of the foraminifera. The invention provides accurate scientific basis and quick problem-solving scheme for the accurate identification of types of deep-sea foraminifera and the research on indications to the marine environment, paleoenvironment reconstruction research, global change research and other subject fields.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI +1

Force control method for lap surface control of stressed lap and equipment thereof

InactiveCN100486767CReduce volumeQuick responseOptical surface grinding machinesLensMicrocontrollerEngineering

The invention relates to a method for controlling the force when actively burnishing the disc. It comprises that: the computer transfers the data and control instruction to the single chip; the single chip control the drawing motor to rotate the ball lead screw and the nut pushes the lever to frap steel wire; the pull sensor measures the tension force of steel wire; the measured result is transferred to single chip; at the same time, the current signal of control motor is feedback to the single chip; the single chip processes PID calculation via power amplifier to be transferred to control motor to regulate rotation speed to adjust the pull of steel wire. Since said steel wire can continuously change the shape of active burnishing surface to keep the same with adhesive part of burnished optical mirror face. The invention also provides a relative device. Since it uses a pull ring-current ring control system while integrates the computer signal process, motor driving, and the process of pull sensor into one circuit to simplify the circuit structure, the invention has small volume, lighter load and quick dynamic response.

Owner:NANJING INST OF ASTRONOMICAL OPTICS & TECH NAT ASTRONOMICAL OBSE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com