Diesel engine in-cylinder spraying and combustion visualization testing apparatus and testing method

A test device, diesel engine technology, applied in the direction of internal combustion engine testing, etc., can solve problems such as inaccurate temperature field analysis, influence of test results, complex system, etc., and achieve resource sharing, visualization, and high accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0054] Example 1: Multiple spray test of electronically controlled common rail diesel under anaerobic conditions.

[0055] Test conditions: a 4-cylinder electronically controlled high-pressure common rail diesel engine, fuel injection pressure 100MPa, "ω" type combustion chamber with boss, diesel engine speed 1500rpm, fuel injection timing -10°CA. The basic setting parameters in the test process: the exposure rate is 10kHz, the image resolution is 640×480 pixels, and the exposure time is 80μs. According to the structure of the combustion chamber and the position of the injector nozzle, a 60° endoscope lens is selected. The air in the diesel engine test cylinder was replaced with industrial-purity nitrogen. The specific method is as follows: isolate the intake air pipe of the diesel engine test cylinder from the air, and connect it to the cylinder filled with nitrogen through the pressure regulator barrel, so that the cylinder cannot burn because there is no oxygen after injec...

example 2

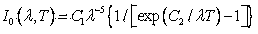

[0057] Example 2: On a 4105 electronically controlled high-pressure common rail diesel engine, set the diesel engine speed to the rated speed of 1500r / min, and when the load is 50%, the B90E10 ethanol biodiesel and pure petrochemical diesel are respectively burned under the same working condition, and the device is used to measure Combustion pictures were obtained, and the image processing system was used for calculation and analysis. Compared with pure petrochemical diesel fuel, the flame temperature in the cylinder was significantly lower when burning B90E10 ethanol biodiesel. The maximum flame temperature was 2400K, which was about 300K lower than pure diesel oil. When the crank angle is moved backward, the soot concentration is also reduced by about 20 KL factors.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com