Safety monitoring system used in power lines repairing operation and operating method based on safety monitoring system

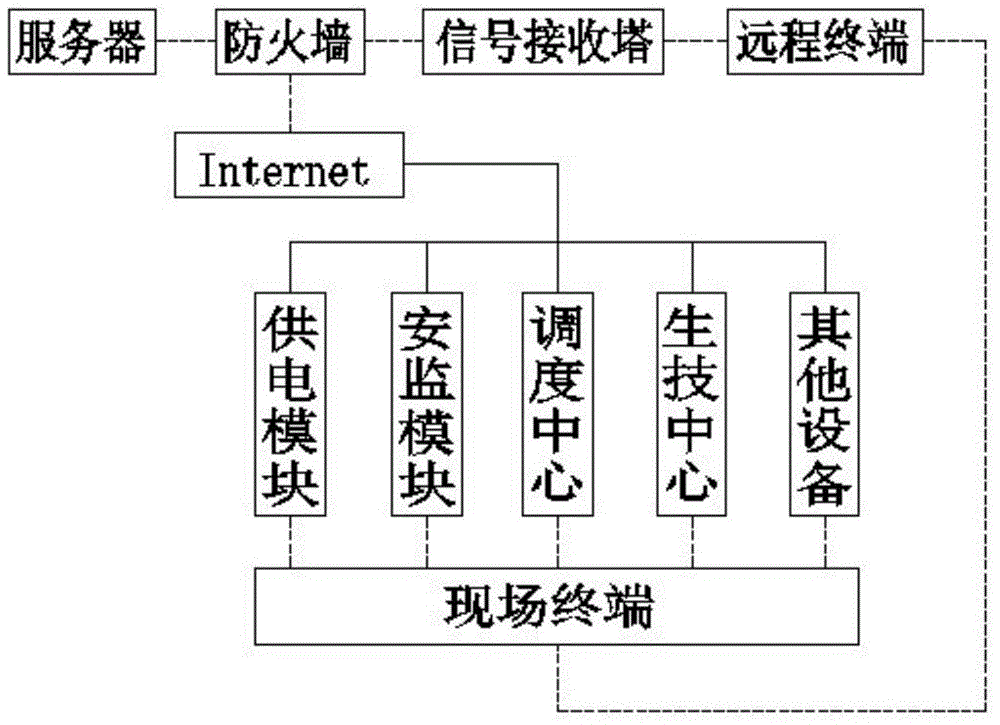

A safety monitoring system, power repair technology, applied in general control systems, control/regulation systems, comprehensive factory control, etc., can solve the lack of safety risk prevention and self-protection awareness, lack of safety production awareness, management and practical disconnection, etc. problems, to achieve the effect of improving safety risk prevention and self-protection awareness, improving consistency and maintenance efficiency, and improving coordination and communication efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

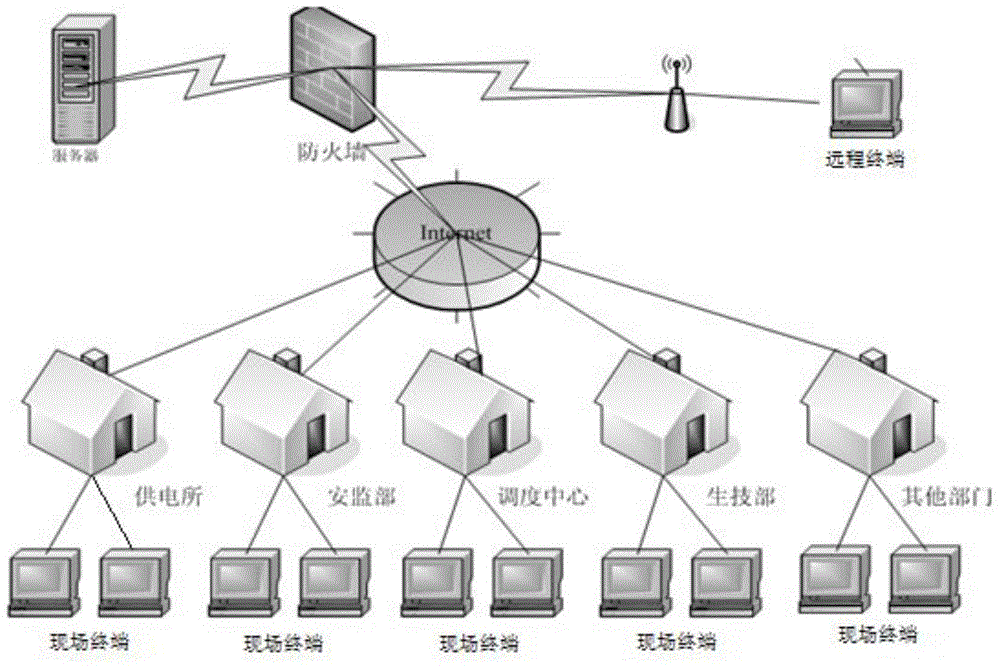

Method used

Image

Examples

Embodiment 1

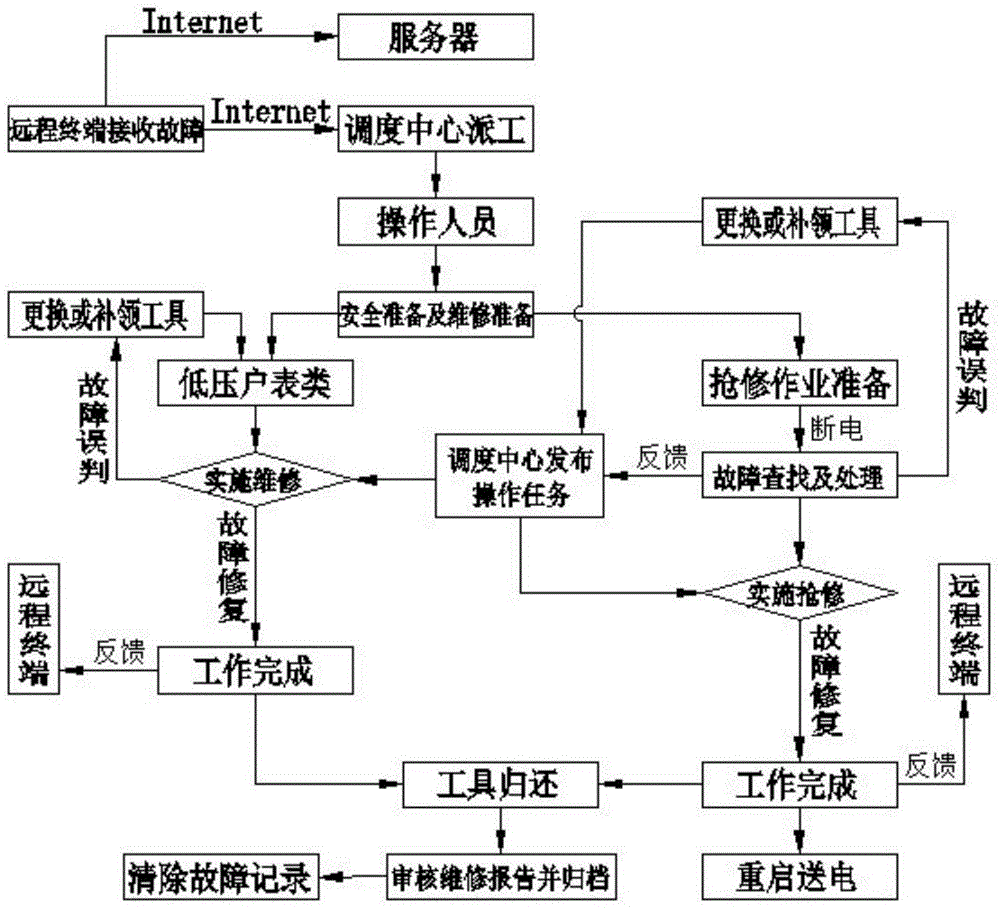

[0037] Low-voltage household meter maintenance

[0038]When a fault occurs on site, the agents in the dispatching center receive a repair call from the user, or the remote terminal receives a fault signal from the on-site terminal. The remote terminal or the agent sends the information to the main server and the Internet respectively through 3G or 4G signals, and the fault signal passes through The Internet transmits to the safety monitoring module, dispatching center, and biotechnology center respectively; the safety monitoring module performs fault prediction and feeds the predicted fault back to the biotechnology center; Pre-judged failure dispatches manpower to the site for maintenance, and transmits the maintenance plan to the on-site terminal; after receiving the instructions, the maintenance personnel make maintenance and safety preparations, and receive tools to go to the site according to the predicted failure, take pictures of the fault site, and call it through the o...

Embodiment 2

[0042] Repair work

[0043] When a fault occurs on site, the agents in the dispatching center receive a repair call from the user, or the remote terminal receives a fault signal from the on-site terminal. The remote terminal or the agent sends the information to the main server and the Internet respectively through 3G or 4G signals, and the fault signal passes through The Internet is transmitted to the power supply module, safety monitoring module, dispatching center, and biotechnology center respectively; the safety monitoring module performs fault prediction and feeds the predicted fault back to the biotechnology center; the biotechnology center formulates a repair plan and feeds back to the dispatching center Prediction of faults and maintenance plans transmits information to the power supply module, and at the same time transmits the emergency repair plan to the on-site terminal. The power supply module controls the temporary interruption of the grid power supply in the fau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com