Angle-adjustable stirring machine

A technology for agitator and angle adjustment, which is applied in the direction of agitator accessories, chemical instruments and methods, dissolution, etc., can solve problems such as costing money and time, and achieve the effects of improving work efficiency, shortening experiment cycle, and reducing scientific research funds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will now be further described in conjunction with specific examples, and the following examples are intended to illustrate the present invention rather than further limit the present invention.

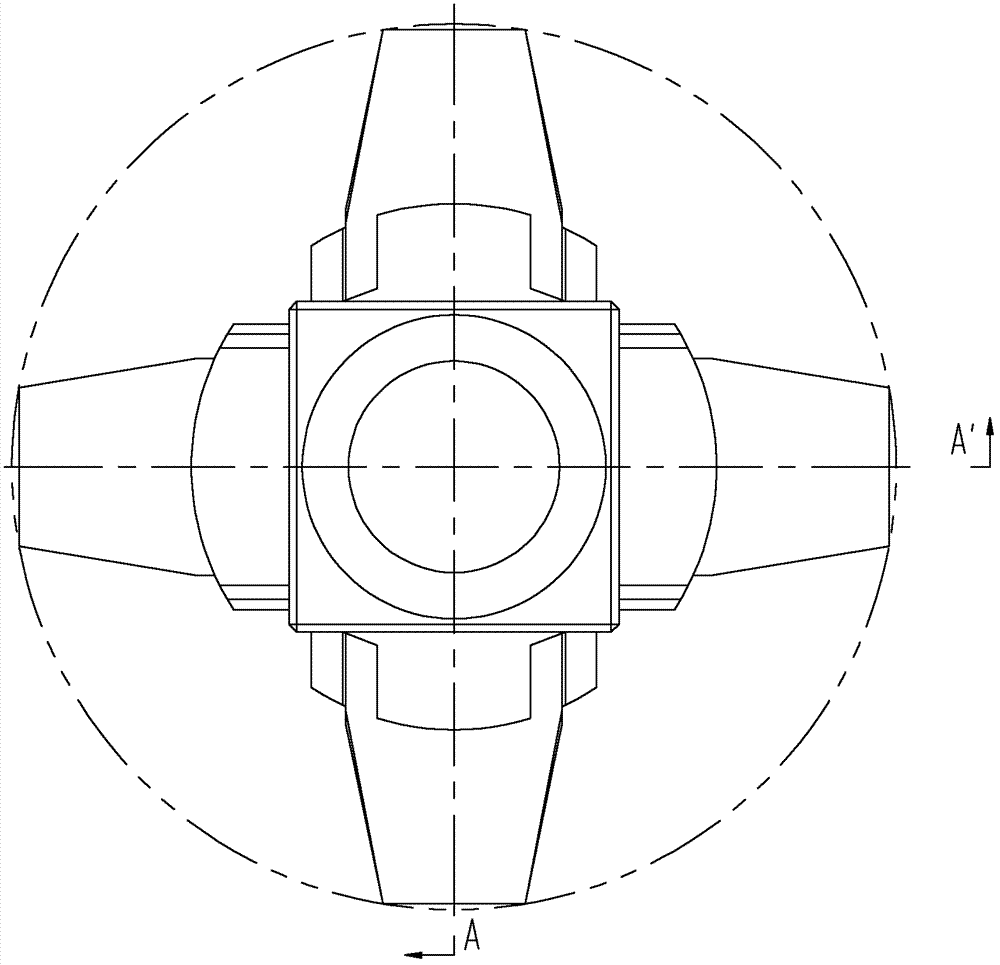

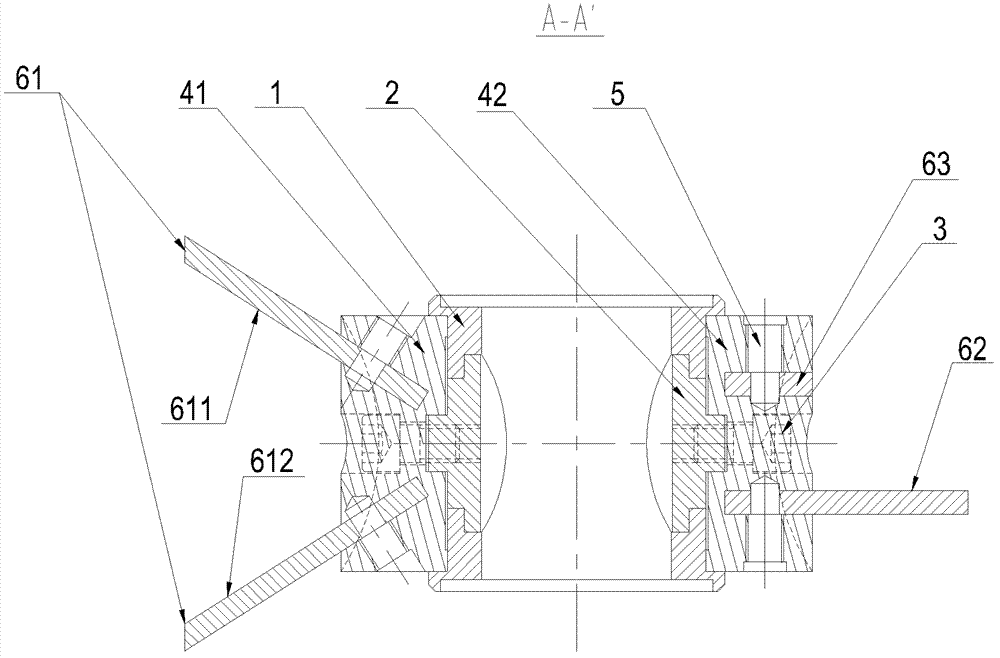

[0013] Such as Figure 1~2 The angle-adjustable agitator shown in the figure includes a hub and an axisymmetric stirring blade. A hub 1 is arranged outside the hub, and a connecting plate 2 that can rotate 360° is connected to the hub 1. The connecting plate 2 is connected by a hexagon socket bolt. 3. Connect the blade seat, the blade seat includes a beveled blade seat 41 and a flat angled blade seat 42, the beveled blade seat 41 is connected to the beveled blade 61 through the blade connecting screw 5, and the flat angled blade seat 42 is connected to the flat angled blade 62 through the blade connecting screw 5 , oblique blades 61 and flat blades 62 are adjacently distributed.

[0014] Further, the angled blade 61 includes a first angled blade 611 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com