Rapid Preparation Method of Internal Cavity Polishing of Deep-sea Foraminifera

A foraminifera and deep-sea technology, applied in the field of science, can solve problems such as difficulty in controlling the baking process, slag falling off specimens, and experimental failures, and achieve time-saving and labor-saving processing methods, colloid and insect body bonding, and experimental The effect of the rapid process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

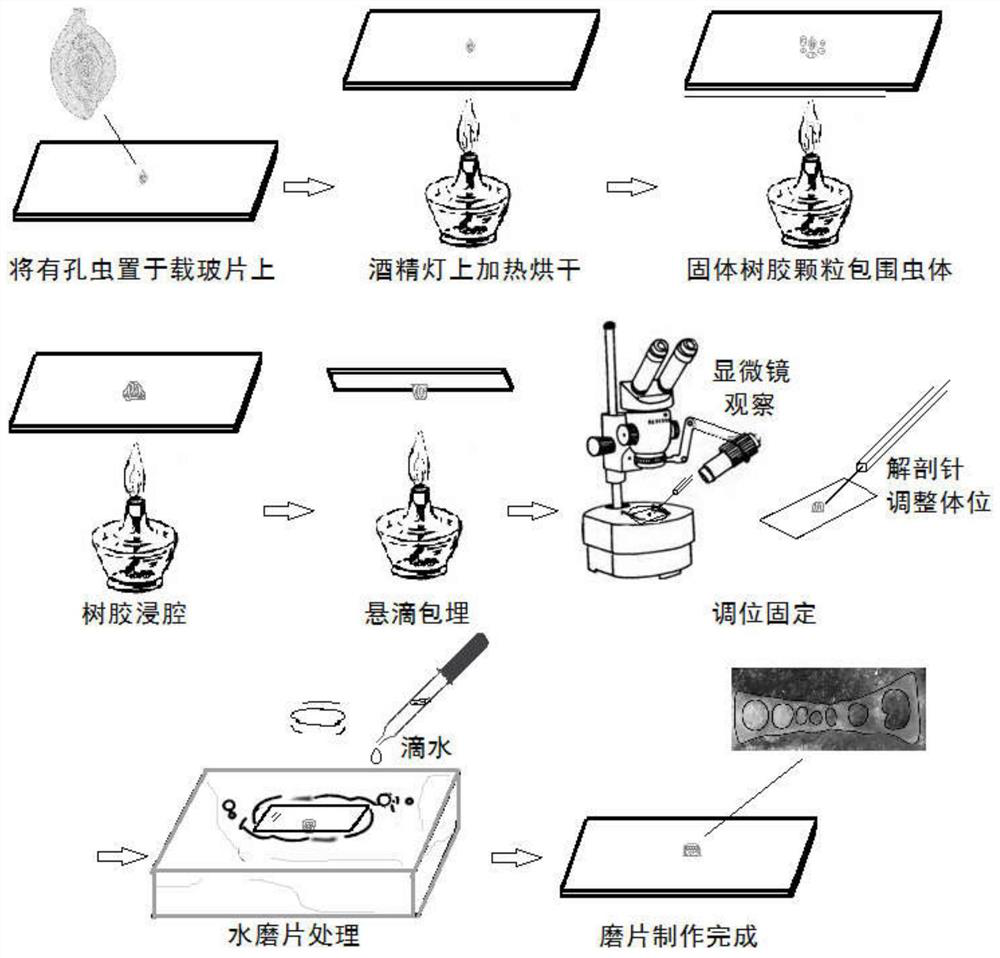

[0026] 1. Tools: alcohol lamp, solid gum, dissecting needle (medical skin test needle), fine grinding stone, glass slide, fine brush.

[0027] 2. Extract the sample of deep-sea foraminifera, stick the foraminifera with a brush and place it on a glass slide, and heat it through an alcohol lamp (lightly above the alcohol lamp) to dry the inside, otherwise it will affect the dipping.

[0028] 3. Take gum particles (the particle size is from rice grains to soybean grains), and embed the foraminifera on the above-mentioned glass slide, that is, surround the insect body with gum, close to the insect body, and lightly heat the alcohol lamp to make the air bubbles in the gum escape.

[0029] 4. Heating on the alcohol lamp, the temperature is 100°C-150°C, the gum gradually melts, dipped into the insect body, remember to heat too fast, lest the glue is too old and easy to break. If the glue discoloration is obvious, it means that the overheating will cause aging and brittleness, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com