Device for testing powder combustion characteristics in vacuum condition

A technology of combustion characteristics and testing equipment, which is applied in the direction of fuel oil testing, chemical analysis by means of combustion, material inspection products, etc., to achieve the effect of saving scientific research funds and reliable testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

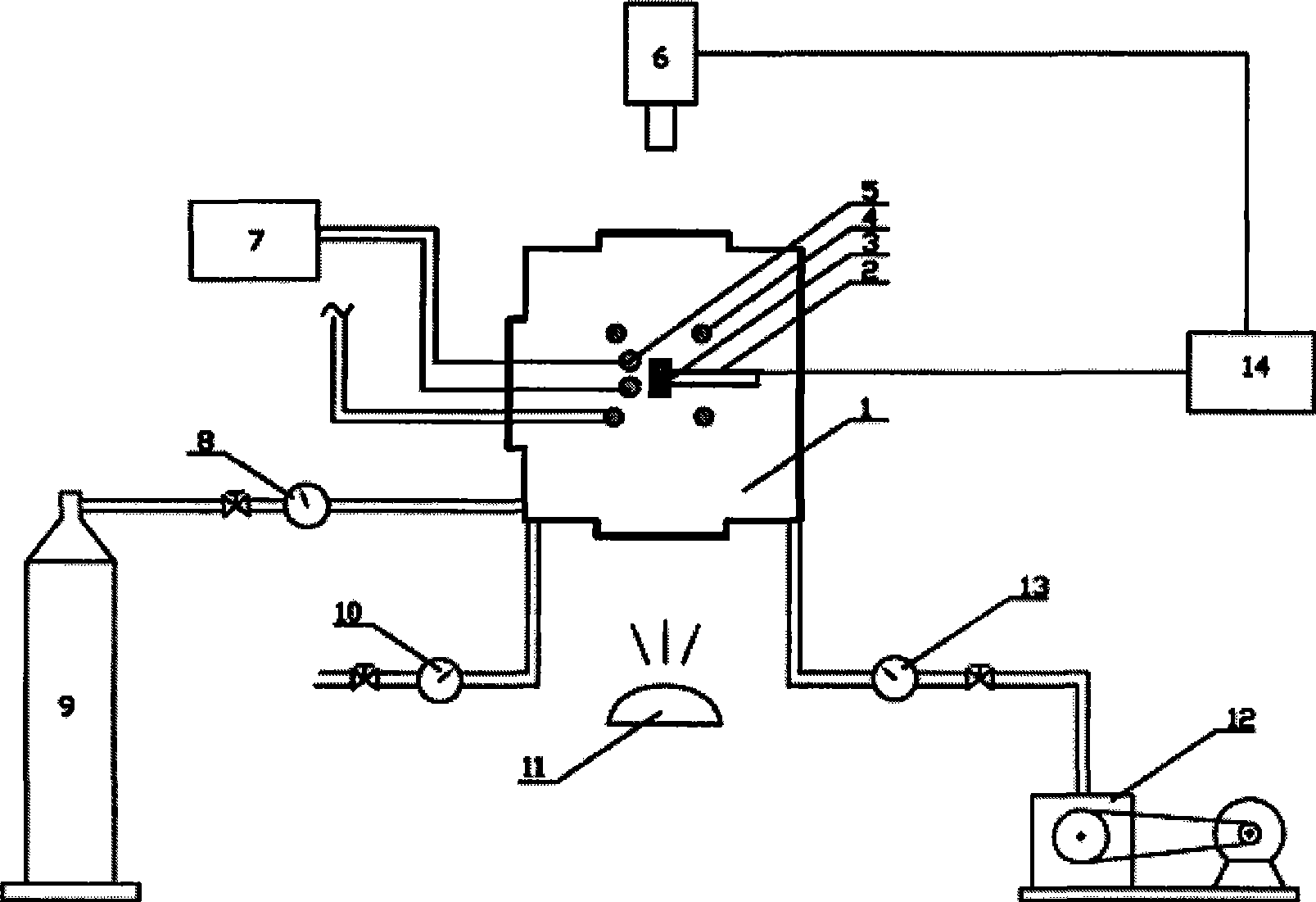

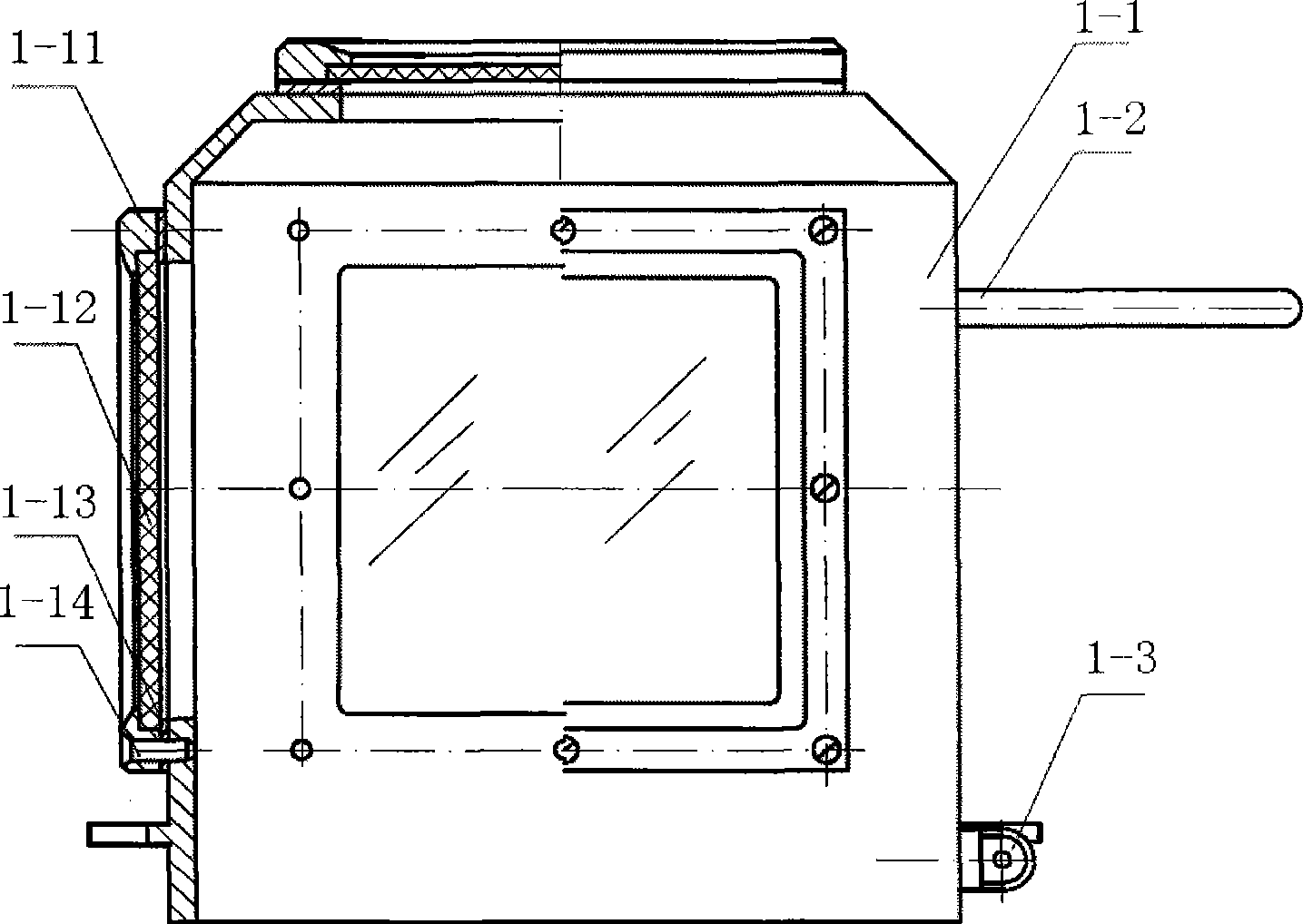

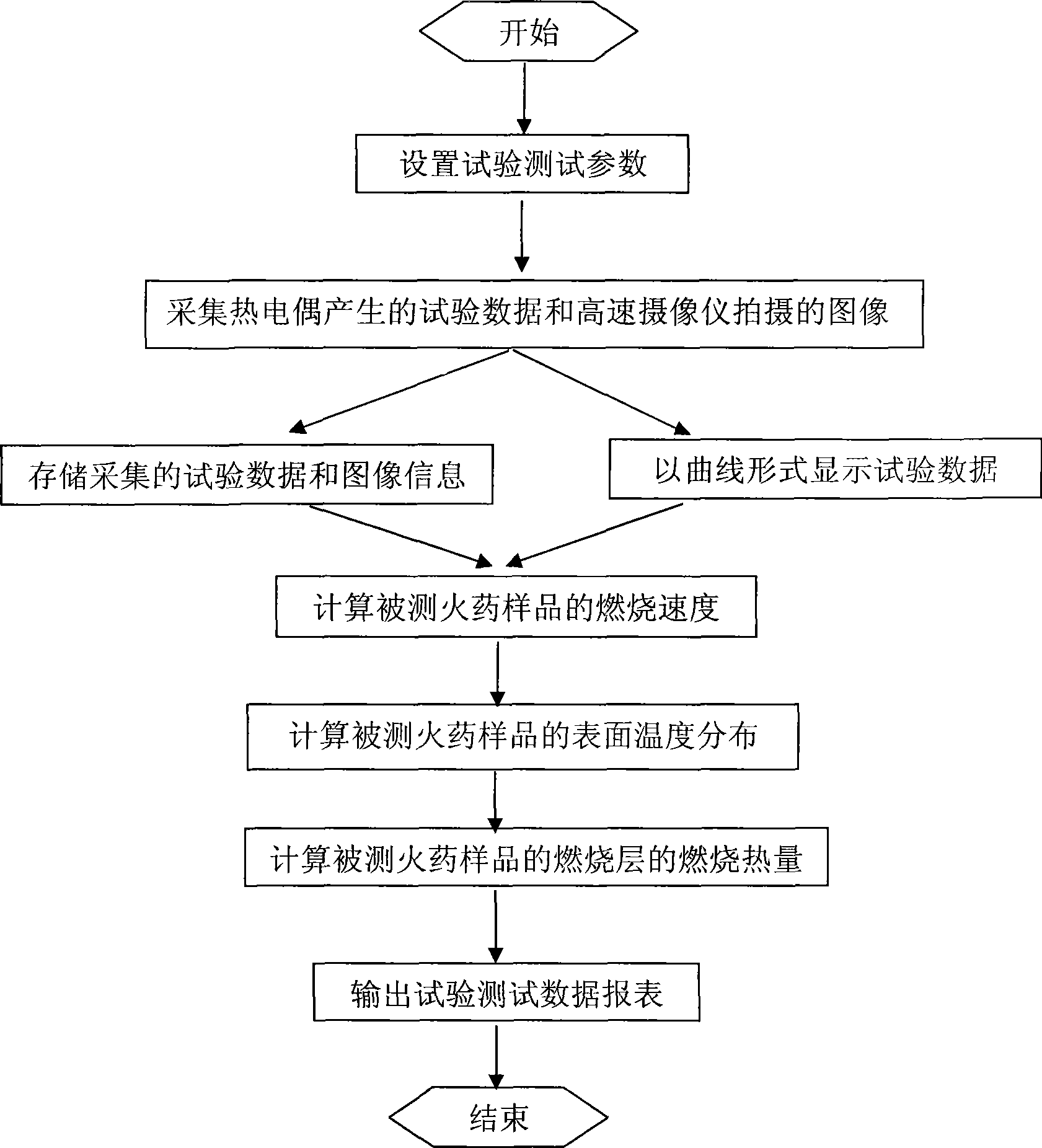

Method used

Image

Examples

example 1

[0037] Example 1: Using a thermocouple with a diameter of 7 μm to measure a ternary mixture (45% C 3 h 8 N 4 o 4 , 45%C 4 h 10 N 4 o 4 , 15% C 3 h 12 N 4 o 4 )+3%NC (nitrocellulose) sample flame temperature as shown in Table 2, the sample diameter is 10mm, no dark area can be seen on the image taken by the high-speed camera 6, indicating complete combustion.

[0038] Table 2 Combustion temperature of a certain gunpowder sample measured by thermocouple

[0039]

example 2

[0040] Example 2: The burning speeds of three propellant samples were obtained under different vacuum pressures, see Table 3.

[0041] Table 3 Burning rates of different powder samples measured under different vacuum pressures

[0042]

example 3

[0043] Example 3: Under the pressure of 200Pa, the gunpowder sample composed of 57% nitrocellulose, 28% nitroglycerin, 11% dinitrotoluene and 4% other components was tested, and the highest temperature on the burning surface of the sample was measured to be 300°C. Based on this, the heat of combustion is calculated to be 292.6kJ / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com