A psm high-voltage power supply system and its feedback control implementation method

A technology of high-voltage power supply and implementation method, which is applied in the direction of converting irreversible AC power input to DC power output, etc., can solve the problems of system disturbance, increased development difficulty, and increased cost, and achieves the effect of meeting control requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

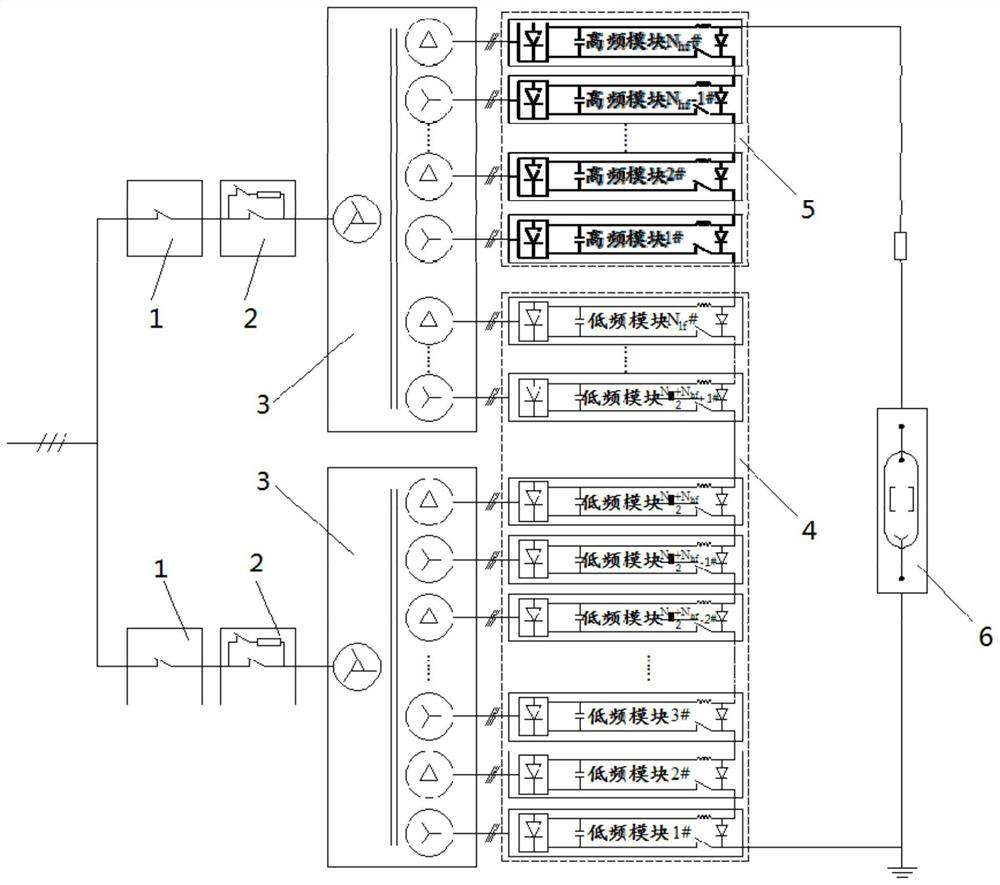

[0025] Such as figure 1 As shown, a PSM high-voltage power supply system includes a high-voltage incoming line unit, and the high-voltage incoming line unit is composed of two high-voltage circuit breaker cabinets 1 connected in series and a high-voltage contactor cabinet 2 respectively, and two high-voltage contactor cabinets 2 A multi-winding high-voltage isolation transformer 3 is respectively connected, and the multi-winding high-voltage isolation transformer 3 is respectively connected to a low-frequency rectification power module 4 and a high-frequency rectification power module 5, and the low-frequency rectification power module and the high-frequency rectification power module are all connected in series to the load 6, The number of low-frequency rectification power supply modules is N lf "lf" means "Low Frequency", and the module numbers are (1#, 2#,..., N lf #), the number of high-frequency rectification power supply modules is N hf "hf" means "High Frequency", and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com