Gunpowder combustion property test device under pressure reduction condition

A technology of pressure drop and combustion characteristics, applied in the direction of fuel oil testing, material inspection products, etc., can solve the problems of less pressure points and narrow initial pressure range of gunpowder flameout environment, and achieve the effect of saving scientific research funds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

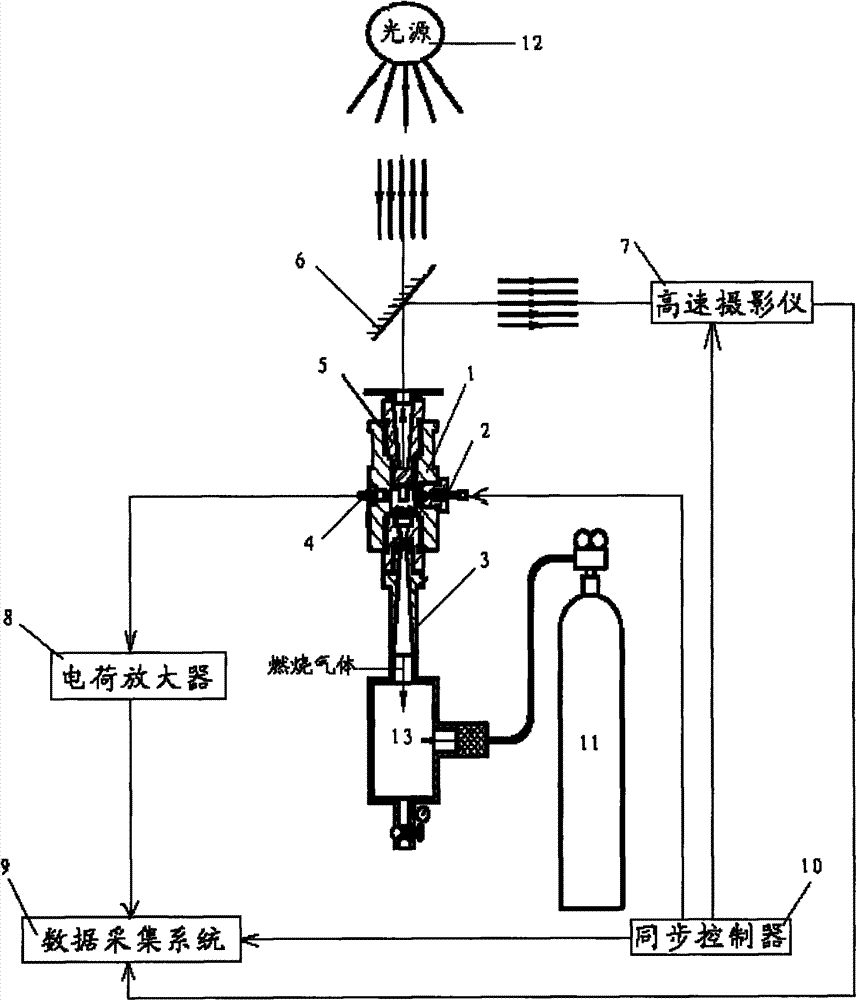

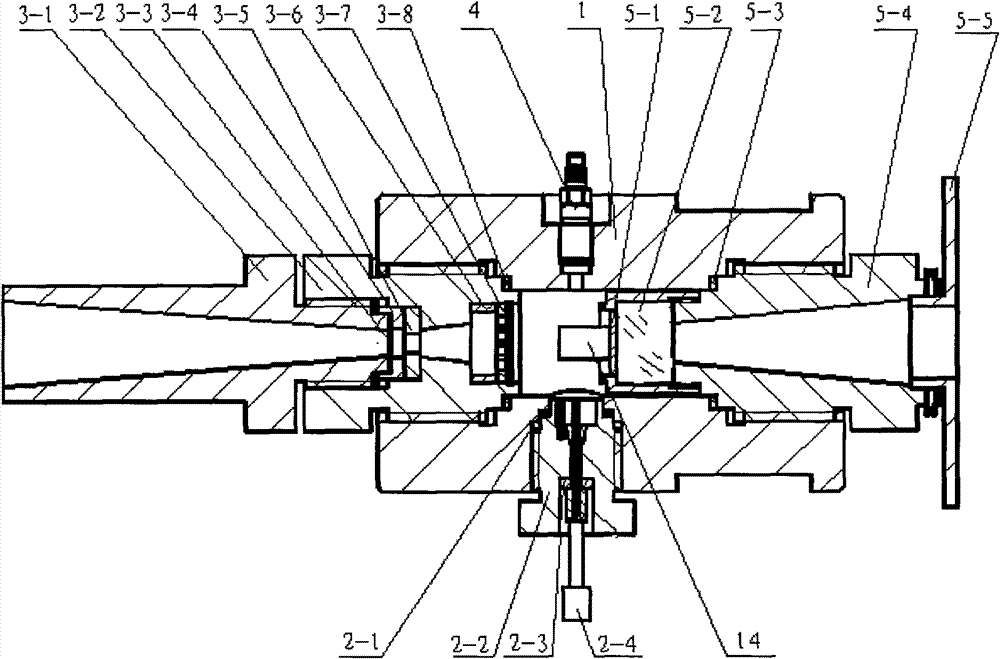

Method used

Image

Examples

example 1

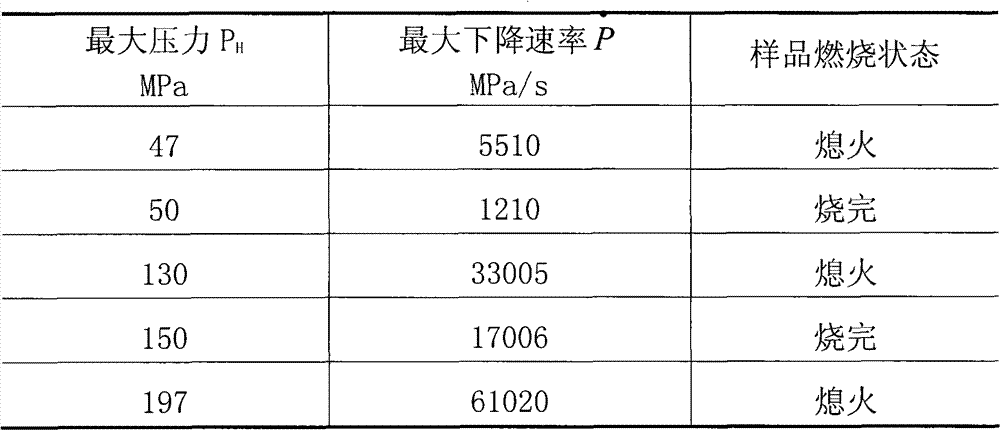

[0035] Example 1: At different maximum pressure P H and different maximum rate of descent , the pressure drops to P K =0.1MPa, that is, under 1 atmospheric pressure, the combustion state of the propellant sample (56% of nitrocellulose, 28% of nitroglycerin, 11% of dinitrotoluene, and other 5%) of a test diameter of 7.5mm and a length of 15mm is shown in Table 1 .

[0036] Table 1

[0037]

example 2

[0038] Example 2: At different maximum pressure P H (30MPa and 100MPa), different maximum rate of descent , the pressure drops to P K >0.1MPa means greater than 1 atmospheric pressure, h=P K / P H =(0.08~0.5), the combustion state of the propellant sample (56% of nitrocellulose, 28% of nitroglycerin, 11% of dinitrotoluene, other 5%) of 7.5mm in test diameter and 15mm in length is shown in Table 2.

[0039] Table 2

[0040]

example 3

[0041] Example 3: A kind of diameter is 8mm, length is 15mm the burning velocity and flame-out time of double-base drug sample under different pressure drop rates are shown in table 3.

[0042] table 3

[0043]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com