Reaction thermogravimetric analysis system for synergistic heating process of electrical heating and microwave heating

A technology of thermogravimetric analysis and microwave heating, which is applied in the direction of analyzing materials, weighing materials, measuring devices, etc., can solve the problems of lack of electric and microwave synergistic heating reaction thermogravimetric equipment, and can not reflect the temperature field well, etc., to achieve The effect of small error, various functions, and increased contact probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

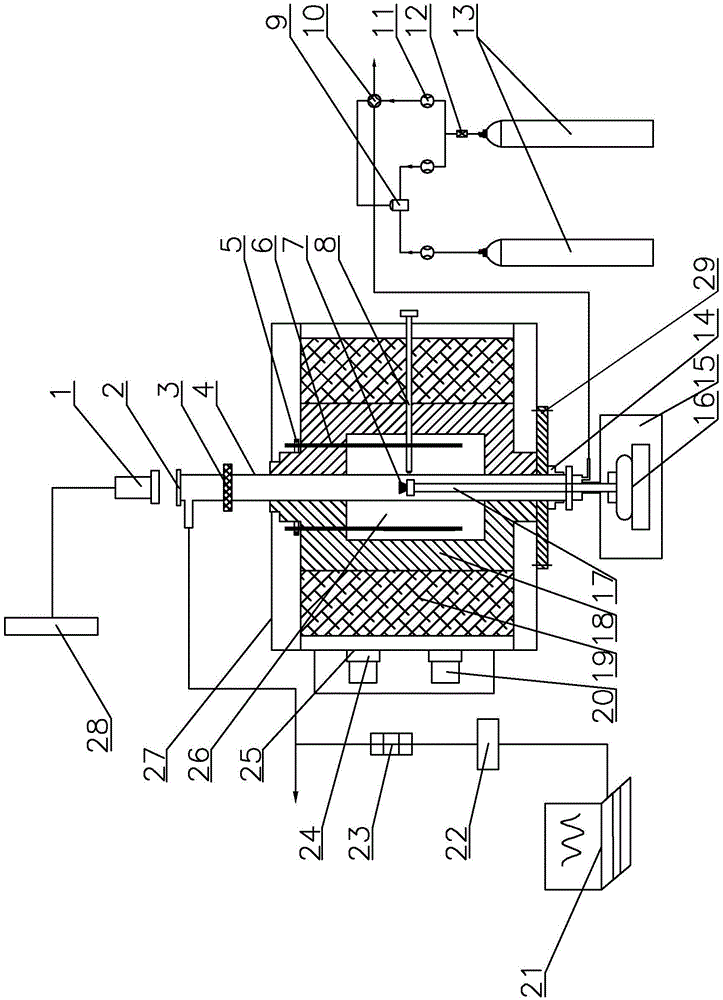

[0030] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, this embodiment includes a flue gas analyzer 22, a filter barrel 23, a microwave heating system, a silicon carbide rod heating source, an experimental reactor, a heat preservation system, a quality measurement system, a temperature measurement system and an atmosphere adjustment system;

[0031] The silicon carbide rod heating source includes at least two silicon carbide rods 6;

[0032] The experimental reactor comprises a reaction box 27 and a furnace tube 4;

[0033] The heat preservation system includes a furnace liner 18 and a heat preservation layer cover 19;

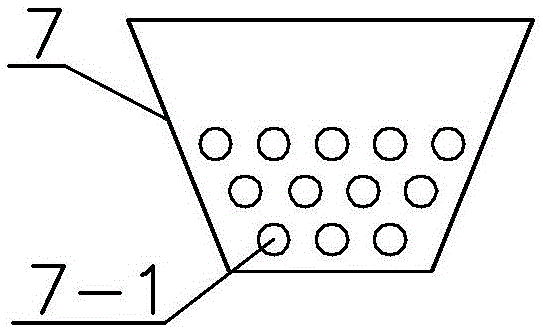

[0034] The mass determination system includes a sample crucible 7, an electronic balance 16 and a sample holder 17;

[0035] The temperature measurement system includes an infrared window 2 and a thermocouple 8;

[0036] The outer wall of the reaction box 27 is provided with a microwave heating system, and the ins...

specific Embodiment approach 2

[0041] Specific implementation mode two: combination figure 1Describe this embodiment, the atmosphere adjustment system described in this embodiment includes gas mixing tank 9, four-way valve 10, deaerator 12, two mass flow meters 11, two gas cylinders 13 and two regulating valves, each The gas cylinder 13 communicates with the bottom end of the furnace tube 4 through the gas mixing tank 9 and the four-way valve 10 successively. One gas cylinder in the two gas cylinders 13 is connected with a deaerator 12, and each gas cylinder 13 A mass flow meter 11 and a regulating valve are provided. The atmosphere regulating system in this embodiment is connected to the furnace tube 4, and the atmosphere in the furnace tube 4 is adjusted according to the actual situation. The heating atmosphere can be an air atmosphere, an inert atmosphere, an oxidizing atmosphere or a reducing atmosphere. Other structures and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0042] Specific implementation mode three: combination figure 1 Describe this embodiment, the silicon carbide rod heating source described in this embodiment also includes at least two clips 5 for silicon carbide rods, the clips 5 for silicon carbide rods and the silicon carbide rods 6 are set in one-to-one correspondence, and each silicon carbide rod 6 The top end is detachably connected to the outer wall of the furnace liner 18 by the clip 5 corresponding to the silicon carbide rod. In this embodiment, the silicon carbide rod 6 is installed in the furnace liner 18 and the furnace chamber 26 through the silicon carbide rod clamp 5, which can achieve a heating temperature of up to 1400°C; other structures and connections are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com