Method for washing and recycling membranate glass slide for microdissection

A technology for microdissection and glass slides, which is applied in the direction of cleaning methods using tools, cleaning methods and utensils, cleaning methods using liquids, etc. The effect of scientific research funds, low price and quantity saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

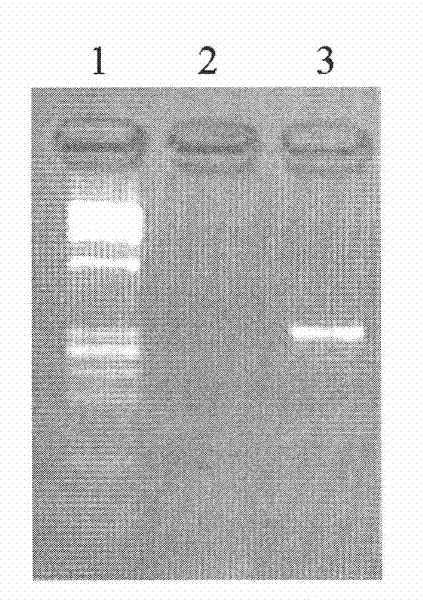

[0030] Use this method to clean microdissected membrane slides of residual lung cancer tissue (paraffin-embedded specimen).

[0031] Take two microdissected membrane glass slides pasted with lung cancer tissue (paraffin-embedded specimen), one of which is not cleaned by this method, and one is cleaned by this method.

[0032] Place the microdissected membrane slides in xylene and incubate in a 50°C incubator for 20 minutes (this step is not required for frozen tissue specimens); place the slides in boric acid, alcohol, EDTA mixed solution A (mixed solution A is a mixed solution of 1% boric acid, 70% alcohol, and 0.25mol / L EDTA, and its volume ratio is 1:98:1) Soak in, shake for 4 minutes, and repeat once; rinse with double distilled water for 2 minutes; Transfer slides to pH 6, 80μg / ml proteinase K solution, incubate at 56°C for 2 hours; place slides in clean water, lightly touch the specimens on the membrane with fingers with plastic gloves, rinse with double distilled water ...

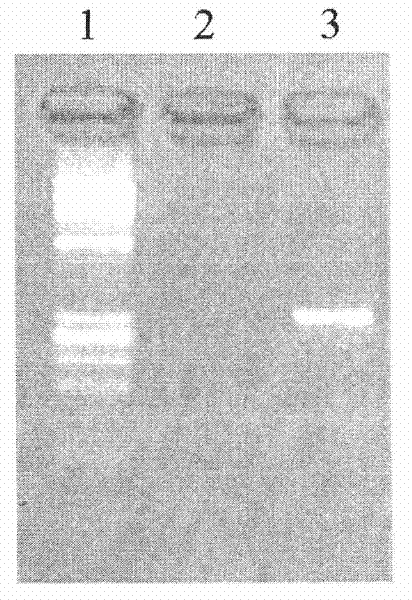

Embodiment 2

[0034] The cleaning and reuse method of the microdissection membrane glass slide can be implemented sequentially according to the following steps:

[0035] (1) Place the microdissected membrane slide in xylene and incubate in an incubator at 45-50°C for 20-30 minutes;

[0036] (2) Place the membranous slide in boric acid, alcohol and EDTA mixed solution A to soak, shake for 3 minutes, and repeat once; the concentration of the boric acid is 1%, the concentration of alcohol is 70%, and the concentration of EDTA is 0.25mol / L; the volume ratio of boric acid, alcohol and EDTA is 0.5:96.5:0.5.

[0037] (3) Rinse with double-distilled water for 3 minutes; transfer the membrane slide to proteinase K solution, and incubate at 56° C. for 1 hour; the pH of the proteinase K solution is 6, and the concentration is 90 μg / ml.

[0038] (4) Place the glass slide in clear water, lightly touch the specimen on the membrane in the membrane glass slide with fingers with plastic gloves, rinse with ...

Embodiment 3

[0042] The cleaning and reuse method of the microdissection membrane glass slide can be implemented sequentially according to the following steps:

[0043] (1) Soak the membrane glass slide in boric acid, alcohol and EDTA mixed solution A, shake for 5 minutes, and repeat once; the concentration of the boric acid is 1%; the concentration of the alcohol is 70%, the concentration of the alcohol is 70%. The concentration of EDTA is 0.25mol / L, and the volume ratio of boric acid, alcohol and EDTA is 1:97:1.

[0044] (2) Rinse with double distilled water for 3 minutes; transfer the membrane slide to proteinase K solution, and incubate at 56° C. for 2 hours; the pH of the proteinase K solution in the step (2) is 7, and the concentration is 100 μg / ml.

[0045] (3) Place the glass slide in clear water, lightly touch the specimen on the film in the membrane glass slide with fingers with plastic gloves, rinse with double distilled water, and remove large specimens;

[0046](4) Soak the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com