Multi-span simply-supported boundary condition test device

A technology of boundary conditions and test devices, applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve problems such as the inability to adjust the support position, and achieve scientific research funding, strong versatility, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

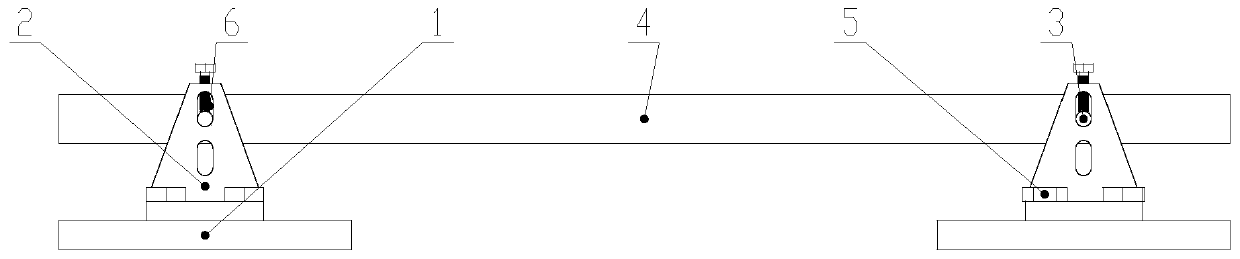

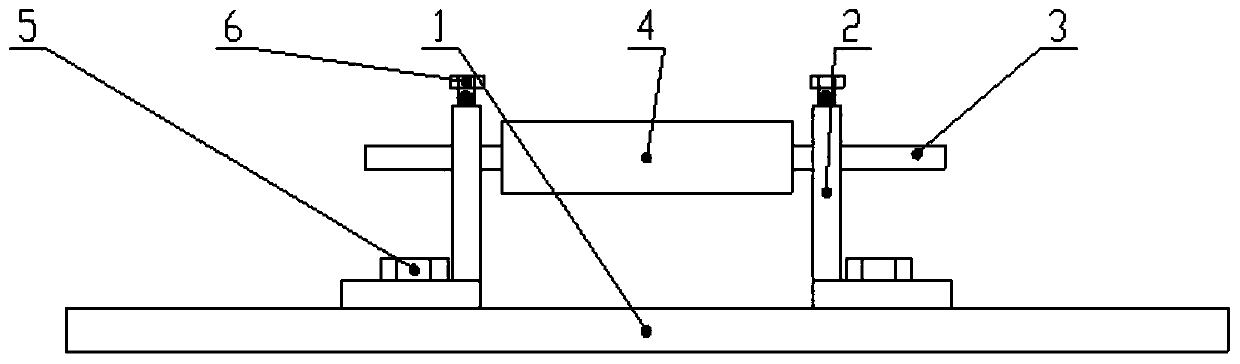

[0025] Specific implementation mode one: combine Figure 1 to Figure 7 Describe this embodiment, a multi-span simply supported boundary condition test device described in this embodiment includes a plurality of base plates 1, a test beam 4 and a plurality of support assemblies, a plurality of base plates 1 are arranged side by side along a straight line, and each base plate 1 is installed For one support assembly, the test beam 4 is horizontally installed on multiple support assemblies.

specific Embodiment approach 2

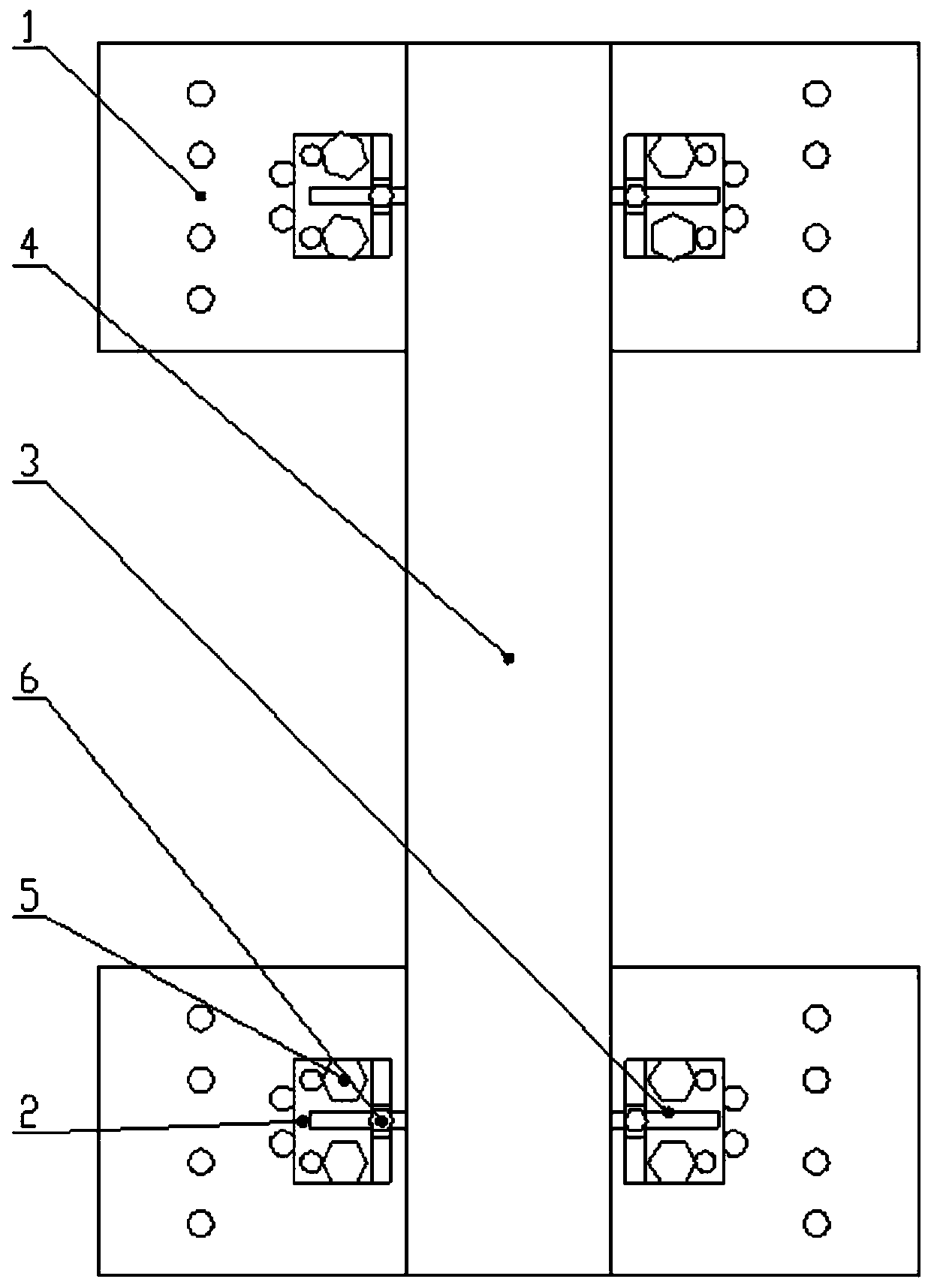

[0026] Specific implementation mode two: combination Figure 4 Describe this embodiment, each support assembly described in this embodiment includes two L-shaped supports 2, round rods 3, fixing bolts 5 and compression bolts 6, and the two L-shaped supports are installed symmetrically along the length direction of the bottom plate 1 , the transverse plate 2-1 of each L-shaped support 2 is fixedly connected to the bottom plate 1 through the fixing bolt 5, the round bar passes through the thicker test beam horizontally, and the two ends of the round bar pass through two holes on both sides of the test beam respectively. The strip hole in the vertical plate of the L-shaped support is used to fix the hold-down bolt 6 of the round bar 3 to be installed in the threaded hole at the upper end of the vertical plate 2-2. For thicker test beams, simple support can be realized by perforating holes on the test beams to cooperate with round rods 3 . Other components and connections are the...

specific Embodiment approach 3

[0027] Specific implementation mode three: combination Figure 5 Describe this embodiment, each support assembly described in this embodiment includes two L-shaped supports 2, two round rods 3, fixing bolts 5 and compression bolts 6, and the two L-shaped supports are along the length direction of the bottom plate 1 Symmetrical installation, the horizontal plate 2-1 of each L-shaped support 2 is fixedly connected with the bottom plate 1 through the fixing bolt 5, and the two ends of the round rod 3 pass through the two vertical plates 2-2 on both sides of the test beam 4 respectively. Long holes, and two round rods 3 are stacked up and down, the test beam 4 is located between the two round rods 3 and between the two L-shaped supports 2, and the compression bolts 6 for fixing the round rods 3 are installed In the threaded hole on the vertical plate 2-2 upper end, screw in the bolt to achieve the purpose of compressing the round bar.

[0028] That is: for thinner beams (slabs), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com