A preparation method and equipment for continuous casting and rolling of magnesium alloy materials assisted by ultrasonic waves

A continuous casting and rolling, ultrasonic-assisted technology, applied in the direction of metal rolling, can solve the problems of uneven size of magnesium alloy, complicated process, complicated operation method, etc., and achieve the effect of eliminating temperature instability, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

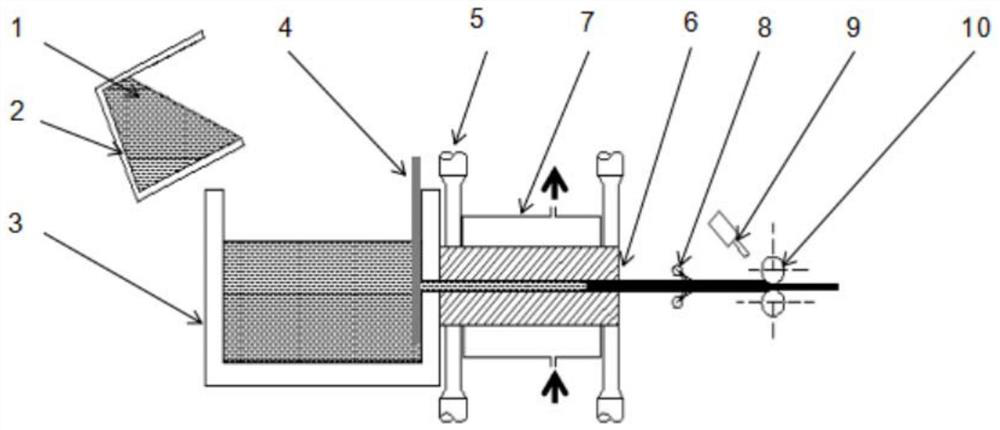

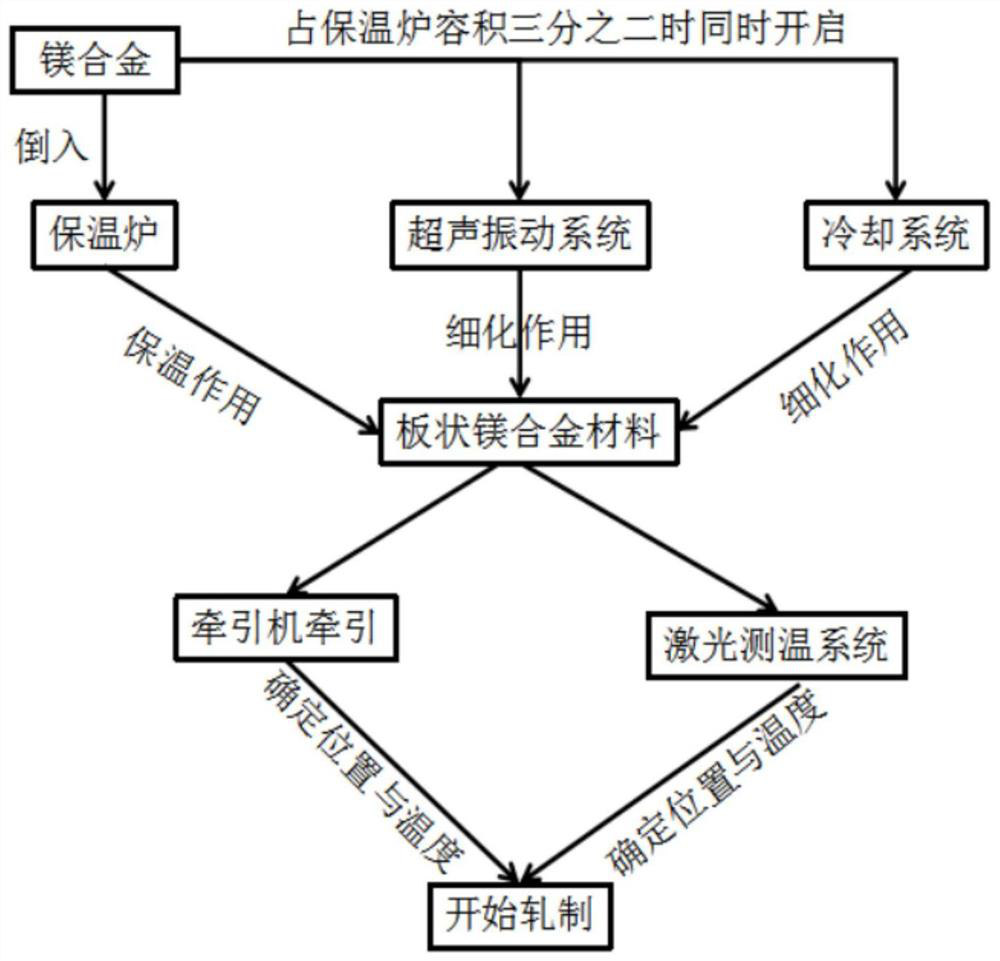

[0038] Specific implementation mode one, has the following steps successively:

[0039] Pour the liquid magnesium alloy 1 metal that has been smelted in the crucible 2 into the holding furnace 3. During the whole process, the holding furnace is carried out under the protection of argon. In this scheme, the temperature of the smelted magnesium alloy and the holding furnace are set It is 730°C. The magnesium alloy material is taken as Mg-10Gd-3Y-2Ag-0.4Zr.

[0040] In order to prevent the magnesium alloy 1 from flowing out prematurely, before the magnesium alloy reaches 2 / 3 of the capacity of the holding furnace 3, the valve 4 of the furnace is in a closed state.

[0041] In order to make the surface temperature of the metal sheath 6 uniform and to reduce energy waste, the cooling device 7 is turned on while adding the amount of liquid magnesium alloy, so that the cooling medium is injected from the lower end and flows out from the upper end. The cooling medium water selected i...

specific Embodiment approach 2

[0046] Specific implementation mode two, following steps are arranged successively:

[0047] Pour the liquid magnesium alloy 1 metal that has been smelted in the crucible 2 into the holding furnace 3. During the whole process, the holding furnace is carried out under the protection of argon. In this scheme, the temperature of the smelted magnesium alloy and the holding furnace are set It is 730°C. The magnesium alloy material is taken as Mg-10Gd-3Y-2Ag-0.4Zr.

[0048] In order to prevent the magnesium alloy 1 from flowing out prematurely, before the magnesium alloy reaches 2 / 3 of the capacity of the holding furnace 3, the valve 4 of the furnace is in a closed state.

[0049] In order to make the surface temperature of the metal sheath 6 uniform and to reduce energy waste, the cooling device 7 is turned on while adding the amount of liquid magnesium alloy, so that the cooling medium is injected from the lower end and flows out from the upper end. The cooling medium water selecte...

specific Embodiment approach 3

[0054] Specific implementation mode three, has the following steps successively:

[0055] Pour the liquid magnesium alloy 1 metal that has been smelted in the crucible 2 into the holding furnace 3. During the whole process, the holding furnace is carried out under the protection of argon. In this scheme, the temperature of the smelted magnesium alloy and the holding furnace are set It is 730°C. The magnesium alloy material is taken as Mg-10Gd-3Y-2Ag-0.4Zr.

[0056] In order to prevent the magnesium alloy 1 from flowing out prematurely, before the magnesium alloy reaches 2 / 3 of the capacity of the holding furnace 3, the valve 4 of the furnace is in a closed state.

[0057] In order to make the surface temperature of the metal sheath 6 uniform and to reduce energy waste, the cooling device 7 is turned on while adding the amount of liquid magnesium alloy, so that the cooling medium is injected from the lower end and flows out from the upper end. The cooling medium water selected...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com