Pipeline type natural gas condensed liquid rotating flow separator

A cyclone separator and natural gas technology, which is applied in the field of multiphase separation of oil and gas gathering and transportation systems, can solve the problems that the vertical structure cannot be directly installed, affects the separation efficiency of the separator, and energy loss, so as to reduce the probability of crushing and rebound , Conducive to the effect of pressure energy and reducing impact loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing, but the present invention is not limited to following embodiment.

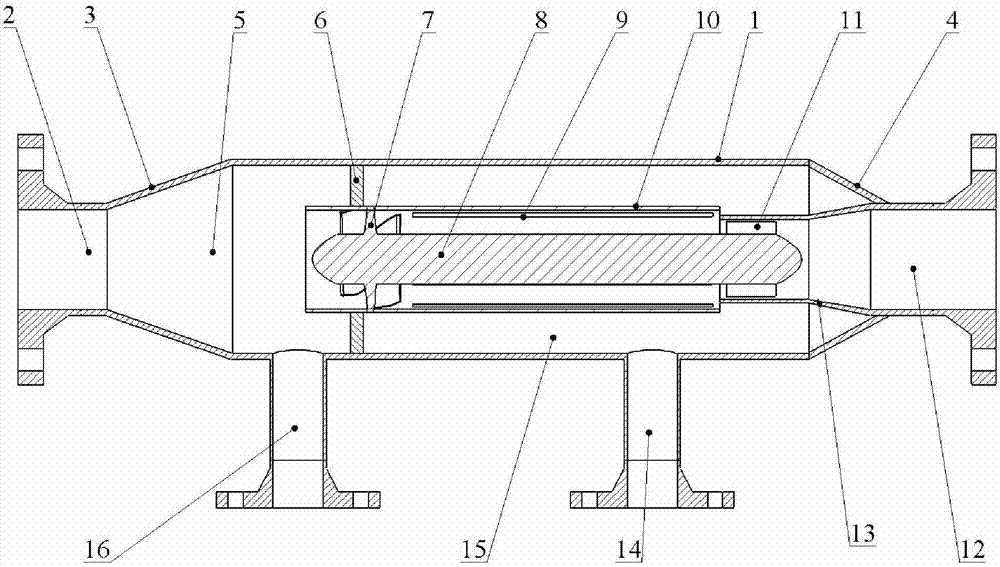

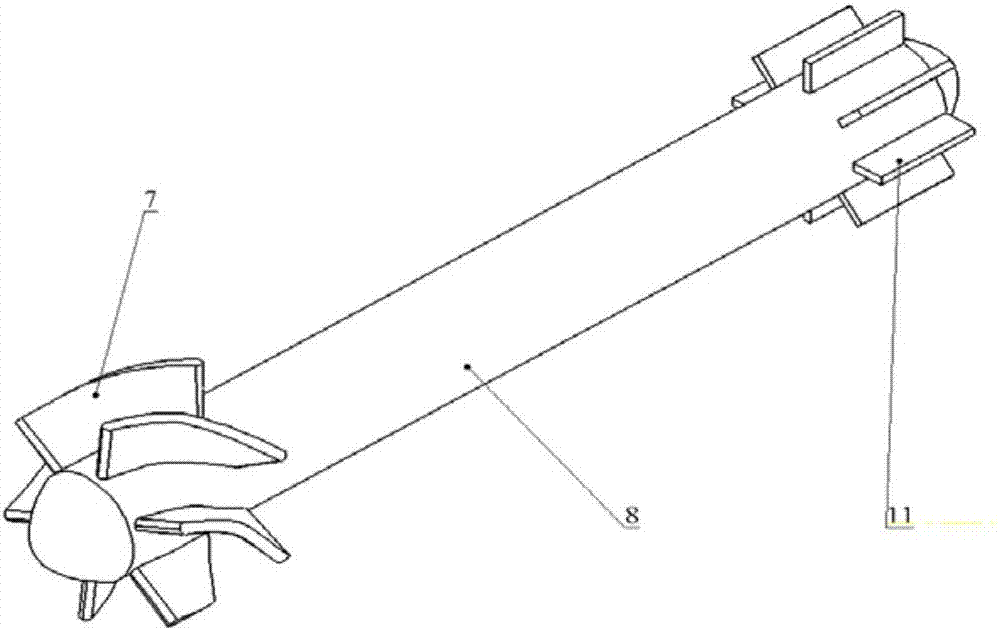

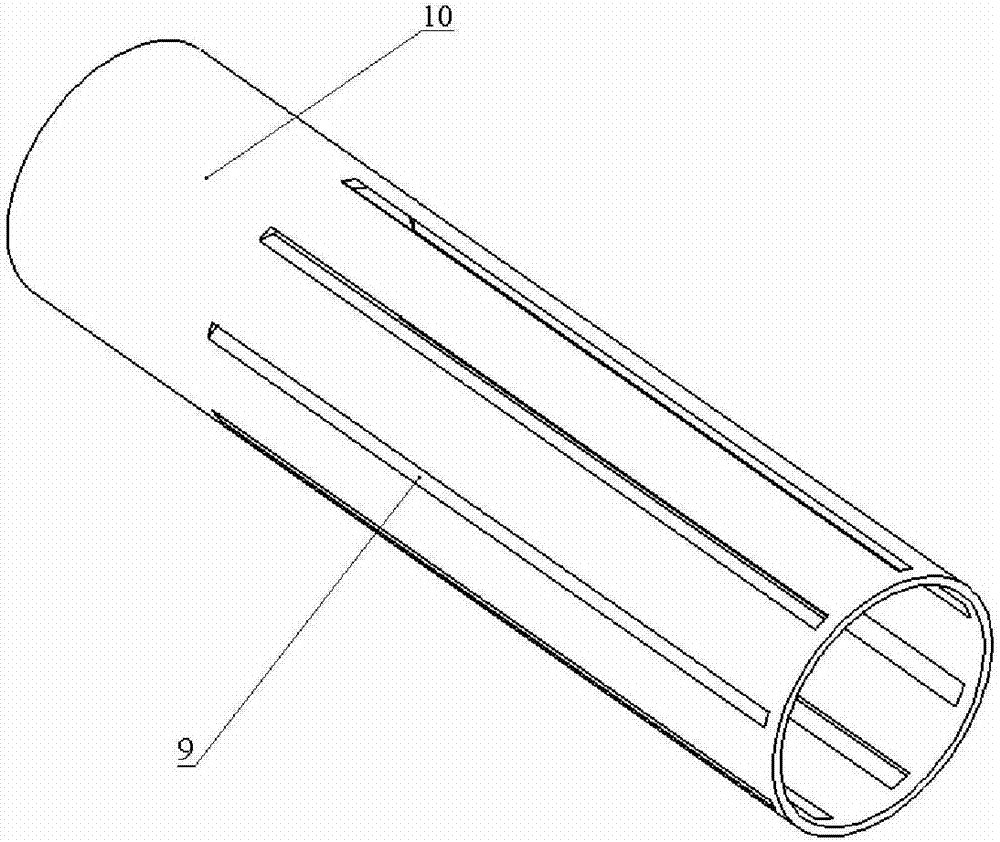

[0023] see figure 1 , a pipeline type natural gas condensate cyclone separator, the separator mainly includes a cylindrical body (1), an axial inlet (2), an inlet cone section (3), an outlet cone section (4), an axial Outlet (12), front liquid discharge pipe (16), rear liquid discharge pipe (14) constitute the outer shell, which is composed of annular plate (6), inner cylinder (10), guide body (8), inlet guide vane (7 ), supporting blades (11), and outlet gradual expansion section (13); among them, the annular plate (6) is located on the front half of the cylinder body (1), the outer ring is connected with the inner wall of the cylinder body (1), and the inner The ring is connected with the outer wall of the inner cylinder (10), and divides the interior of the separator into a pre-separation zone (5) and a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com