Aero-engine test bed mounting system

An aero-engine and installation system technology, which is applied in engine testing, jet engine testing, gas turbine engine testing, etc., can solve the problems of inaccurate testing, low testing efficiency, and high cost, and achieve accurate testing data and disassembly and assembly efficiency. High, high-precision installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

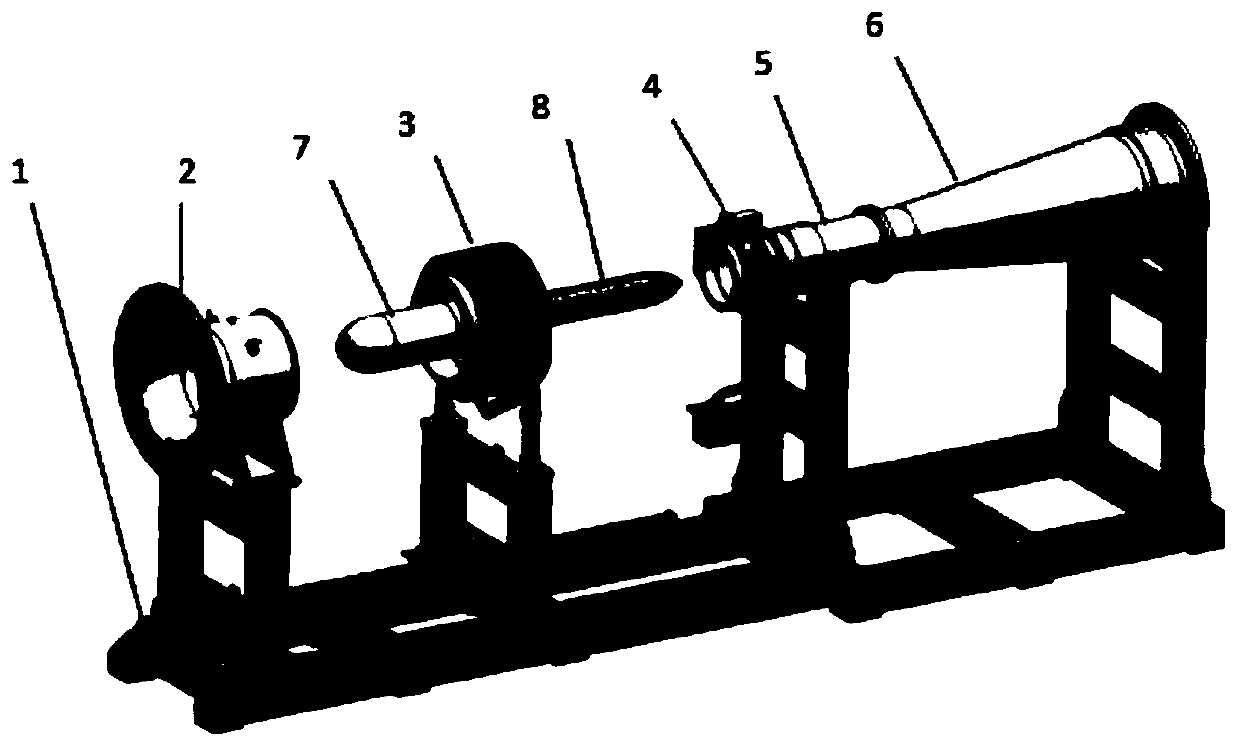

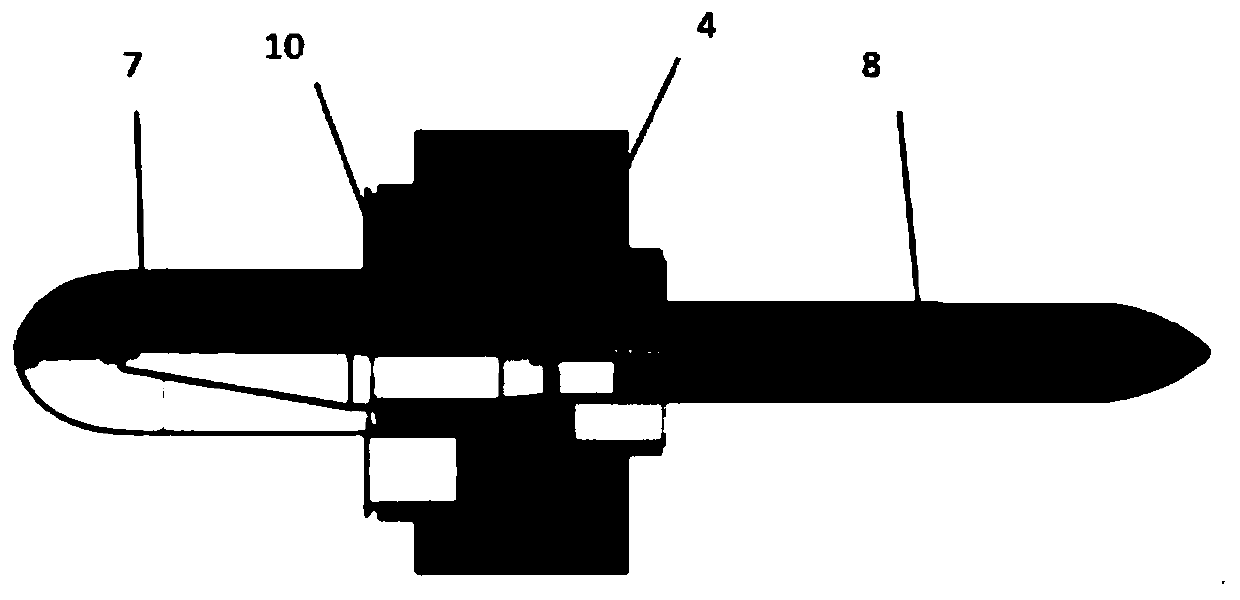

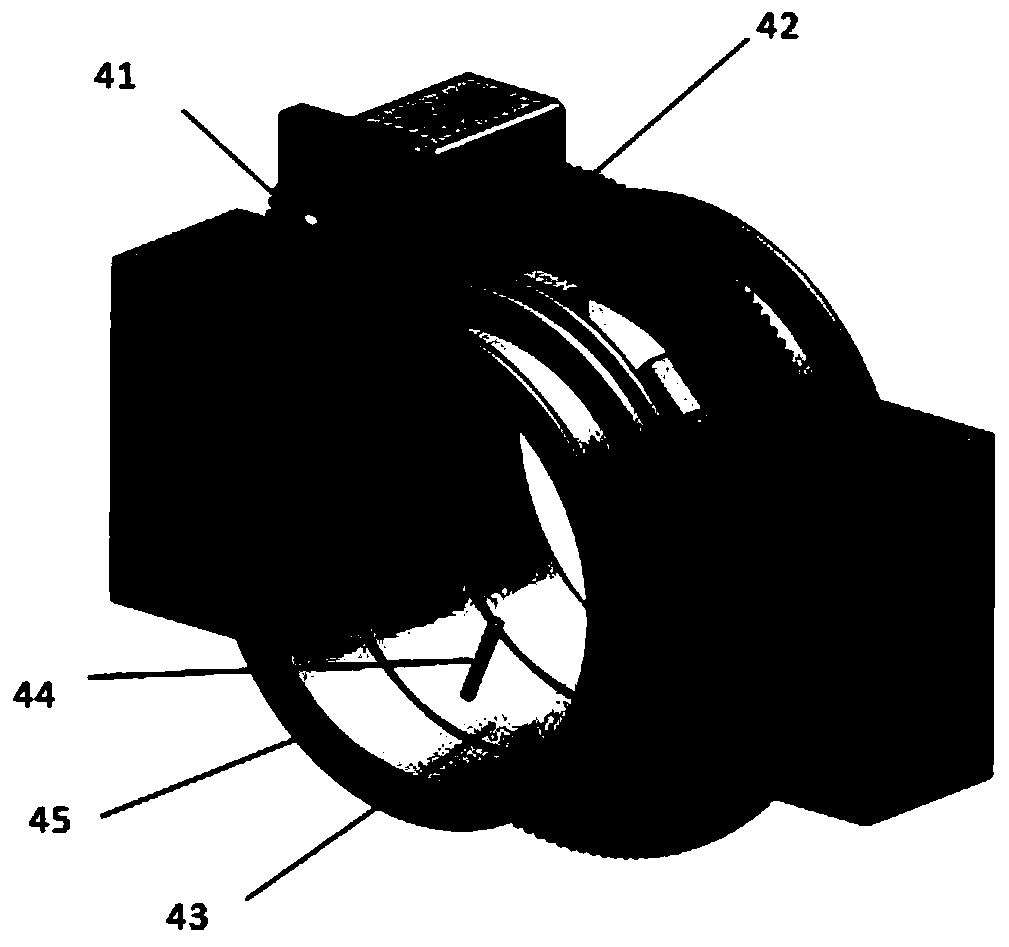

[0029] An aeroengine test bench installation system. Such as figure 1 , including a test bench 1, an air intake fairing 2 installed on the test bench 1, a test piece installation mechanism 3, a rotating measuring mechanism 4, an exhaust pipe; the exhaust pipe includes an exhaust straight pipe 5 and an expansion pipe 6. An intake cone 7 is provided in the air intake fairing, and an exhaust cone 8 is provided in the exhaust pipe. The intake shroud 2, the test piece mounting mechanism 3, the rotating measuring mechanism 4, the exhaust straight pipe 5 and the expansion section 6 are sequentially connected to form a circular tubular shape, and the intake cone assembly 7 and the exhaust cone assembly 8 are arranged in the pipe.

[0030] Such as Image 6 , 7 As shown, the test bench includes a base 11, an air intake shroud moving support 12, a test piece moving support 13, an exhaust straight pipe section mounting seat 14, and an expansion section mounting seat 15, etc. The insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com