Shell structure of air-breathing stamping rotary knocking engine adopting liquid state fuel

A detonation engine and liquid fuel technology, applied in ramjet engines, engine components, machines/engines, etc., can solve the problems of rapid atomization and difficult evaporation, shorten preparation time, shorten axial length, enhance effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

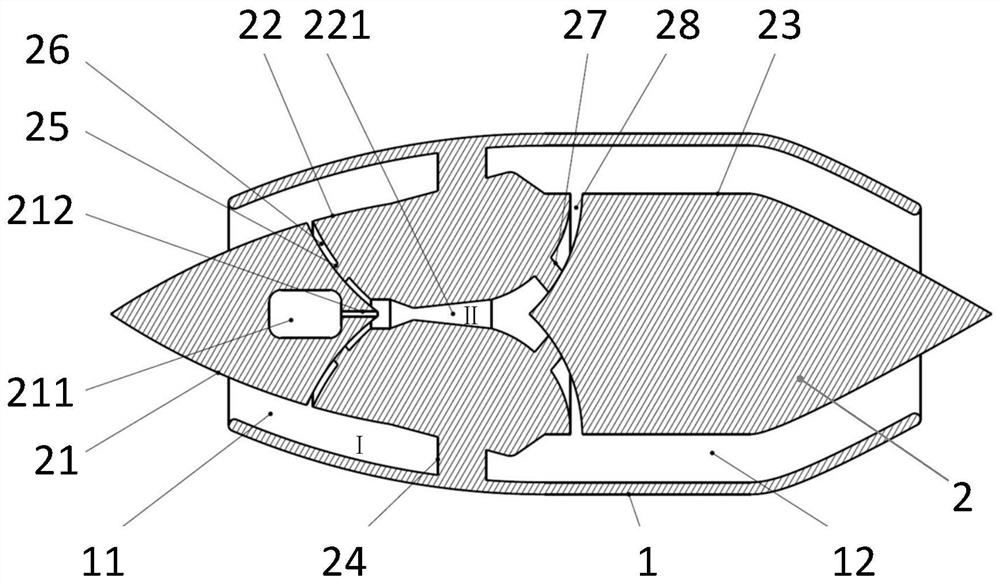

[0045] A shell structure of a liquid fuel air-breathing ram rotary detonation engine, comprising an intake cone 21 , a central body 22 of an isolation section, a central body 23 of a combustion chamber and an outer casing 1 of the engine. The intake cone 21 is connected to the center body 22 of the isolation section through four front support rods 25 arranged in the circumferential direction, and the center body 22 of the isolation section is connected to the center body 23 of the combustion chamber through four rear support rods 27 arranged in the circumferential direction. The outer shell 1 and the central body 22 of the isolation section are connected by four main support rods 24 arranged in the circumferential direction. Fuel tank and fuel injector are arranged in the air intake cone 21, and the annular slot-shaped air intake channel 26 is arranged between the air intake cone 21 and the center body 22 of the isolation section, and the mixing chamber 221 is arranged in the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com