Equipment and technology for piercing and rolling anchor rod integrally

An anchor rod and equipment technology is applied in the field of anchor rod rolling, which can solve the problems of consumption cost and prolong the process, and achieve the effects of improving efficiency, reducing production steps, reducing costs, environmental pollution and equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described with reference to the drawings and specific embodiments, but the present invention is not limited to these examples.

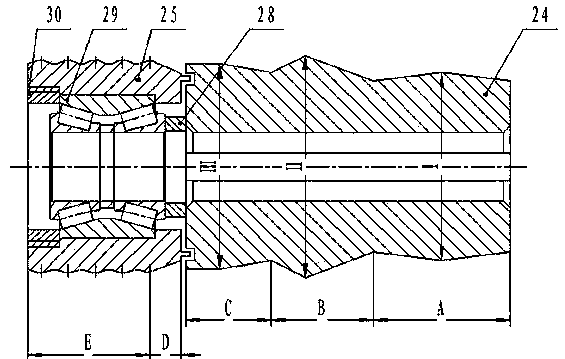

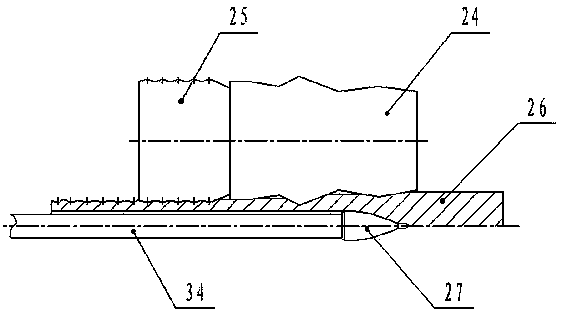

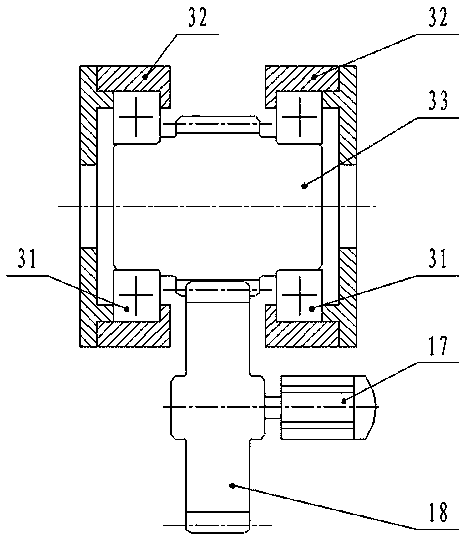

[0021] Such as figure 1 As shown, a piercing and rolling bolt integrated equipment, the equipment includes a heating device and a piercing mill 9; the heating device and the piercing mill 9 are arranged in parallel, and the heating device and the The piercing and rolling mills 9 are connected by an inclined frame; the heating device is a mature equipment in the prior art, and the heating device includes a furnace front conveying roller table 1 arranged in sequence along the forward direction of the bar, an intermediate frequency induction heating Furnace 3 and rear conveying roller table 4, wherein the rear conveying roller table 4 is provided with a jacking frame 20 for pushing the heated bars out of the heating device; corresponding to the furnace front conveying roller table 1, the furnace The conveying roller tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com