Helical spring high pressure water pipe for high pressure water cutting machine having multi-degree of freedom

A technology of coil spring and water cutting machine, applied in the direction of metal processing, etc., can solve the problems of affecting the performance of high-pressure water cutting machine, short life, easy deformation or rupture to reduce the performance of high-pressure water jet, and achieve smooth and smooth flow state, improve Stress and deformation conditions, the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

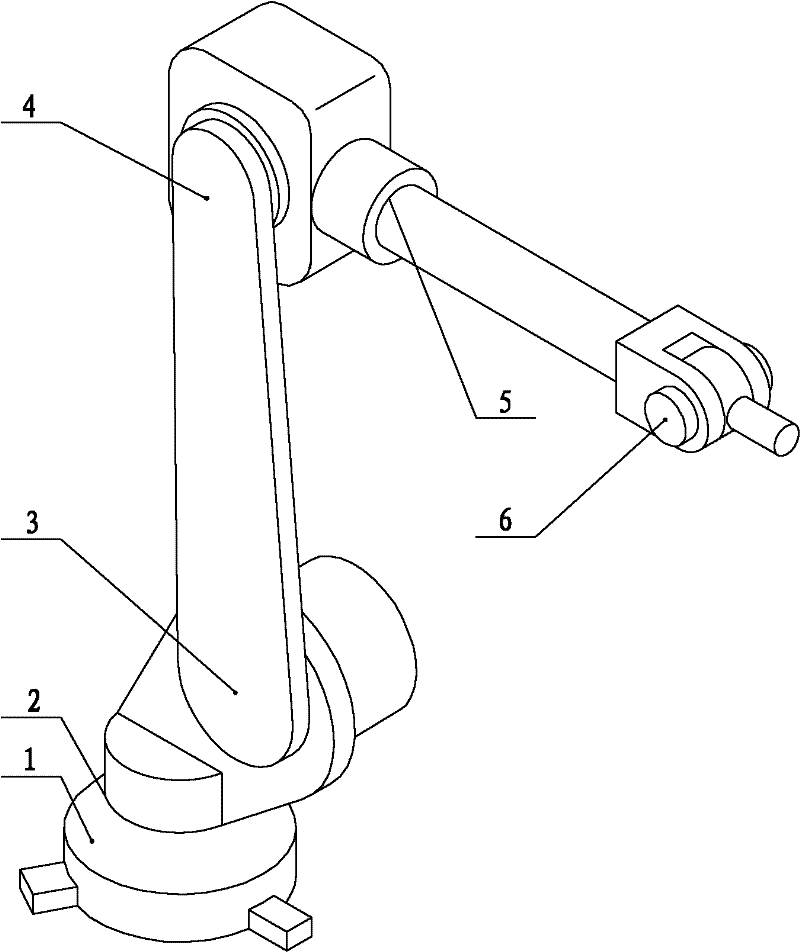

[0032] The spiral spring high-pressure water pipe for a multi-degree-of-freedom high-pressure water cutting machine of the present invention is used for high-pressure water transportation on a multi-degree-of-freedom high-pressure water cutting machine, and a structure of a multi-degree-of-freedom high-pressure water cutting machine without a spiral spring high-pressure water pipe The diagram is attached figure 1 As shown, from the base 1 for fixed installation to the position where the nozzle is installed, there are sequentially provided the first rotary joint 2, the second rotary joint 3, the third rotary joint 4, the first mobile joint 5 and the fourth rotary joint 6 .

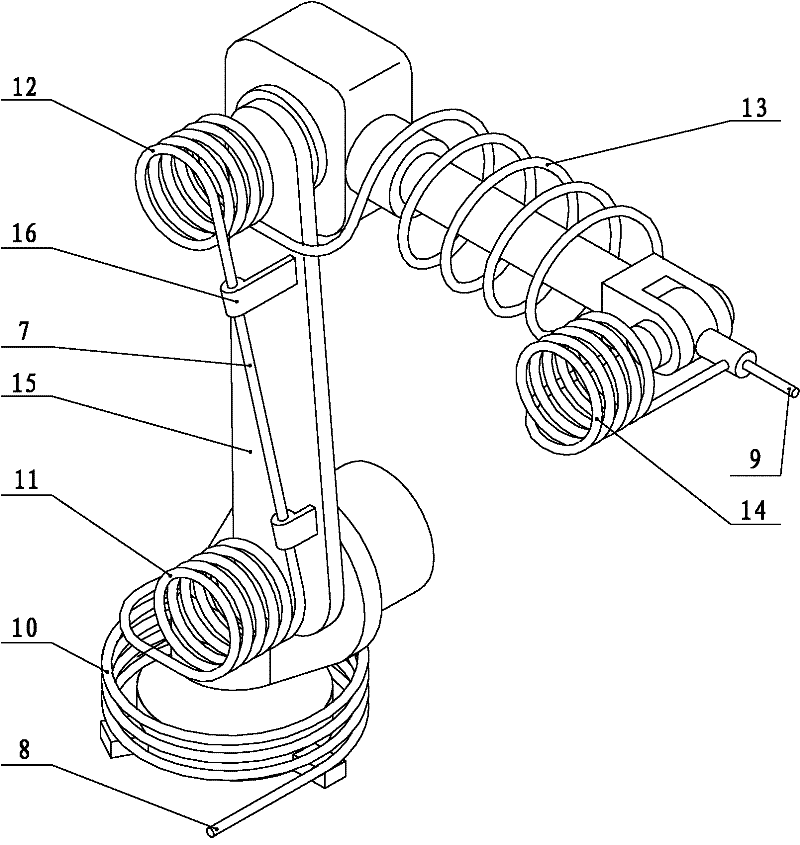

[0033] The spiral spring high-pressure water pipe used for the multi-degree-of-freedom high-pressure water cutting machine of the present invention has a structure as attached figure 2 As shown, it includes the water pipe 7 and the input end 8 and the output end 9 at the two ends of the water pipe. The i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The way to | aaaaa | aaaaa |

| The way to | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com