Expansion method and expansion equipment thereof of thermal shrinkage pipe material with large caliber

A heat-shrinkable tube and large-diameter technology, which is applied to tubular objects, other household appliances, and household appliances, can solve the problems of low production efficiency and slow expansion speed of large-diameter heat-shrinkable tubes, so as to improve production efficiency and reduce pulling Force, the effect of increasing the expansion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

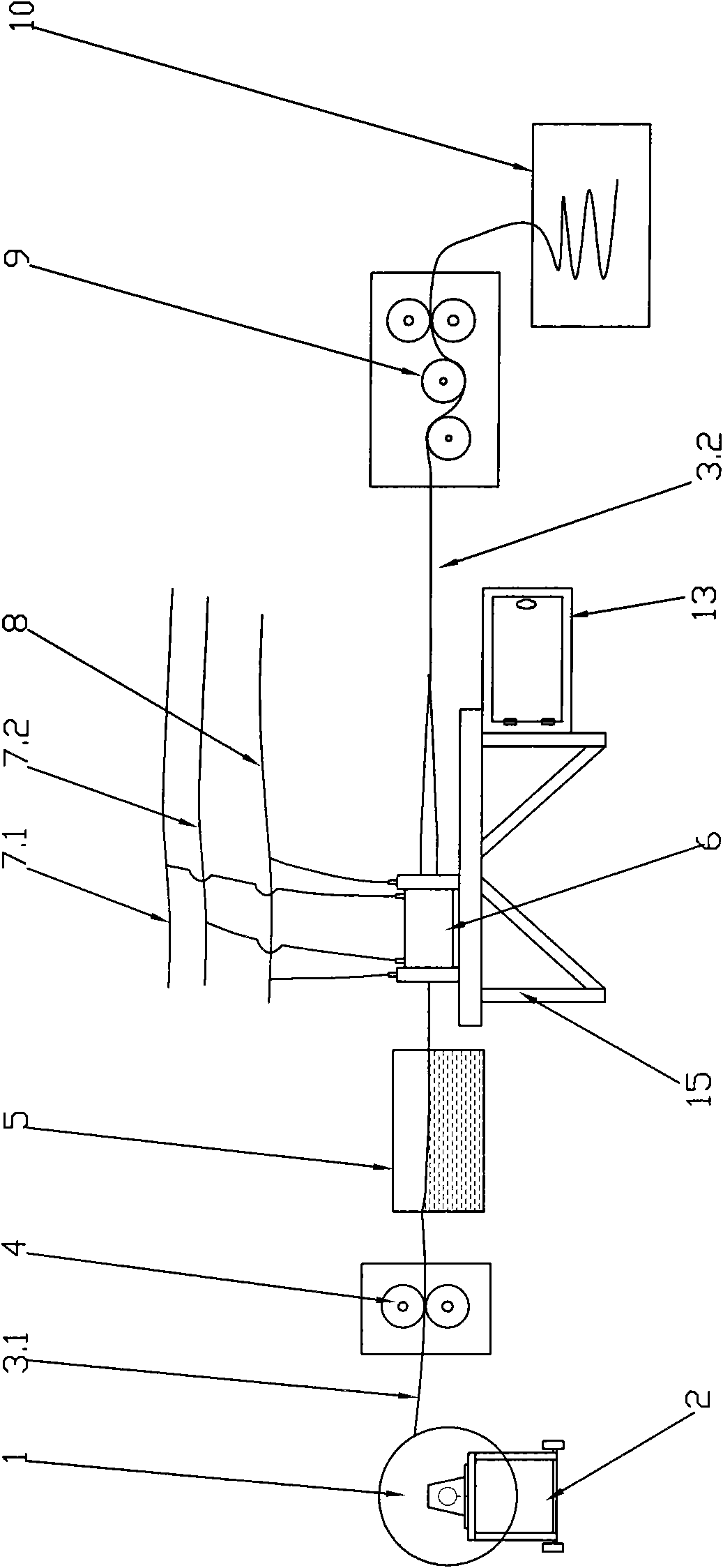

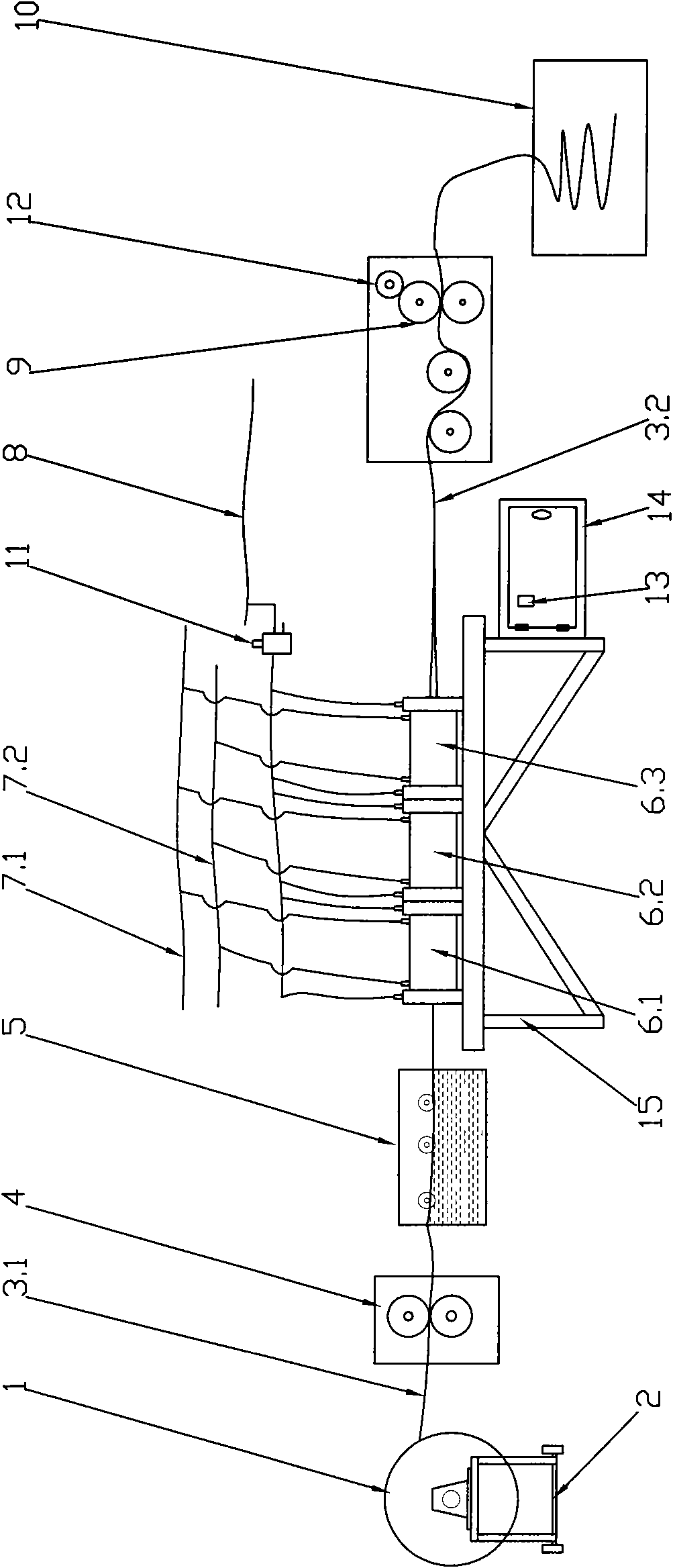

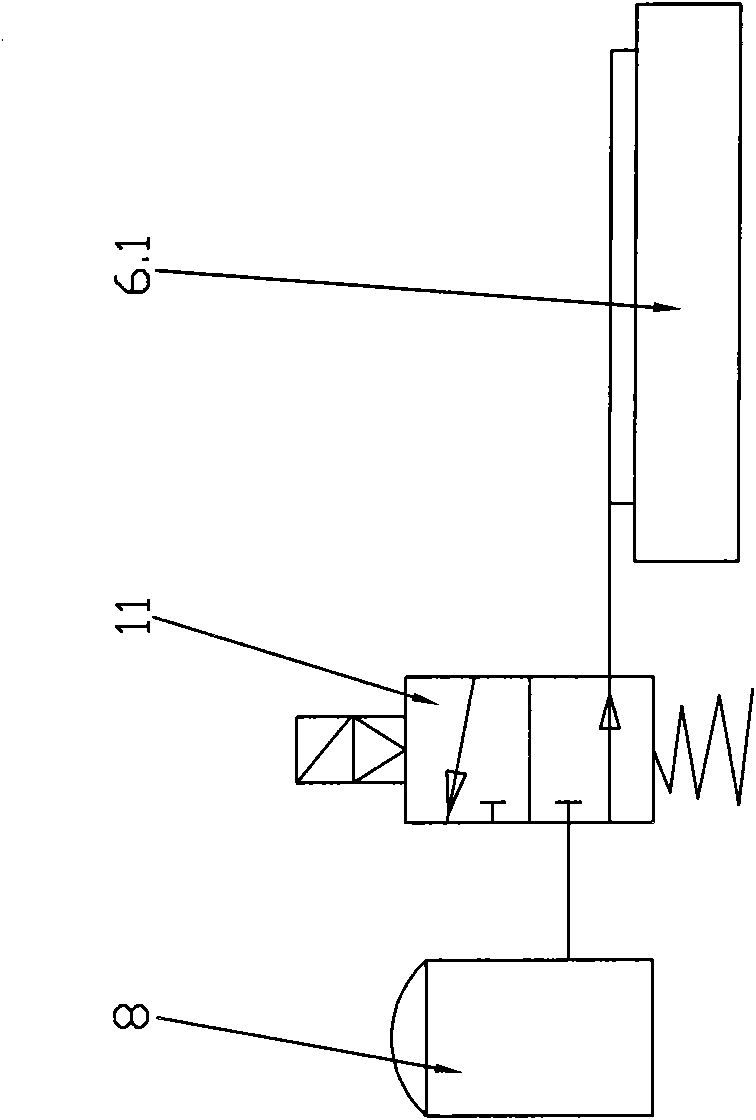

[0013] exist figure 1 It can be seen from the embodiment that in the prior art, the expansion mold 6 is connected to the vacuum system 8 and the cooling circulation system 7.1 and 7.2 respectively, the inner cavity of the mold 6 is kept in a vacuum state and a cooling state, and the tube feeder 9 will heat shrink the tubing 3.1 Send it into the heating oil tank 5 for soaking and heating. Under the action of the tube collector 9, the heated pipe 3.1 enters the expansion mold 6 from one end, expands, cools and shapes in the mold 6, and then is pulled out from the other end of the mold 6 , which is characterized by: in the process of expansion, processes such as expansion and management have been carried out simultaneously and continuously. Because the heat-shrinkable tubing produces pressure on the inner wall of the mold when it expands, causing frictional resistance between the two, the tube retractor 9 must have a certain pulling force when retracting the tube, so as to overco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com