High quality spinning dyeing mechanism

A high-quality, textile technology, applied in the field of textile printing and dyeing, can solve problems such as uneven dyeing and easy fading, and achieve uniform dyeing, improved fastness, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The embodiments are described below with reference to the accompanying drawings. The embodiments shown below do not limit the invention content described in the claims. required for the solution.

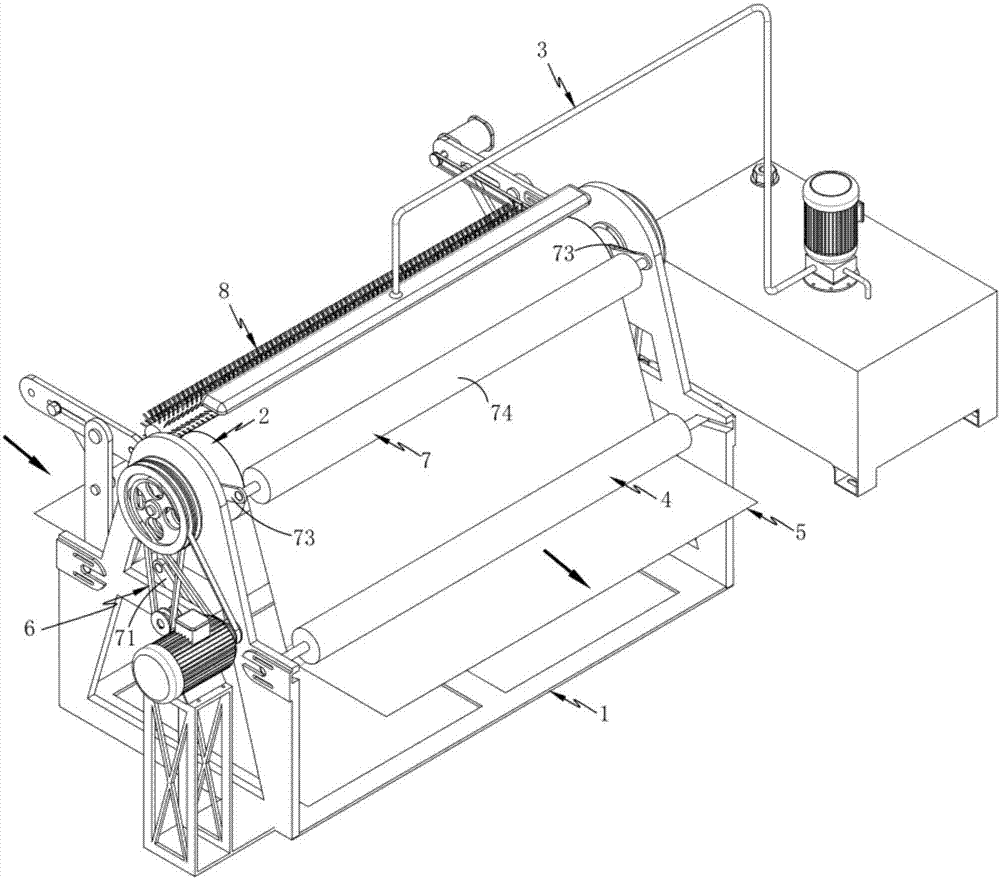

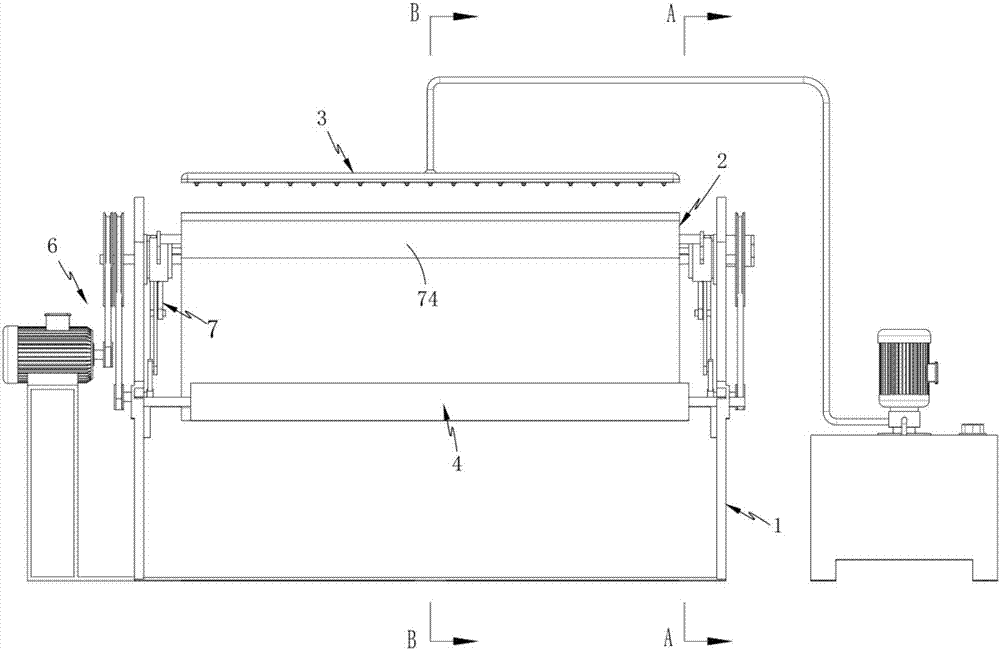

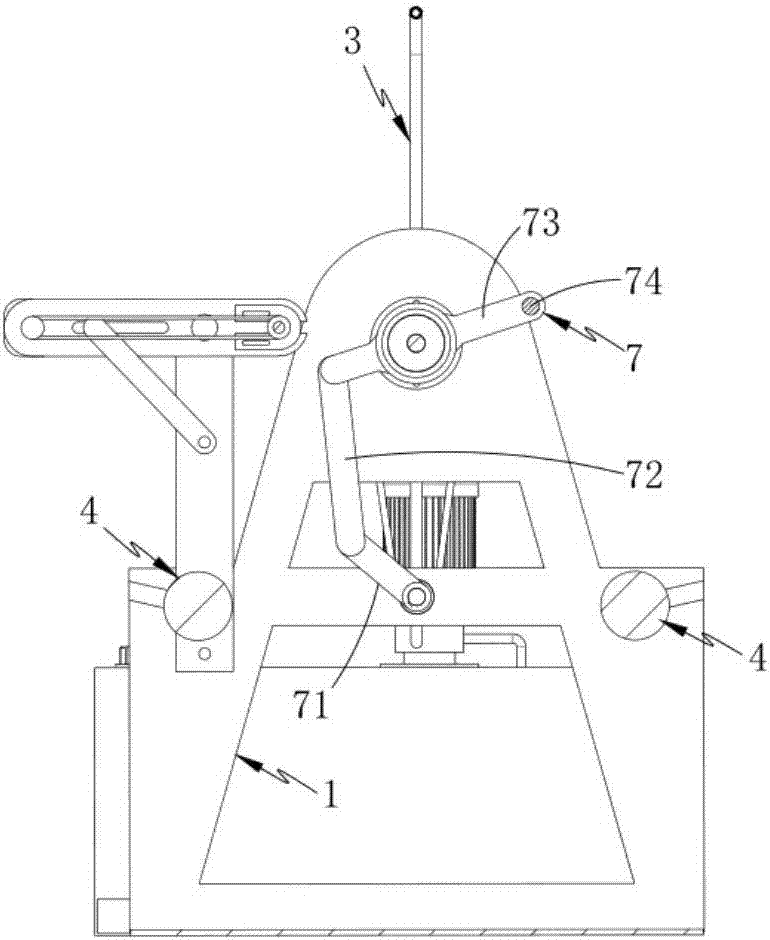

[0038] Such as figure 1 , 2 , 3, a high-quality textile dyeing mechanism, including a frame 1, a transmission roller 2 rotatably mounted on the frame 1, a dyeing assembly 3 fixedly arranged above the transmission roller 2, and a rotatably mounted frame 2 1 and the cloth guide roller 4 located on both sides of the transfer roller 2 and the driving assembly 6 that drives the transfer roller 2 to carry out the transfer of the gray cloth 5; The upper surface is in contact; it also includes a smear assembly 7 located on one side of the transmission roller 2 and moving along its outer circumferential surface. The greige cloth carries out the even application of dye liquor, and this application assembly 7 comprises:

[0039] A first connecting rod 71, one end of the first connec...

Embodiment 2

[0053] Components that are the same as or corresponding to those in the first embodiment use the reference numerals corresponding to those in the first embodiment. For the sake of simplicity, only the differences from the first embodiment are described below. The difference between this embodiment two and embodiment one is: as Figure 6 As shown, in this embodiment, the spraying dyeing assembly 3 is arranged directly above the conveying roller 2, and the axes of the two are located in the same vertical plane. During the spraying process, the dyeing liquid is sprayed on the gray cloth 5 , form pre-dyeing area 31, dyeing area 32 and touch-up area 33 successively along its conveying direction, wherein dyeing area 32 is positioned at the area that forms directly below the spraying mouth of spray-dye assembly 3, and pre-dyeing area 31 and touch-up area 33 with The dyeing areas 32 are arranged symmetrically.

[0054] Further, 1 and 4 also include a cleaning mechanism 8 located in t...

Embodiment 3

[0058] Components that are the same as or corresponding to those in Embodiment 2 use reference numerals corresponding to those in Embodiment 1. For the sake of simplicity, only the differences from Embodiment 2 will be described below. The difference between the third embodiment and the second embodiment is: as Figure 7 As shown, the spray dyeing assembly 3 is arranged above the transmission roller 2 and is biased toward the applicator roller 74. During the spray dyeing process, the dye solution is sprayed on the gray cloth 5, and the dyeing area 32' and touch-up are followed along the conveying direction. Area 33', wherein the dyeing area 32' is located in the area formed directly below the dyeing port of the spraying assembly 3, the spraying liquid volume of the spraying assembly 3 is constant, and the area of the embryo cloth 5 sprayed and dyed is reduced, thereby improving the quality of the embryonic cloth. Cloth 5 dyeing efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com