Rolling-type auxiliary device for spray dyeing

A rolling and equipment technology, applied in the field of textile printing and dyeing, can solve the problems of easy color fading and uneven dyeing, and achieve the effects of uniform dyeing, improving flatness and improving dyeing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The embodiments are described below with reference to the accompanying drawings. The embodiments shown below do not limit the invention content described in the claims. required for the solution.

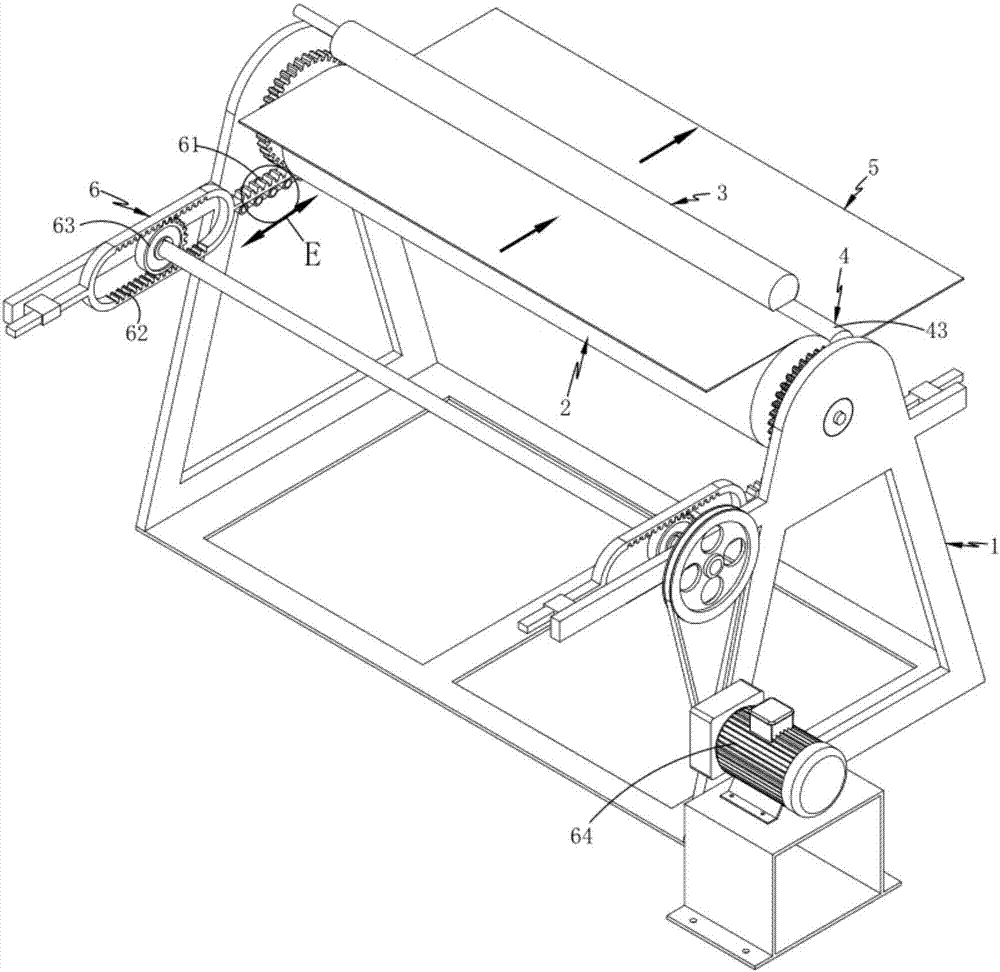

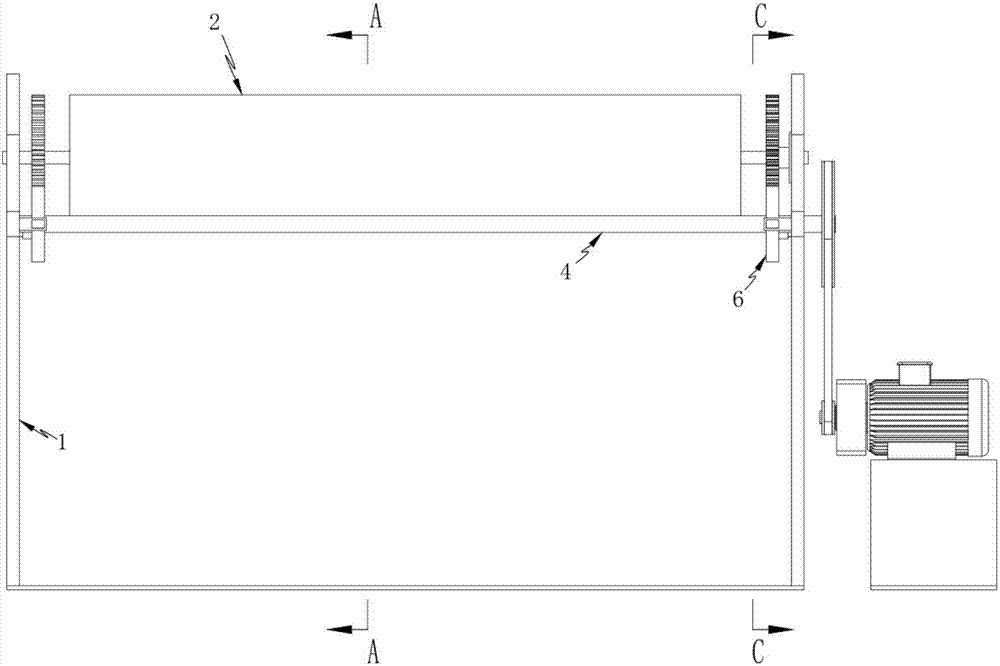

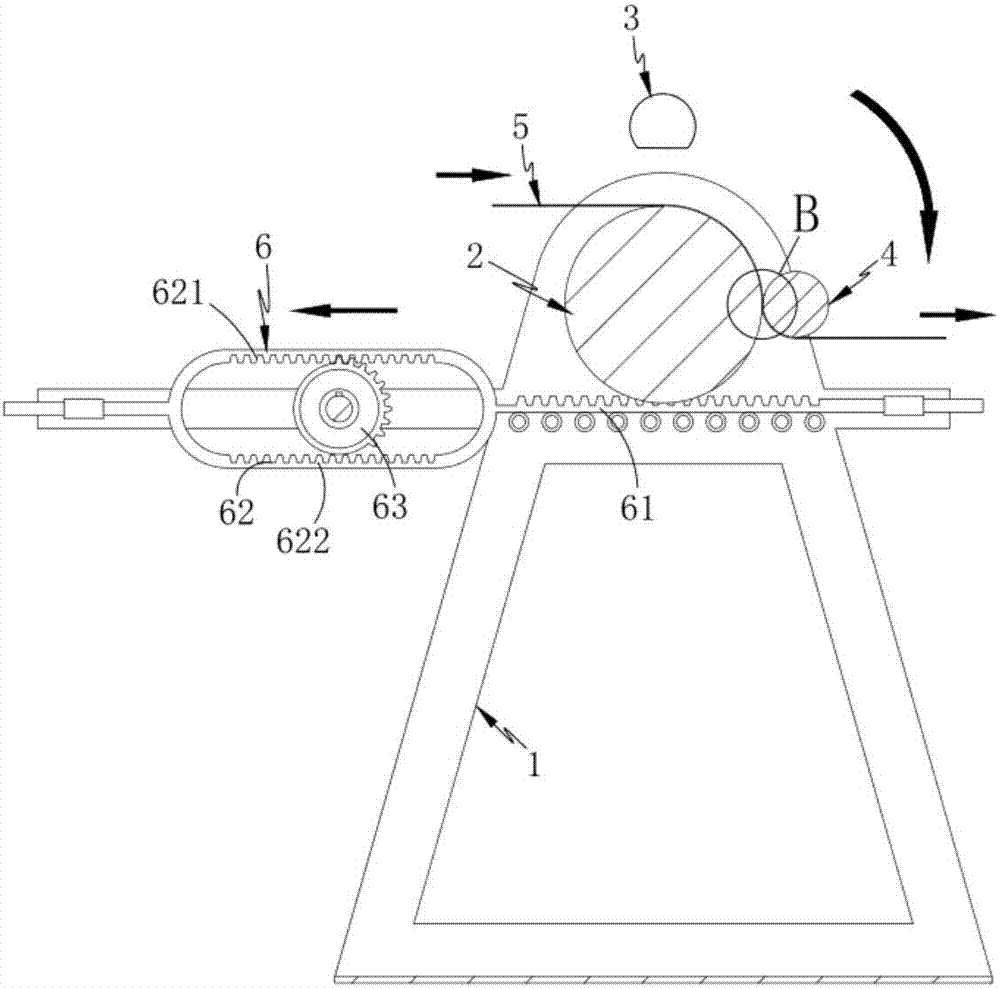

[0042] Such as figure 1 , 2 , 3, a rolling auxiliary dyeing equipment, including a frame 1, a coloring roller 2 that is rotatably mounted on the frame 1, and a dyeing nozzle 3 that is arranged on the coloring roller 2, and also includes:

[0043] Smudge component 4, such as image 3 , 4 As shown, the smearing assembly 4 is located on one side of the coloring roller 2, and the transfer channel 51 of the gray cloth 5 is formed between the two, and the height of the transfer channel 51 is smaller than the thickness of the gray cloth 5 in this embodiment;

[0044] Drive components 6, such as figure 2 , 3 As shown, the driving assembly 6 is symmetrically arranged on the frame 1 and located on both sides of the coloring roller 2, and the driving assembly 6 drives the smearin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com