Device for testing performance of aerostat capsule pull tab and test method thereof

A testing device and aerostat technology, applied in the testing of machine/structural components, measuring devices, testing of mechanical components, etc., can solve the problems of inconvenient movement, use, complicated operation, hidden danger of internal gas, etc., and achieve simple installation. , Easy to operate, precise control of the effect of pulling force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

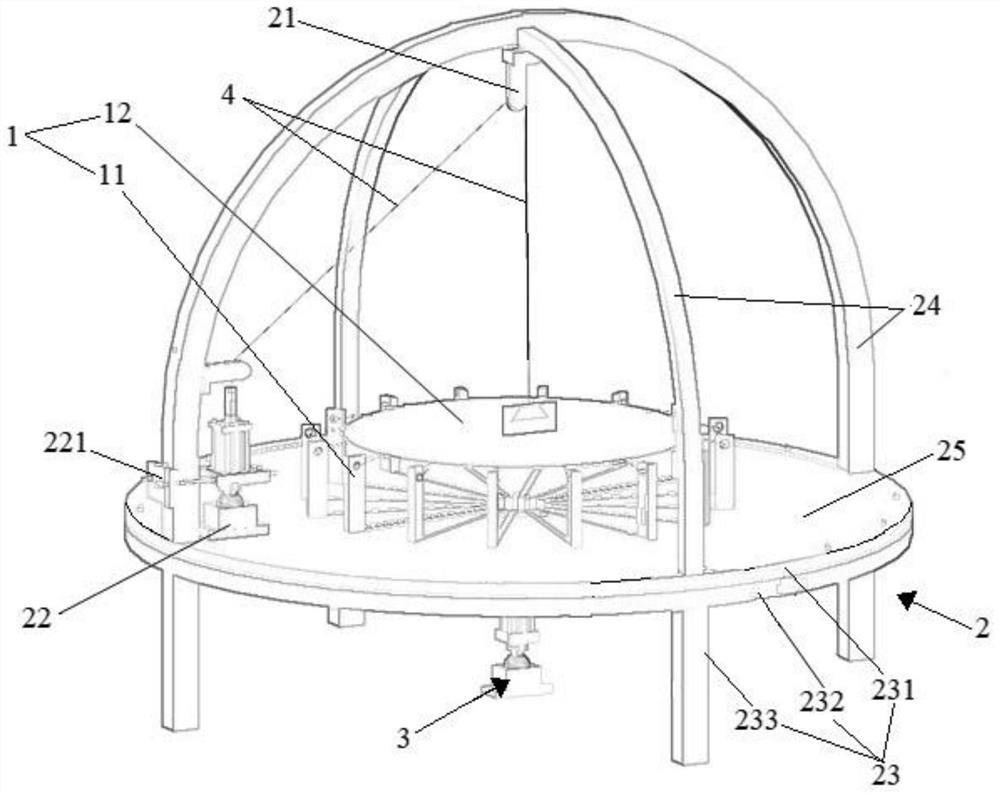

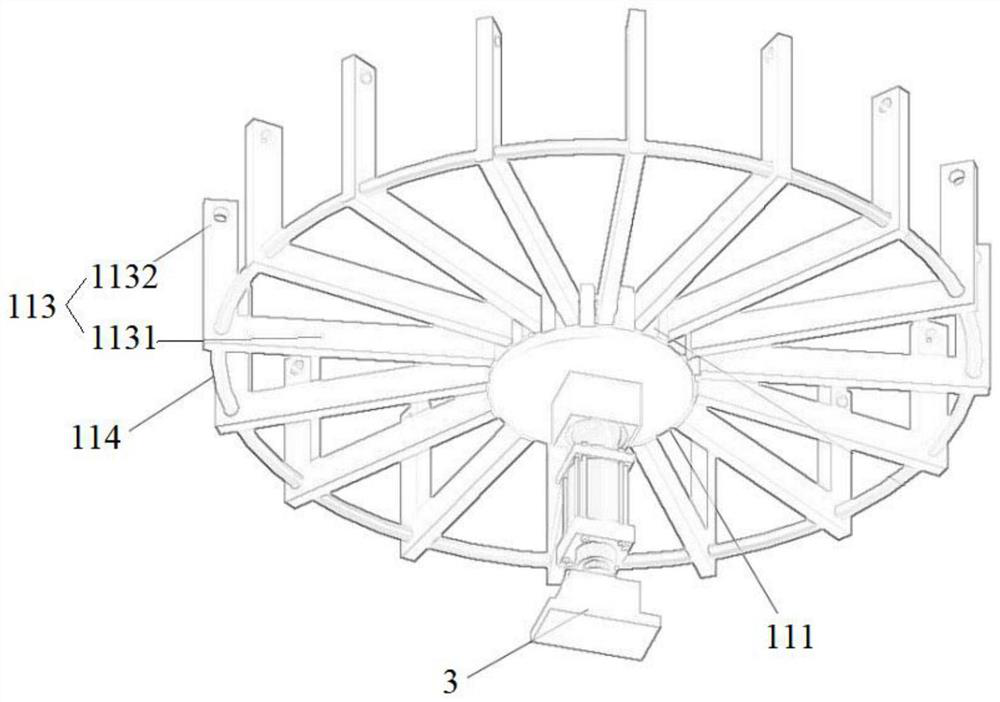

[0099] Such as figure 1 As shown, a test device for the tab performance of the aerostat capsule includes an inner body 1 , an outer frame 2 and a main body load-bearing mechanism 3 . The inner body 1 includes an umbrella frame 11 and a base cloth carrier 12 . The umbrella frame 11 is arranged inside the outer frame 2 . The base fabric carrier 12 is arranged inside the umbrella frame 11 . The main load-bearing mechanism 3 is arranged below the base fabric carrier 12 . The base fabric carrier 12 is provided with a pull tab 4 . The outer frame 2 is provided with a pulley 21 and a force-measuring loading mechanism 22 . The pull tab 4 is connected with the force-measuring loading mechanism 22 through the fiber rope 41 and the pulley 21 .

Embodiment 2

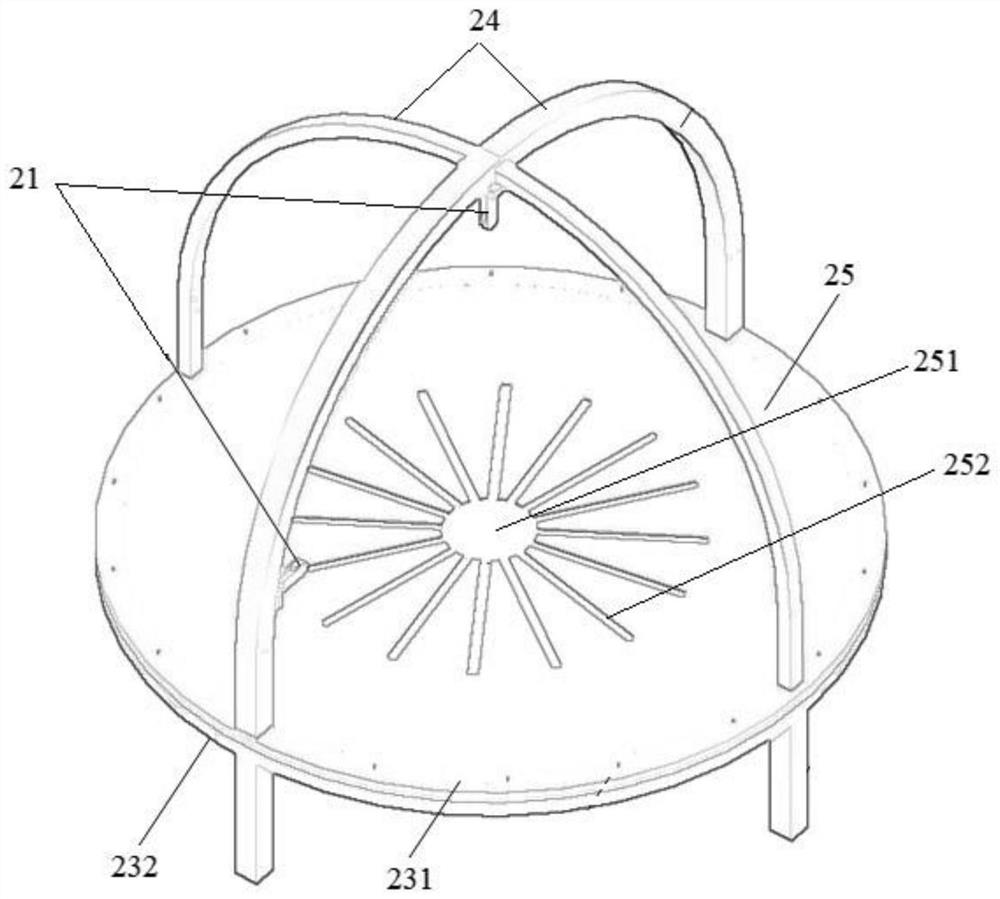

[0101] Embodiment 1 is repeated, except that the outer frame 2 further includes a ring frame support 23 , an arc track beam 24 and an operating table 25 . The curved track beam 24 is designed as an upward convex arc, and both ends of the curved track beam 24 are movably connected to the ring frame support 23 . The operating table 25 is fixedly arranged in the ring of the ring frame support 23 . The pulley 21 is arranged in the arc track beam 24 and can move on the arc track beam 24 .

Embodiment 3

[0103] Embodiment 2 is repeated, except that the outer frame 2 includes a plurality of arc-shaped track beams 24 . The plurality of arc track beams 24 intersect at the beam tops, and the intersection points at the beam tops of the plurality of arc track beams 24 are located on the same vertical line as the ring center of the ring frame support 23 . The pulley 21 can move arbitrarily on several arc track beams 24 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com