Sound field separating method based on single-surface measurement and local acoustical holography method

An acoustic holographic, local technology, applied in the field of noise, which can solve the problems of long calculation time, large measurement volume, and limited measurement aperture size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

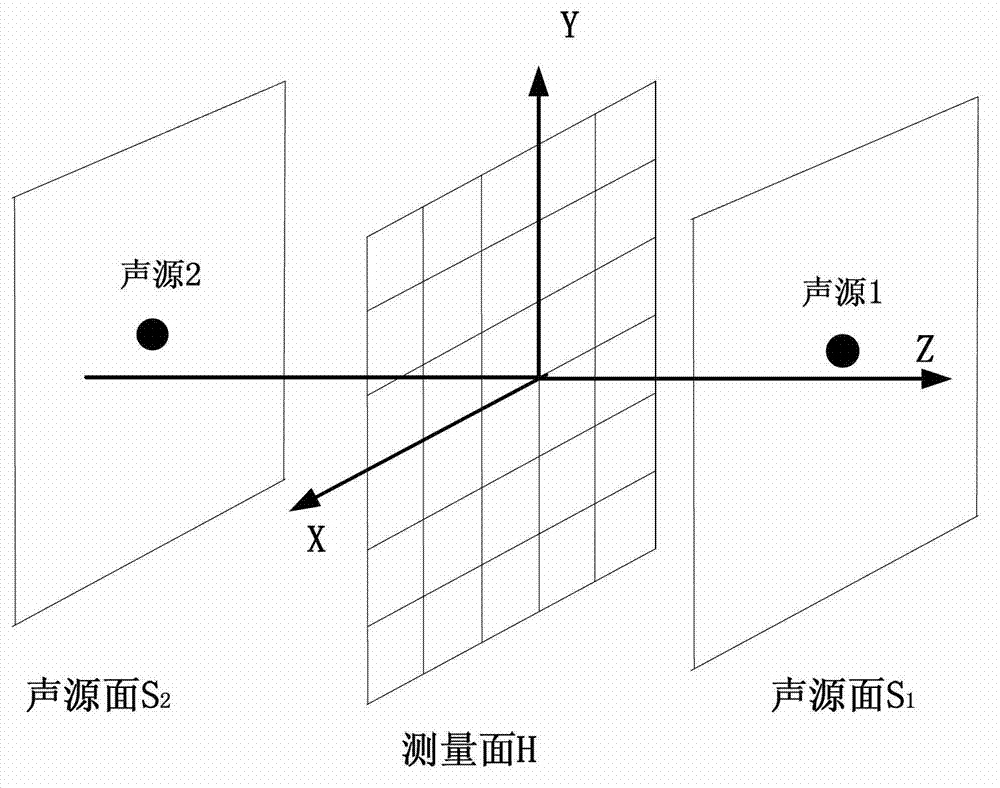

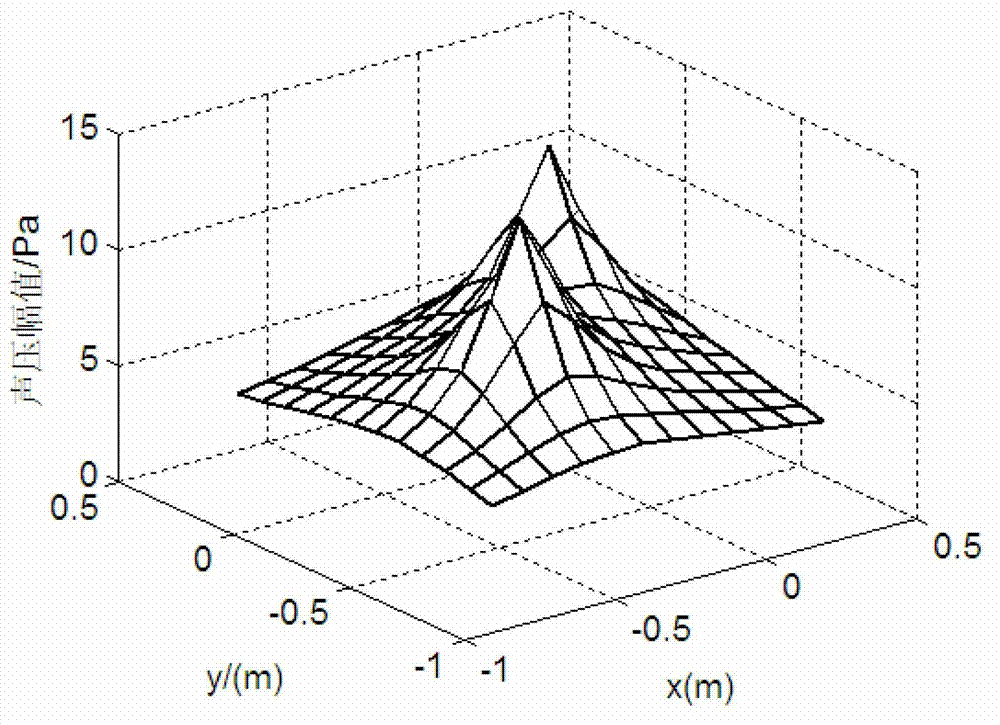

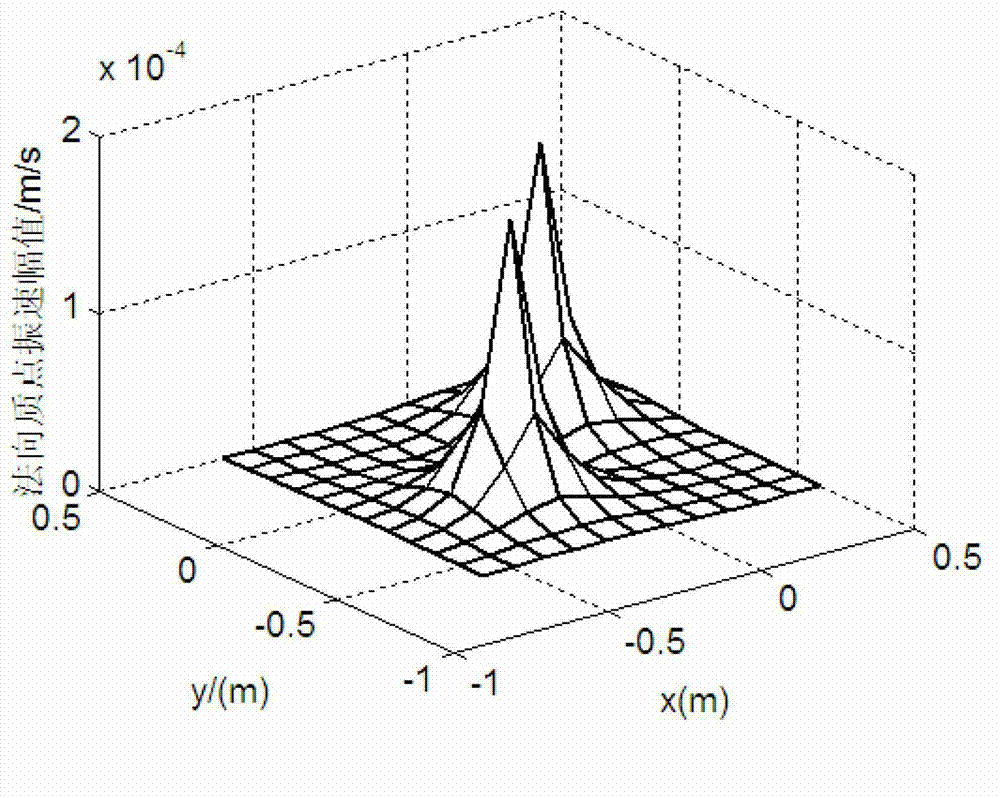

[0036] The method of the present invention is to measure the sound pressure and the normal particle vibration velocity on the measurement surface M, and adopt the local near-field acoustic holography method to realize the separation of the sound pressure and the normal particle vibration velocity radiated by the sound sources on both sides on the measurement surface, and simultaneously realize Reconstruction of sound pressure and normal particle velocity at the source plane.

[0037] see figure 1 , in this embodiment, sound sources are distributed on both sides of the measurement surface, wherein sound source 1 is the main sound source, and sound source 2 is a noise source or a reflection or scattering source. In the measured sound field composed of sound source 1 and sound source 2 Among them, there is a measurement surface M between sound source 1 and sound source 2, and the distance between sound source 1 and the measurement surface is d; measurement points are distributed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com