Method for sound field separation by pressure velocity method

A separation method and field separation technology, applied in the direction of measuring propagation velocity, measuring ultrasonic/sonic wave/infrasonic wave, measuring device, etc., can solve the problems of large separation error, measurement surface shape limitation, error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

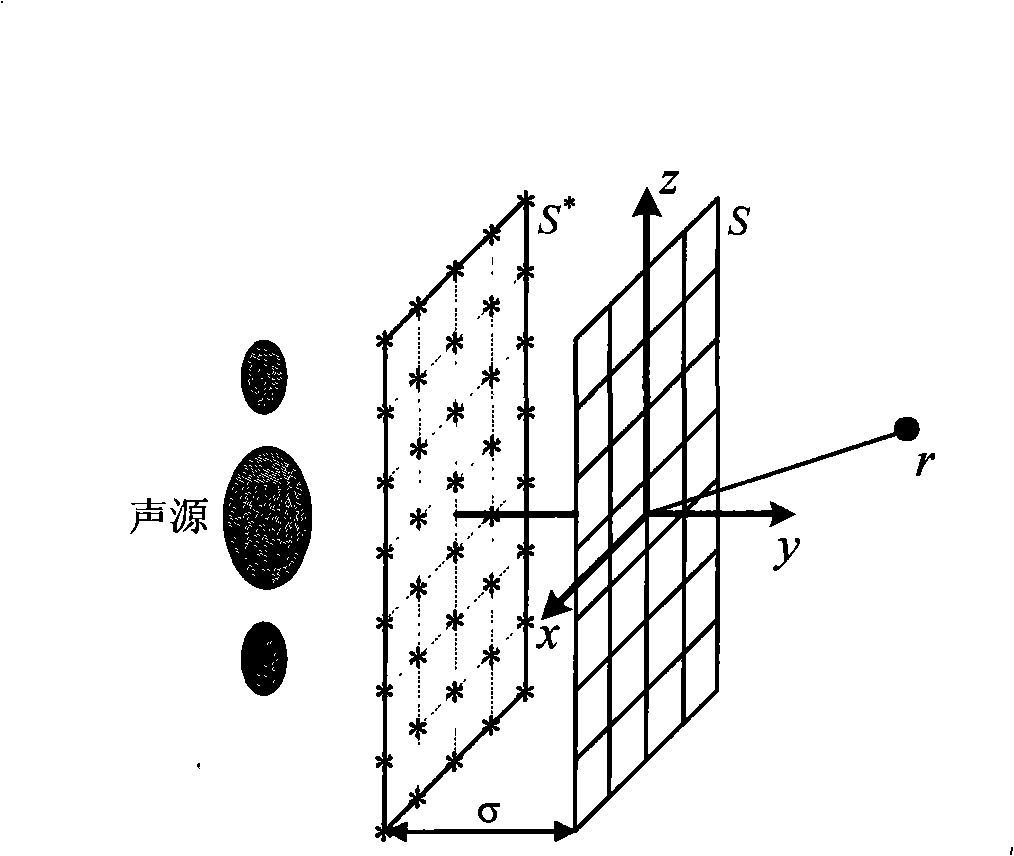

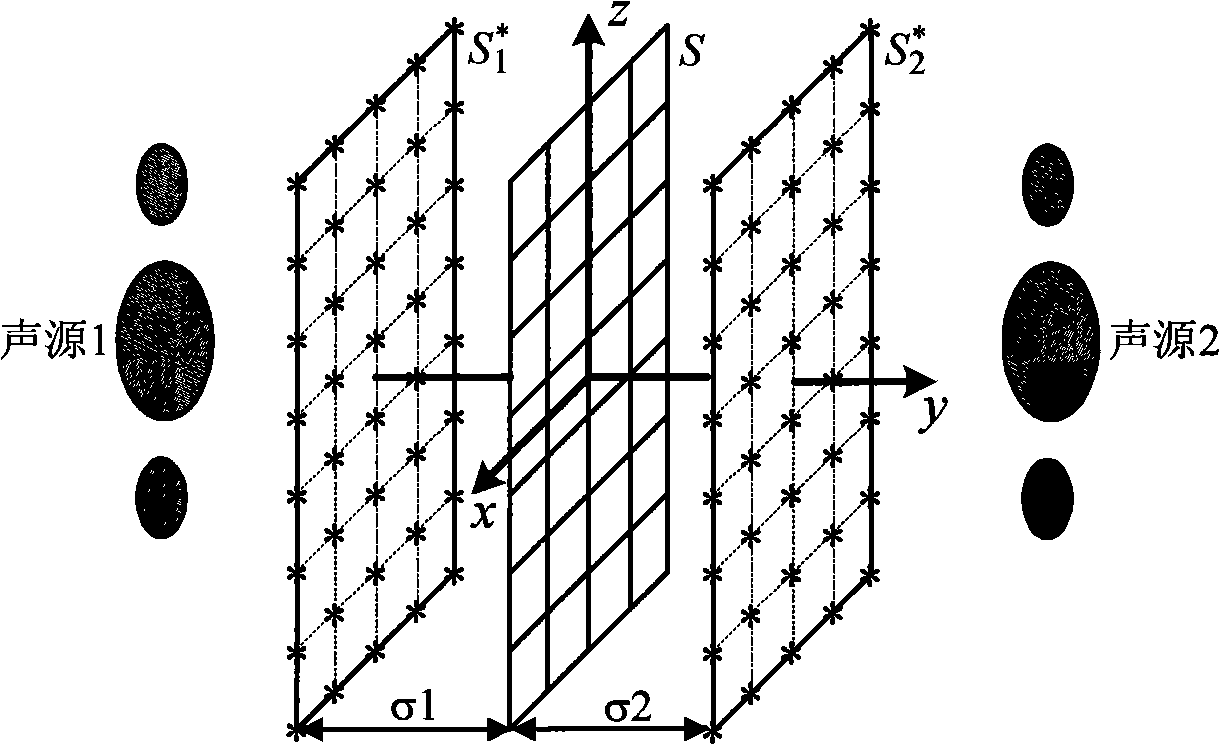

[0099] see figure 2 , in this embodiment, sound sources are distributed on both sides of the measurement surface, wherein sound source 1 is the main sound source, and sound source 2 is a noise source or a reflection or scattering source. In the measured sound field composed of sound source 1 and sound source 2 Among them, there is a measurement surface S located between the sound source 1 and the sound source 2; measurement grid points are respectively distributed on the measurement surface, and the distance between adjacent grid points is less than half a wavelength.

[0100] The specific implementation steps are:

[0101] a. Use single or multiple microphones and particle velocity sensors to scan the measurement surface separately, use a sound intensity probe array to take a snapshot of the measurement surface, or use a single or multiple sound intensity probe arrays to scan the measurement surface to obtain the measurement surface S sound pressure and particle velocity in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com