Patents

Literature

161results about How to "Ensure insulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

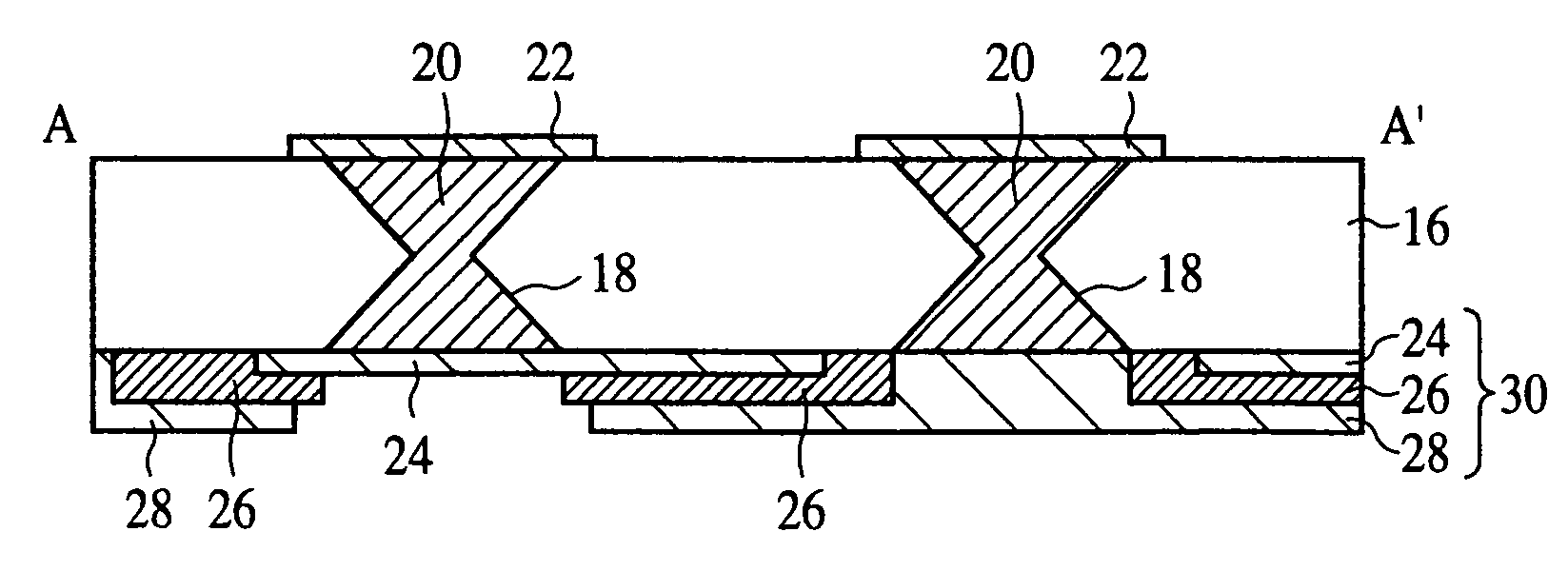

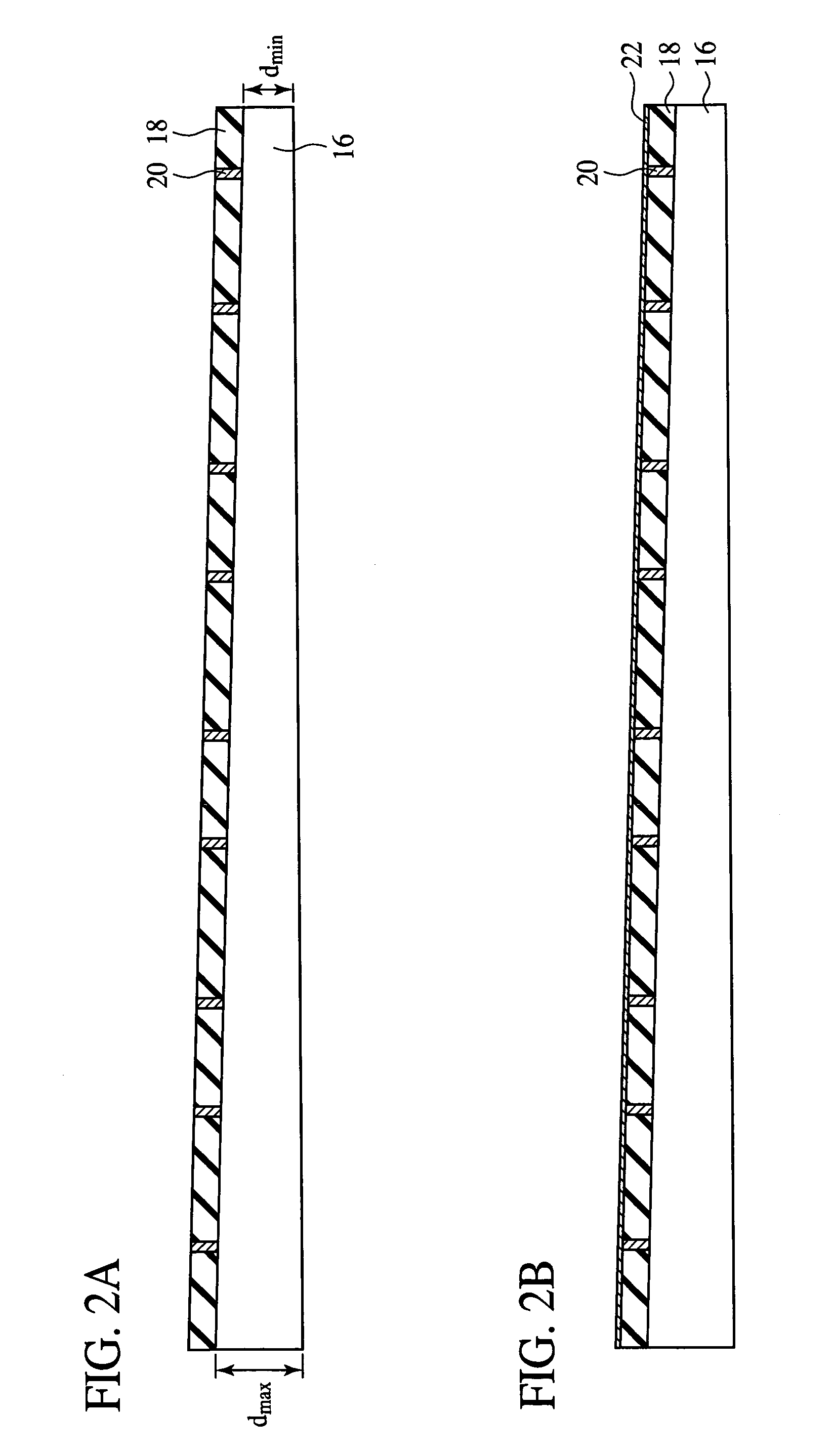

Circuit substrate and method for fabricating the same

InactiveUS7211899B2Improve surface roughnessRelieve stressSemiconductor/solid-state device detailsPrinted circuit aspectsSurface roughnessOptoelectronics

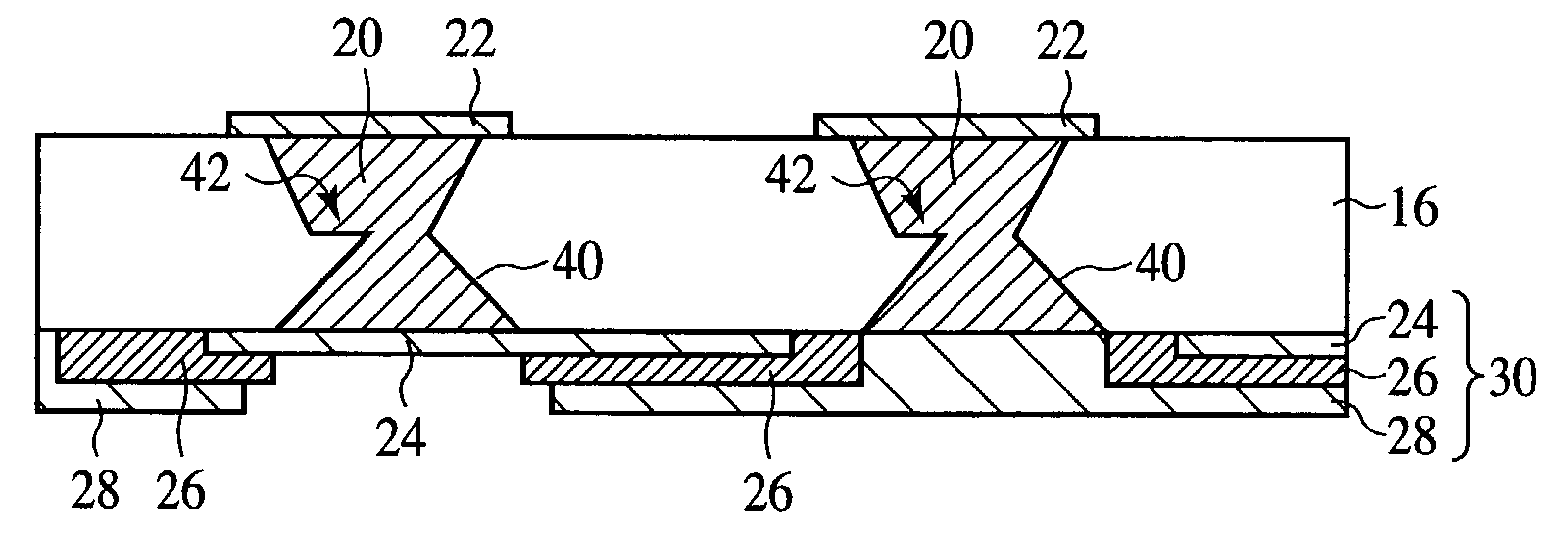

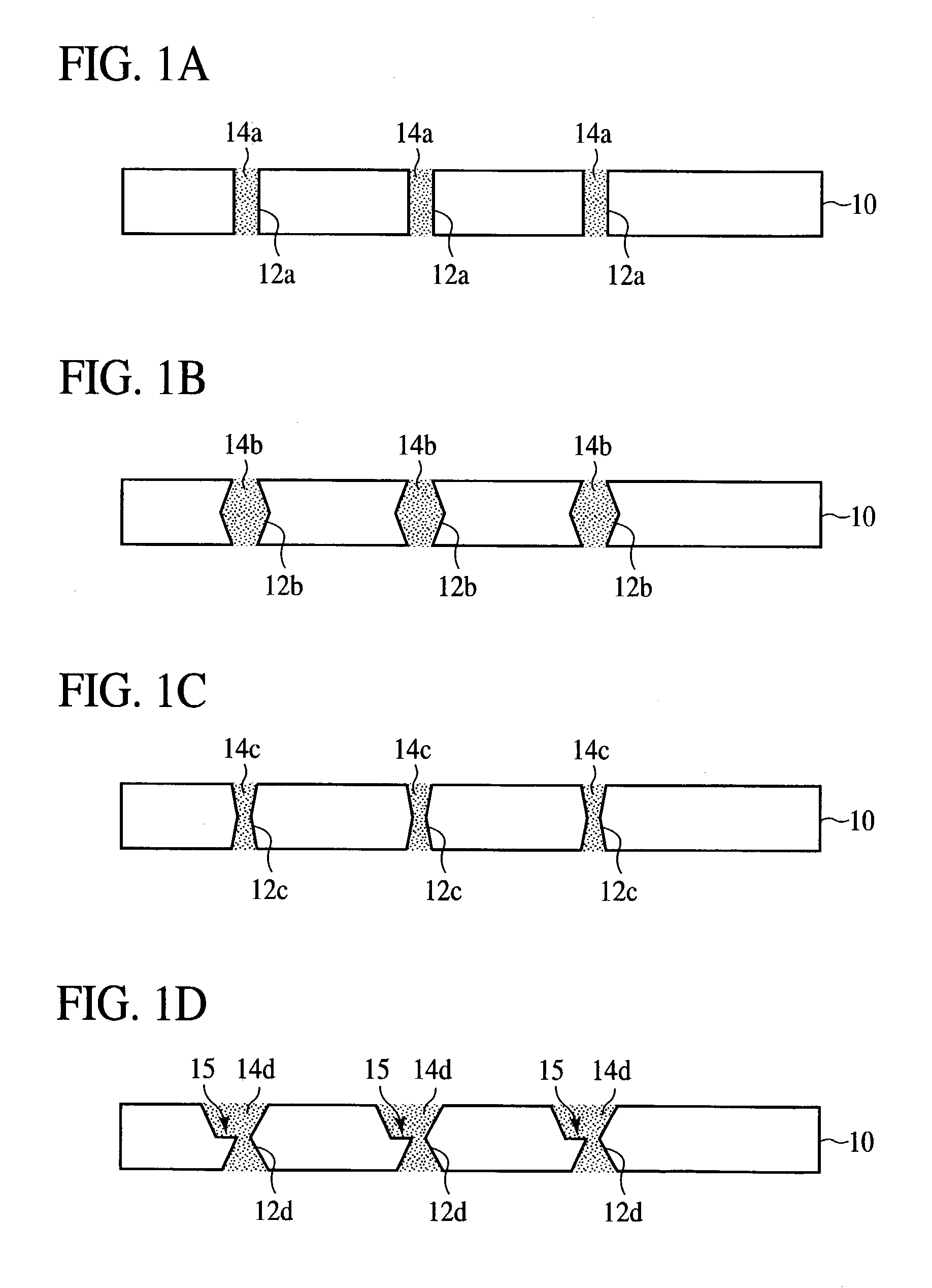

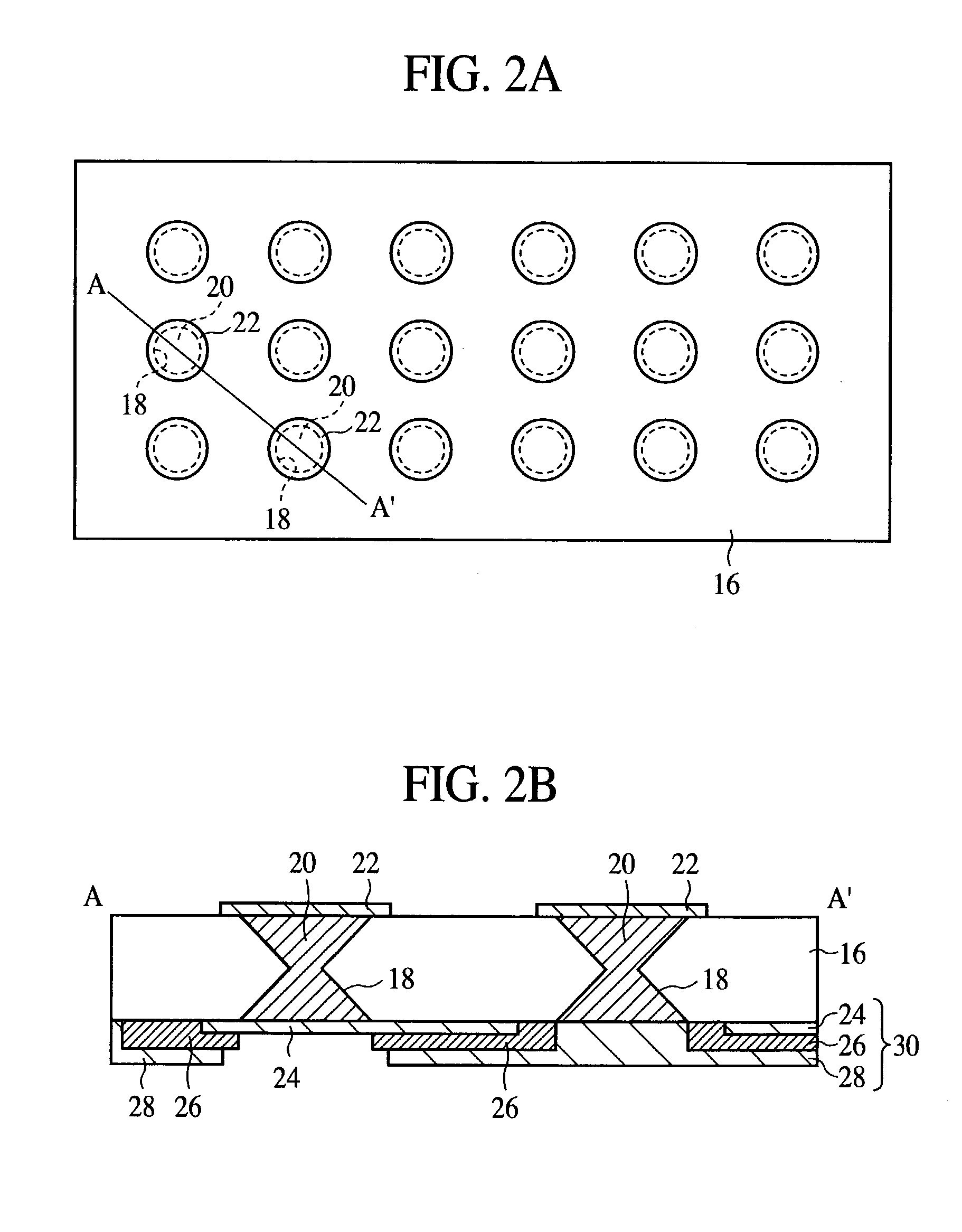

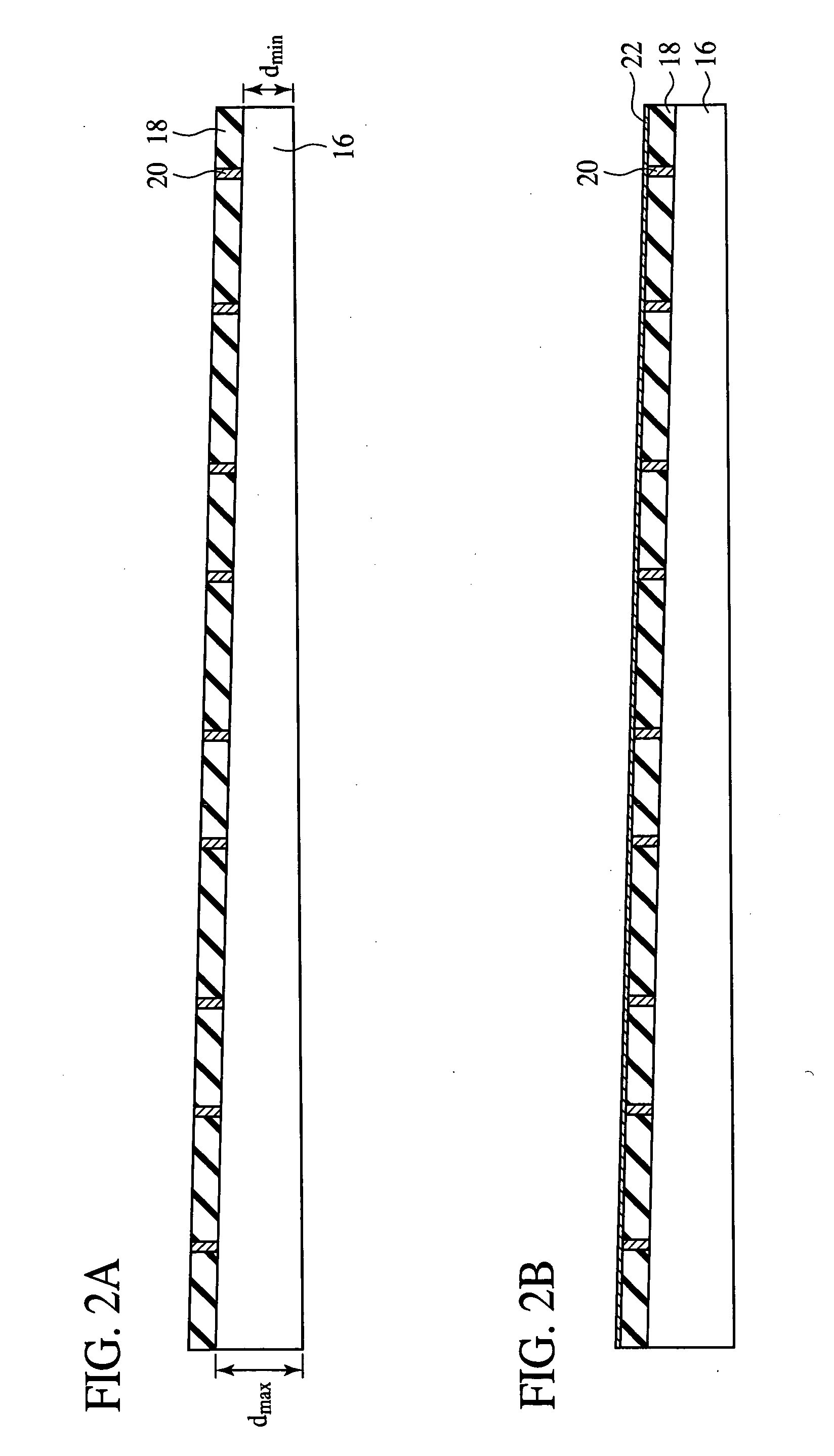

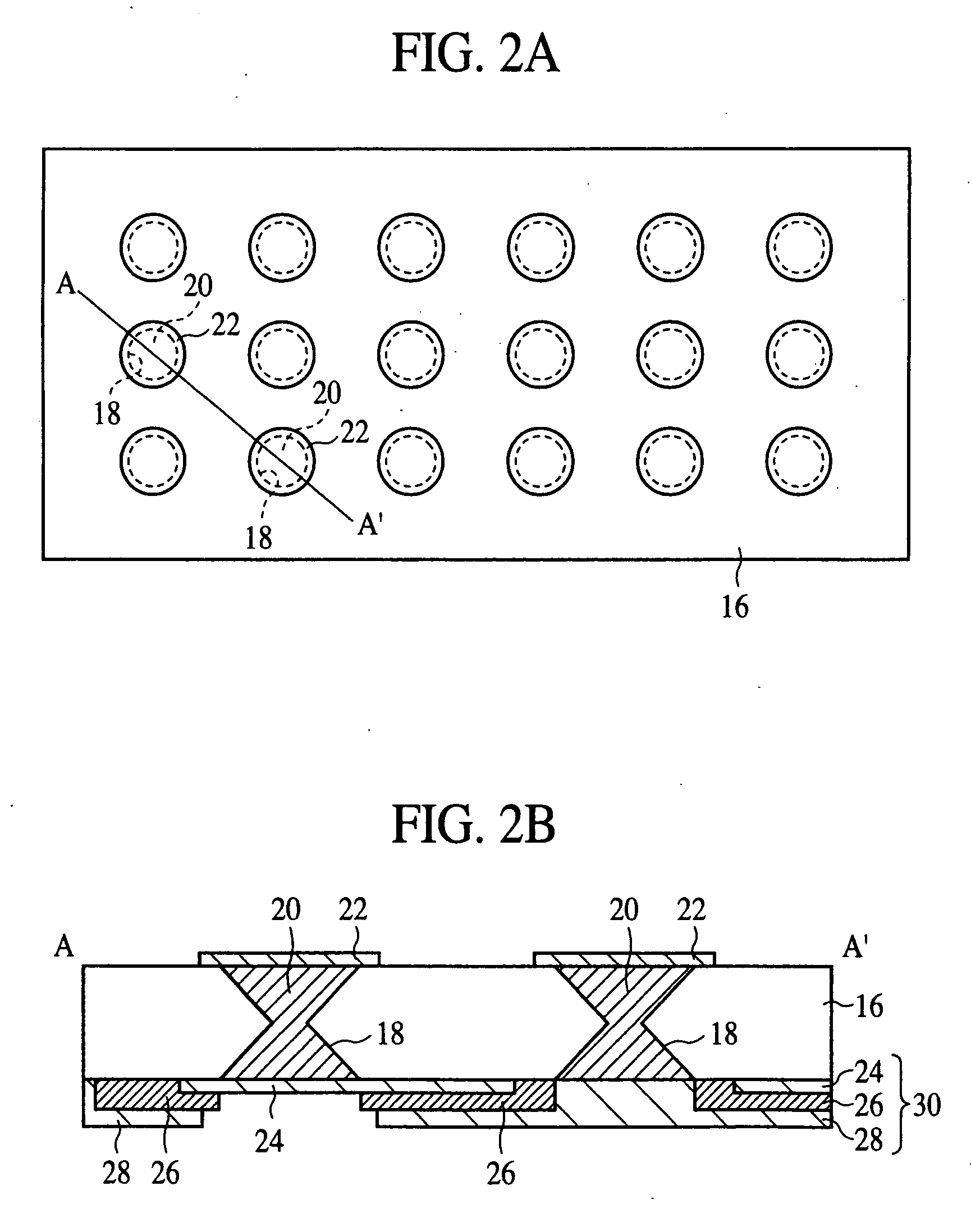

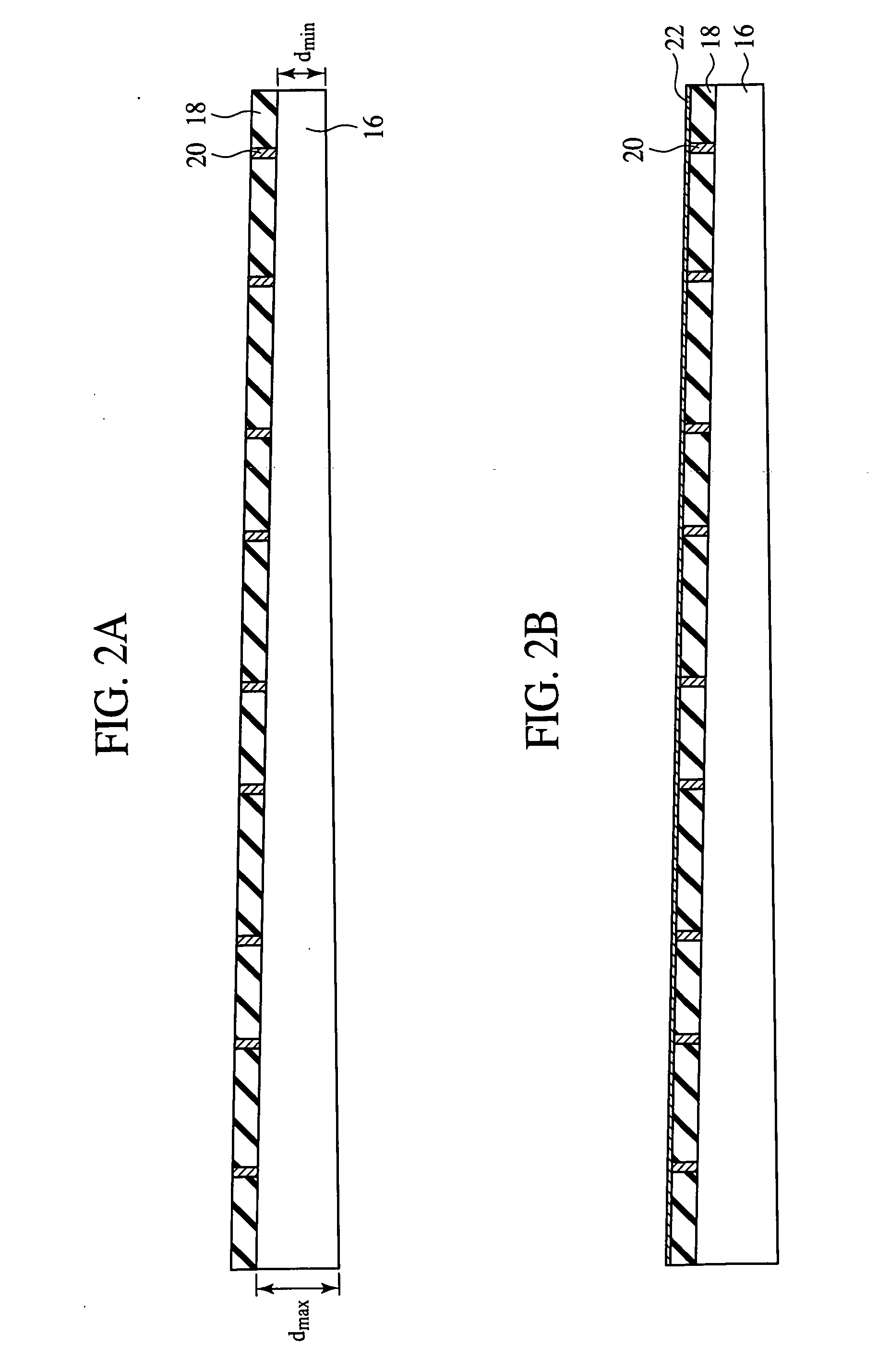

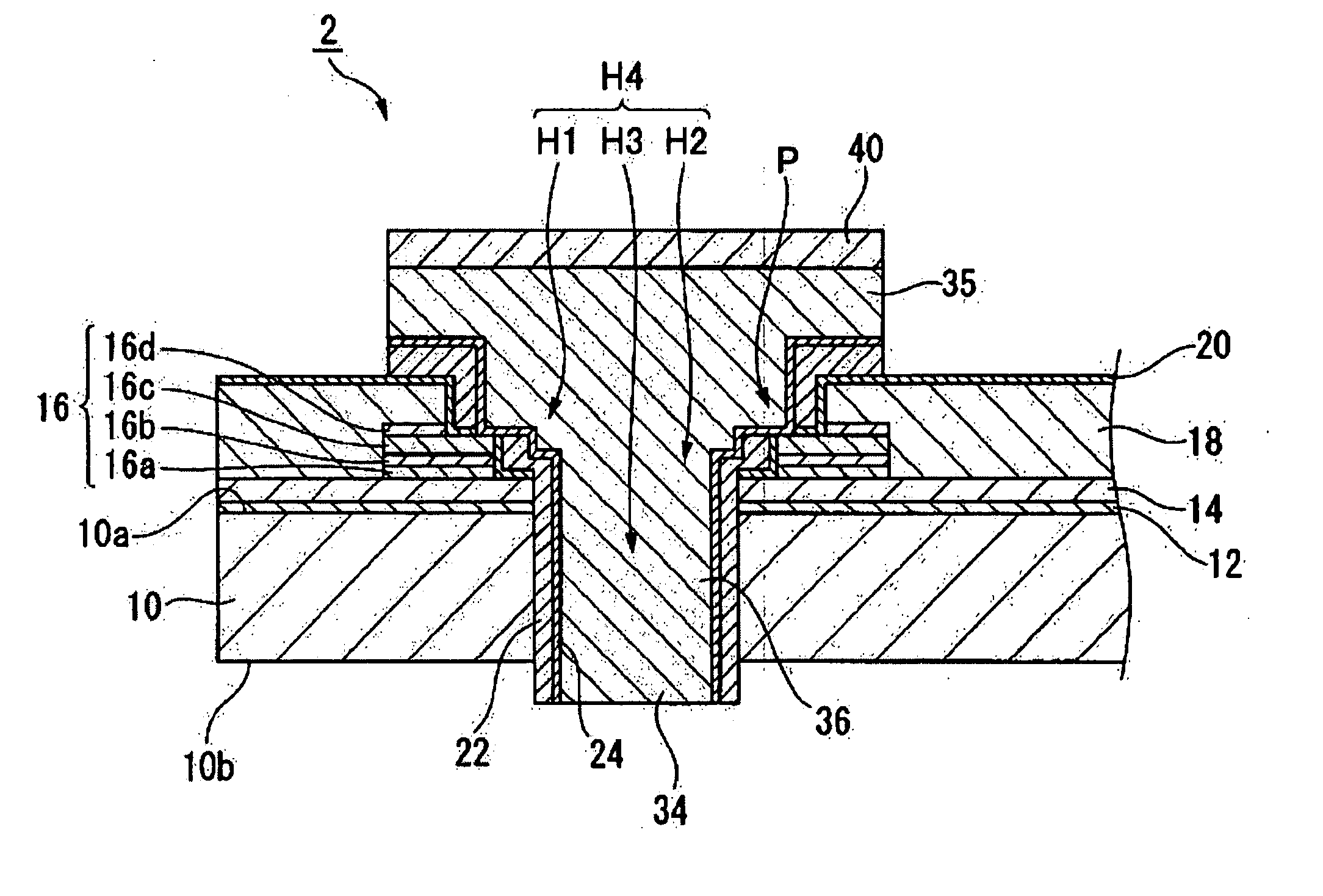

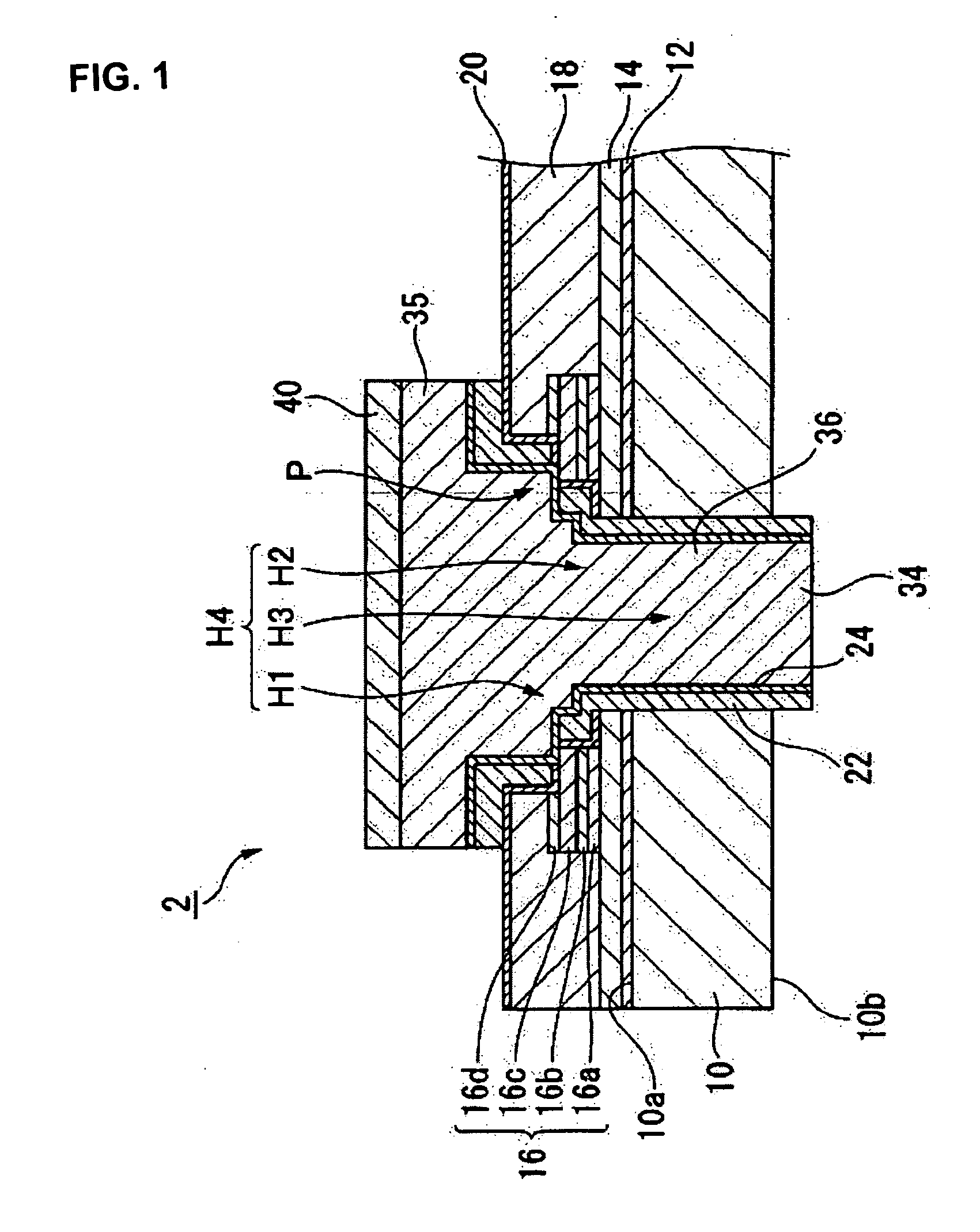

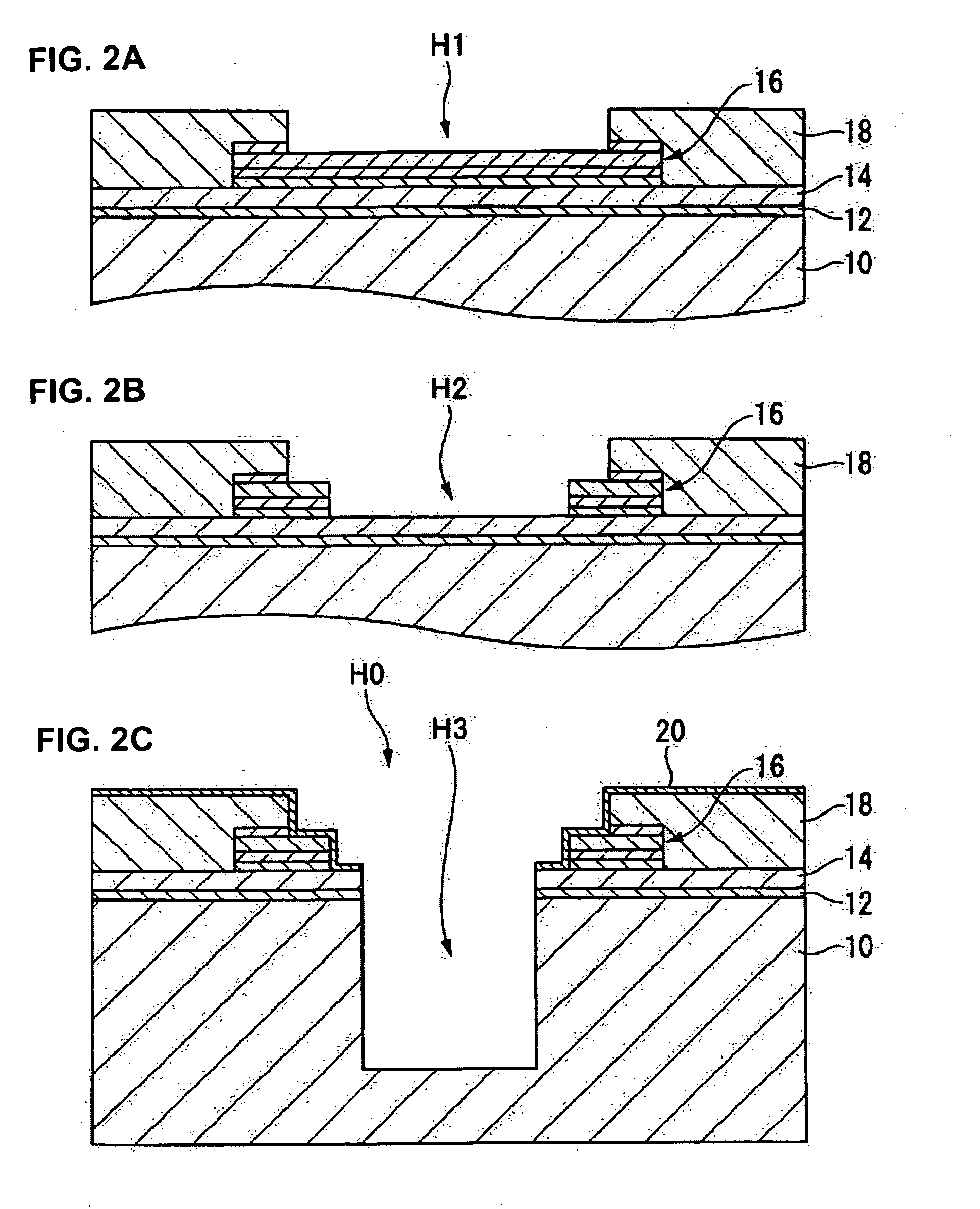

A circuit substrate comprises a glass substrate 16, through-holes 18 formed through the glass substrate 16 and via electrodes 20 buried in the through-holes 18. An opening width of the through-holes 18 is minimum inside the glass substrate and is increased toward both surfaces of the glass substrate 16. Accordingly, the detachment of the via electrodes 20 can be prevented without increasing the surface roughness of the inside walls of the through holes, and stresses generated in the core substrate can be mitigated.

Owner:FUJITSU LTD

Method of making active matrix substrate with pixel electrodes of photosensitive conductive material

InactiveUS7075614B2Reduce processImprove Exposure AccuracySolid-state devicesMaterial analysis by optical meansActive matrixConductive materials

There is provided an active matrix substrate which enables to shorten a fabrication process of a pixel electrode, improve exposure precision by self alignment, and prevent leakage failures between pixel electrodes. On top of the interlayer insulating film, there are formed pixel electrodes, which are connected to the TFTs through contact holes piercing through the interlayer insulating film. The pixel electrodes are formed by applying on the interlayer insulating film a photosensitive transparent resin such as negative acrylic polymerized resin containing ITO, ATO or ZnO as transparent conductive particles, performing exposure from the back side of the substrate, and conducting development.

Owner:SHARP KK

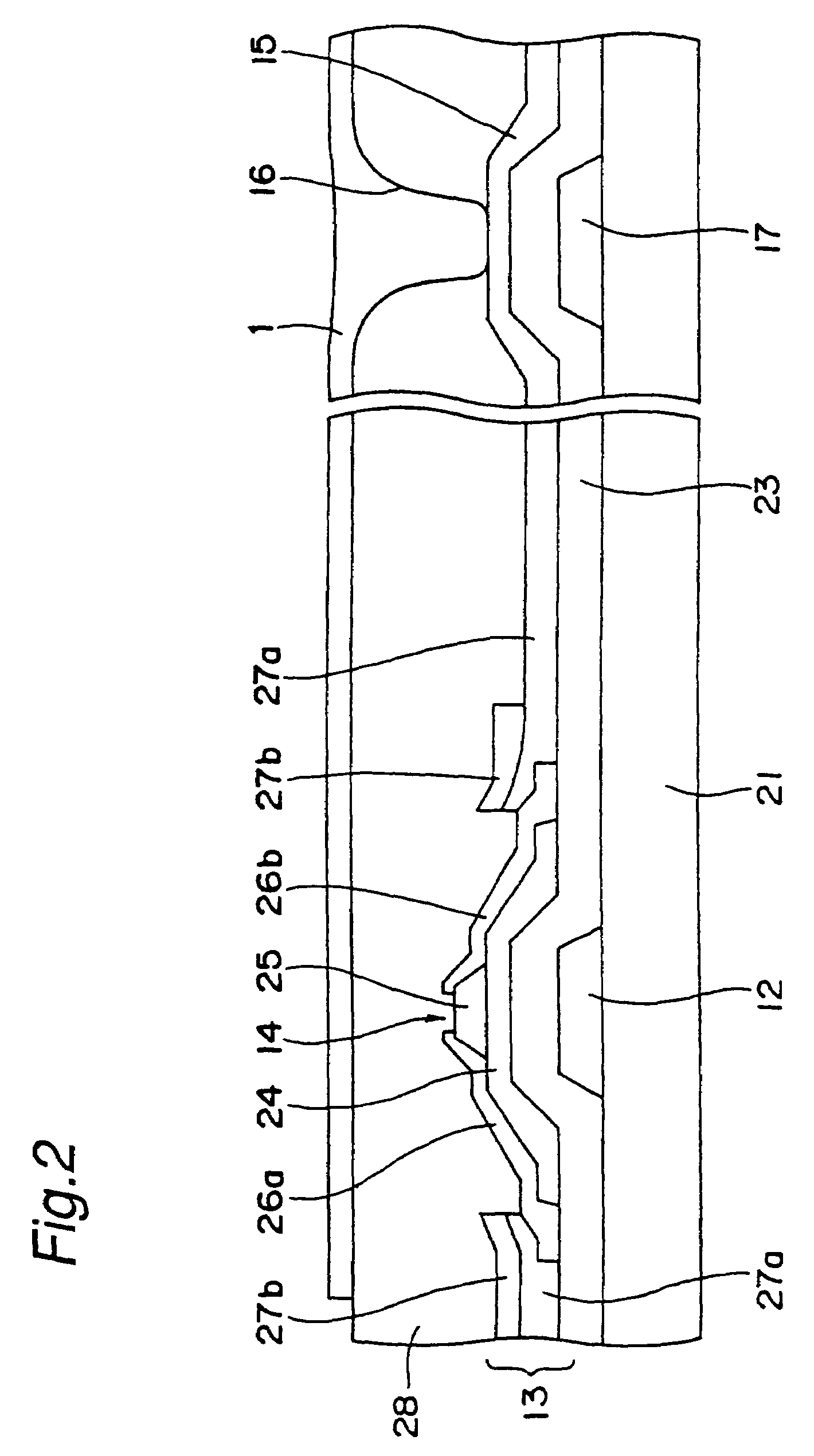

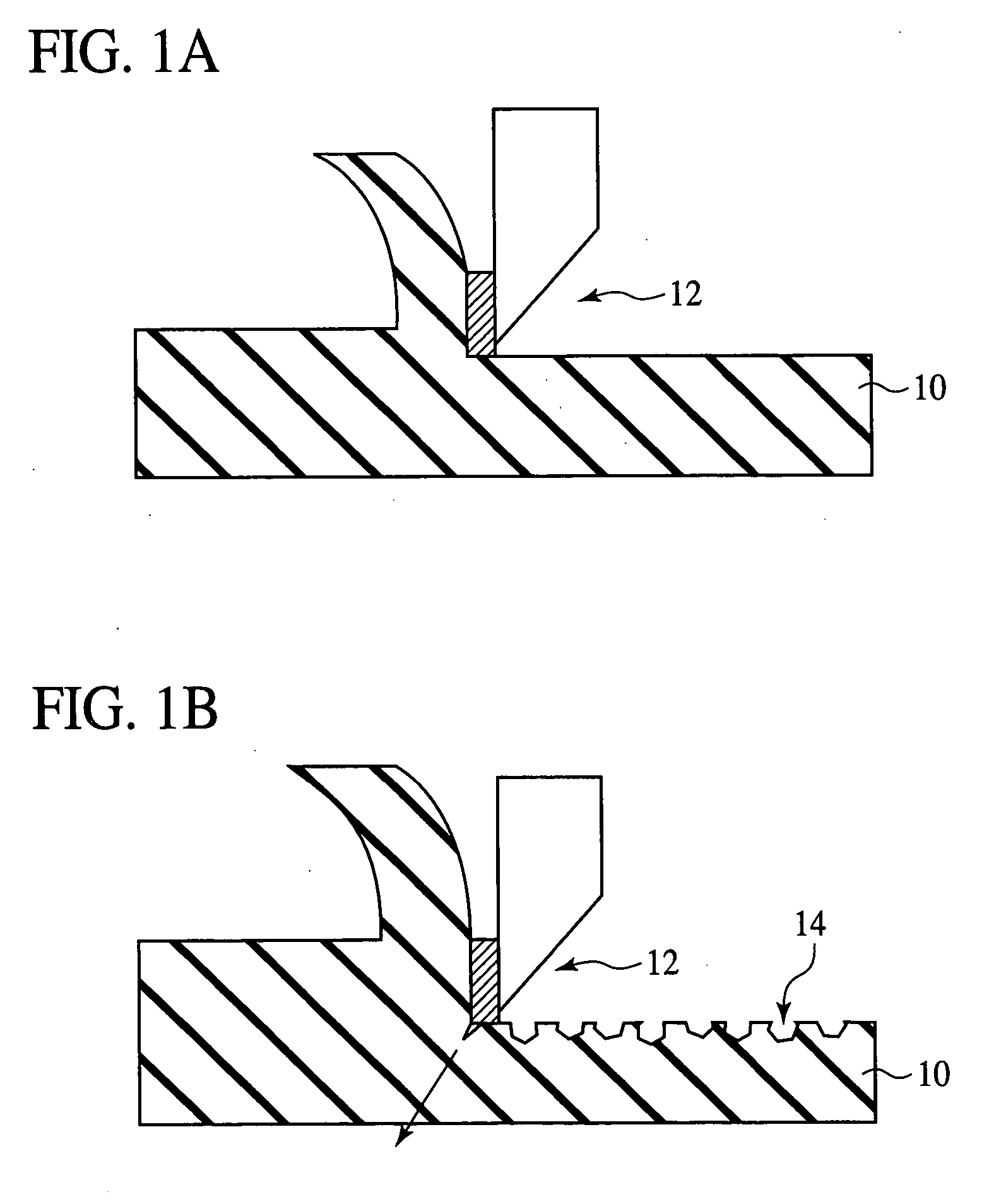

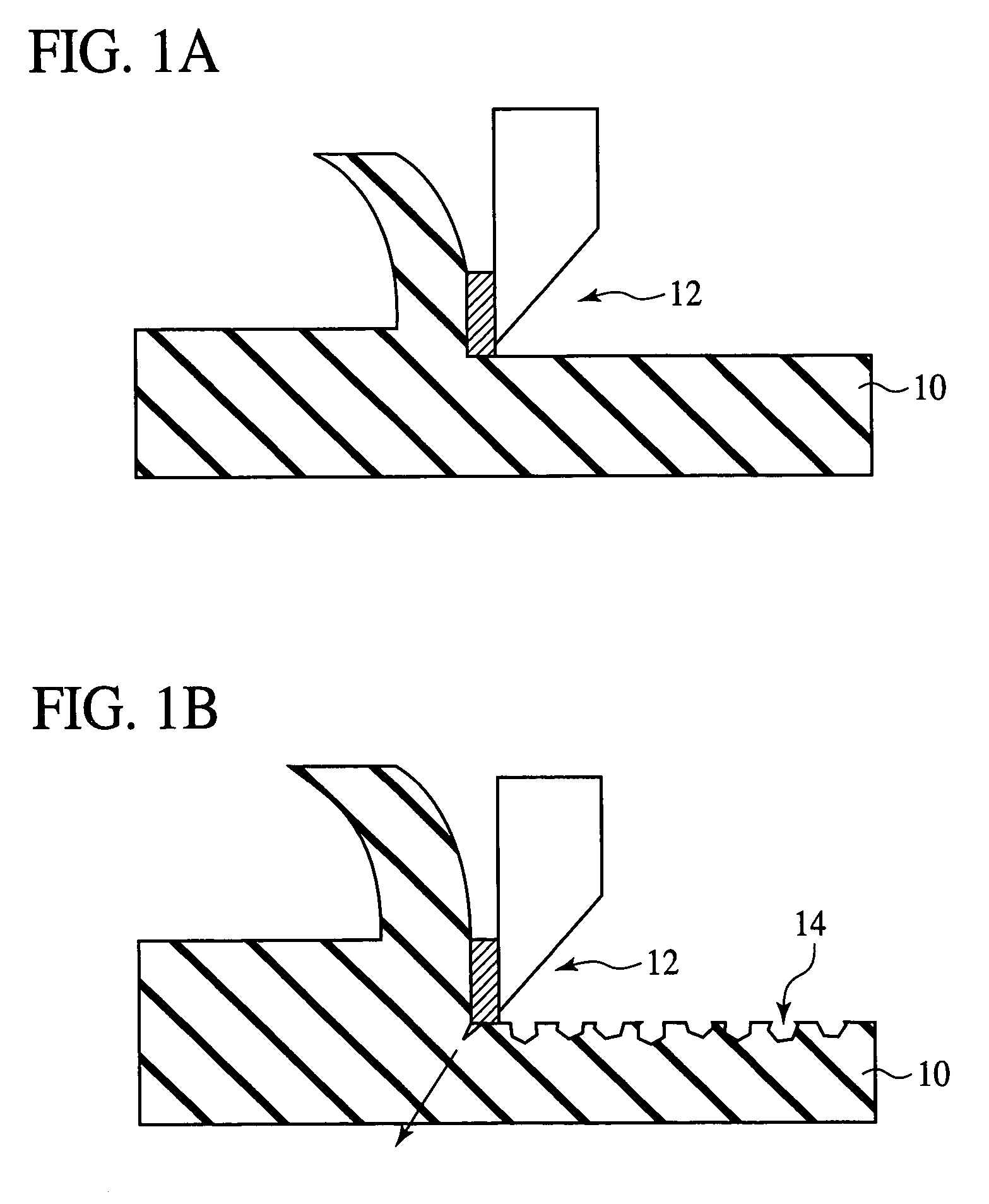

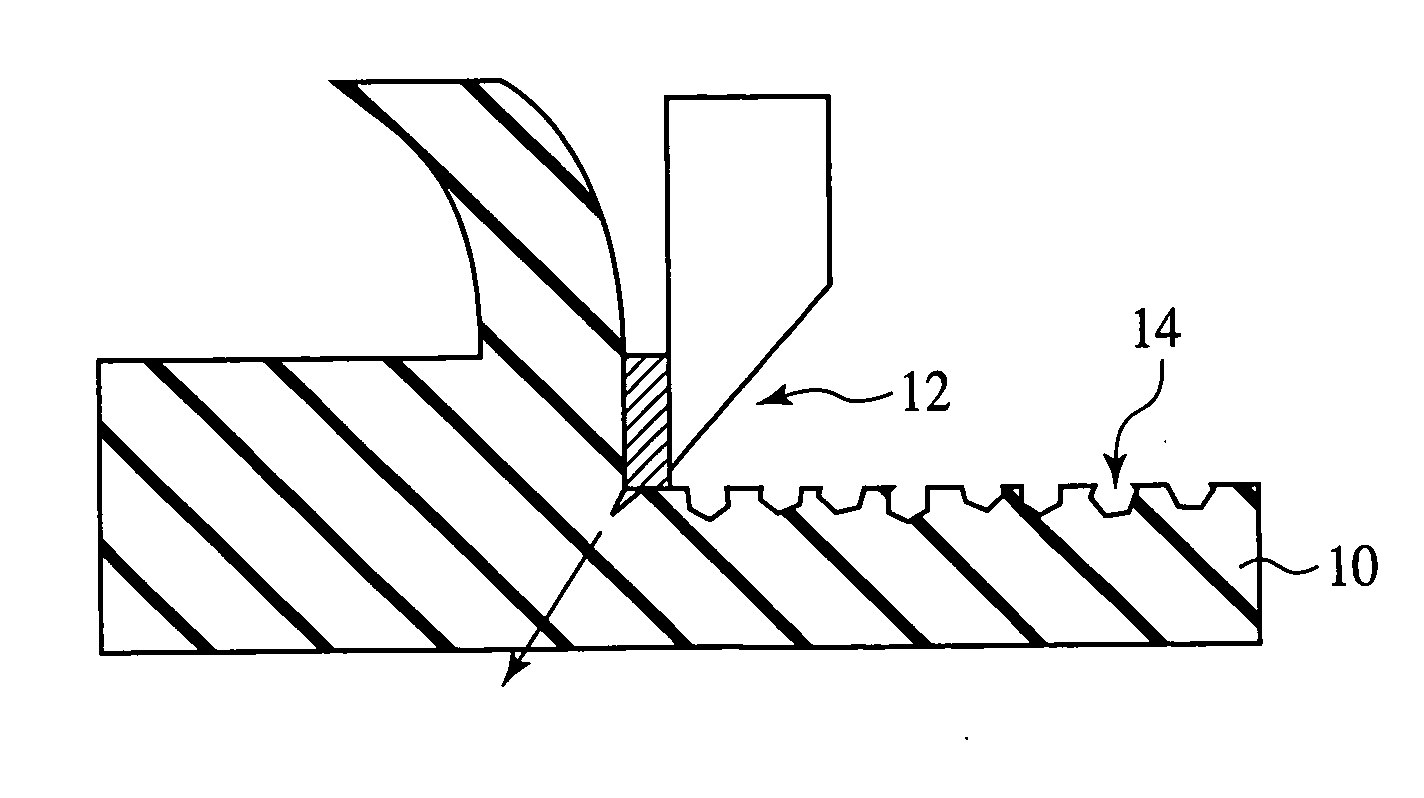

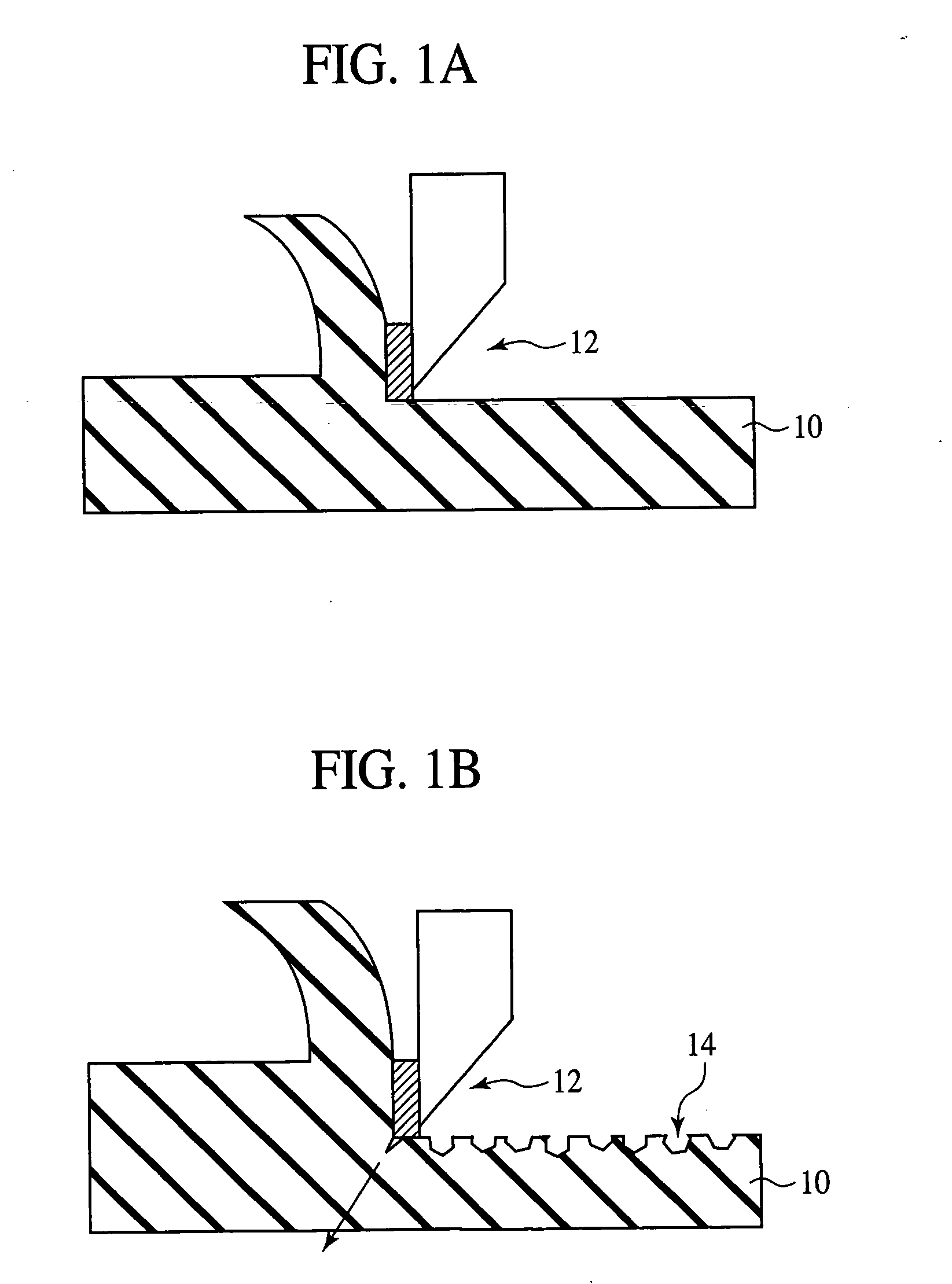

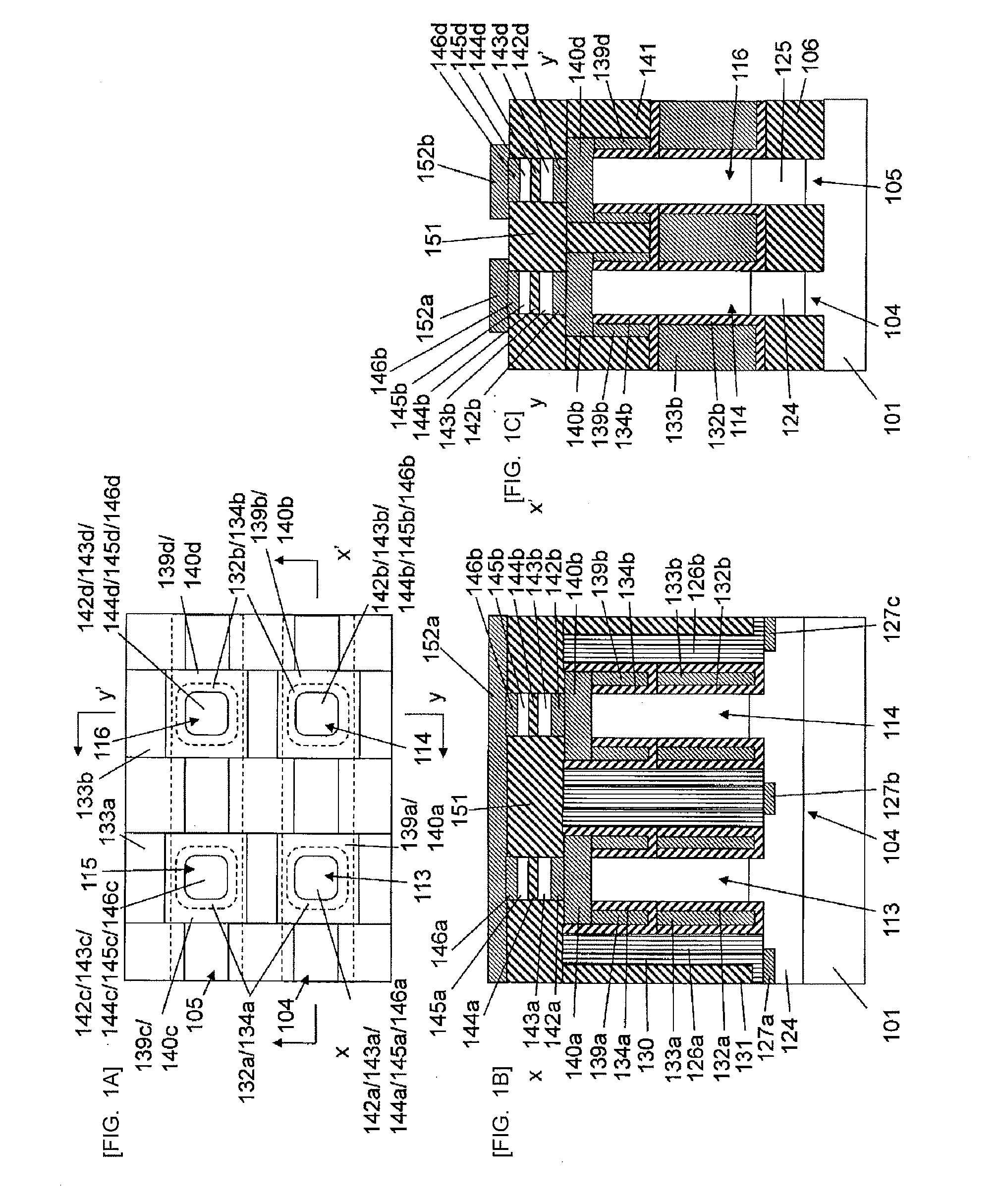

Plating method, semiconductor device fabrication method and circuit board fabrication method

InactiveUS20060084253A1Ensures adhesionSuitable roughnessSemiconductor/solid-state device detailsPrinted circuit aspectsPhotoresistElectroless plating

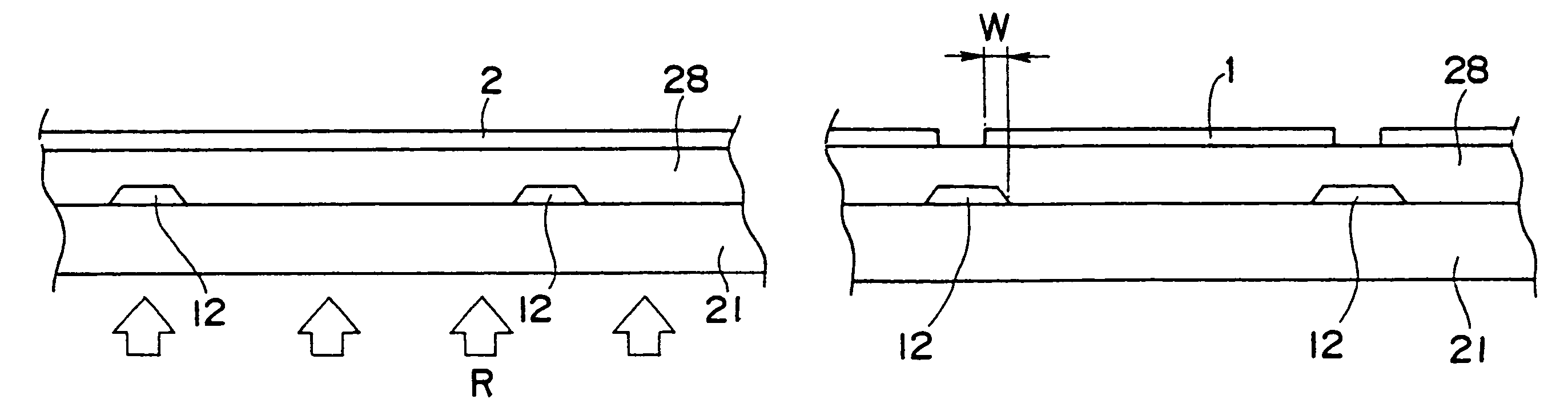

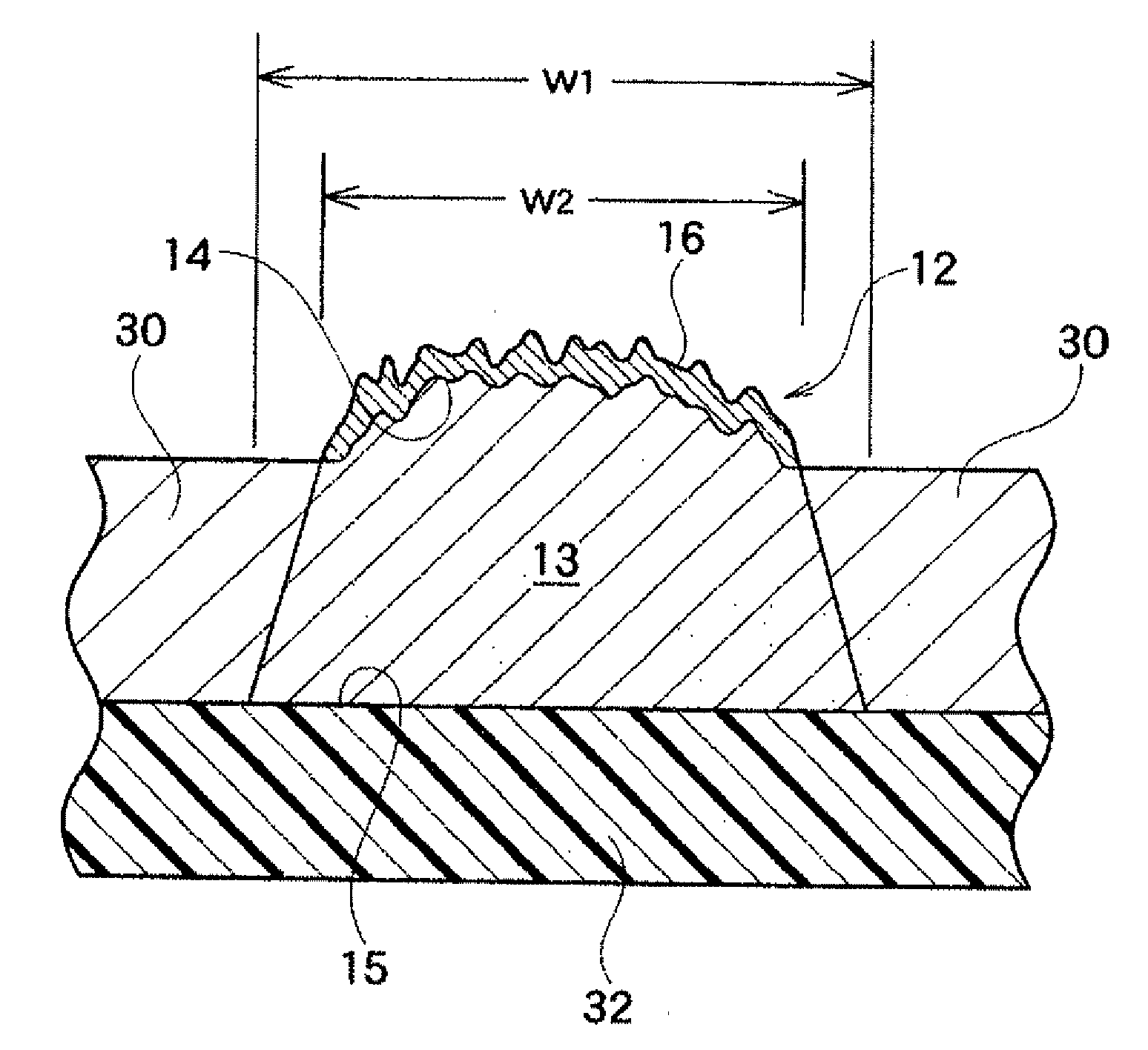

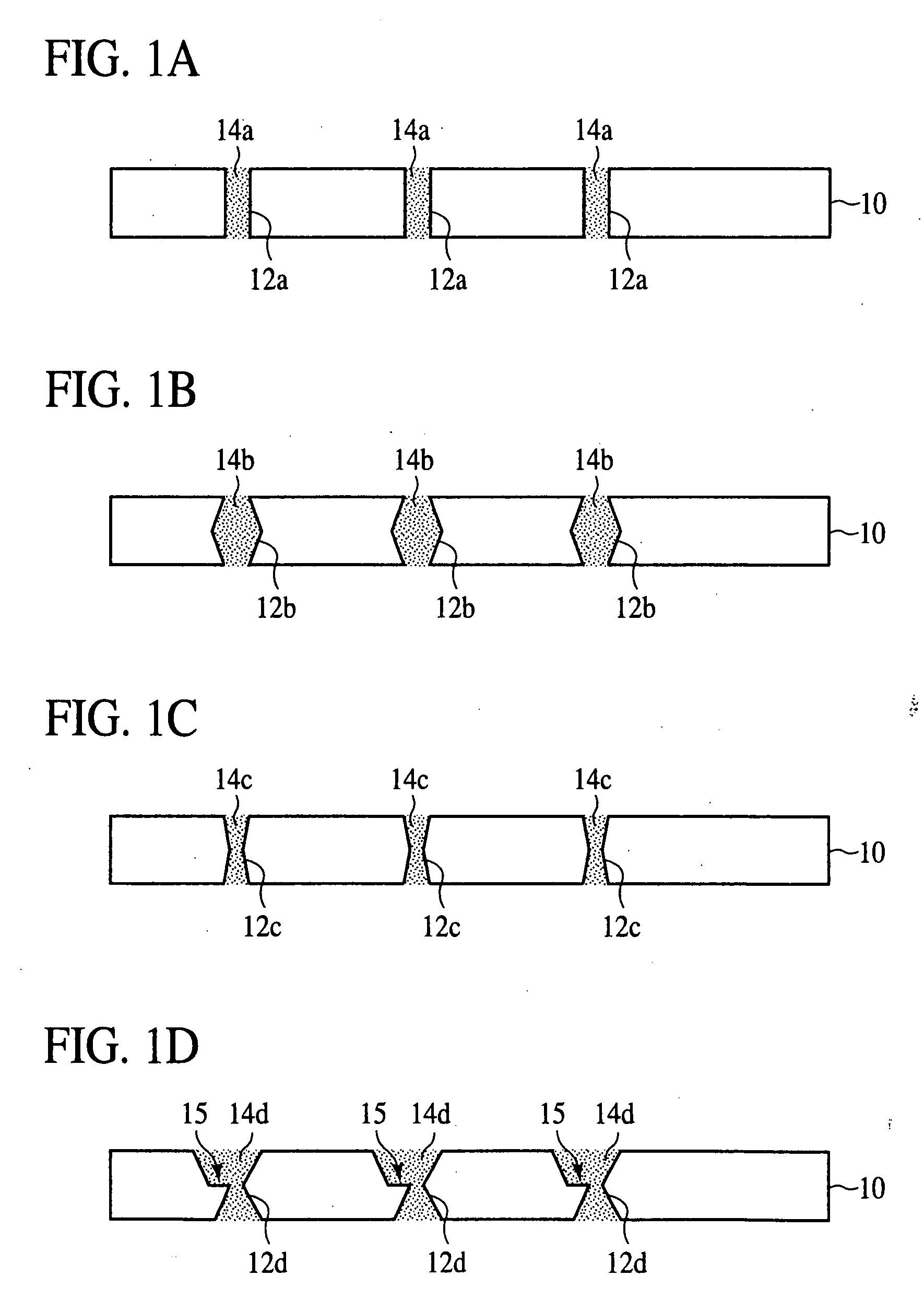

The plating method comprises the step of forming a resin layer 10 over a substrate 16; the step of cutting the surface part of the resin layer 10 with a cutting tool 12; the step of forming a seed layer 36 on the resin layer 10 by electroless plating; and the step of forming a plating film 44 on the seed layer 36 by electroplating. Suitable roughness can be give to the surface of the resin layer 10, whereby the adhesion between the seed layer 36 and the resin layer 10 can be sufficiently ensured. Excessively deep pores are not formed in the surface of the resin layer 10, as are by desmearing treatment, whereby a micronized pattern of a photoresist film 40 can be formed on the resin layer 10. Thus, interconnections 44, etc. can be formed over the resin layer 10 at a narrow pitch with high reliability ensured.

Owner:FUJITSU LTD

Wiring Boards and Processes for Manufacturing the Same

InactiveUS20090183901A1Eliminate the problemReduce the cross-sectional areaSemiconductor/solid-state device detailsPrinted circuit aspectsEngineeringMetal

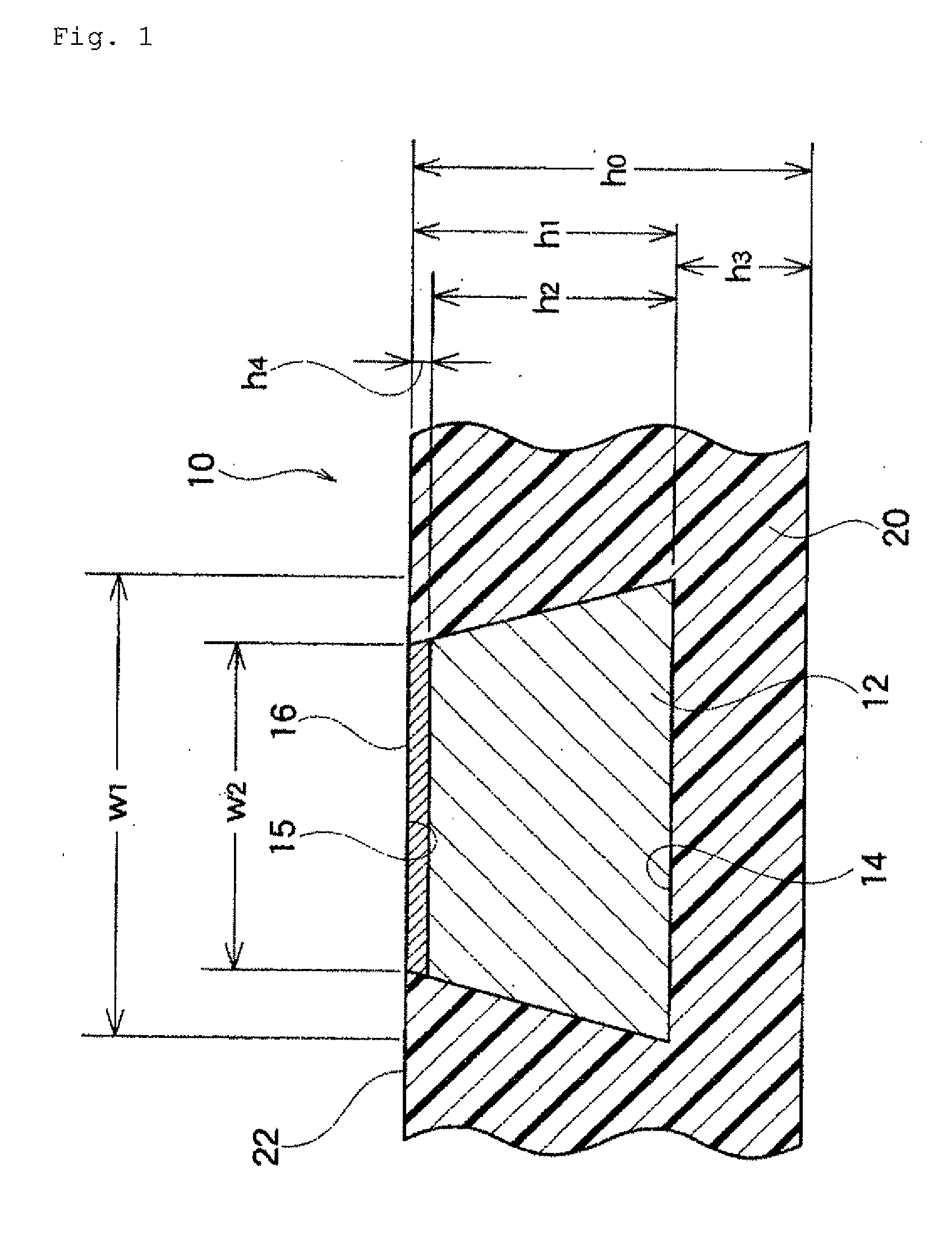

A wiring board includes an insulating substrate and a wiring pattern. The wiring pattern includes a main body and an upper end portion and is embedded in the insulating substrate while exposing at least the upper end portion on a surface of the insulating substrate. The upper end portion has a cross-sectional width smaller than that of a lower end portion of the wiring pattern embedded in the insulating substrate. The upper end portion is formed of a metal that is more noble than a metal of the main body of the wiring pattern.The wiring board having this structure achieves very high adhesion of the wiring pattern to the insulating layer.

Owner:MITSUI MINING & SMELTING CO LTD

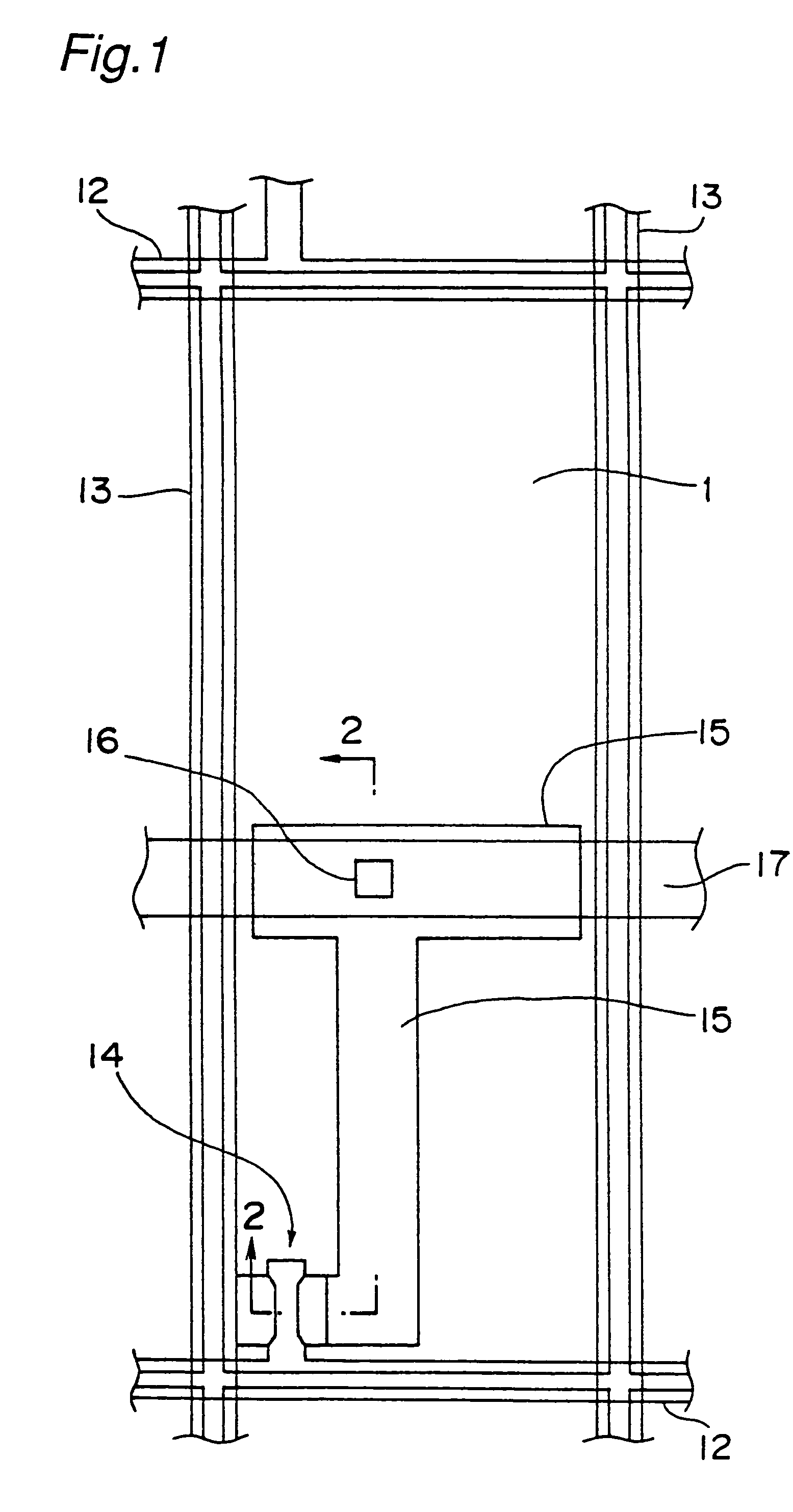

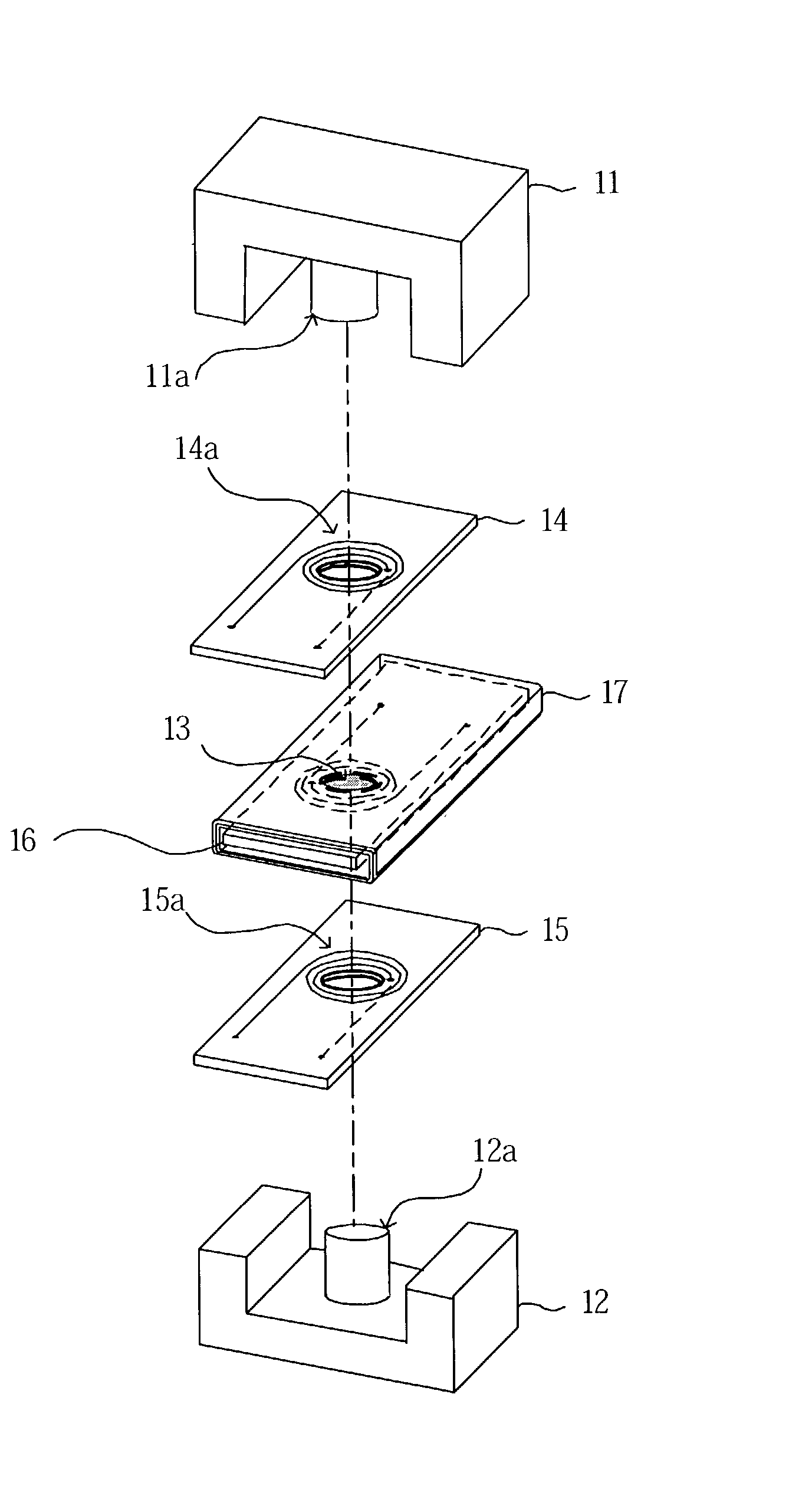

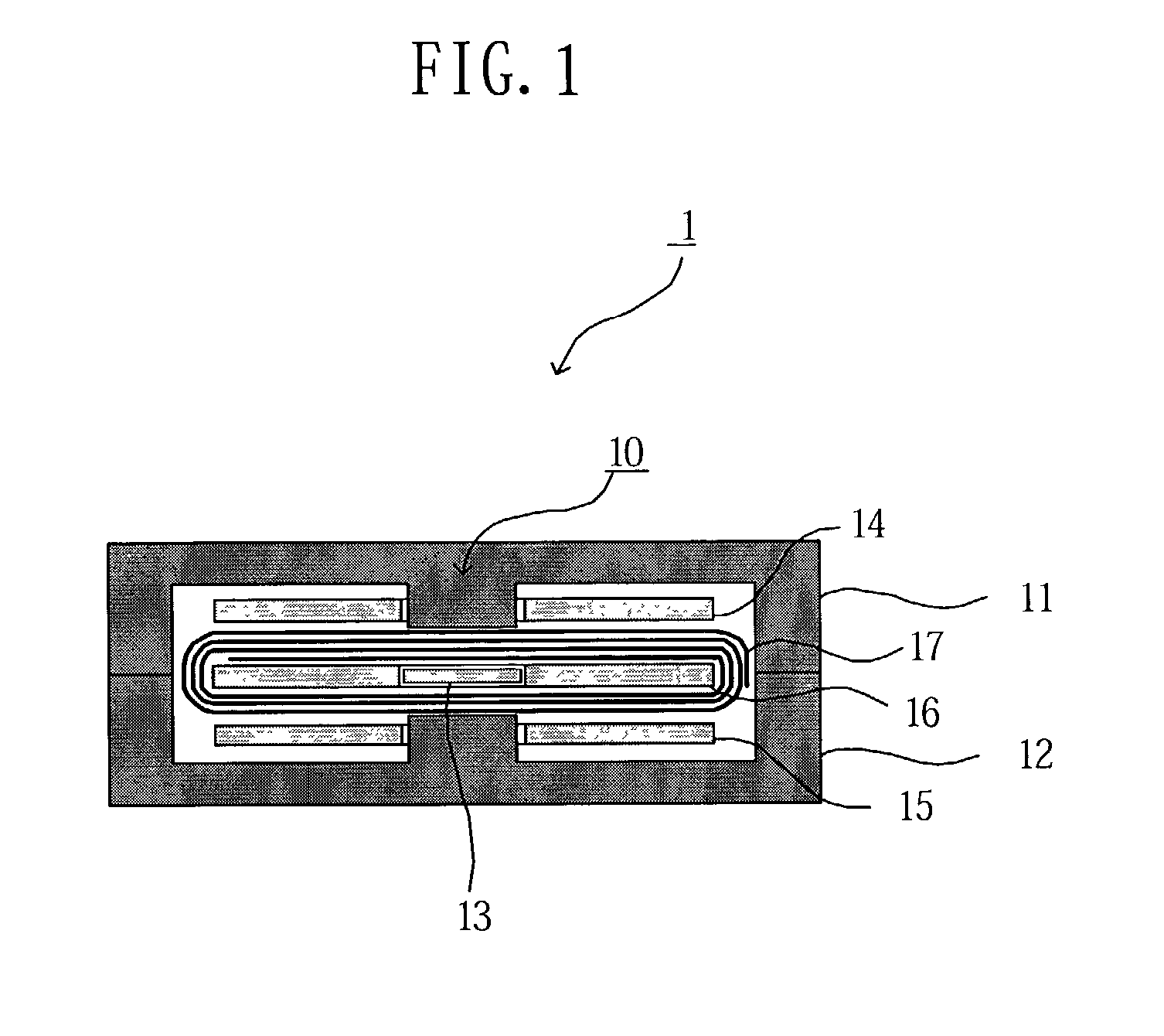

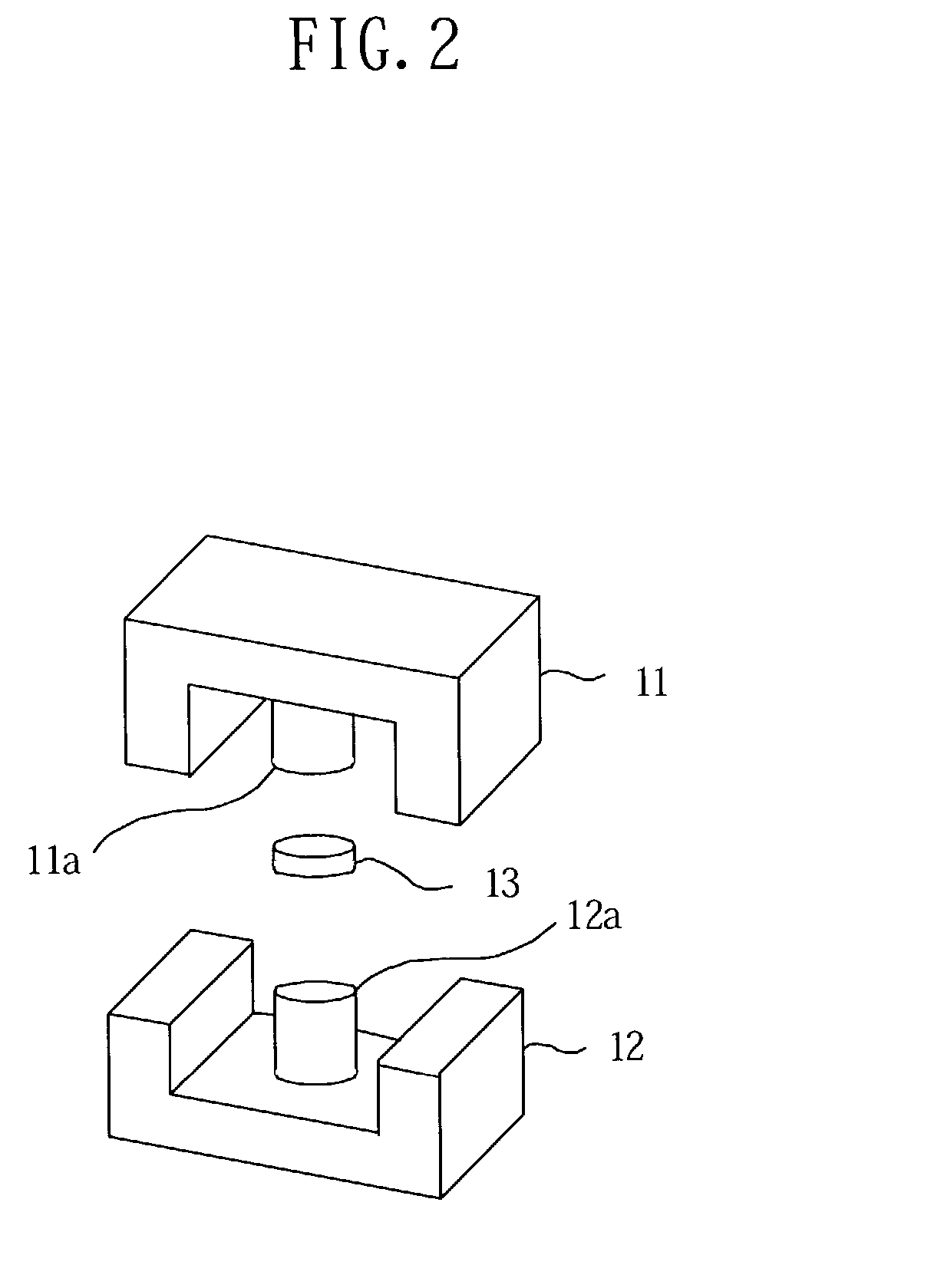

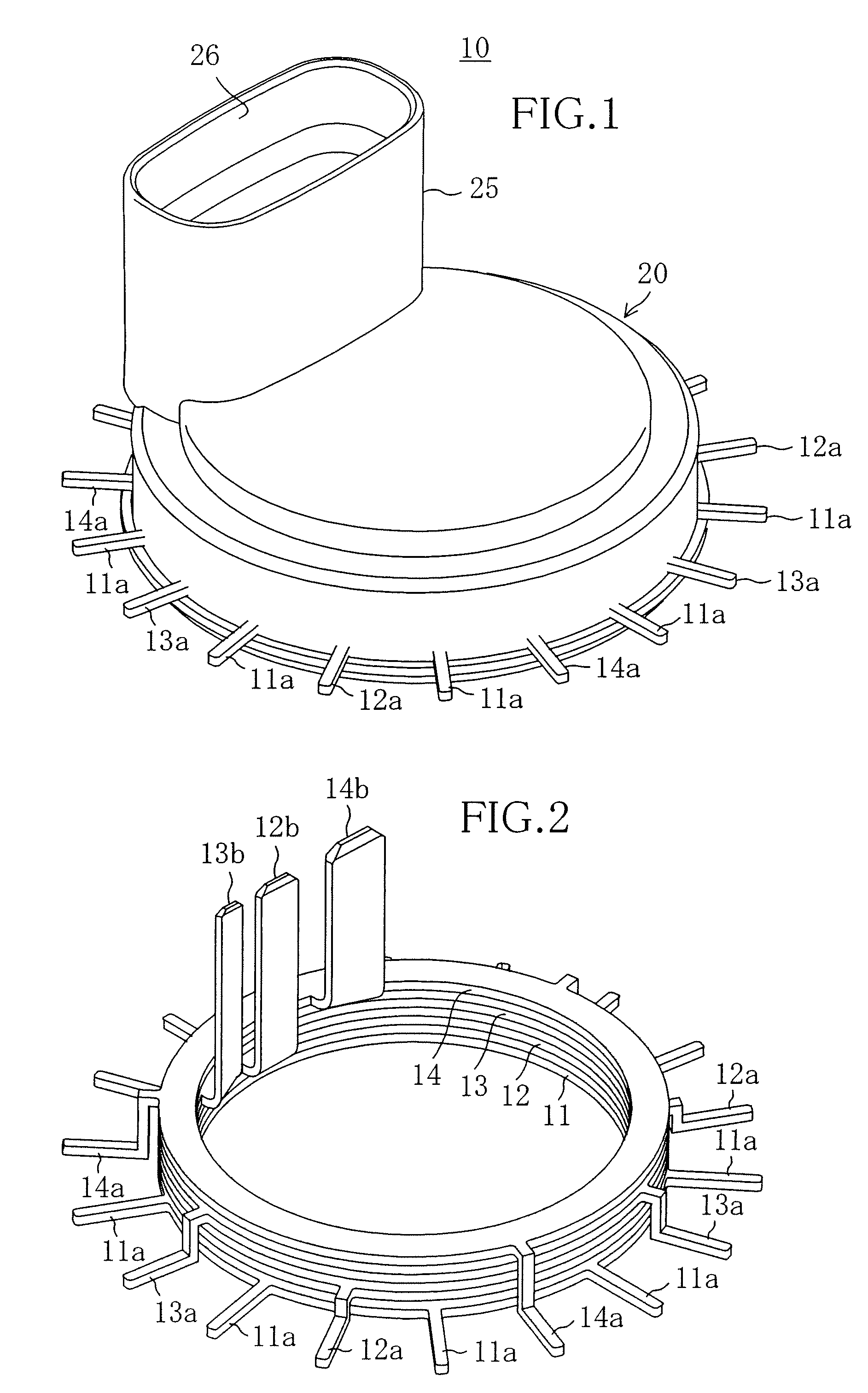

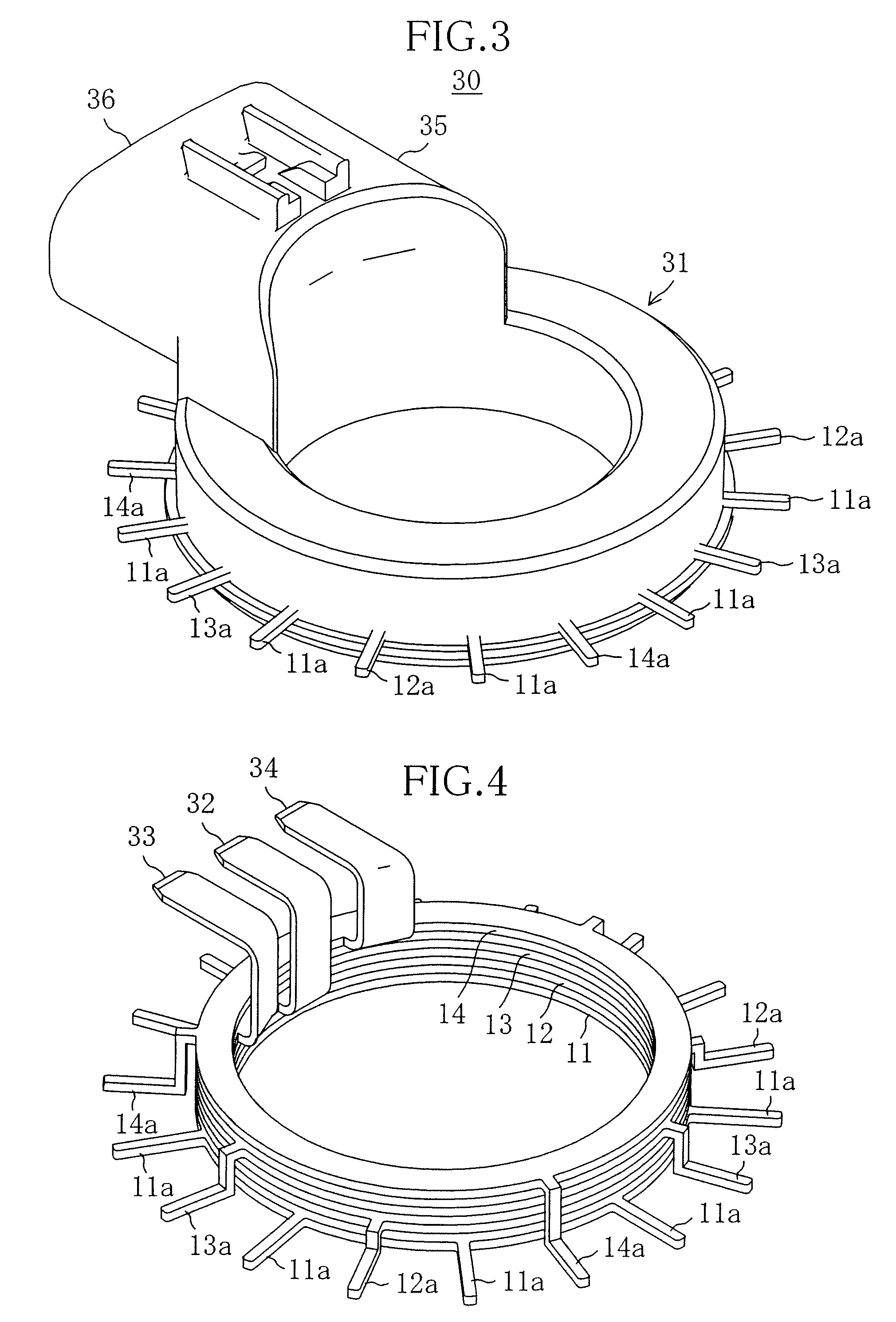

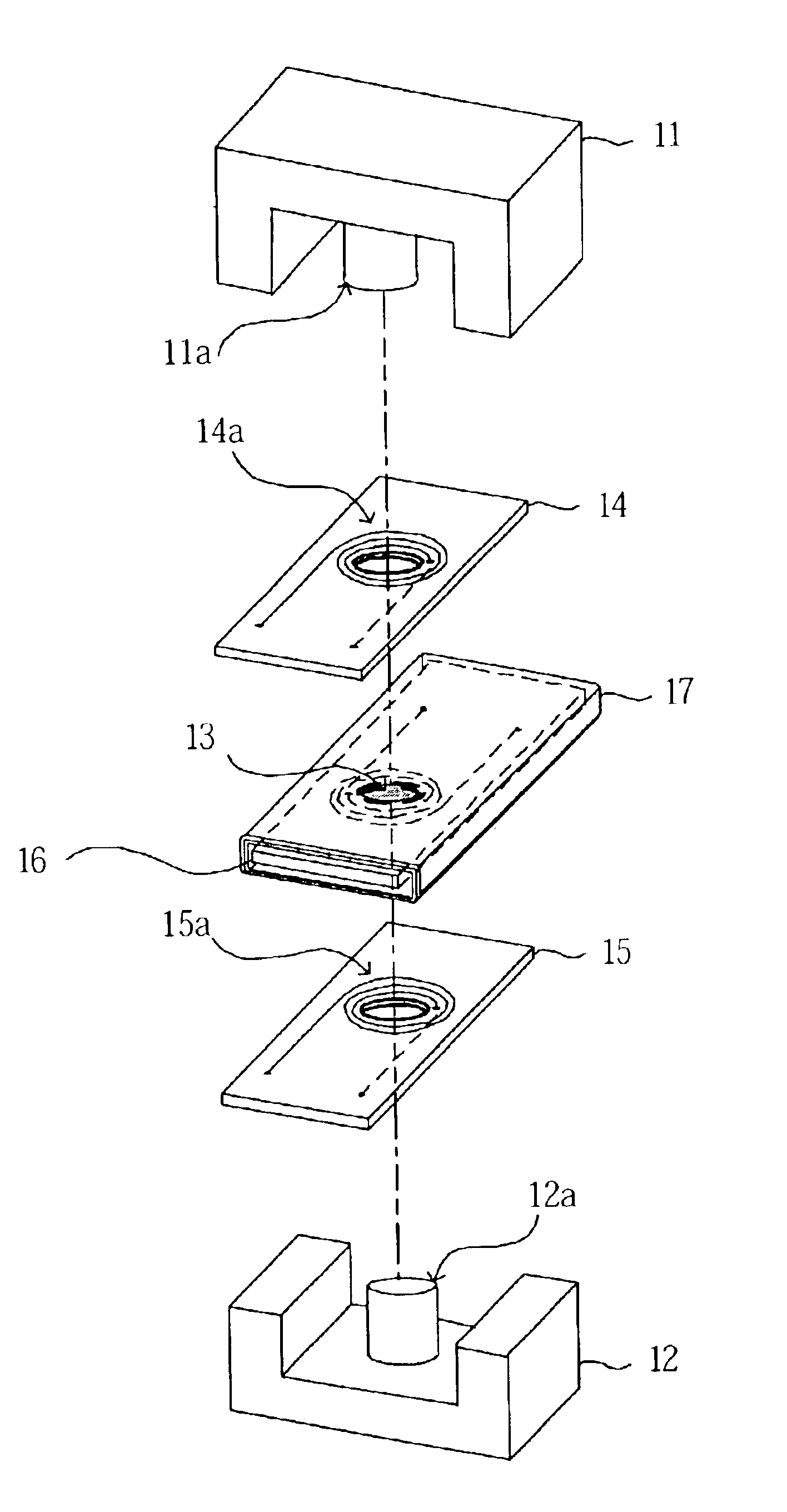

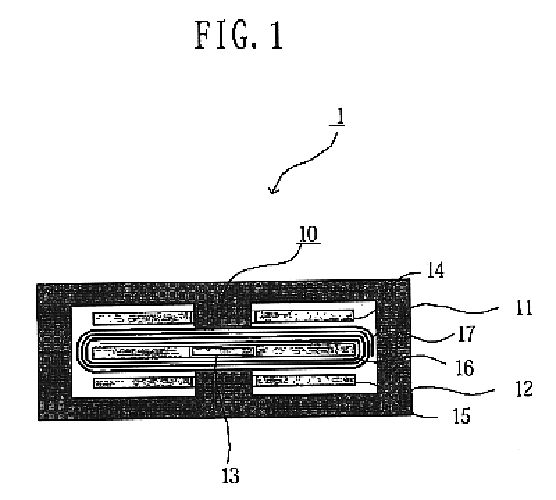

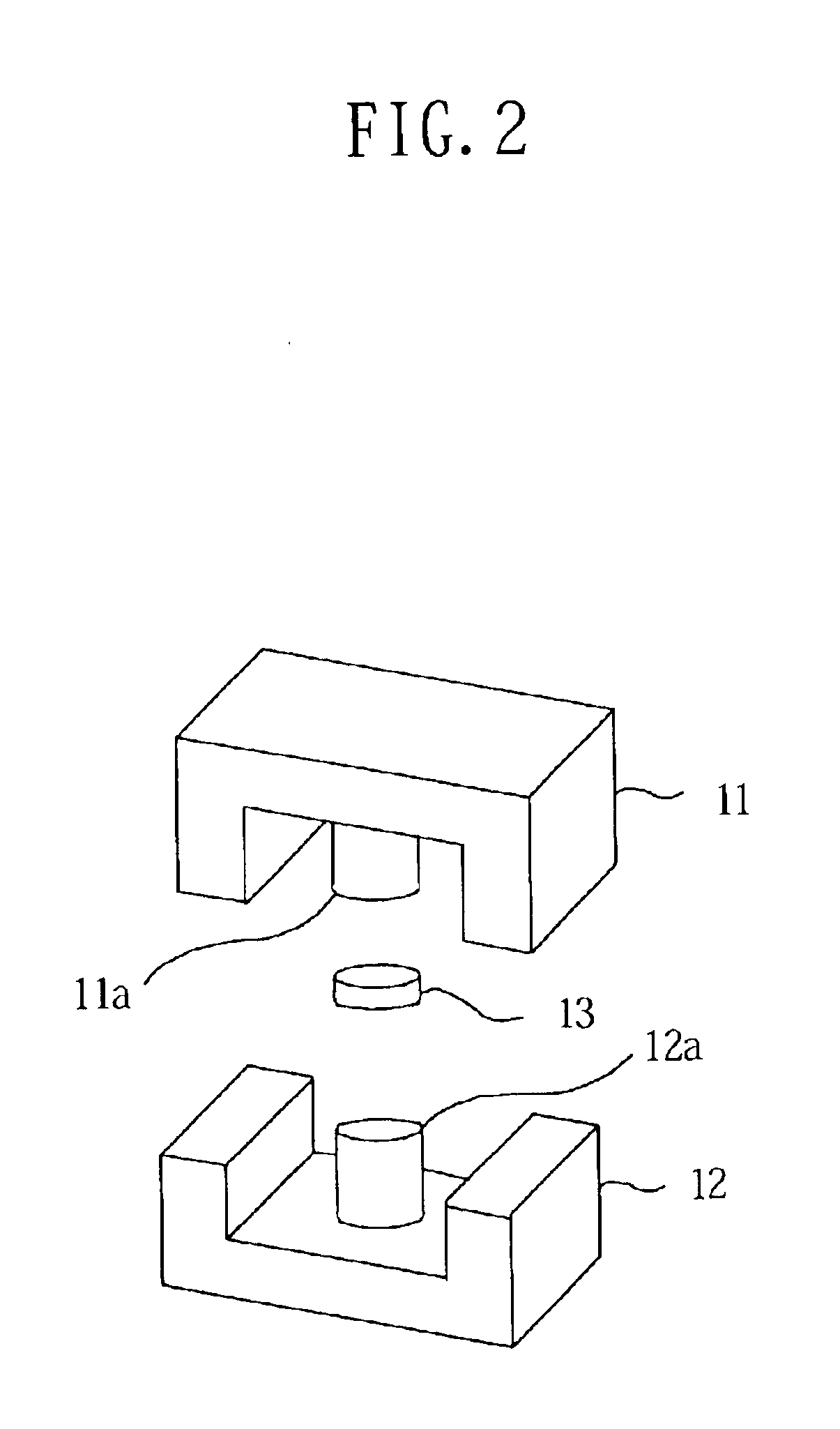

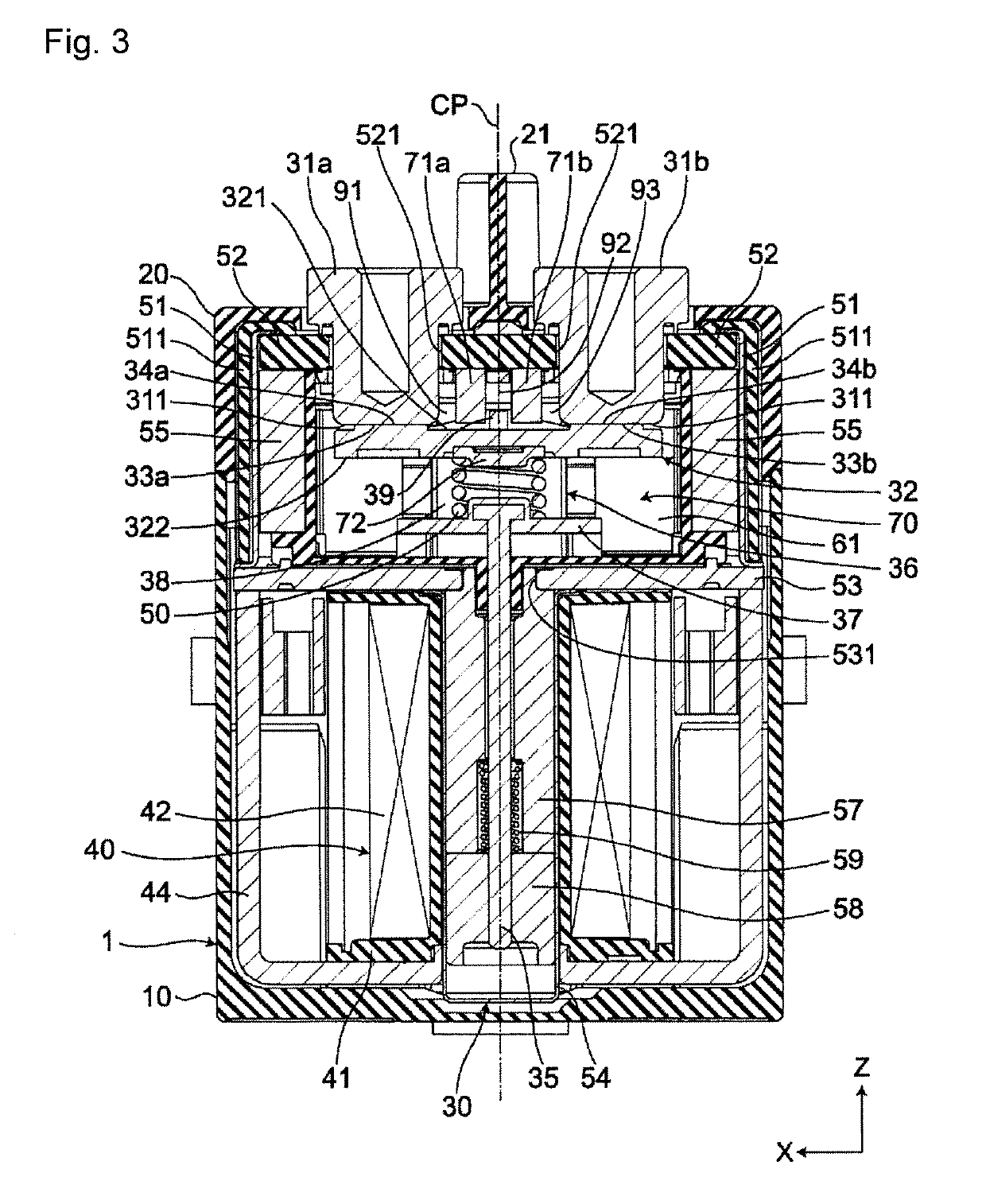

Transformer

InactiveUS20020167388A1Operational securityImprove reliabilityTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresTransformerEngineering

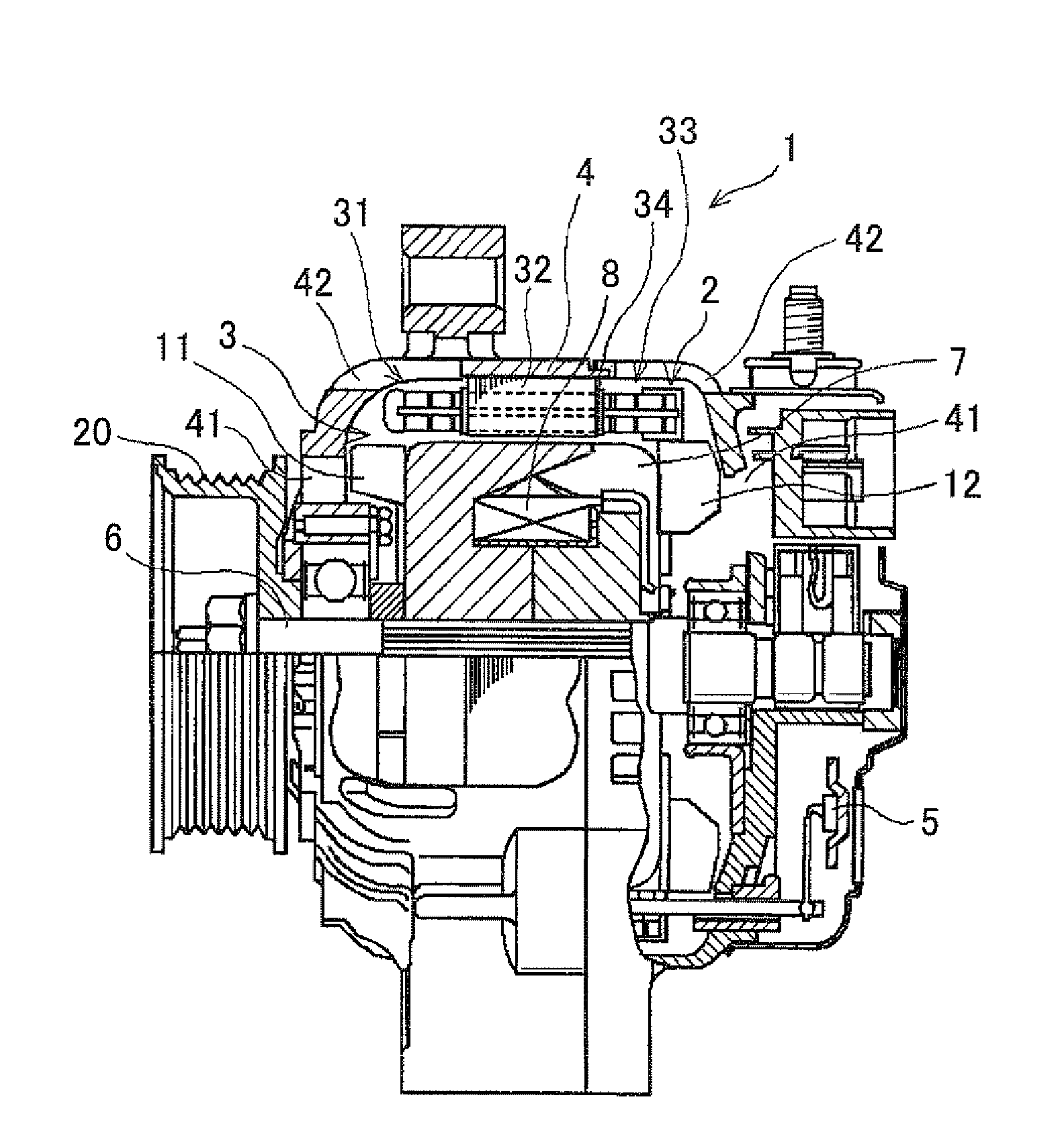

A transformer comprises E-type core parts, a cylindrical core part, a second substrate, first substrates, and an insulating sheet. Each of the second substrate and the fist substrates includes a penetration hole. A coil is wired around the penetration hole. The second substrate is wrapped with an insulating sheet, together with the cylindrical core part. The second substrate and the cylindrical core part are sandwiched between cylindrical core legs of the core parts, through the insulating sheet.

Owner:SANKEN ELECTRIC CO LTD

Circuit substrate and method for fabricating the same

InactiveUS20070155174A1Improve surface roughnessRelieve pressureSemiconductor/solid-state device detailsPrinted circuit aspectsSurface roughnessOptoelectronics

A circuit substrate comprises a glass substrate 16, through-holes 18 formed through the glass substrate 16 and via electrodes 20 buried in the through-holes 18. An opening width of the through-holes 18 is minimum inside the glass substrate and is increased toward both surfaces of the glass substrate 16. Accordingly, the detachment of the via electrodes 20 can be prevented without increasing the surface roughness of the inside walls of the through holes, and stresses generated in the core substrate can be mitigated.

Owner:FUJITSU LTD

Semiconductor device and method of manufacturing the same

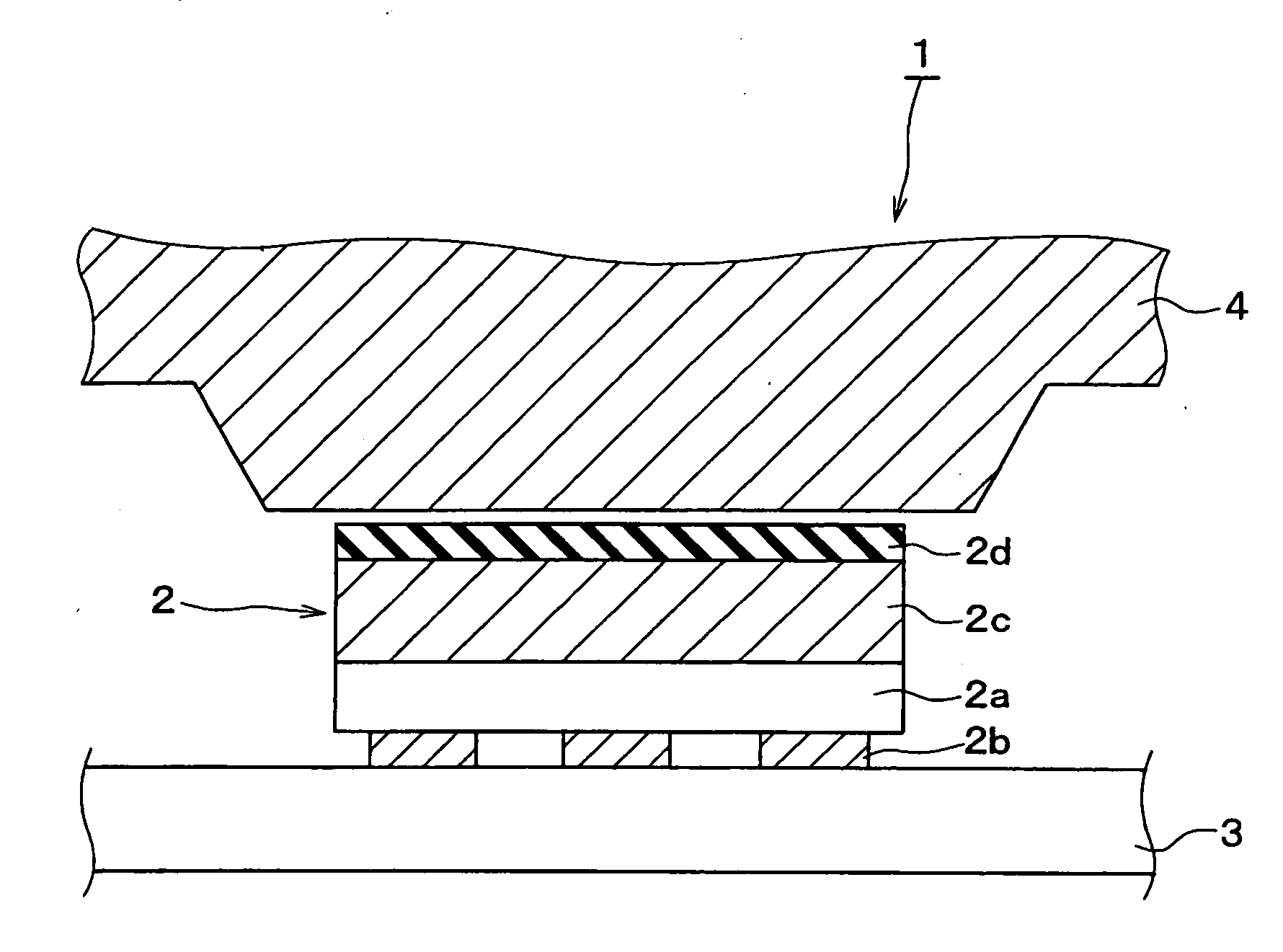

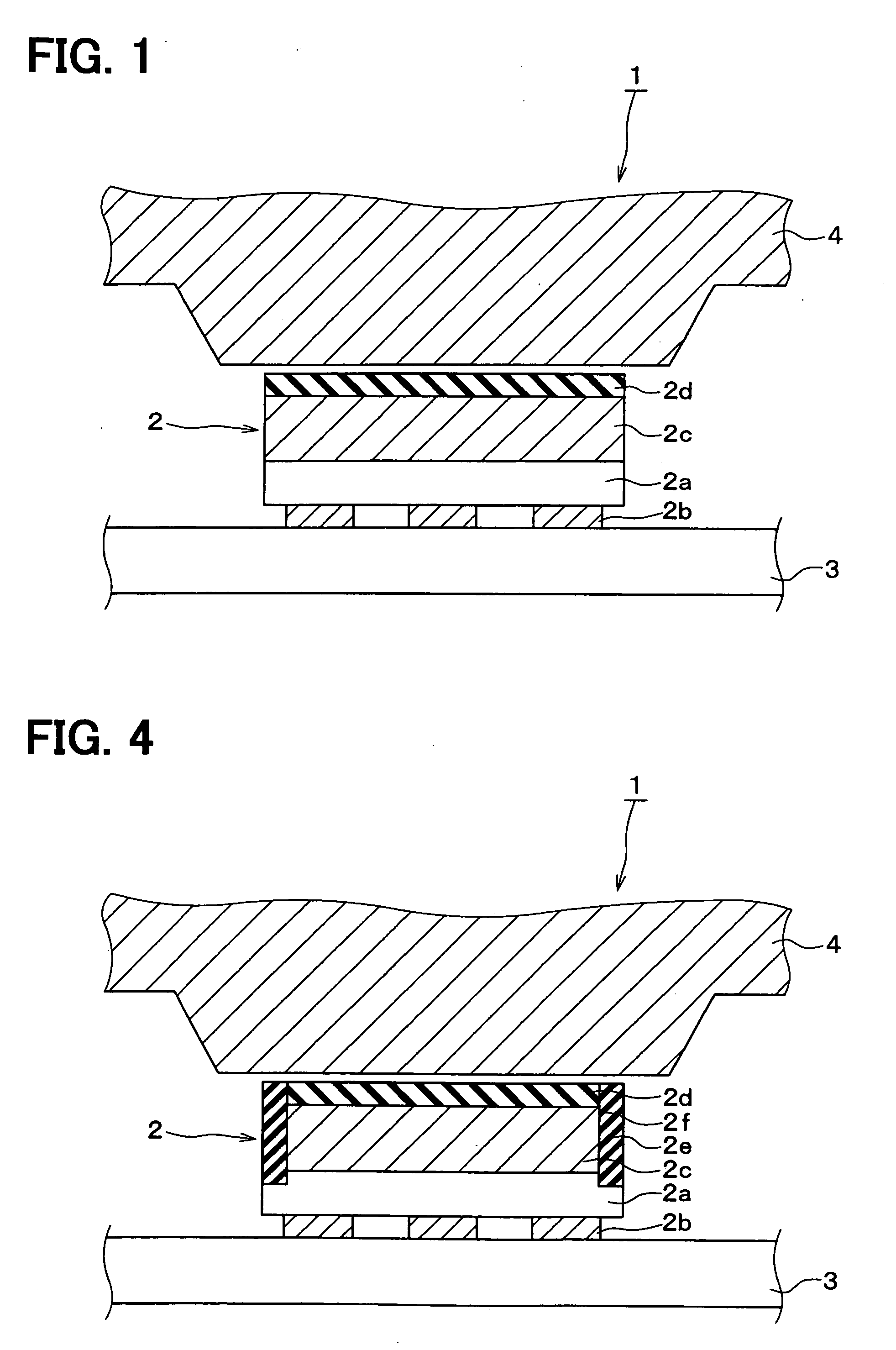

InactiveUS20090227070A1Simple processEnsure insulationSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipHeat spreader

A semiconductor device and a method of manufacturing the same are disclosed. The semiconductor device includes: a casing, a board and a semiconductor chip. The chip includes: an element part; a heat sink bonded to the element part; an insulting layer located on the heat sink so that the heat sink is located between the element part and the insulating layer; and a side wall insulating layer covering all of end faces of the heat sink. The semiconductor chip is located between the casing and the board, so that the insulating layer is directed to the casing to enable heat radiation from the heat sink toward the casing via the insulating layer.

Owner:DENSO CORP

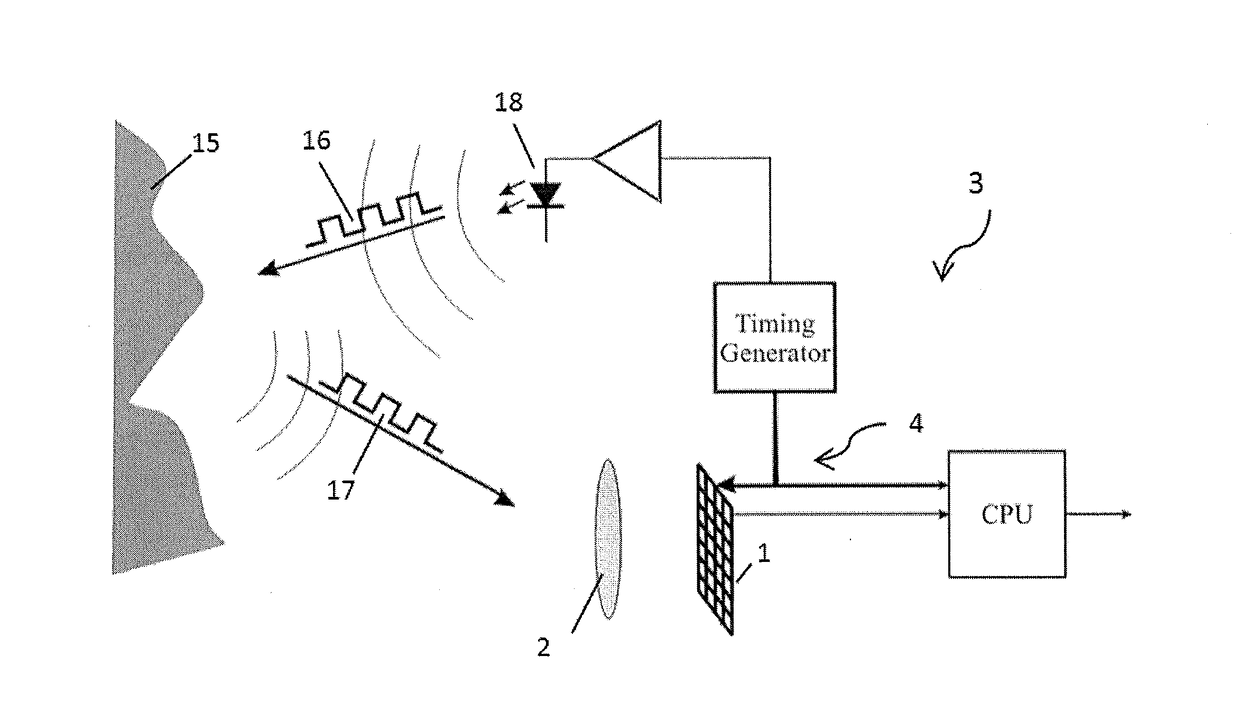

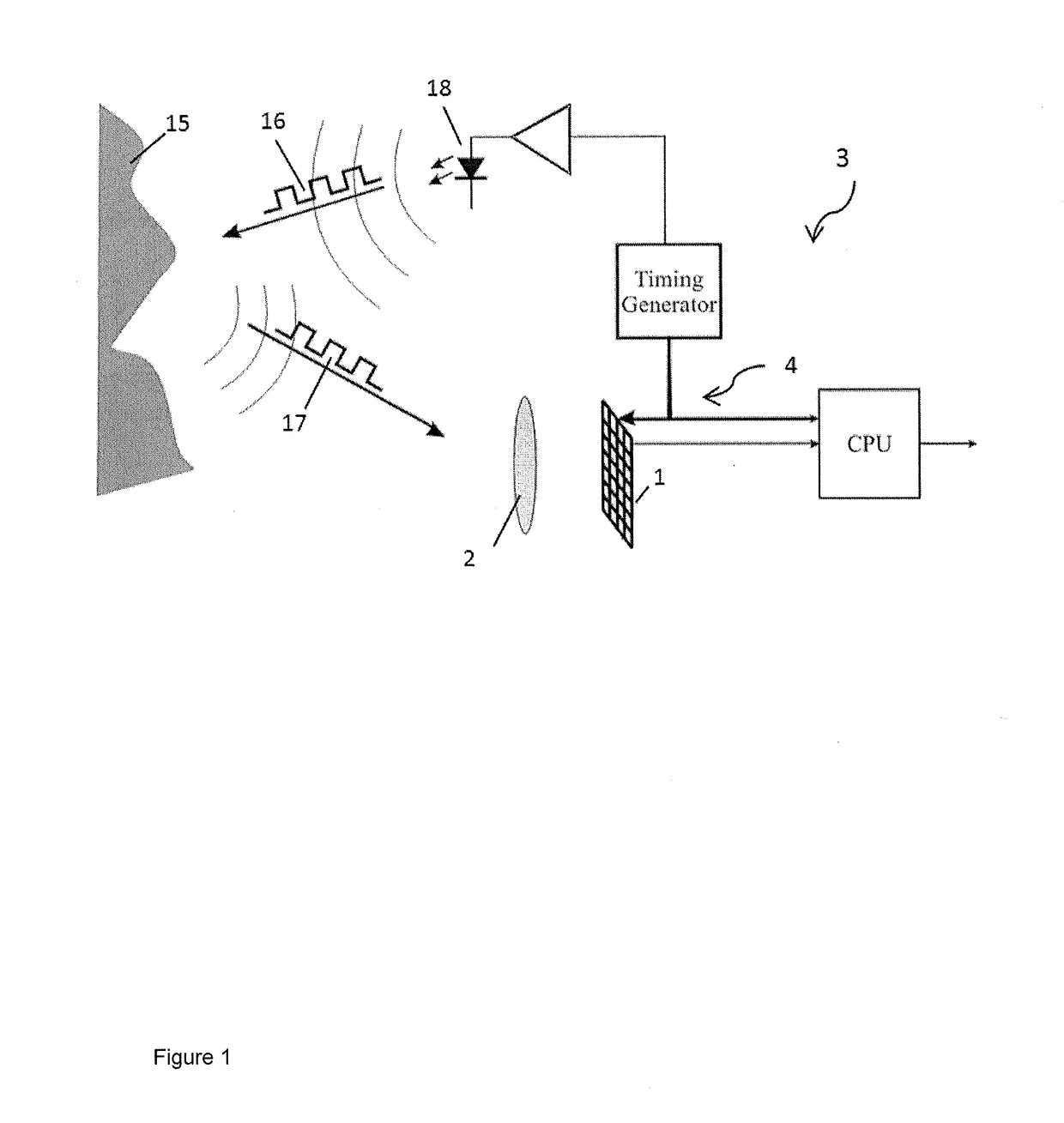

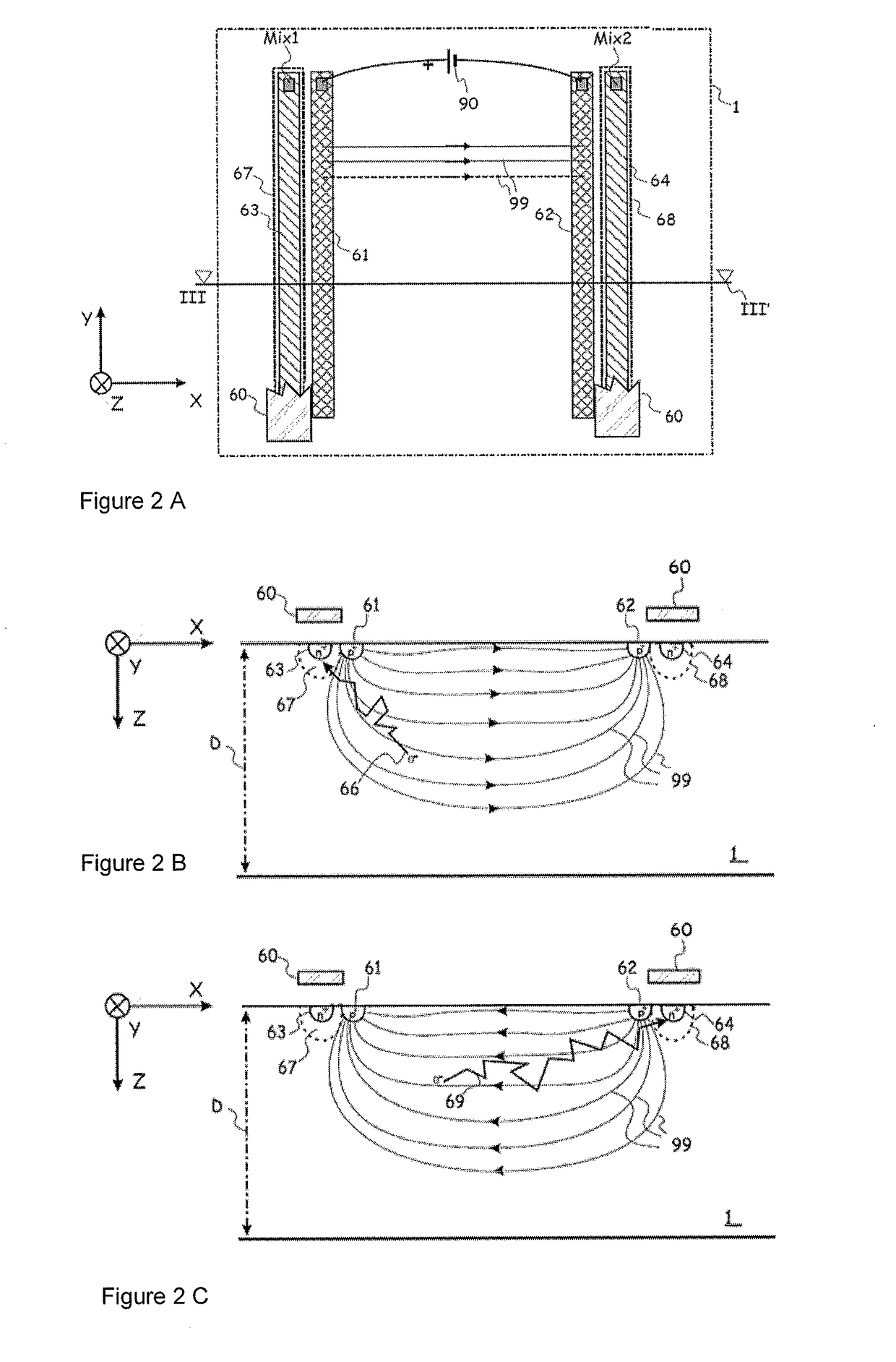

Majority current assisted radiation detector device

ActiveUS20170194367A1Reduce device sizeSmall sizeSolid-state devicesRadiation controlled devicesCarrier currentSemiconductor

The invention relates to a majority current assisted detector device, comprising a semiconductor layer of a first conductivity type epitaxially grown on a semiconductor substrate, at least two control regions of the first conductivity type, at least two detection regions of a second conductivity type opposite to the first conductivity type, and a source for generating a majority carrier current in the semiconductor layer between the two control regions, the majority current being associated with an electrical field. The detection regions surround the control regions, thereby forming at least two taps. The device is configured for backside illumination and further comprises a well of the first conductivity type between the two detection regions for insulating the detection regions. The well comprises pixel circuitry elements.

Owner:SOFTKINETIC SENSORS

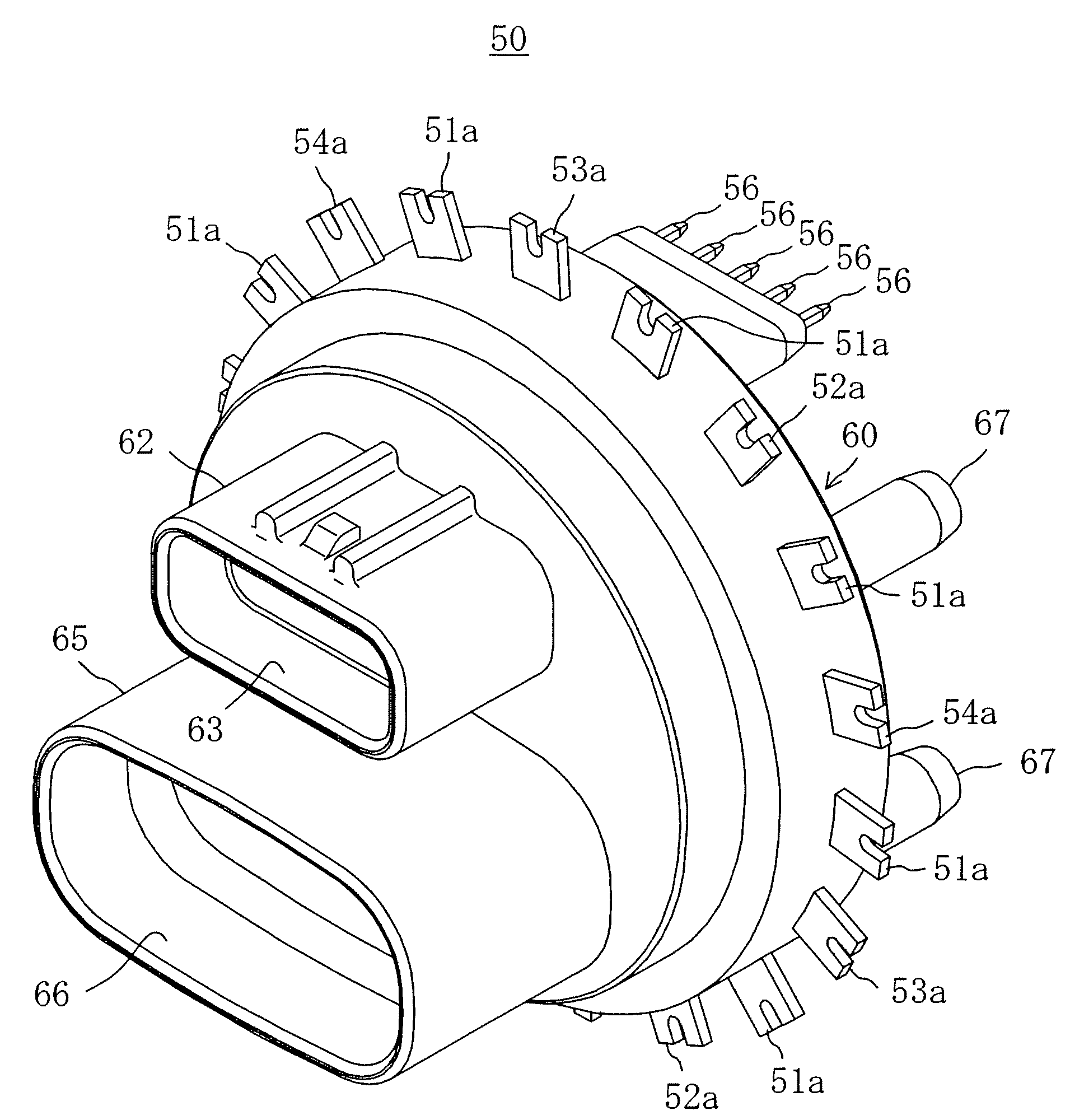

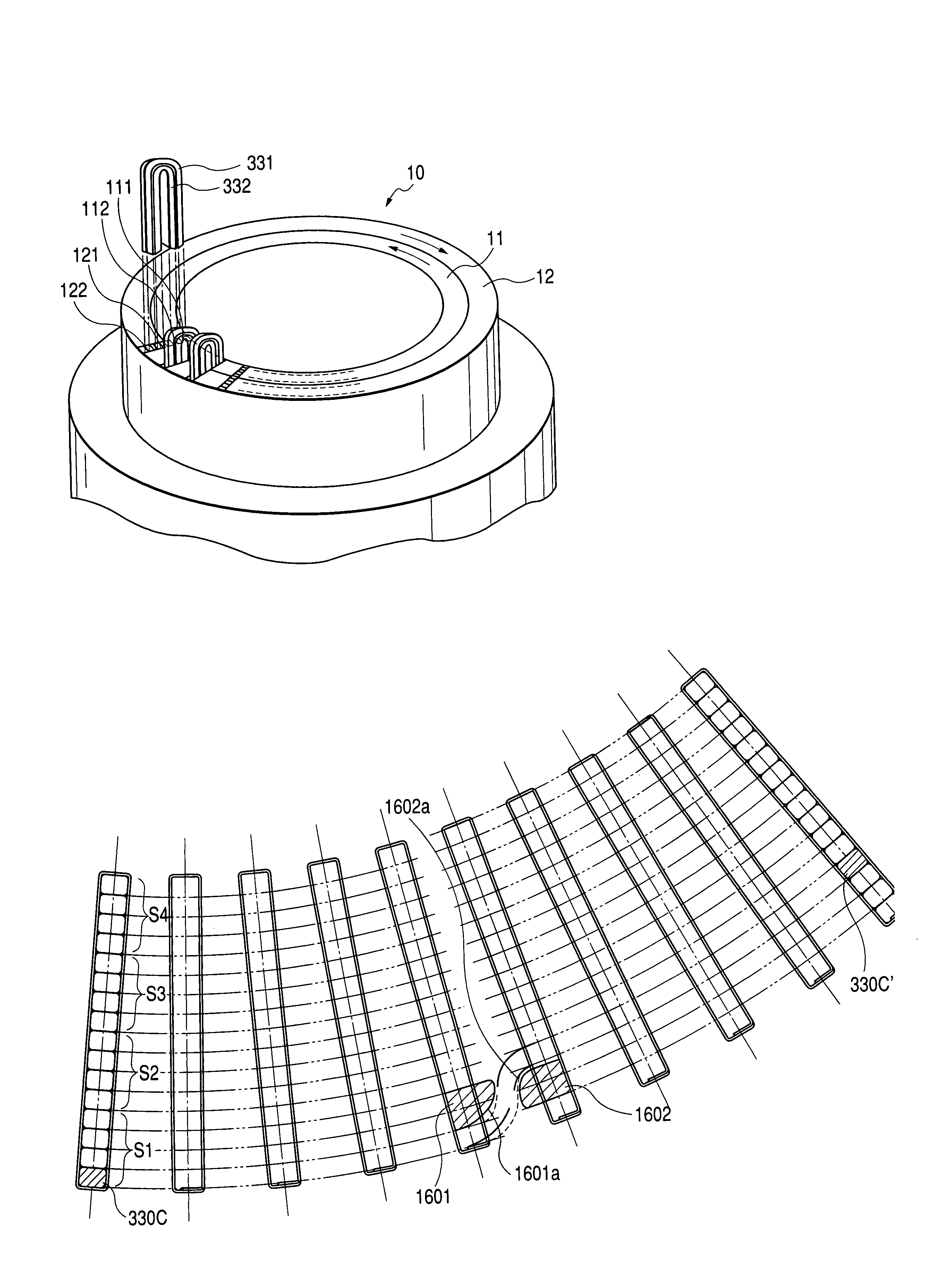

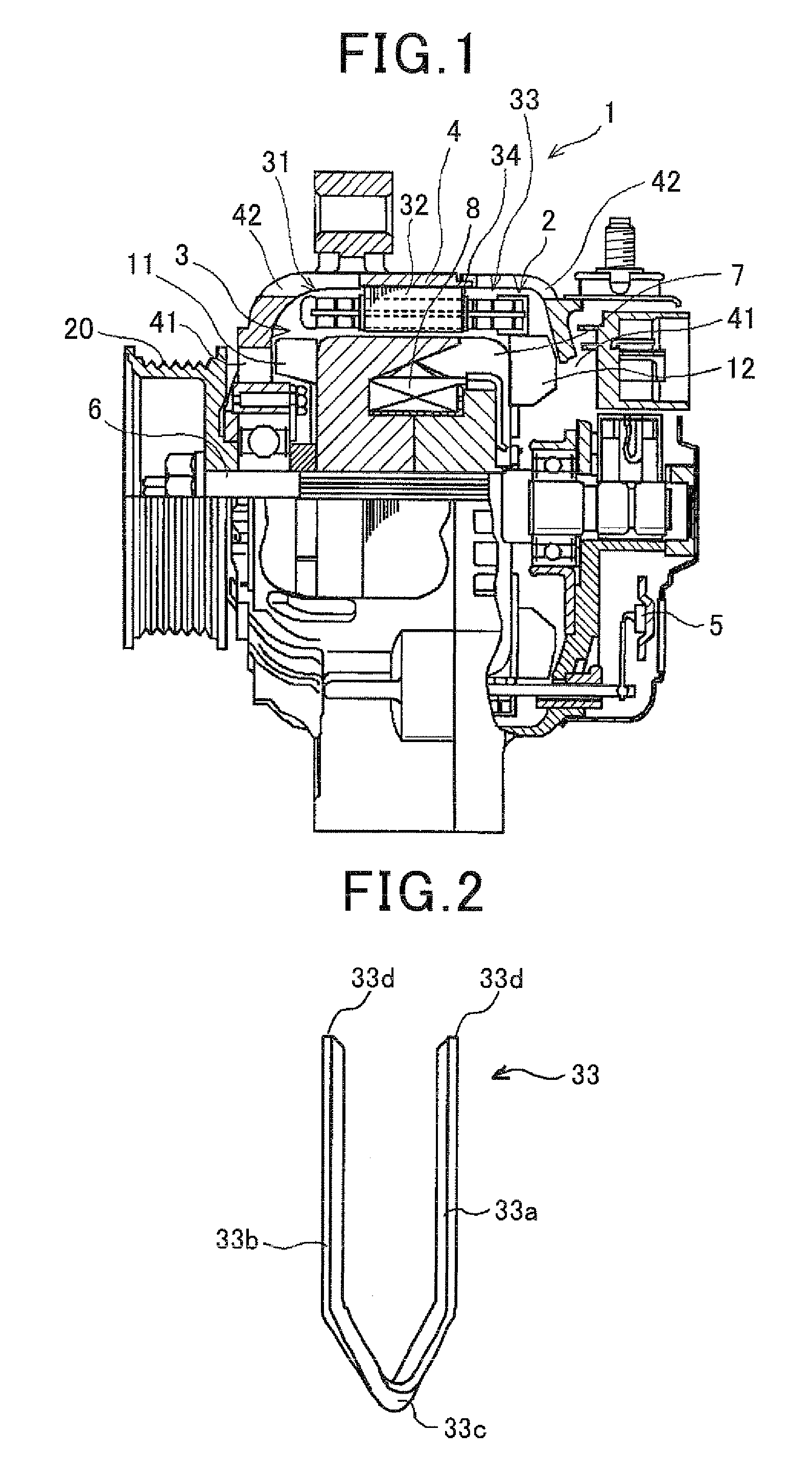

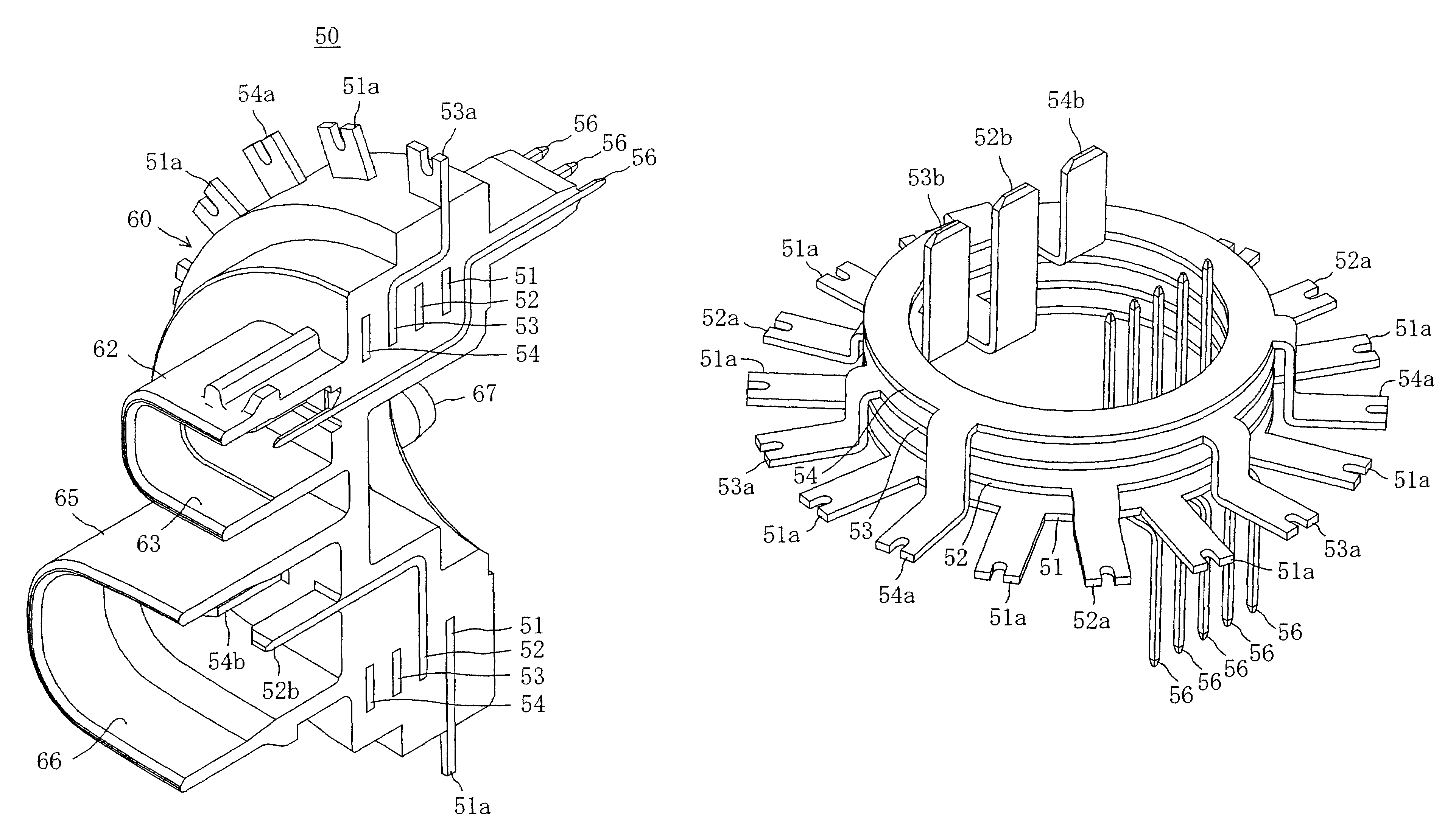

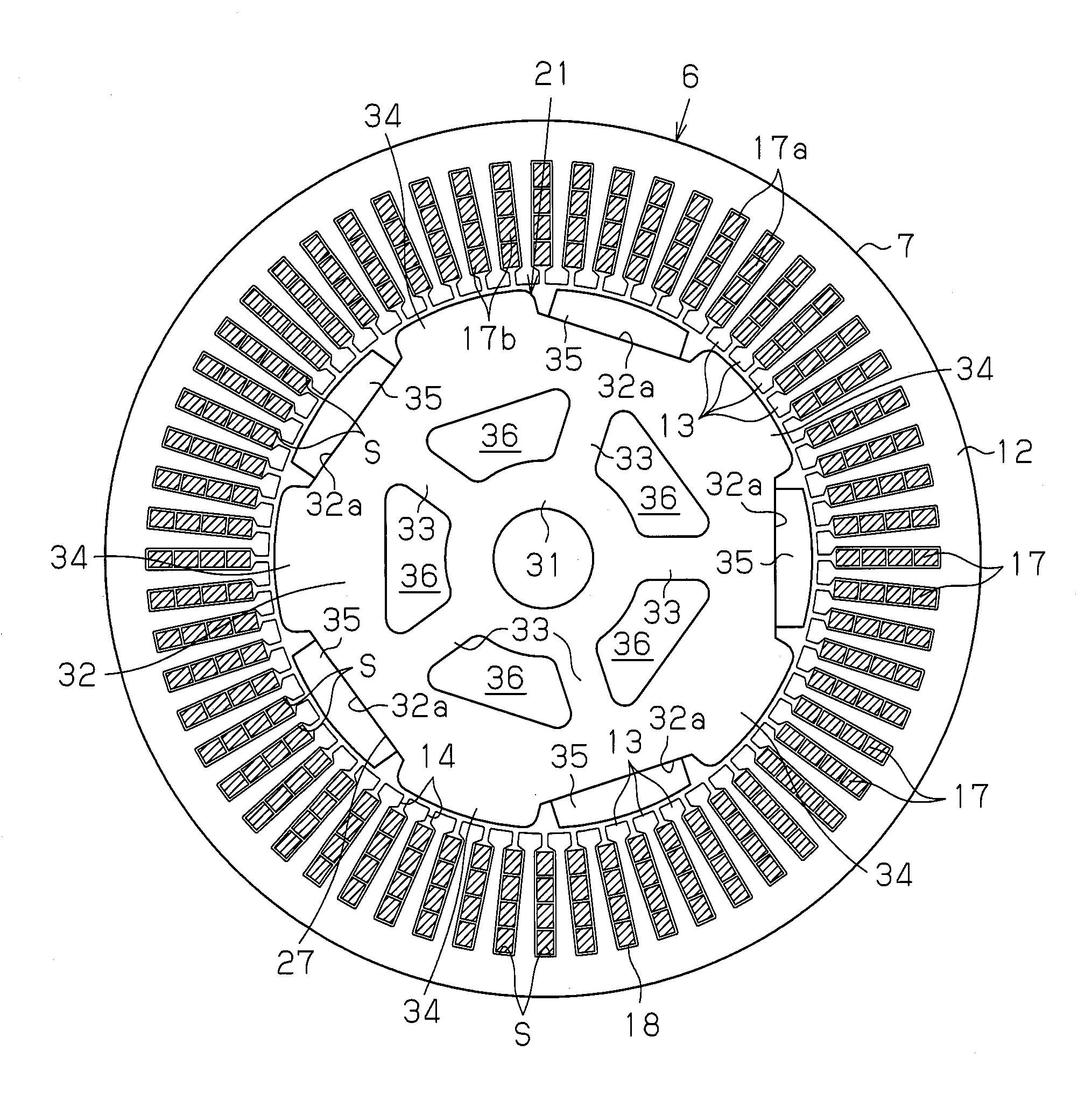

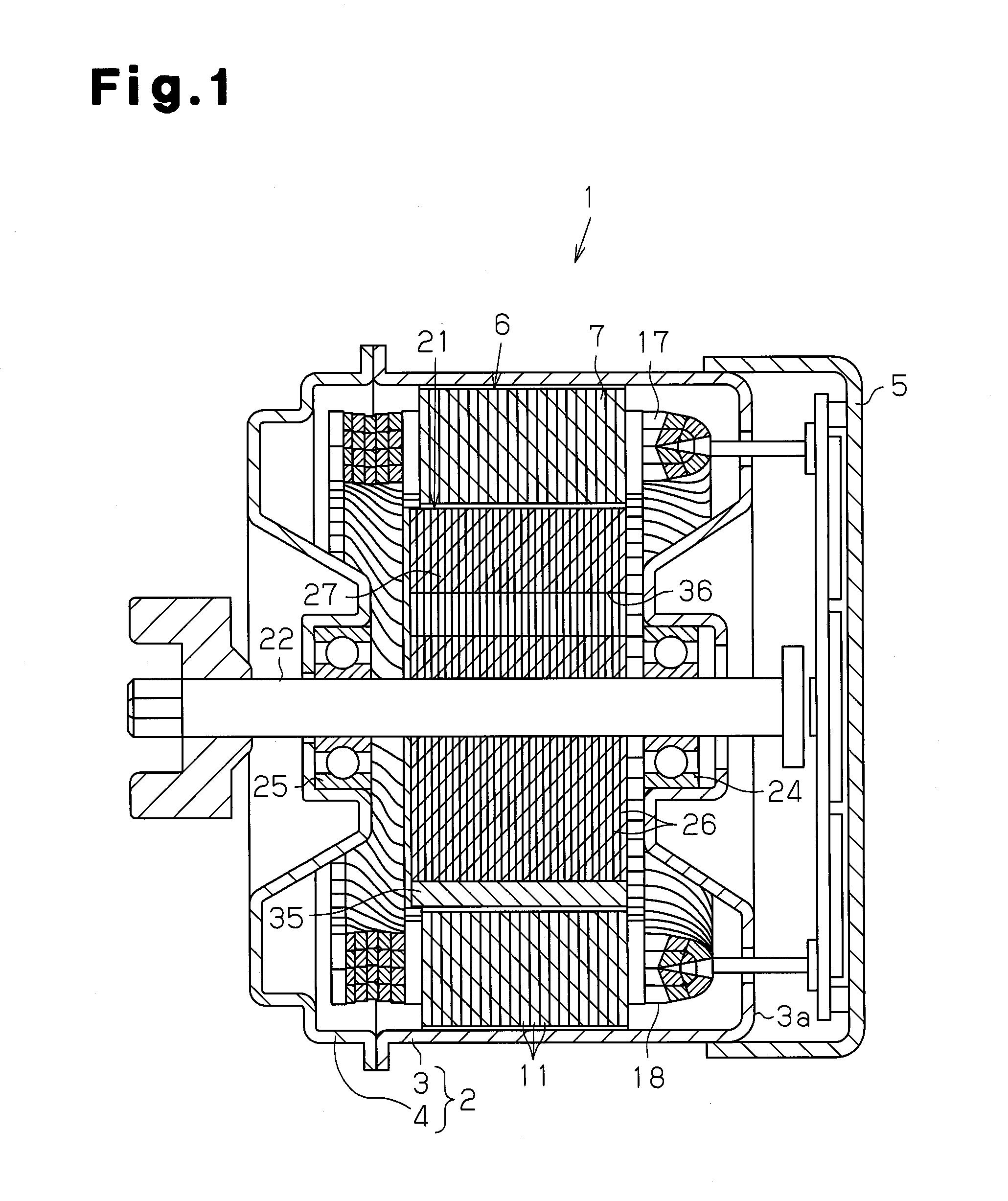

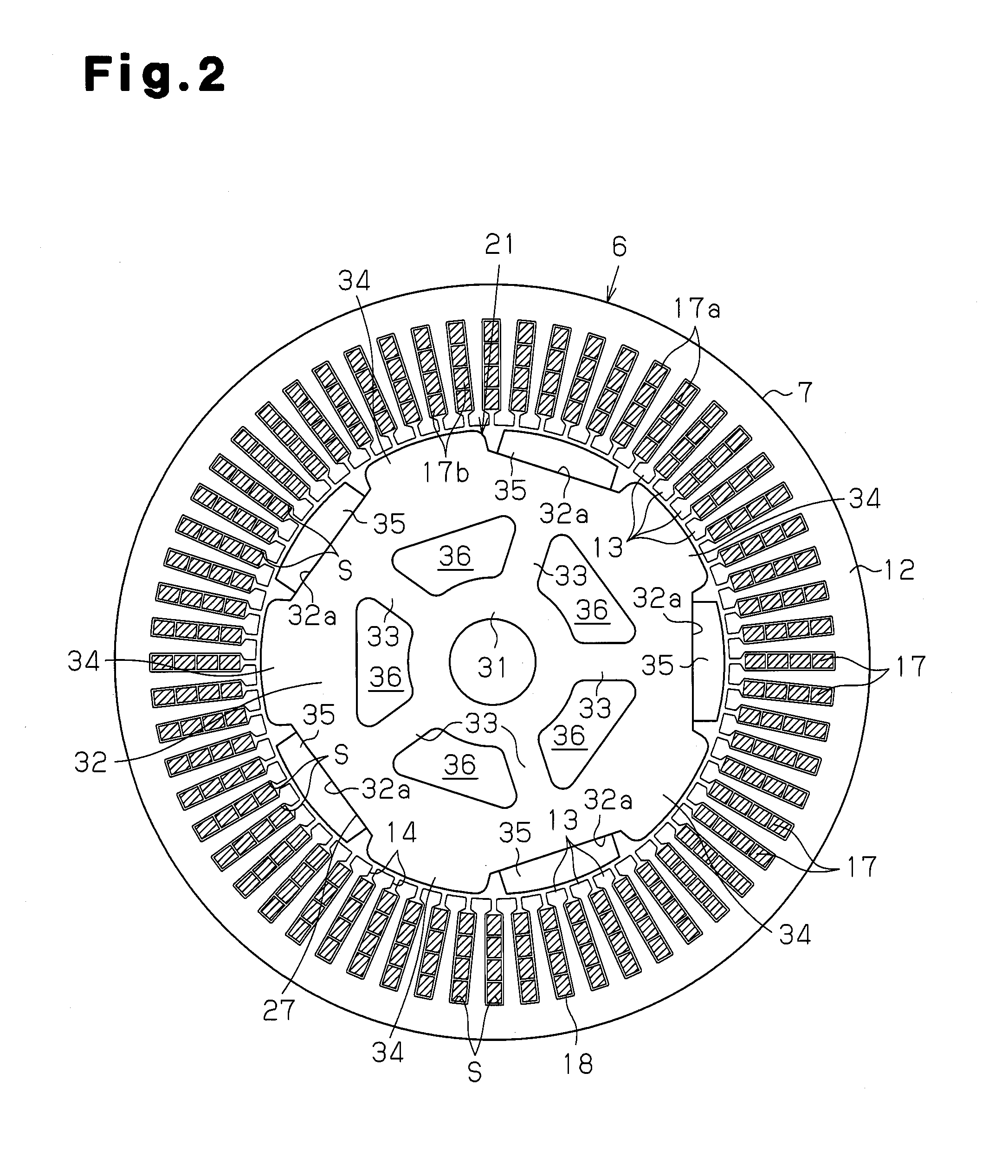

Insulating motor housing

ActiveUS20080150377A1Reduce the burden onIncrease supplyWindingsMagnetic circuit characterised by insulating materialsEngineeringElectrical and Electronics engineering

Owner:MITSUBISHI ELECTRIC CORP +2

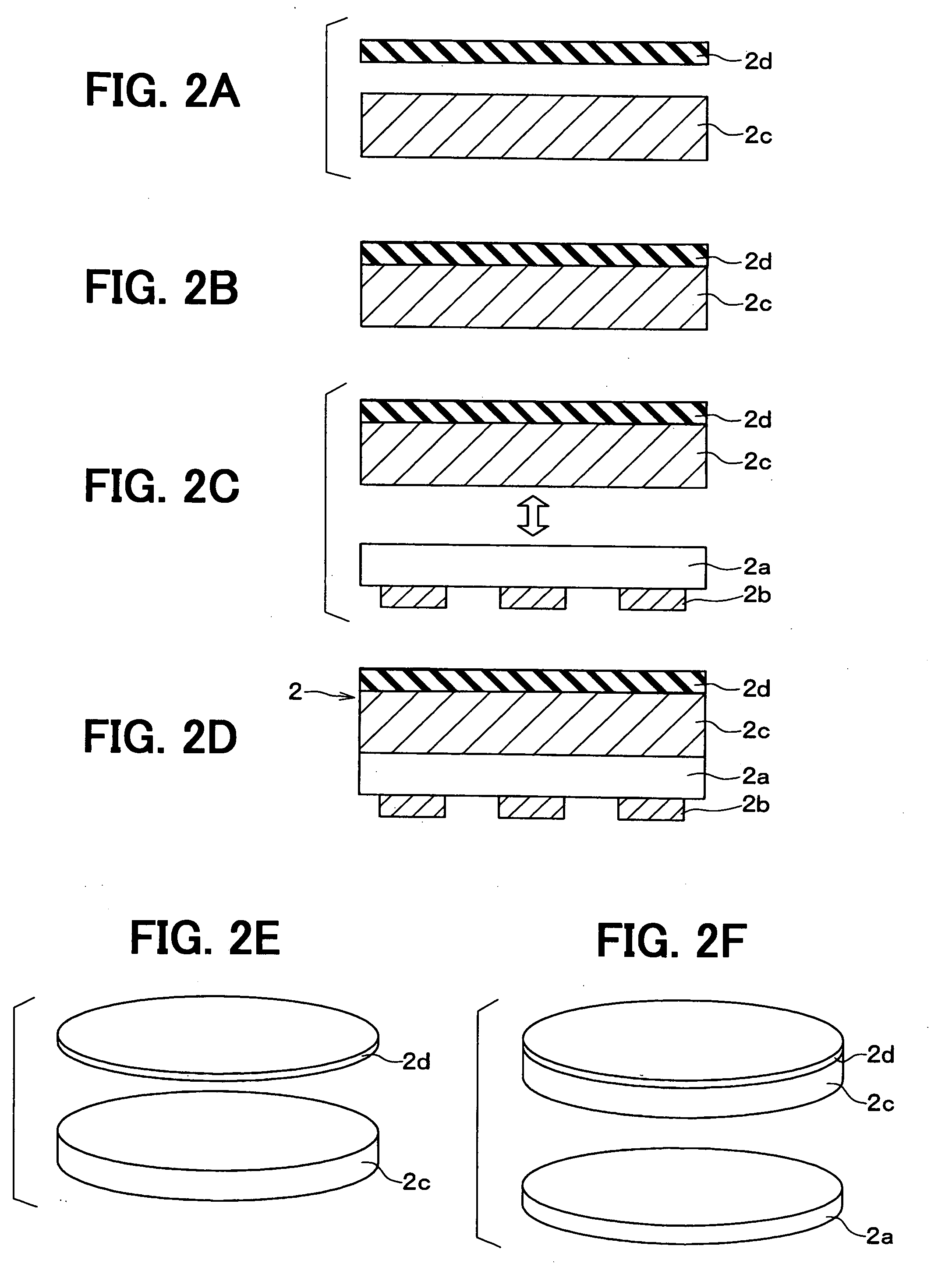

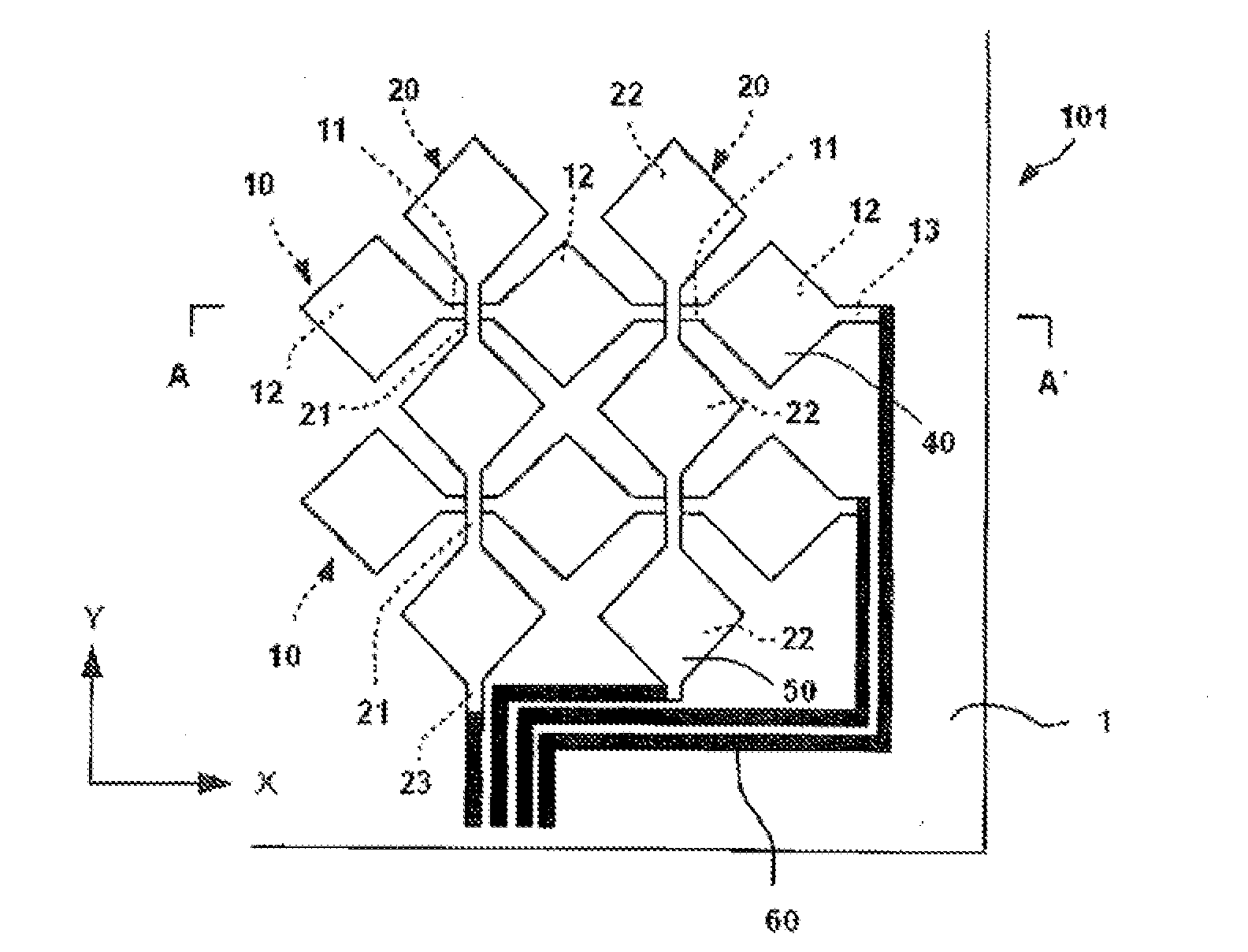

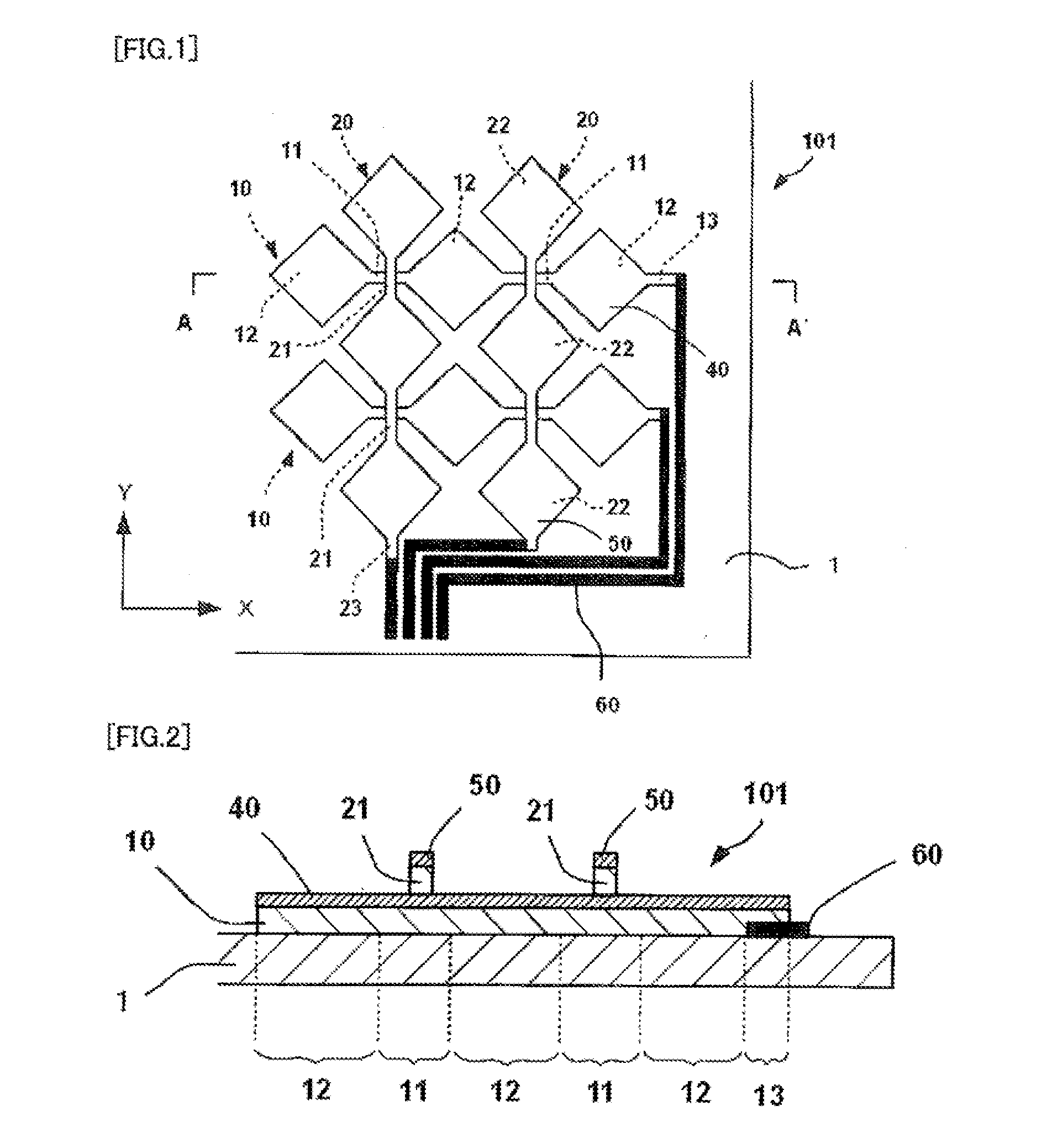

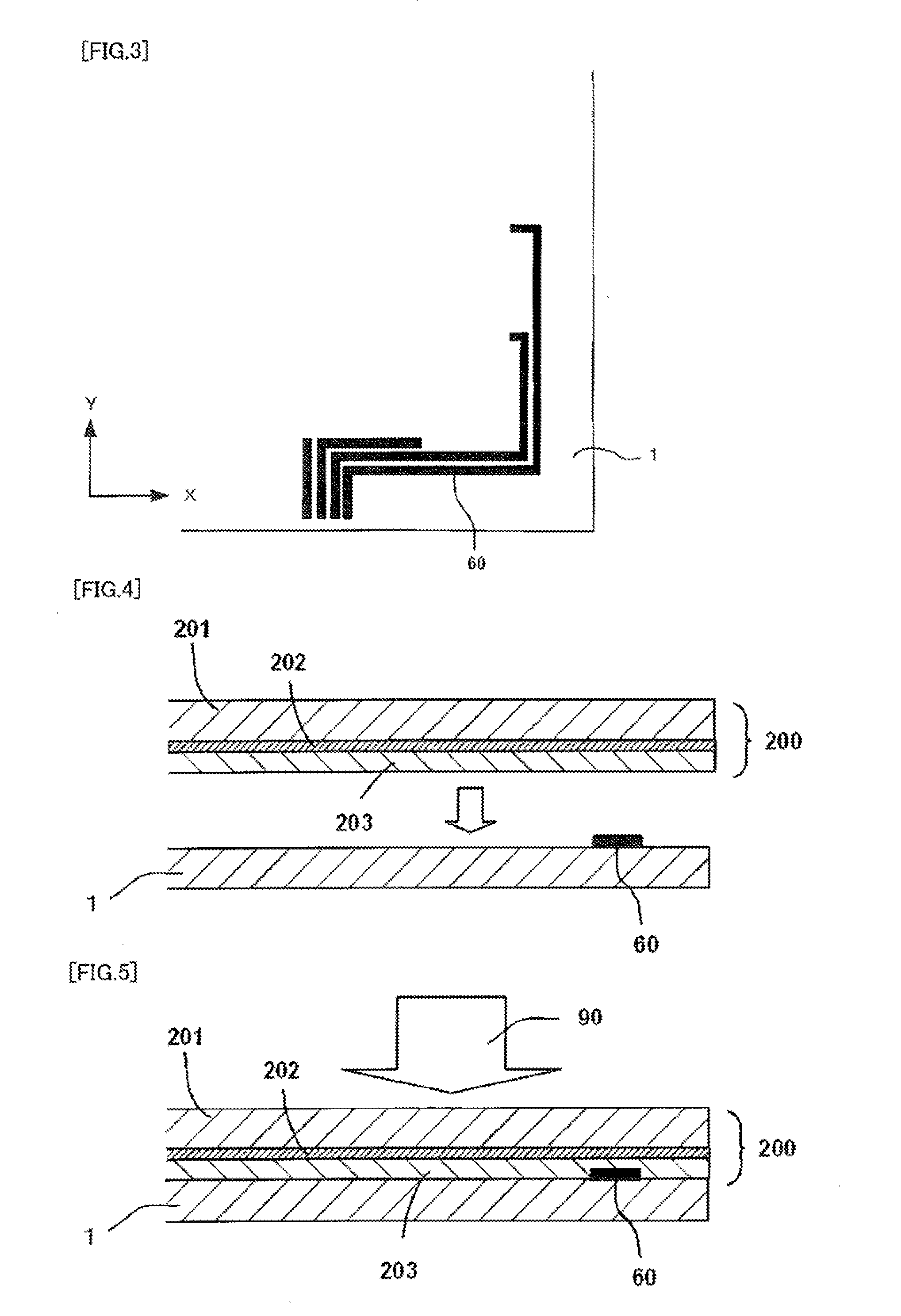

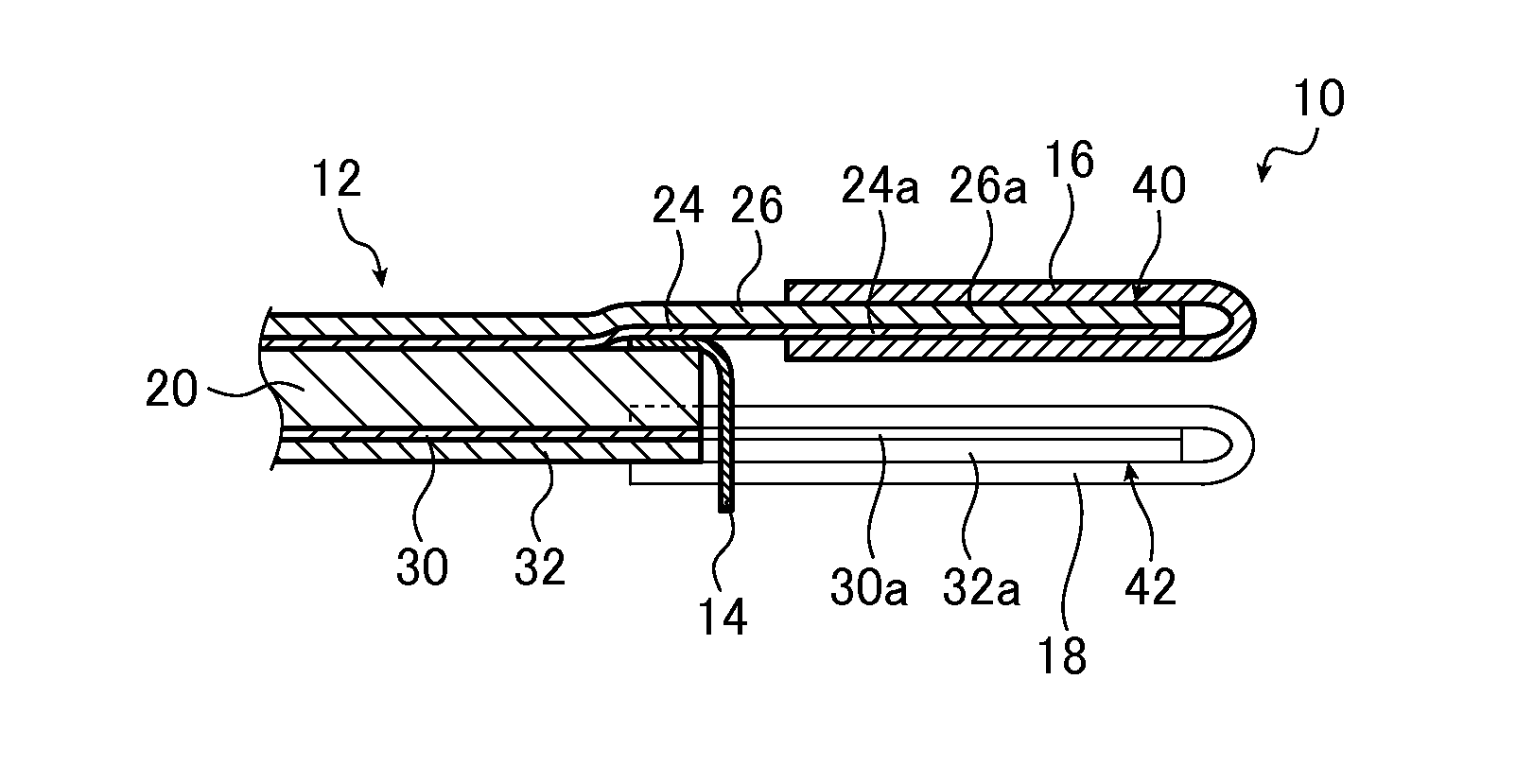

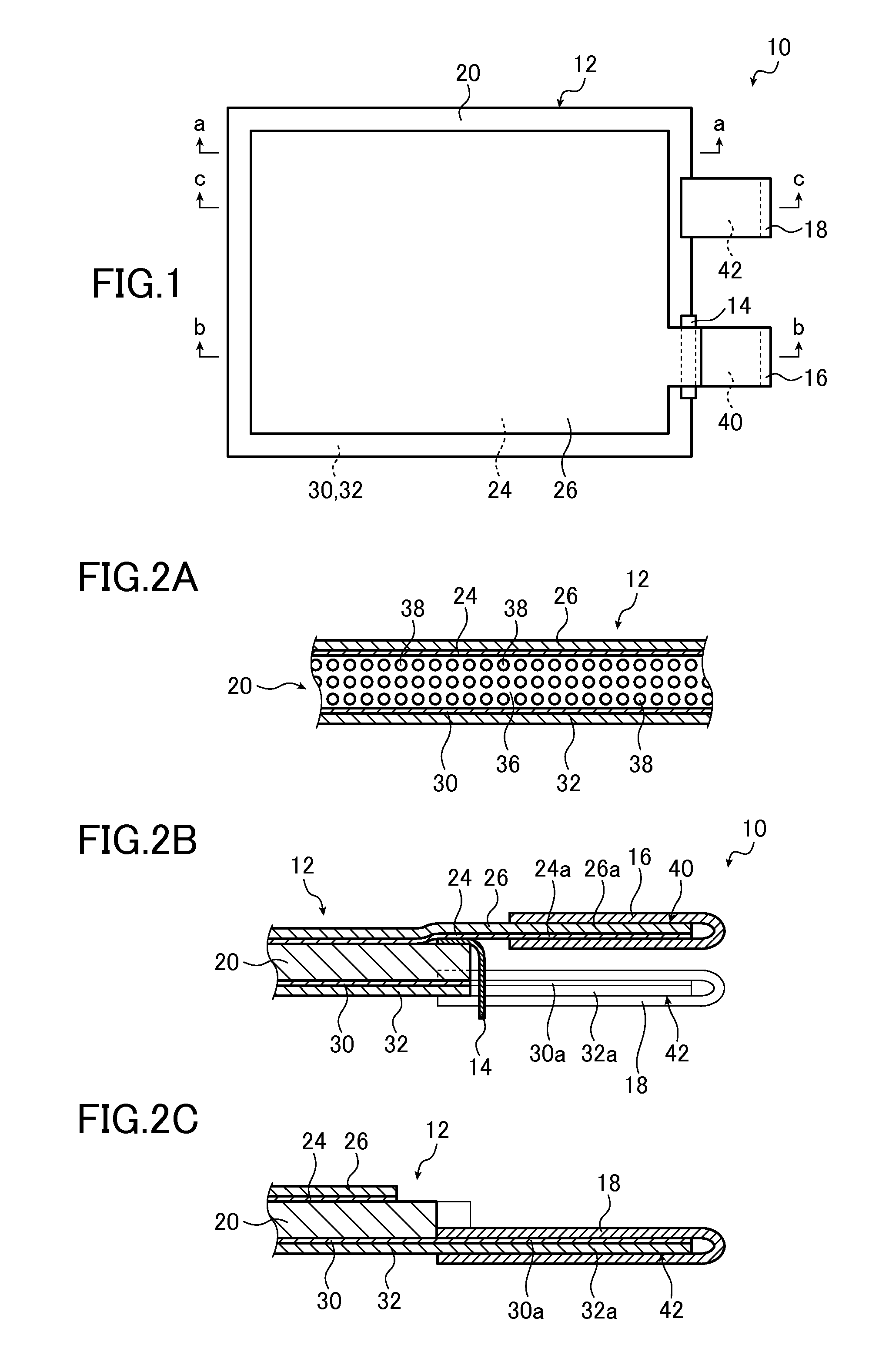

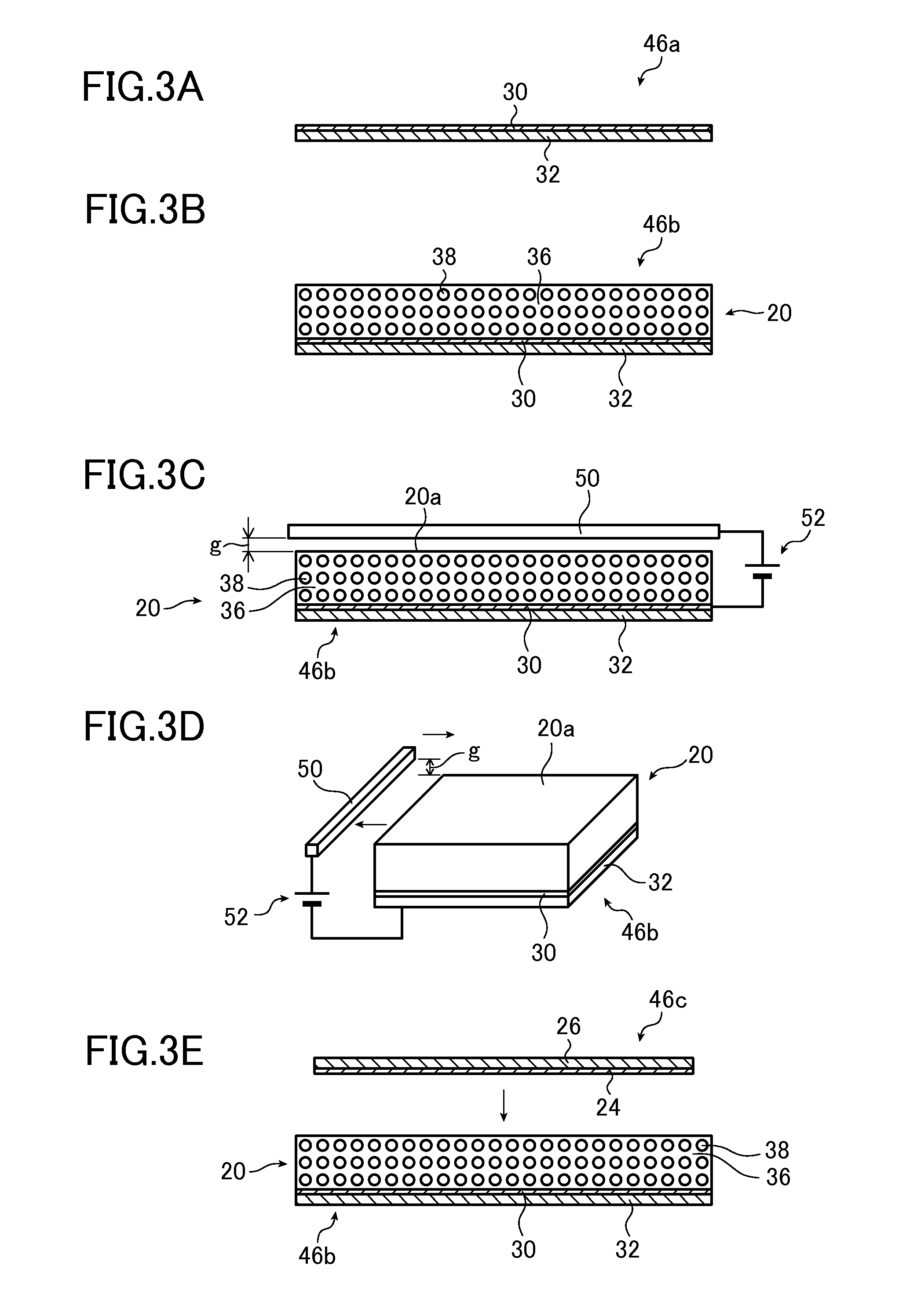

Touch sensor and manufacturing method for the same, as well as transfer ribbon for touch sensor manufacturing

InactiveUS20150041302A1Simple formPoor insulationDecorative surface effectsLaminationElectrical and Electronics engineeringElectrode

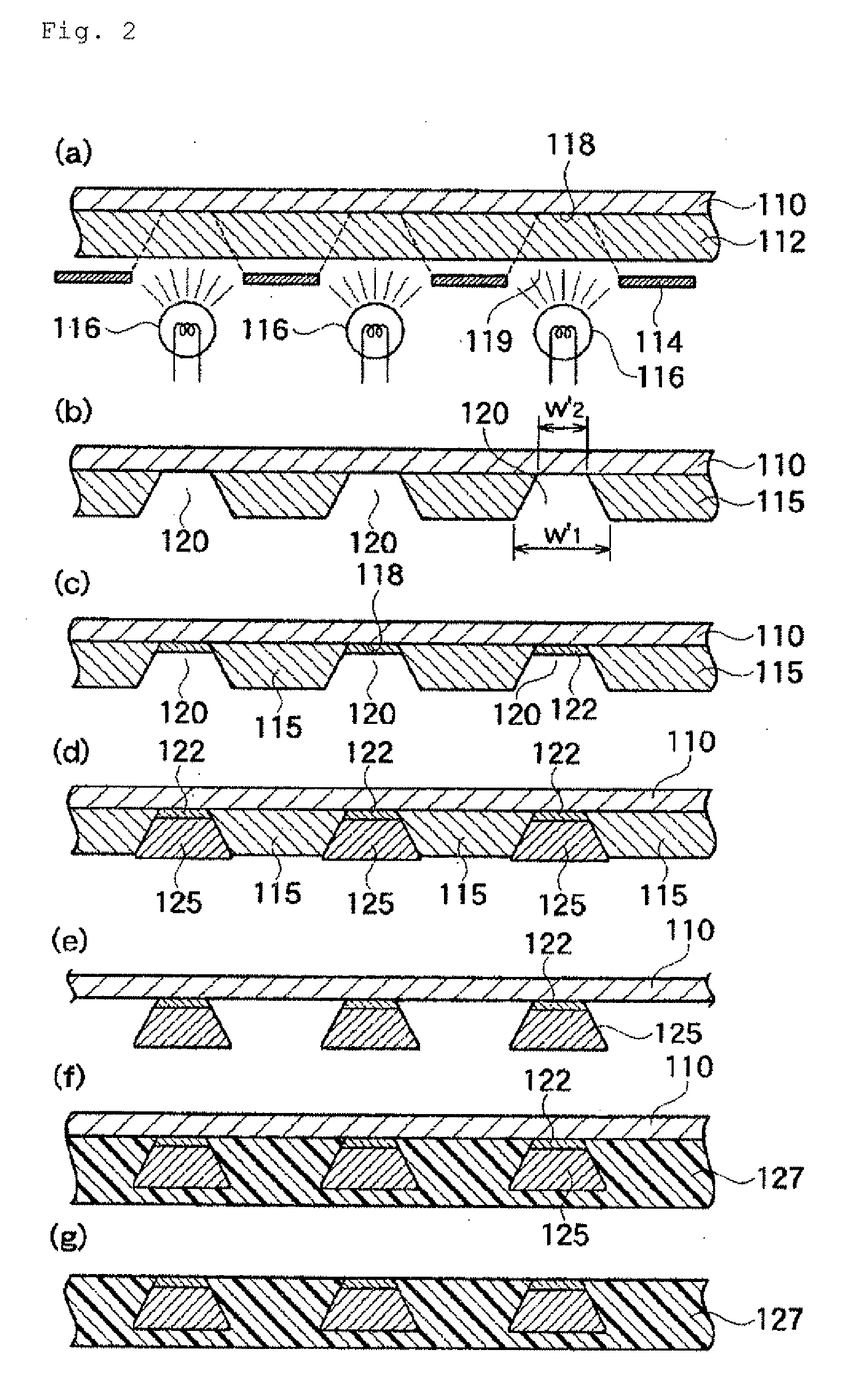

A touch sensor including a plurality of first electrode films and a plurality of second electrode films which are formed on a surface of a substrate and are arranged in different directions from each other; and a manufacturing method for the same. The manufacturing method includes: a first transfer step, which uses a transfer ribbon made by at least an insulating layer and an electrode-imparting layer which are entirely sequentially stacked as a transfer layer upon an elongated release film, attaches to a substrate only a portion of the transfer layer to which heat and pressure have been applied, and by stripping the release film, transfers the transfer layer in at least the shape of a first electrode film; and a second transfer step including attaching only the portion of the transfer layer to which the heat and the pressure had been applied and stripping the release film.

Owner:NISSHA PRINTING COMPANY

Plating method, semiconductor device fabrication method and circuit board fabrication method

InactiveUS7670940B2Well formedImprove adhesionSemiconductor/solid-state device detailsPrinted circuit aspectsResistInterconnection

The plating method comprises the step of forming a resin layer 10 over a substrate 16; the step of cutting the surface part of the resin layer 10 with a cutting tool 12; the step of forming a seed layer 36 on the resin layer 10 by electroless plating; and the step of forming a plating film 44 on the seed layer 36 by electroplating. Suitable roughness can be give to the surface of the resin layer 10, whereby the adhesion between the seed layer 36 and the resin layer 10 can be sufficiently ensured. Excessively deep pores are not formed in the surface of the resin layer 10, as are by desmearing treatment, whereby a micronized pattern of a photoresist film 40 can be formed on the resin layer 10. Thus, interconnections 44, etc. can be formed over the resin layer 10 at a narrow pitch with high reliability ensured.

Owner:FUJITSU LTD

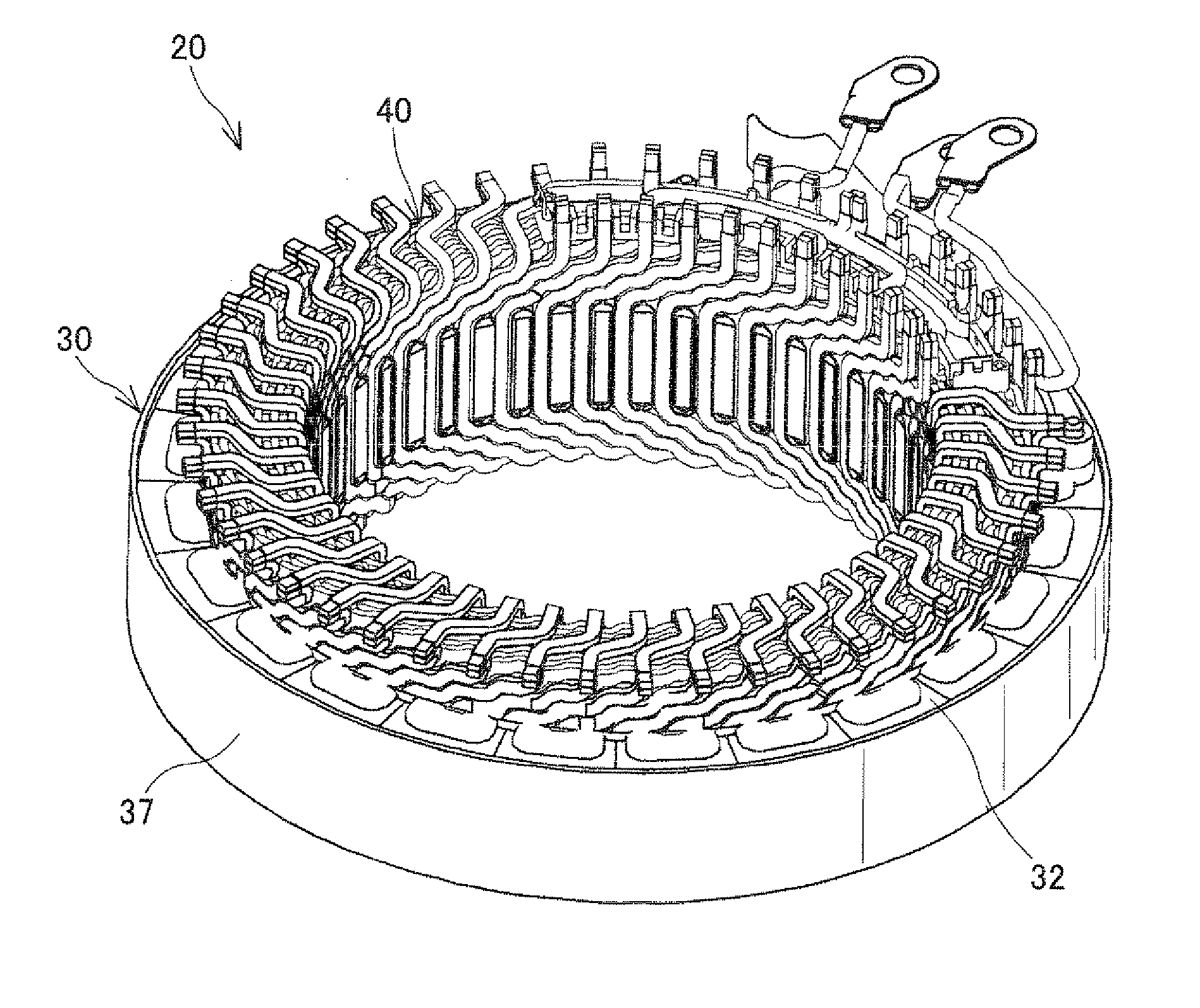

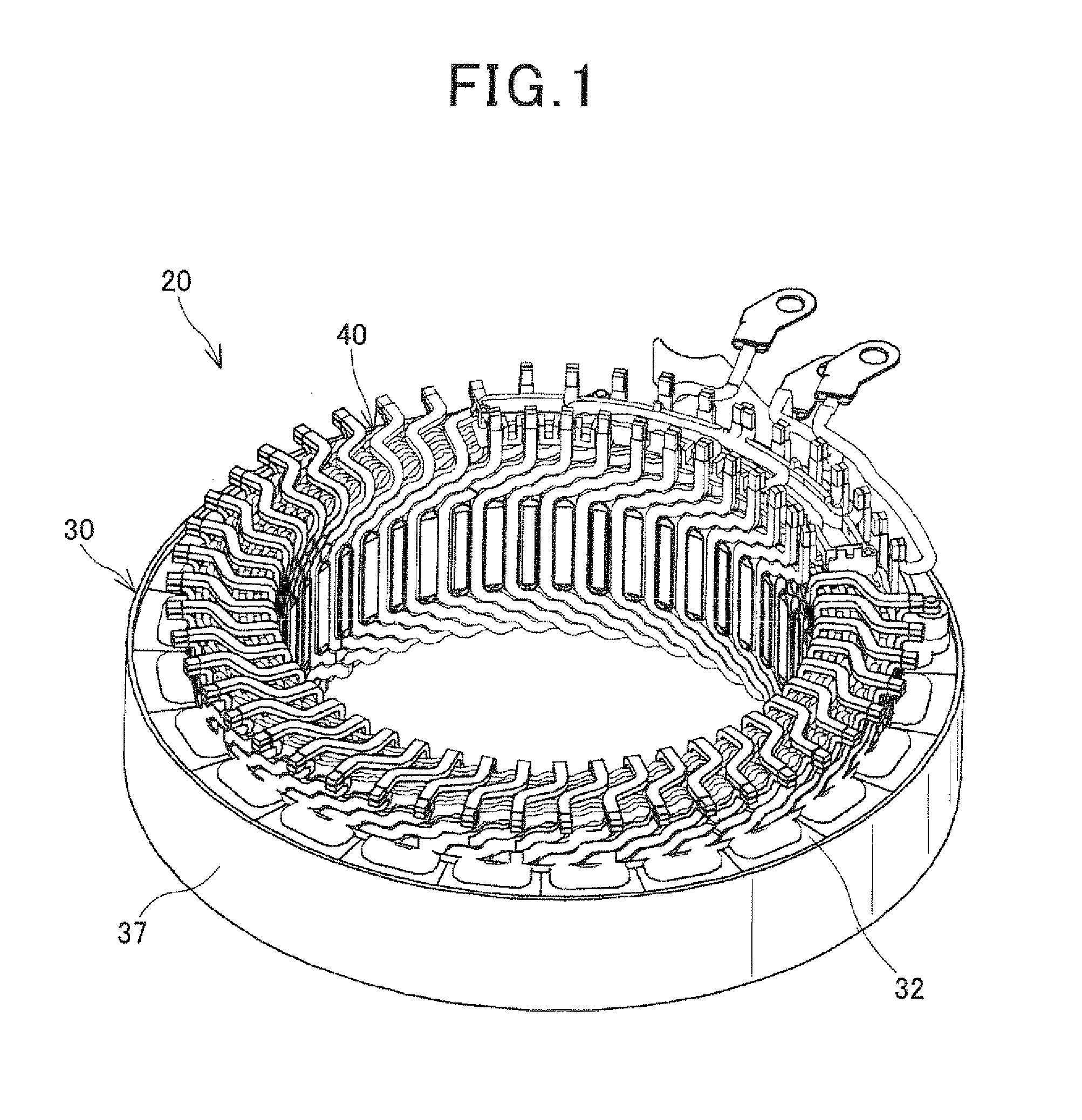

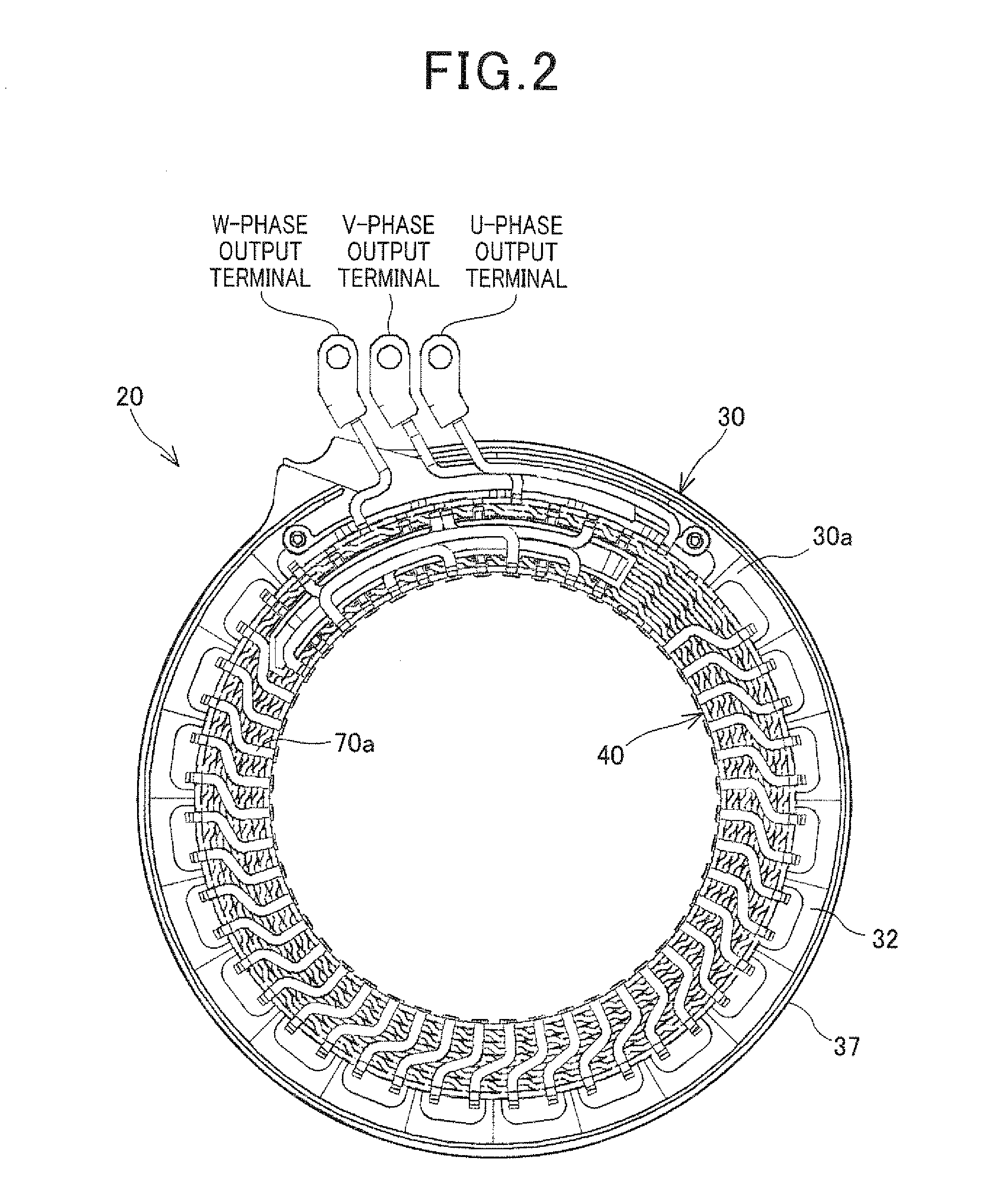

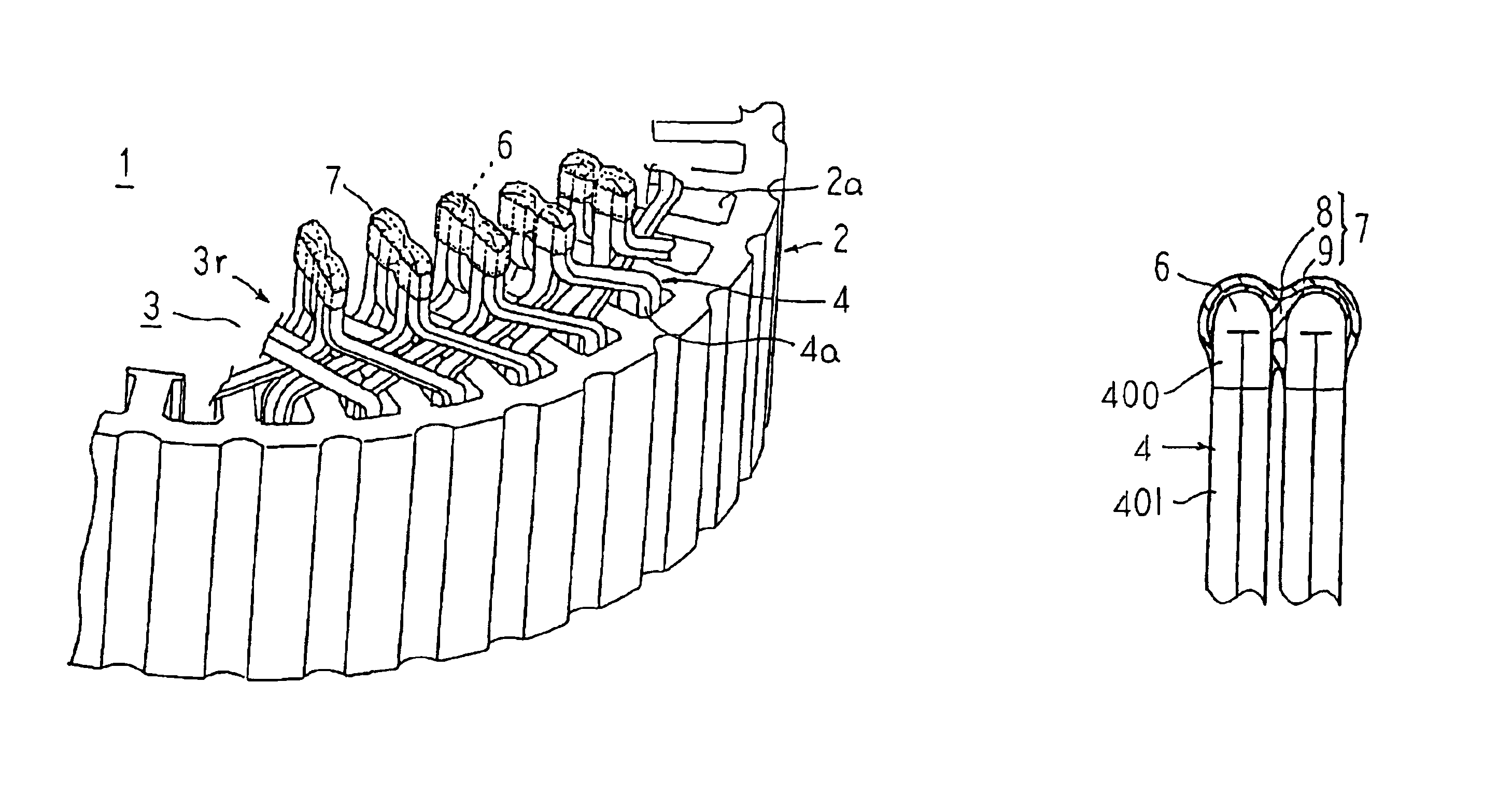

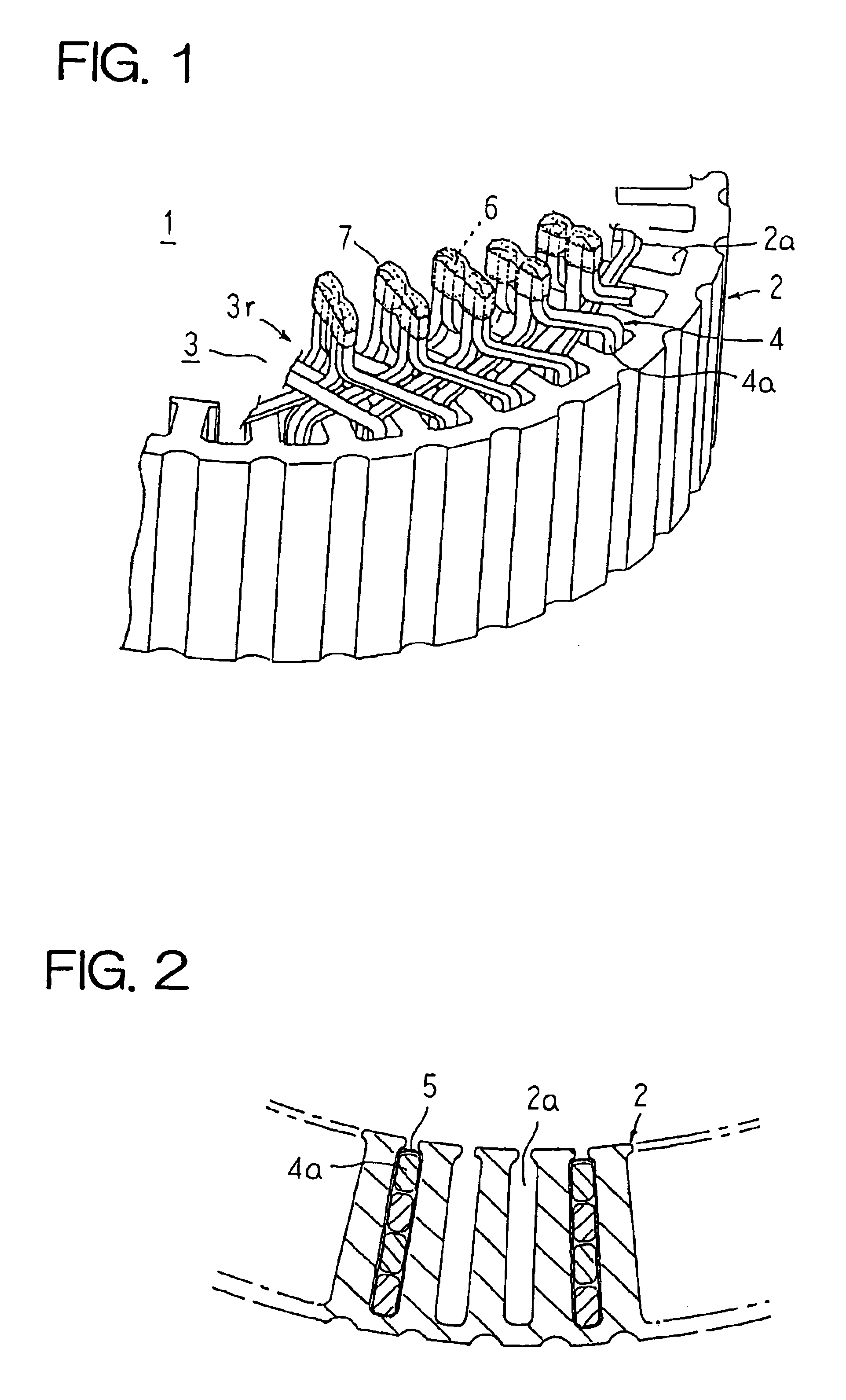

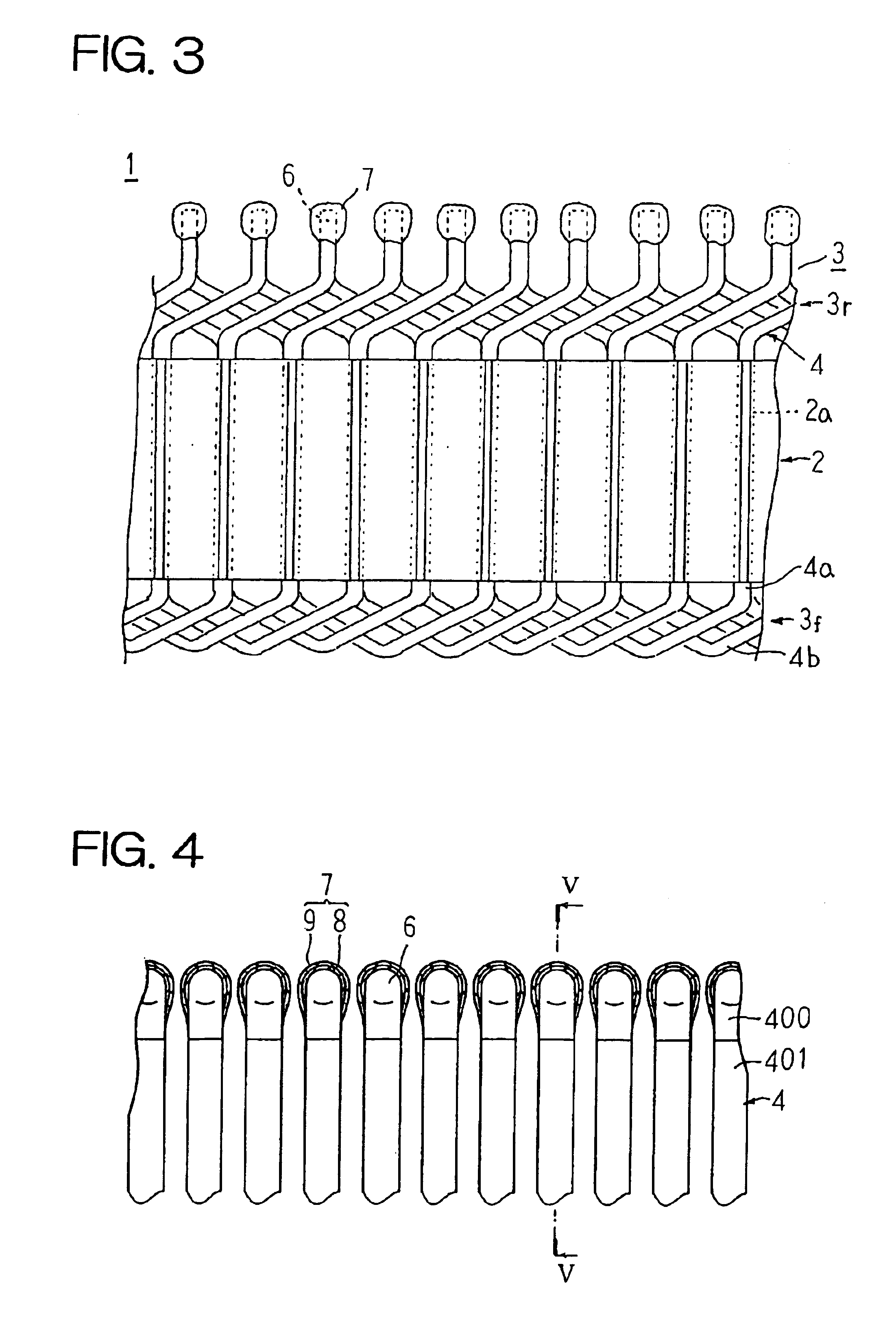

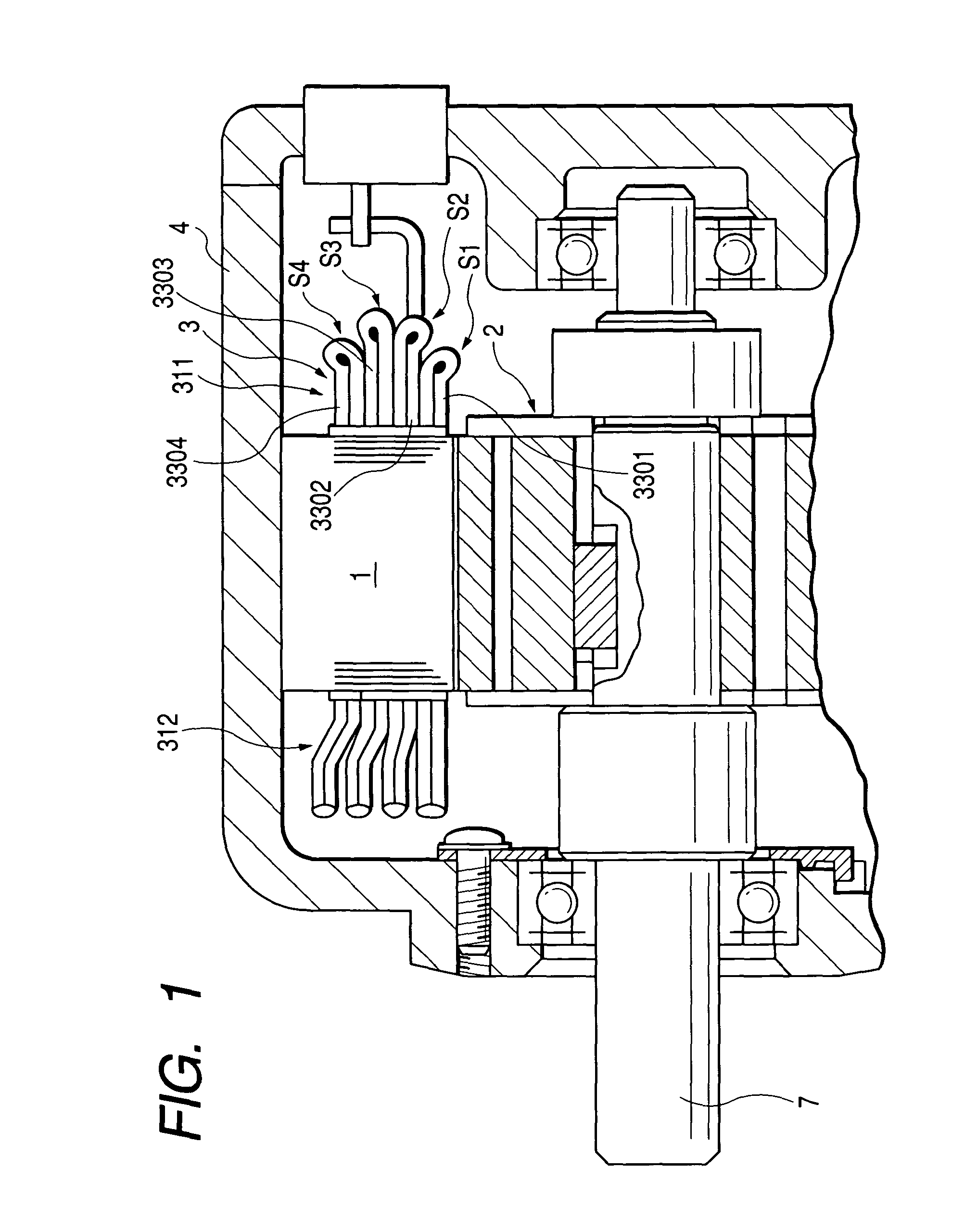

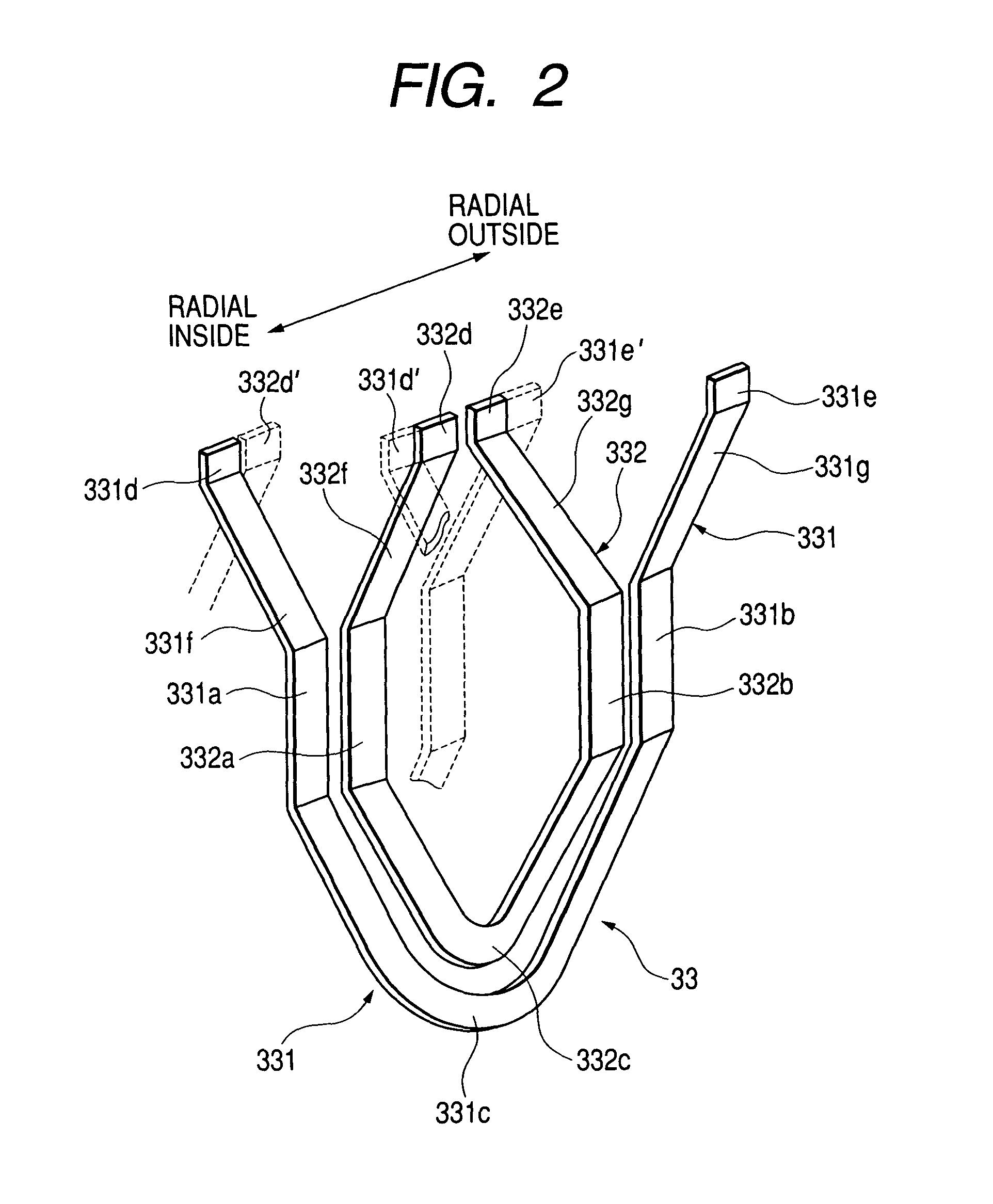

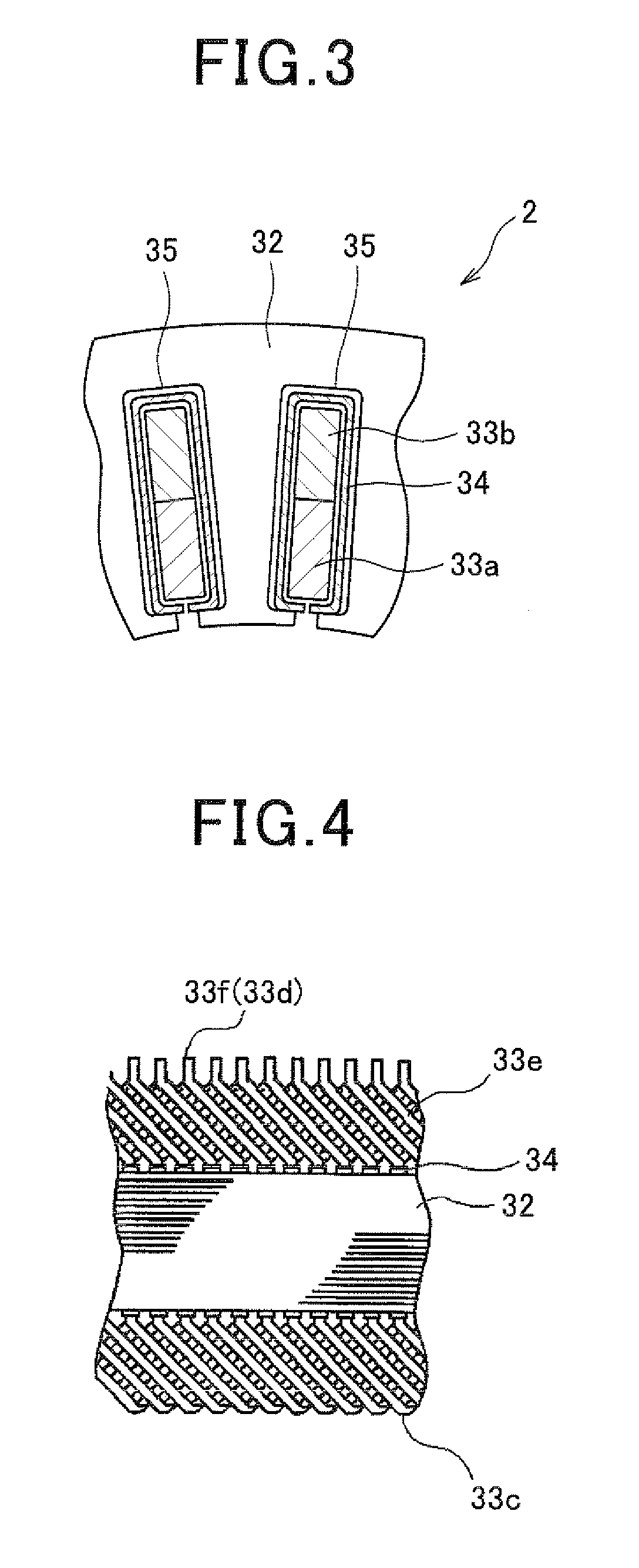

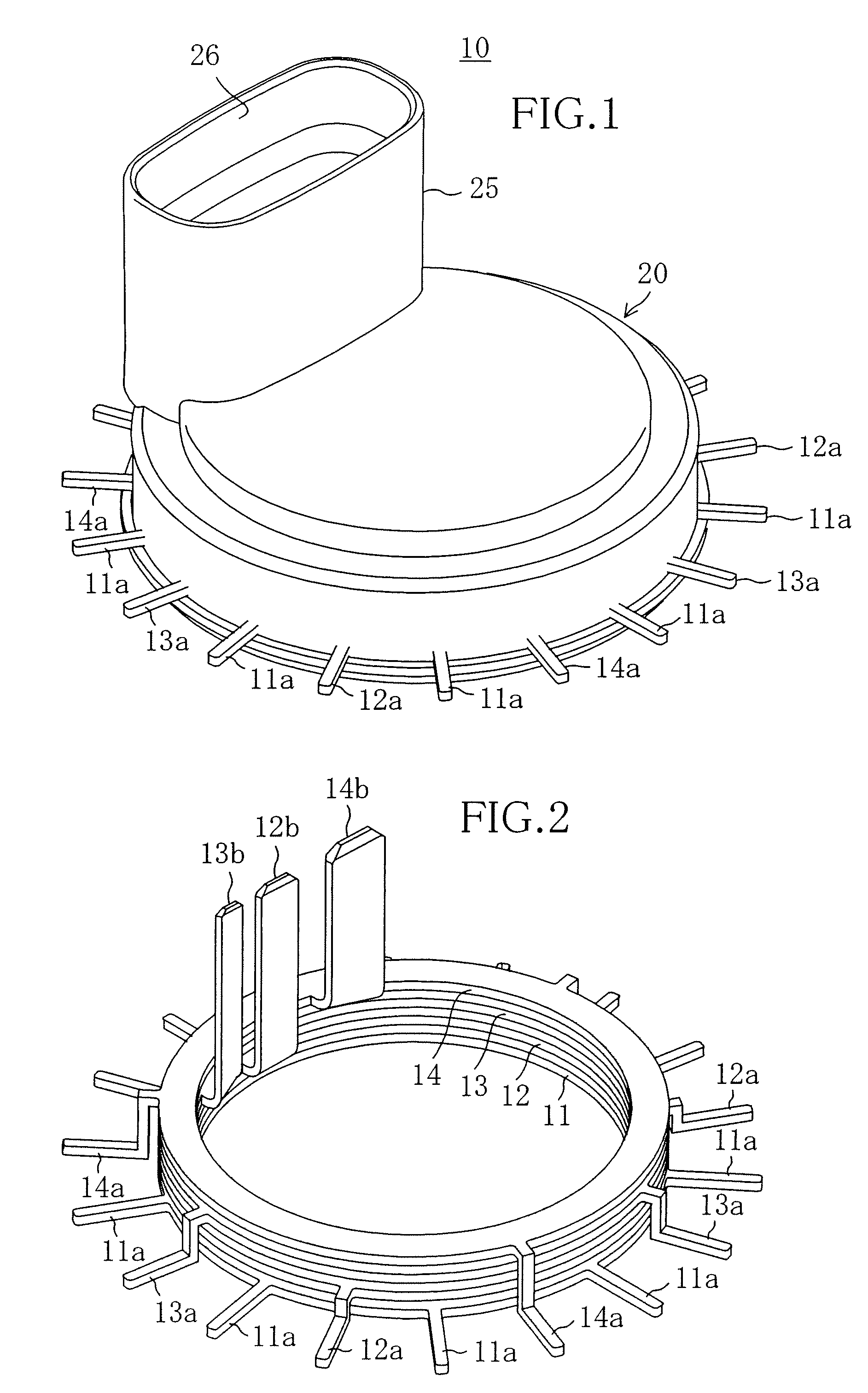

Stator for electric rotating machine

ActiveUS20110175483A1Prevent peelingEnsure insulationSynchronous machinesAsynchronous induction motorsCross overEngineering

A stator includes a stator coil formed of electric wires which include a joined pair of first and second electric wires. The first electric wire has a lead portion led out from the radially inner periphery of a first slot of a stator core and including a crossover part. The crossover part crosses over an axial end face of an end part of the stator coil from the radially inside to the radially outside of the axial end face; the end part protrudes from an axial end face of the stator core. The second electric wire has a lead portion led out from the radially outer periphery of a second slot of the stator core. The lead portions of the electric wires are joined together with a joint formed therebetween. The joint is positioned closer to the axial end face of the stator core than the crossover part is.

Owner:DENSO CORP

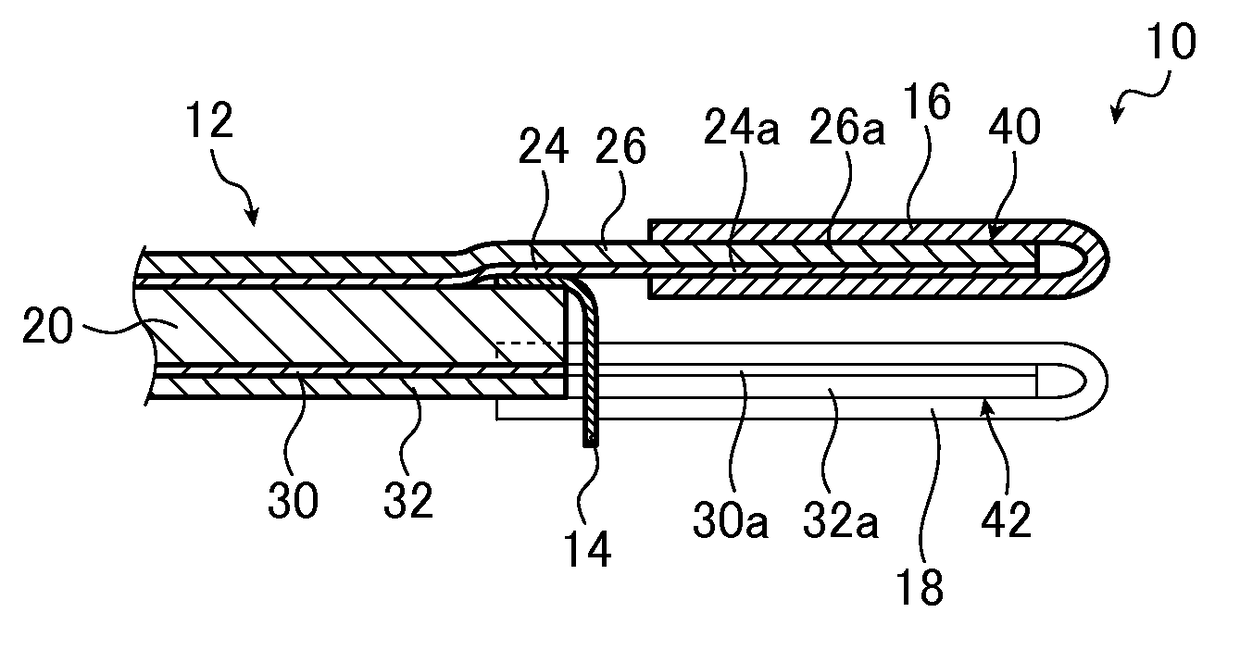

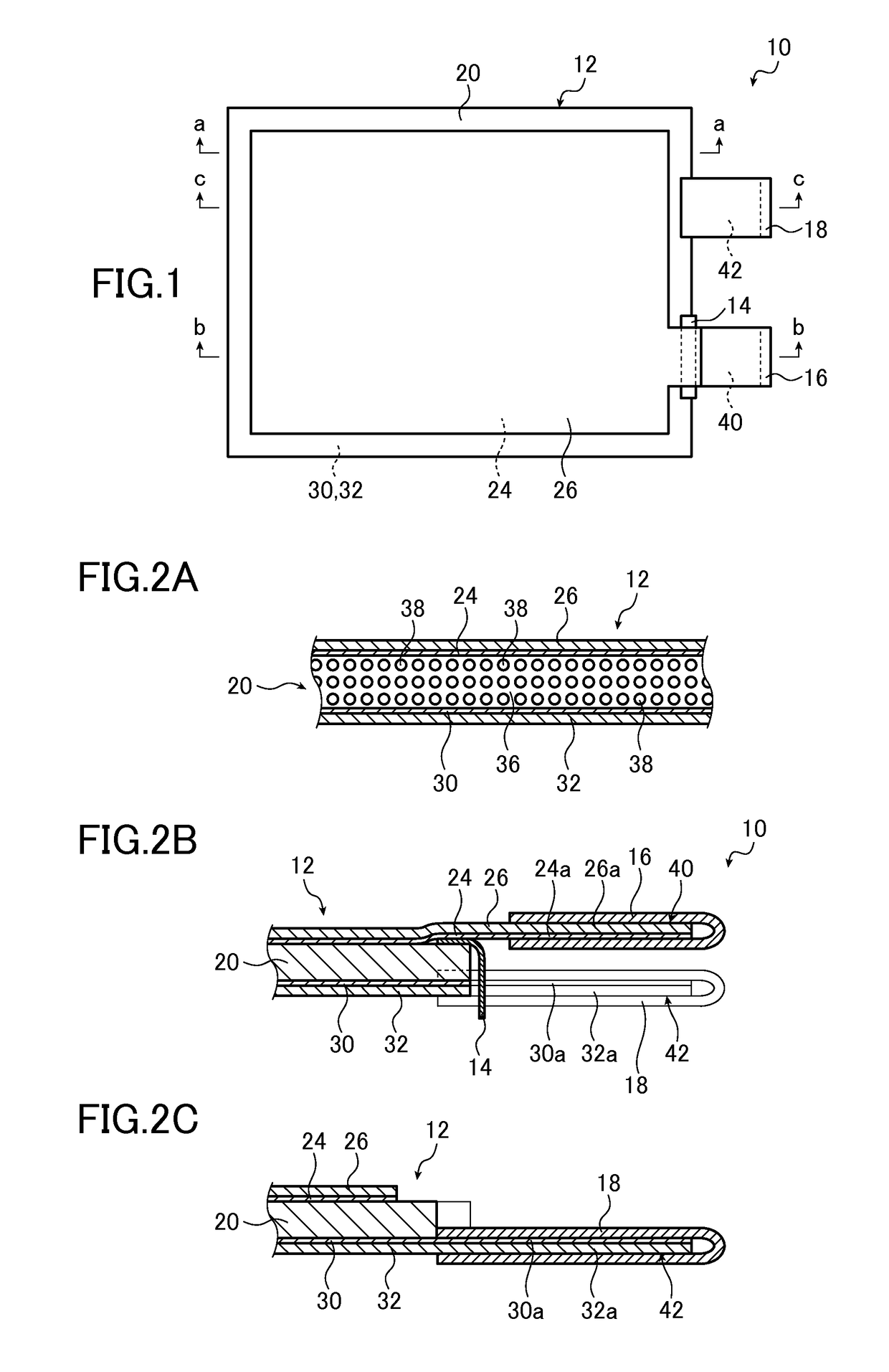

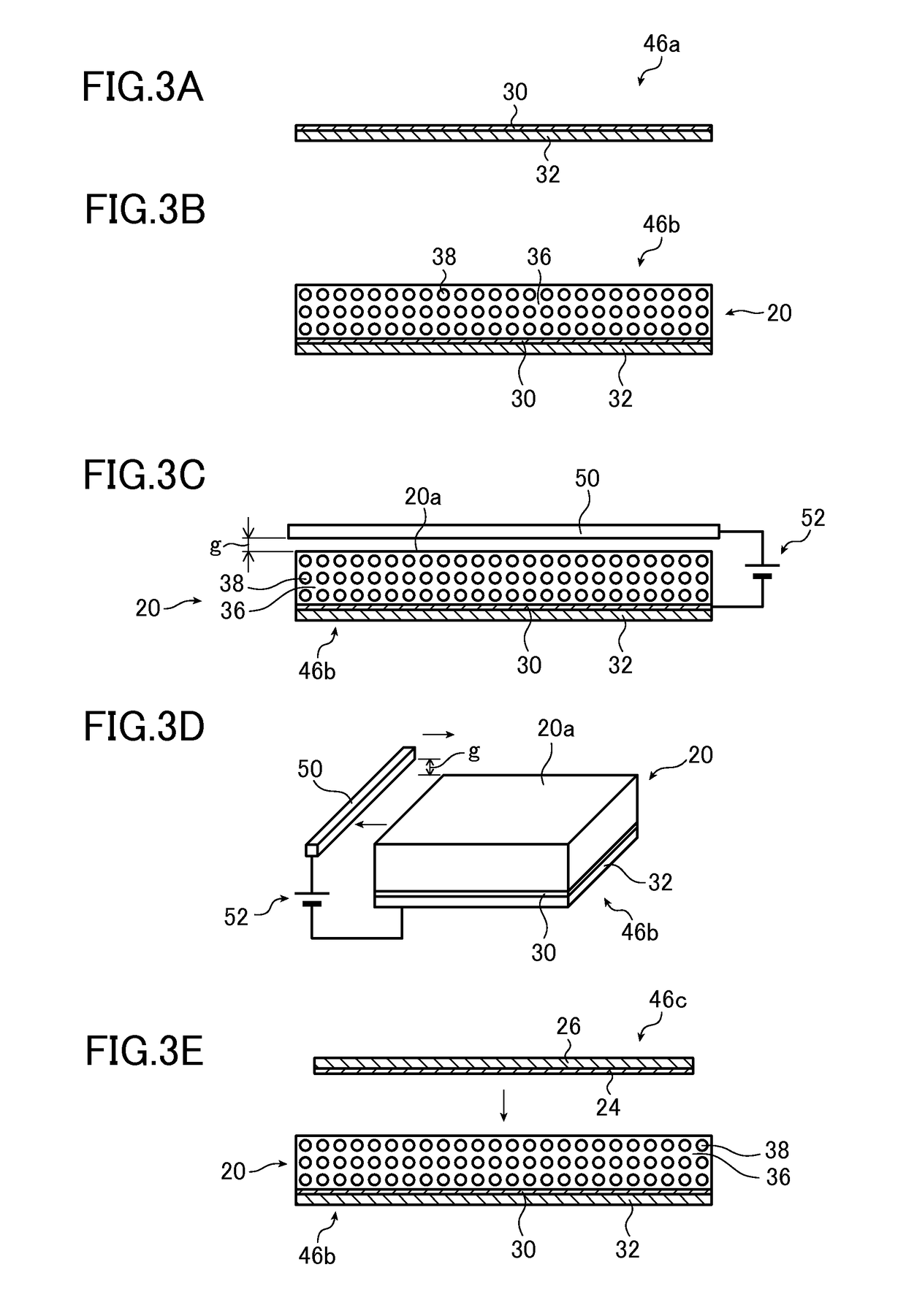

Electroacoustic converter film

ActiveUS9635467B2Minimum of mechanical strengthEasy to operatePiezoelectric/electrostrictive microphonesLoudspeakersThin film electrodeMetal foil

Provided is an electroacoustic converter film including thin film electrodes provided on both surfaces of a polymeric composite piezoelectric body in which piezoelectric body particles are dispersed in a viscoelastic matrix formed of a polymer material that exhibits viscoelasticity at normal temperature, and protective layers formed on the thin film electrodes. The electroacoustic converter film further includes electrode lead-out metal foils laminated on the thin film electrodes, and the electrode lead-out metal foils allows connection to wiring through soldering when electrodes are led out from the thin film electrodes.

Owner:FUJIFILM CORP

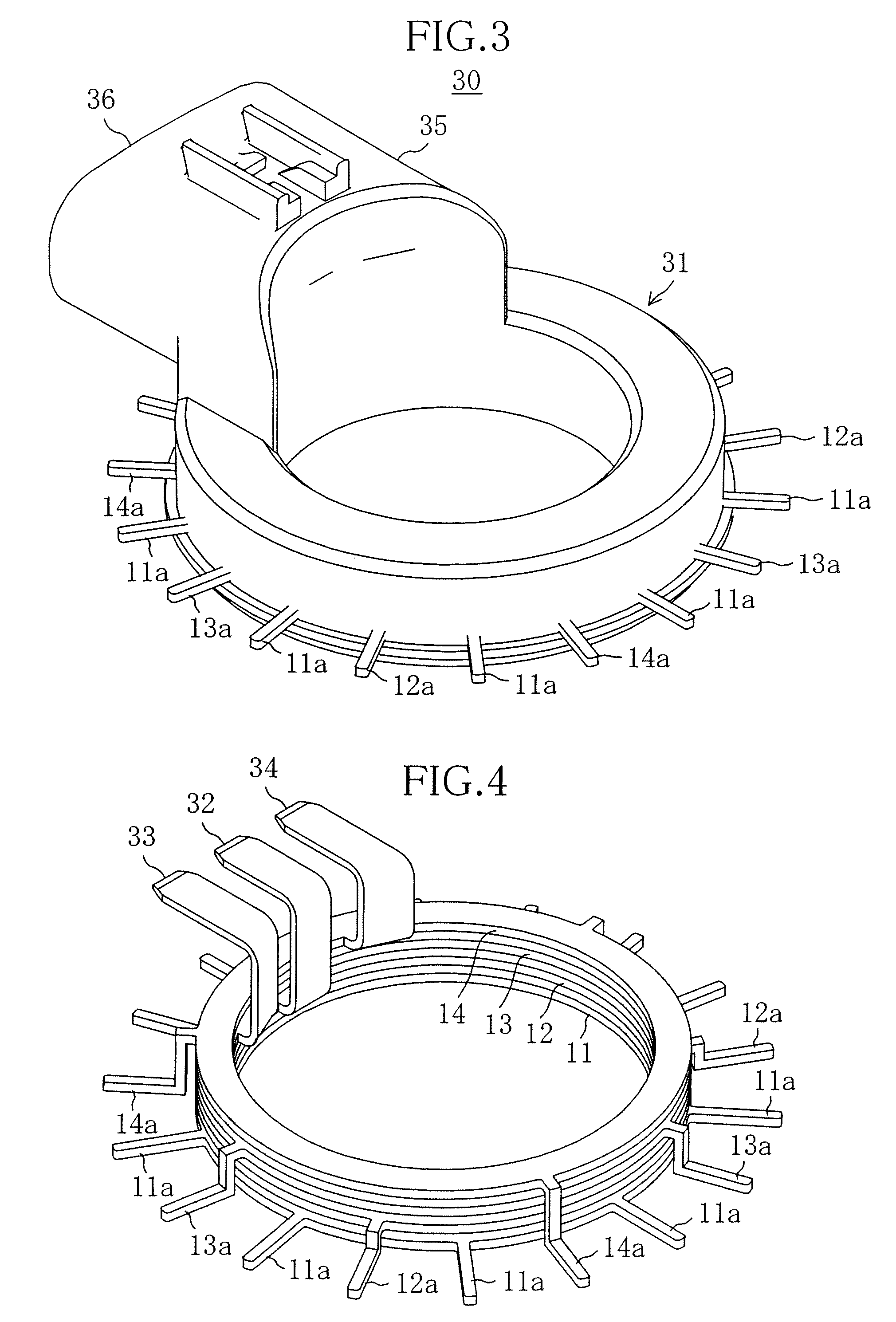

Stator for a dynamoelectric machine

InactiveUS6943466B2Reduce electromagnetic noiseImprove rigiditySynchronous generatorsWindings insulation shape/form/constructionEngineeringConductor Coil

A stator winding is prepared by inserting U-shaped conductor segments into pairs of slots from a first end surface end of a stator core and welding together end portions of the conductor segments projecting outward at a second end surface end of the stator core. Joint portions between the end portions of the conductor segments are arranged into two rows in an annular shape in a circumferential direction at the second end surface end of the stator core. A first electrically-insulating layer is formed by applying an epoxy resin so as to cover each of the joint portions and to bridge radially-adjacent pairs of the joint portions. A second electrically-insulating layer is formed by applying a silicone resin so as to cover the first electrically-insulating layer and to extend to an electrically-insulating coating on the conductor segments.

Owner:MITSUBISHI ELECTRIC CORP

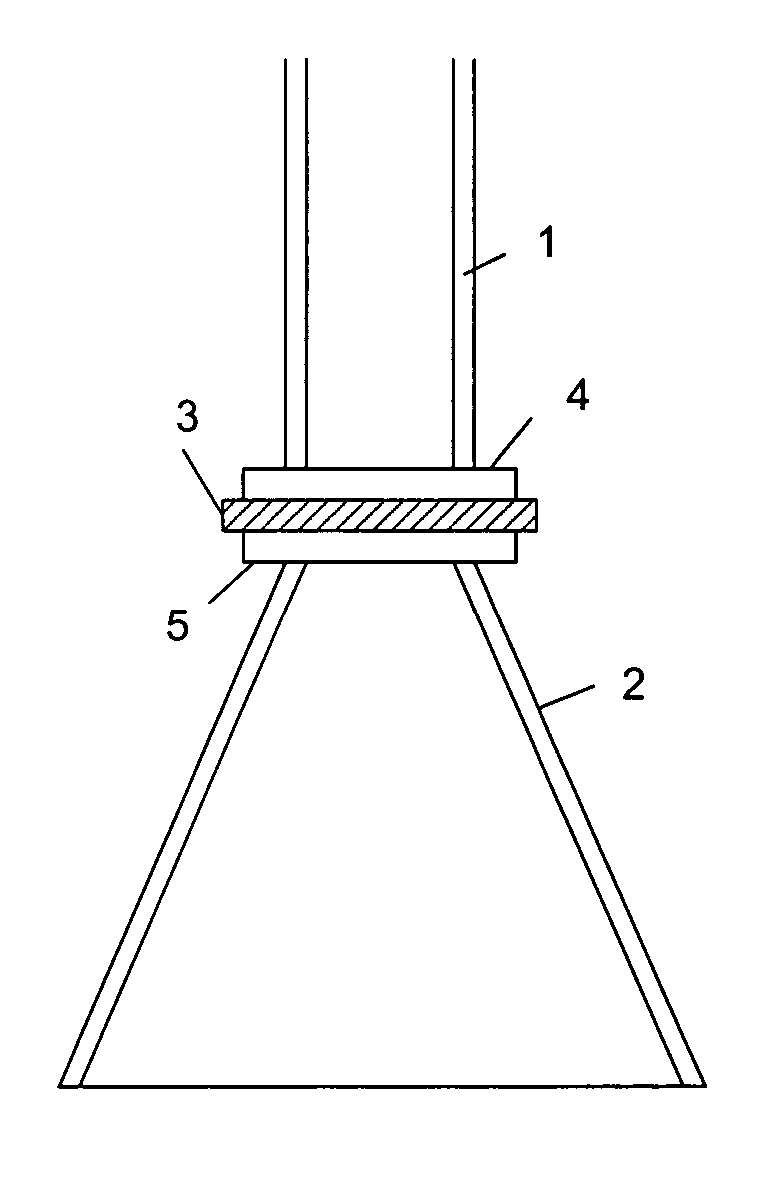

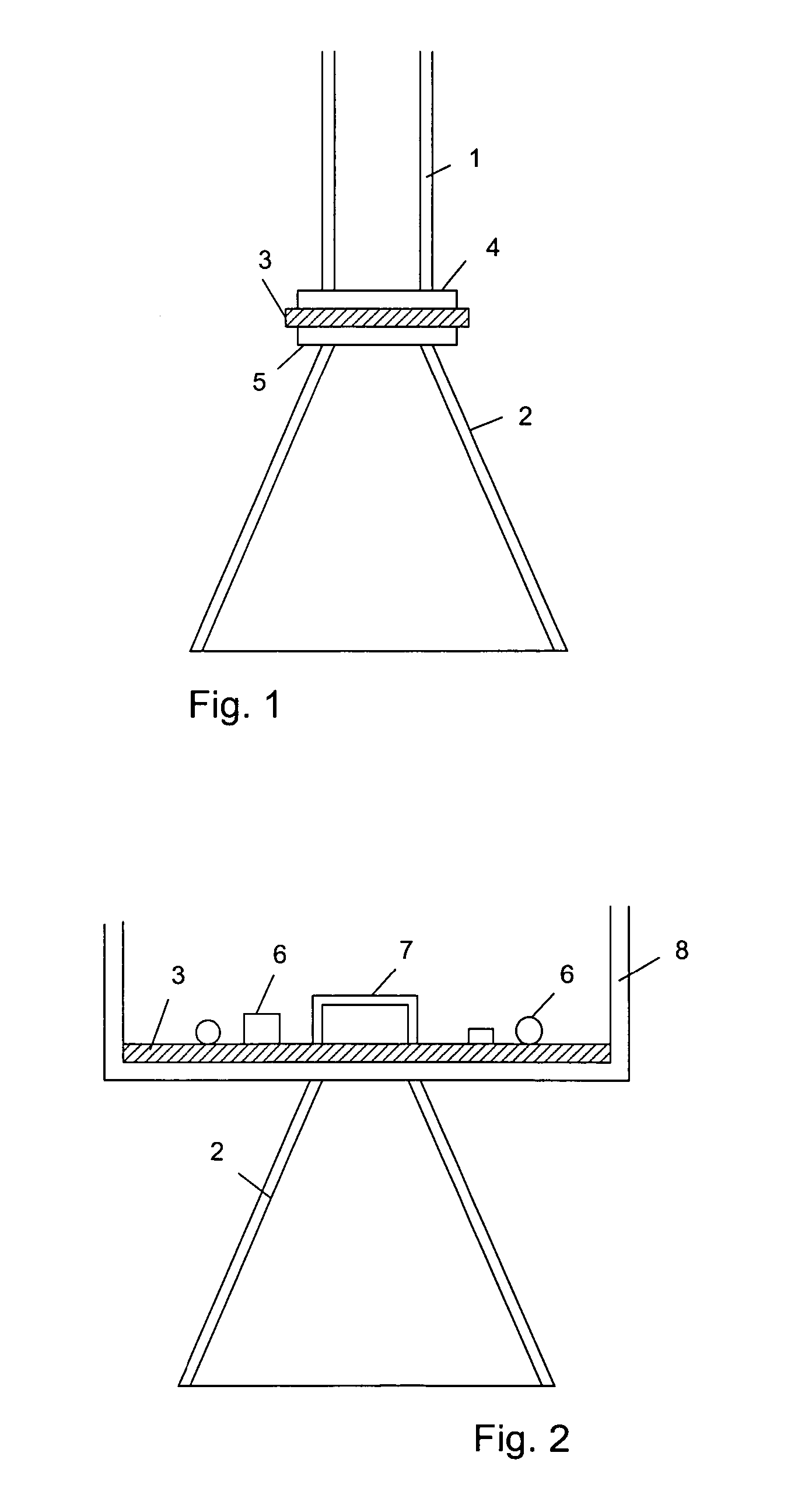

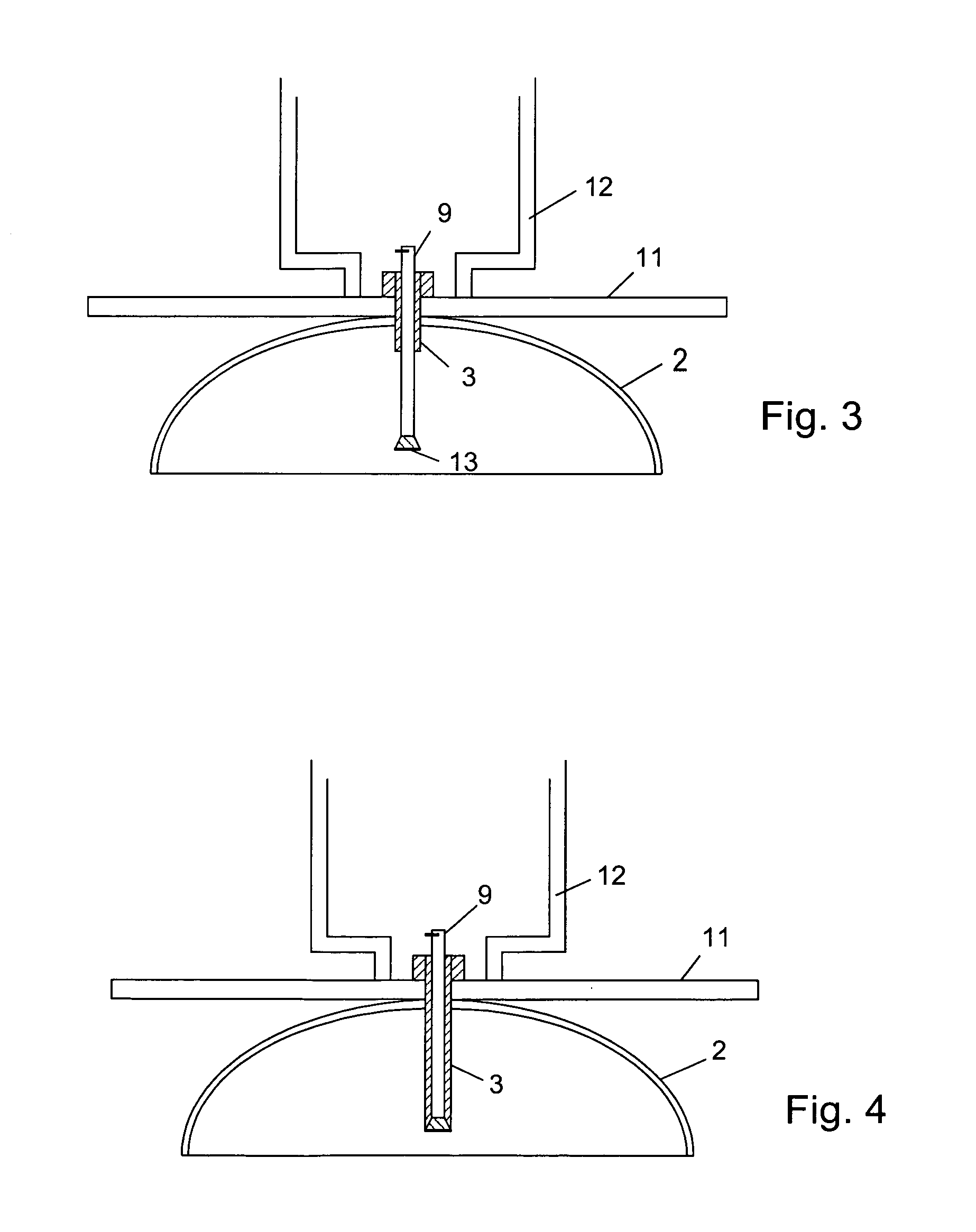

Potential separation for fill level radar

For safety reasons the potential of an electrical supply line of a radar sensor may be separated from the potential of the fill level container. A fill level radar with potential separation includes a separation element for insulating the aerial from a feed device. The separation element is arranged directly at the aerial, or forms part of the aerial. In this way insulation of the aerial from the exterior of the container is provided.

Owner:VEGA GRIESHABER GMBH & CO

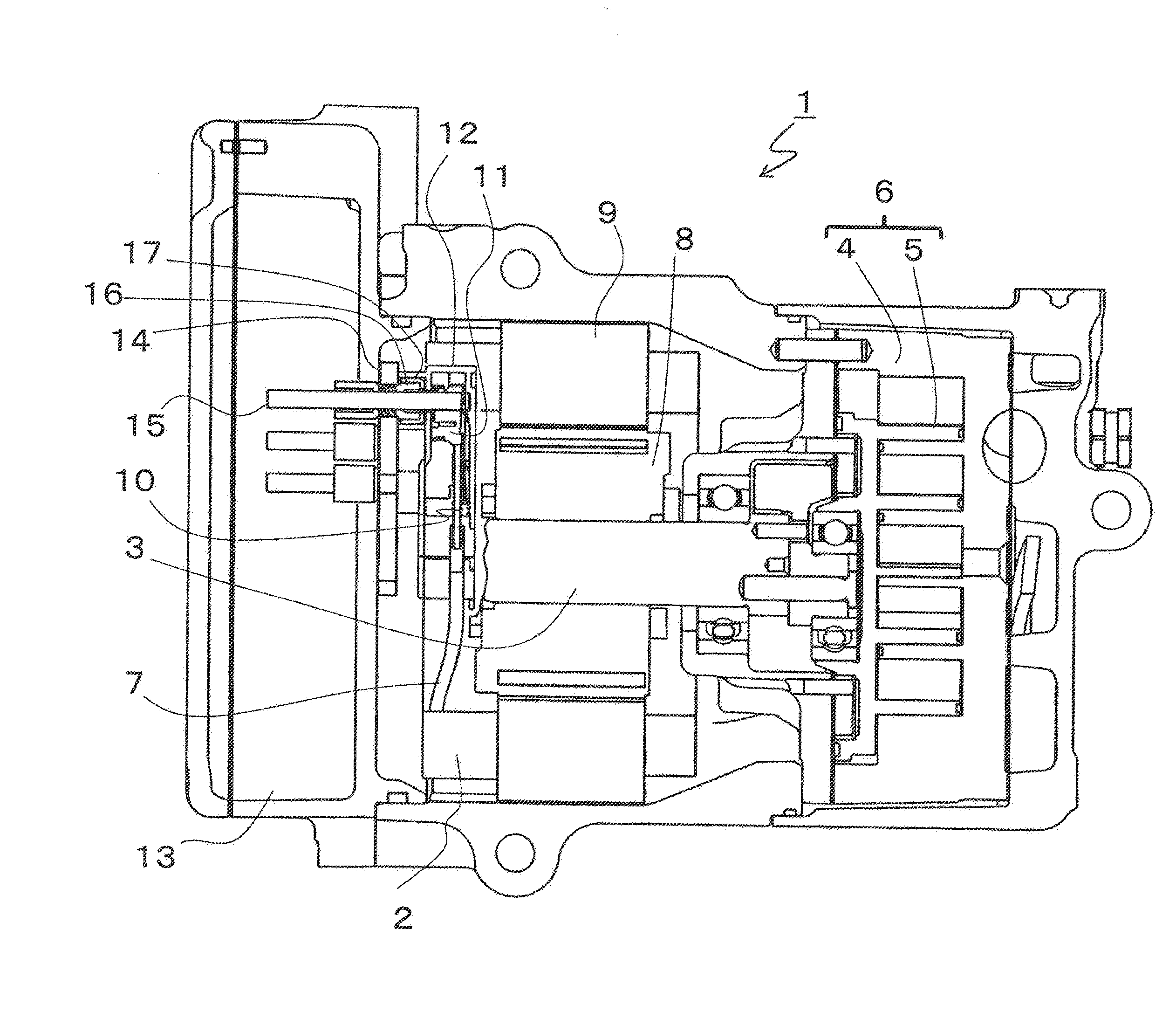

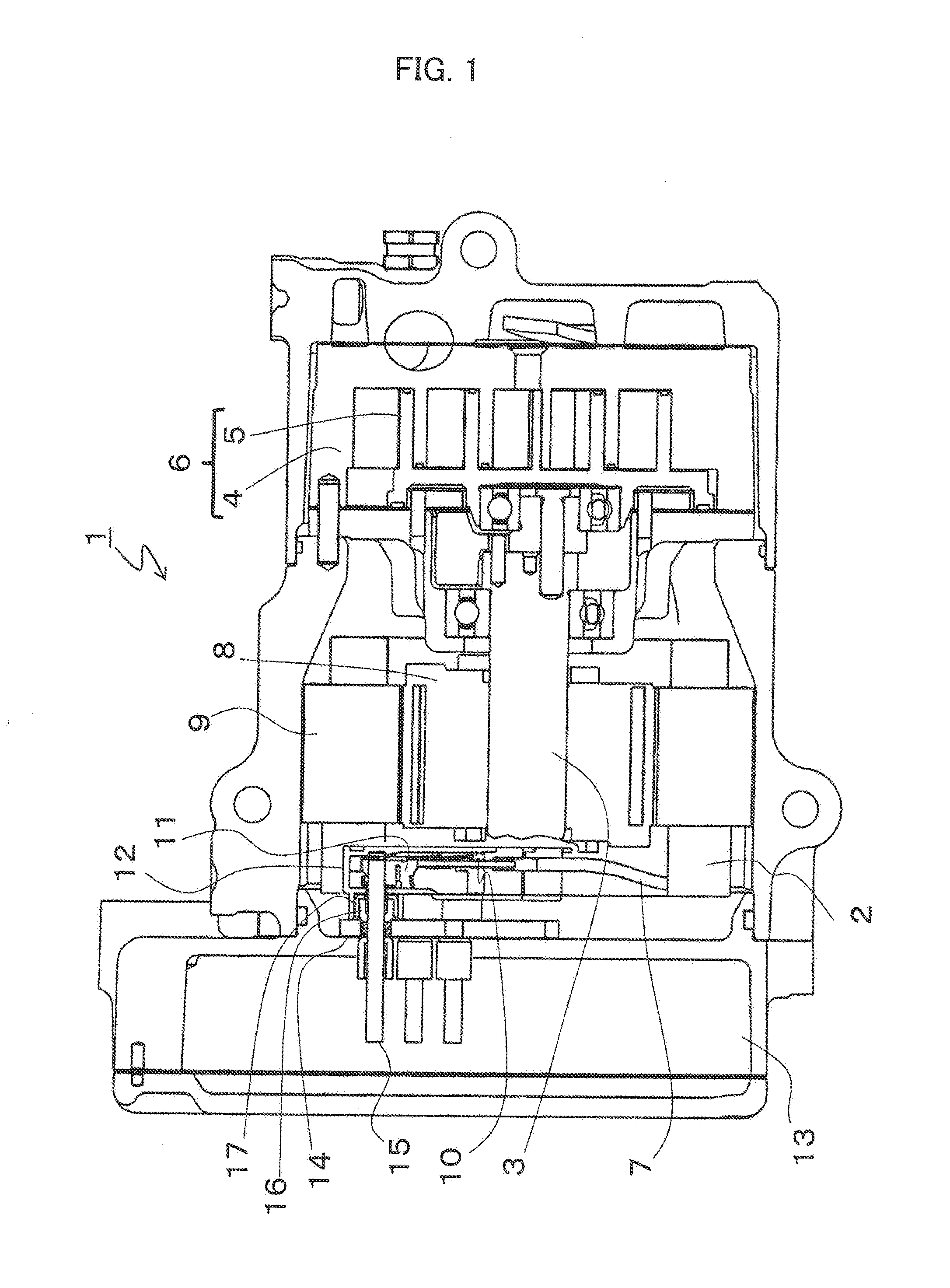

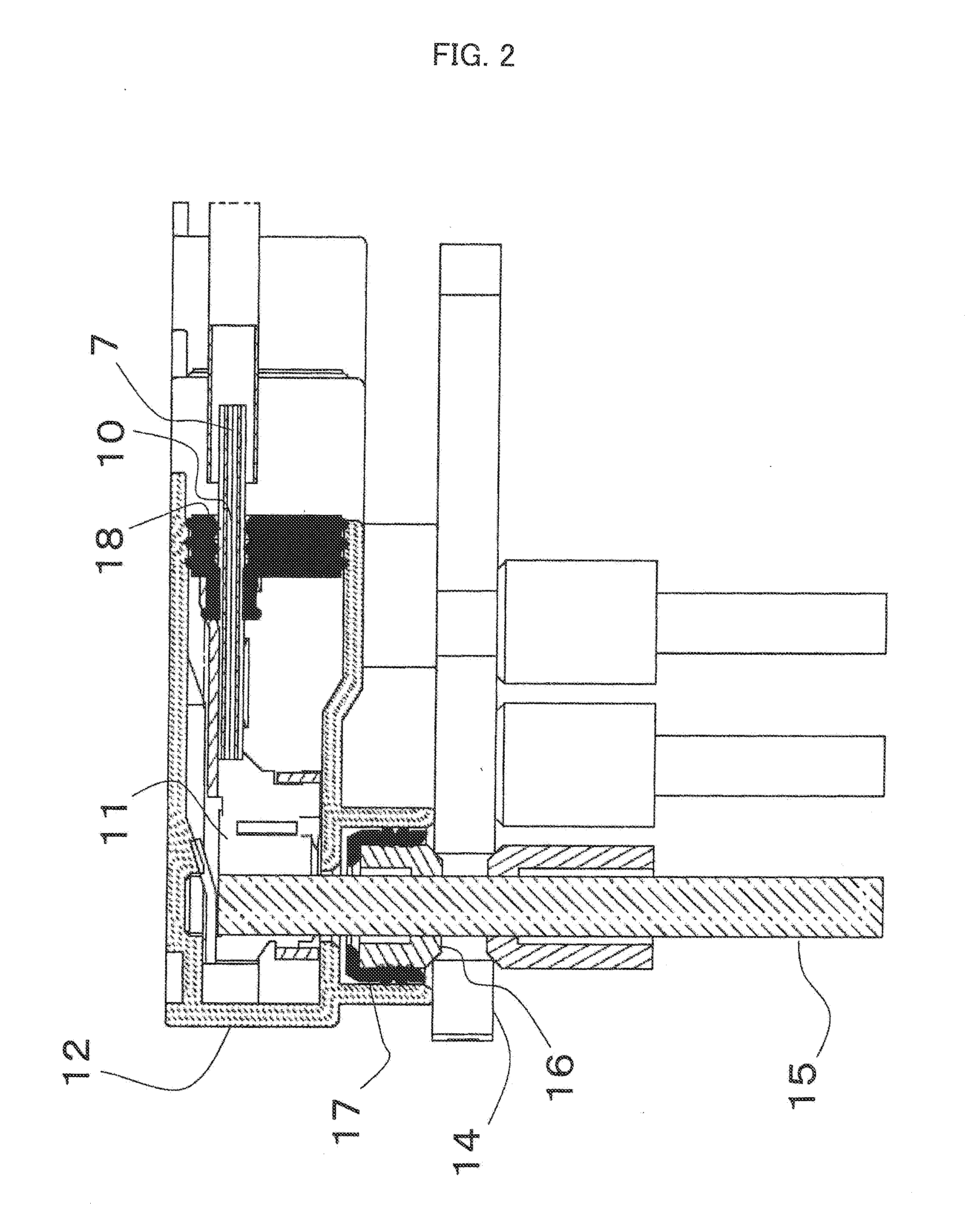

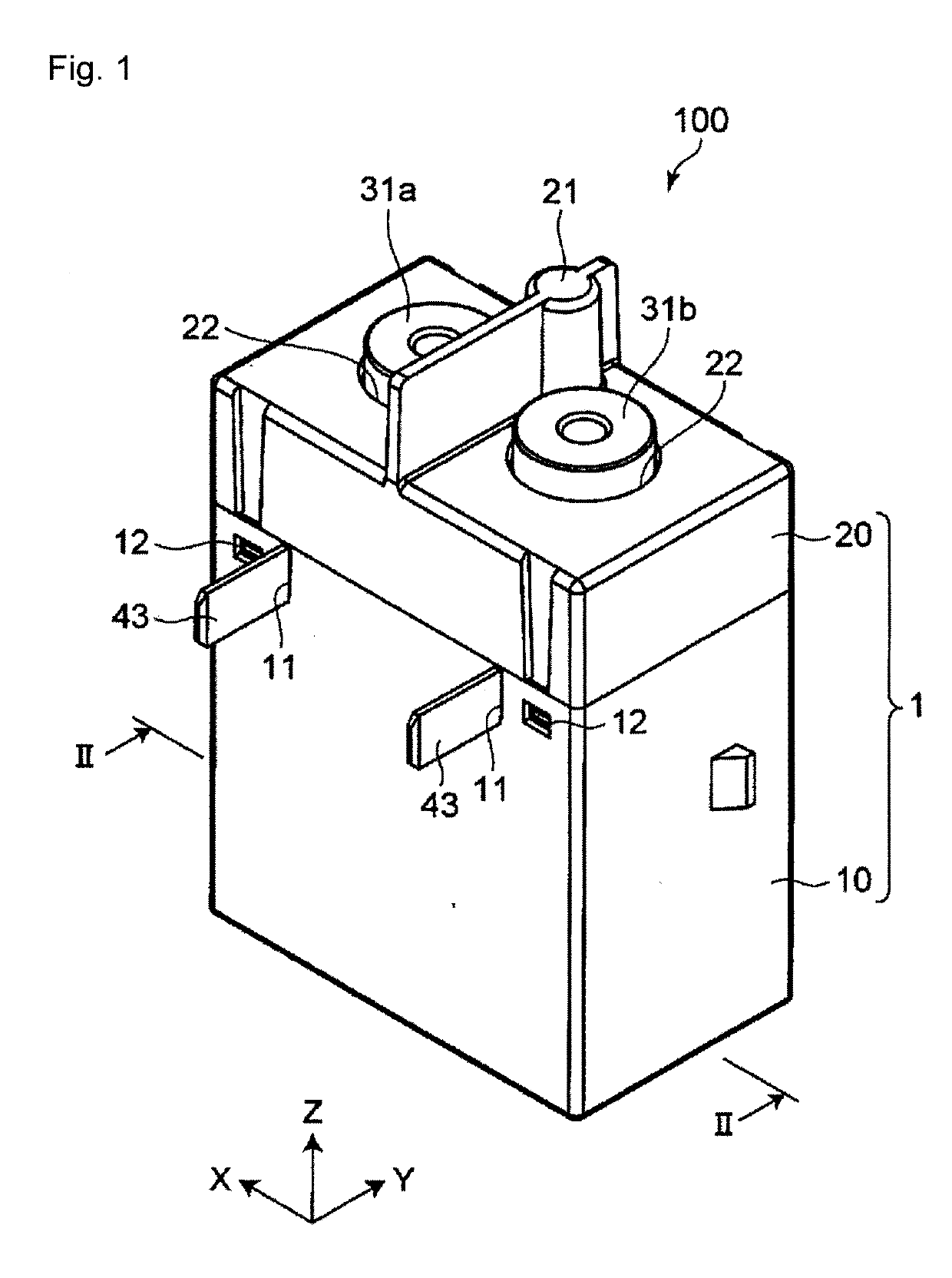

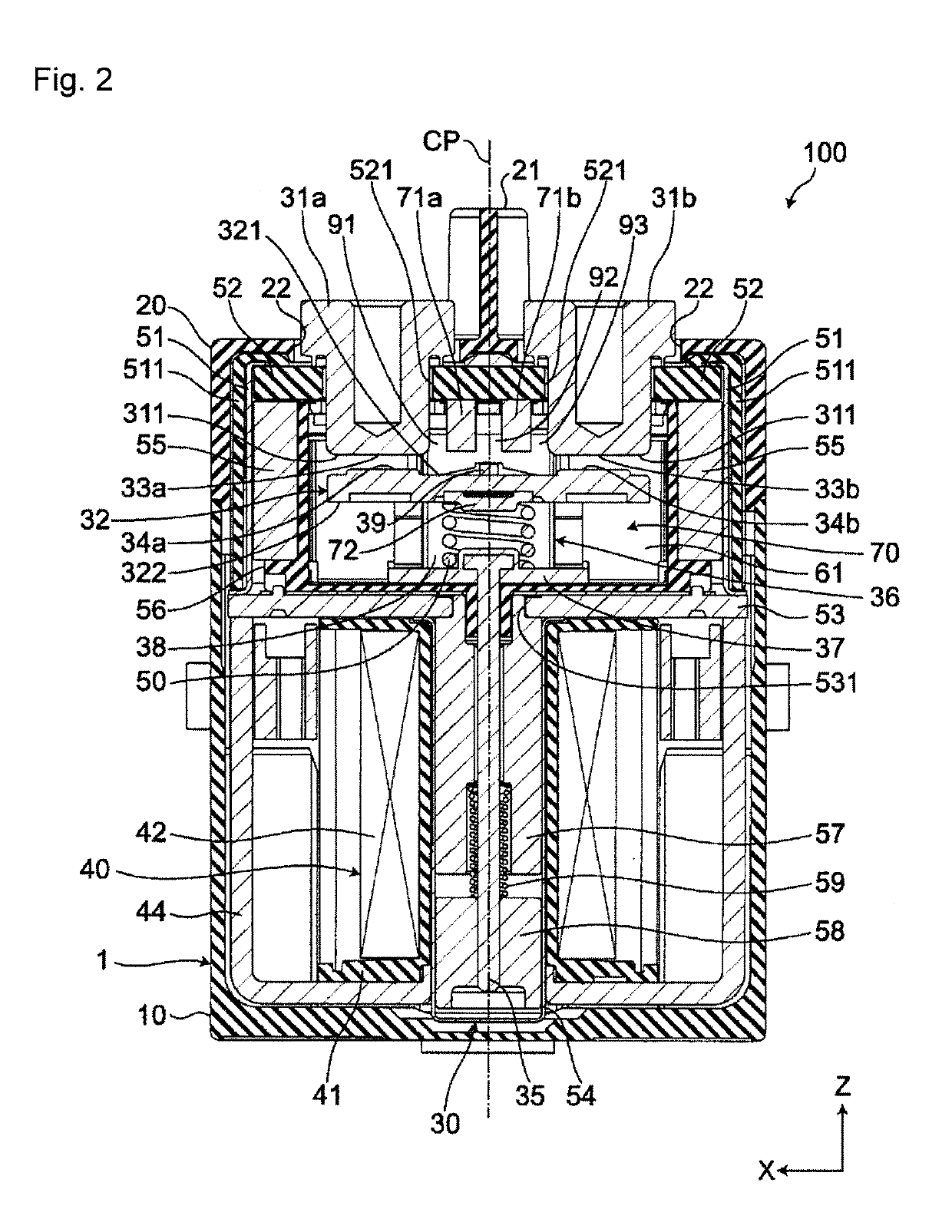

Electric Compressor

ActiveUS20140375157A1Leakage currentEnsure insulationWindingsPositive displacement pump componentsInternal pressureEngineering

An electric compressor which compresses a coolant by driving a compression mechanism with a motor which is drive controlled by a drive circuit, said compressor being characterized by having a lead pin connected to a current output section of the drive circuit, and a connector which, by being mounted on the lead pin, can provide electrical continuity between the current output section of the drive circuit and a current input section of the motor, said connector being provided with a connector terminal which contacts the lead pin at the time of mounting on the lead pin, a connector housing which houses the connector terminal, a vacuum flow path that communicates the inside of the connector housing with the outside thereof, and a sealing member which provides a seal between the connector housing and the vacuum flow path. Thus, provided is a compressor which is easy to produce and for which it is possible to secure the electrical insulation properties of the interior of the compressor while homogenizing the internal pressure thereof.

Owner:SANDEN CORP

Production method of a sequentially joined-segment stator coil of a rotary electrical machine

InactiveUS6910257B1Reduce variationRelieve pressureFilament handlingManufacturing stator/rotor bodiesElectric machineStator coil

A production method of a polyphase sequentially joined-segment coil of a rotary electric machine and a product produced by the same are provided. A production machine includes pairs of tines working to catch heads of conductor segments when they are twisted using rings. The tines are designed to be rotatable about an axis of the rings following rotation of the rings to absorb stress acting on insulating coating on the heads of the segments to minimize rubbing of the insulating coatings, thereby ensuring a desired degree of electrical insulation of the stator coil.

Owner:DENSO CORP

Transformer

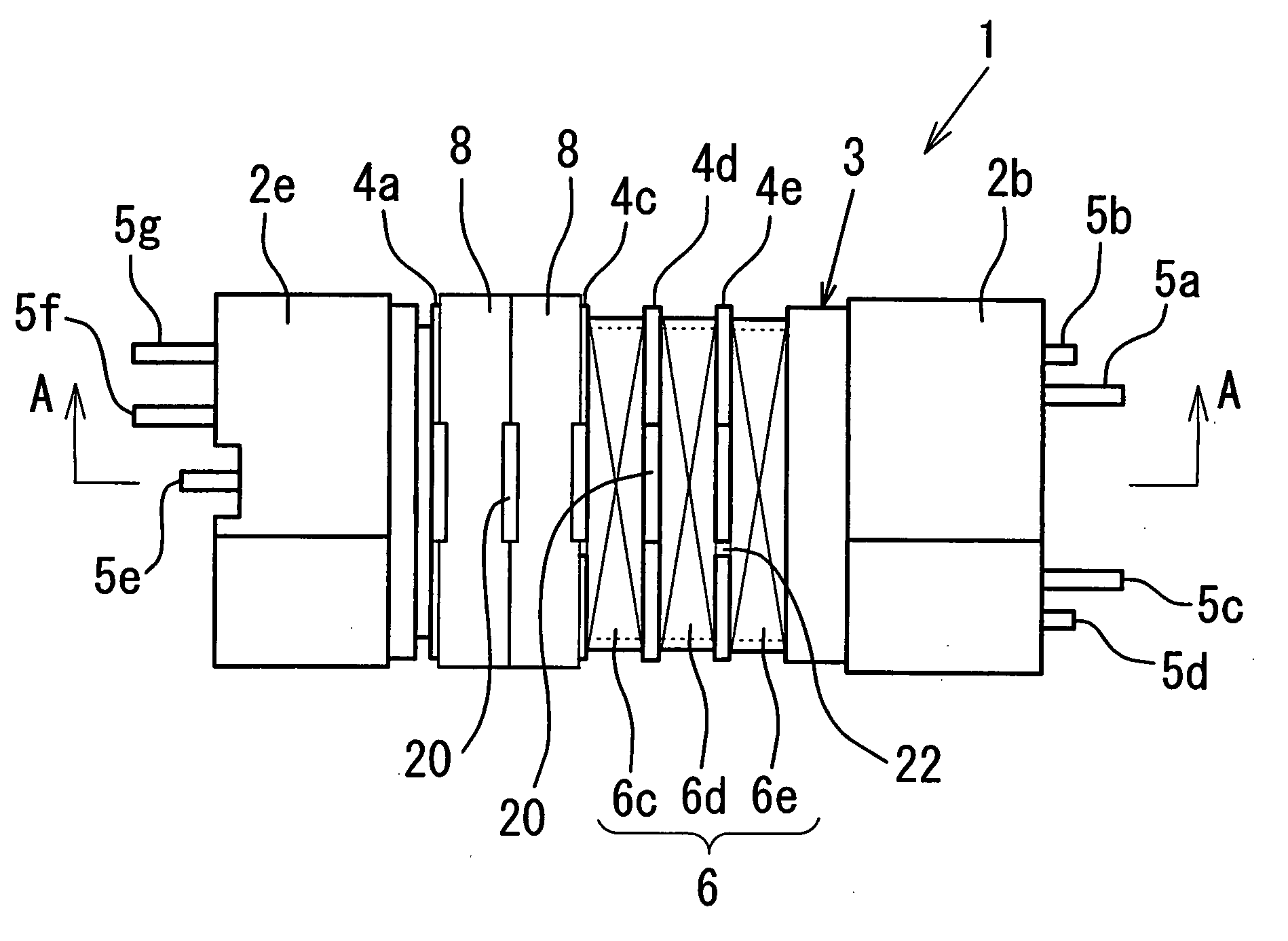

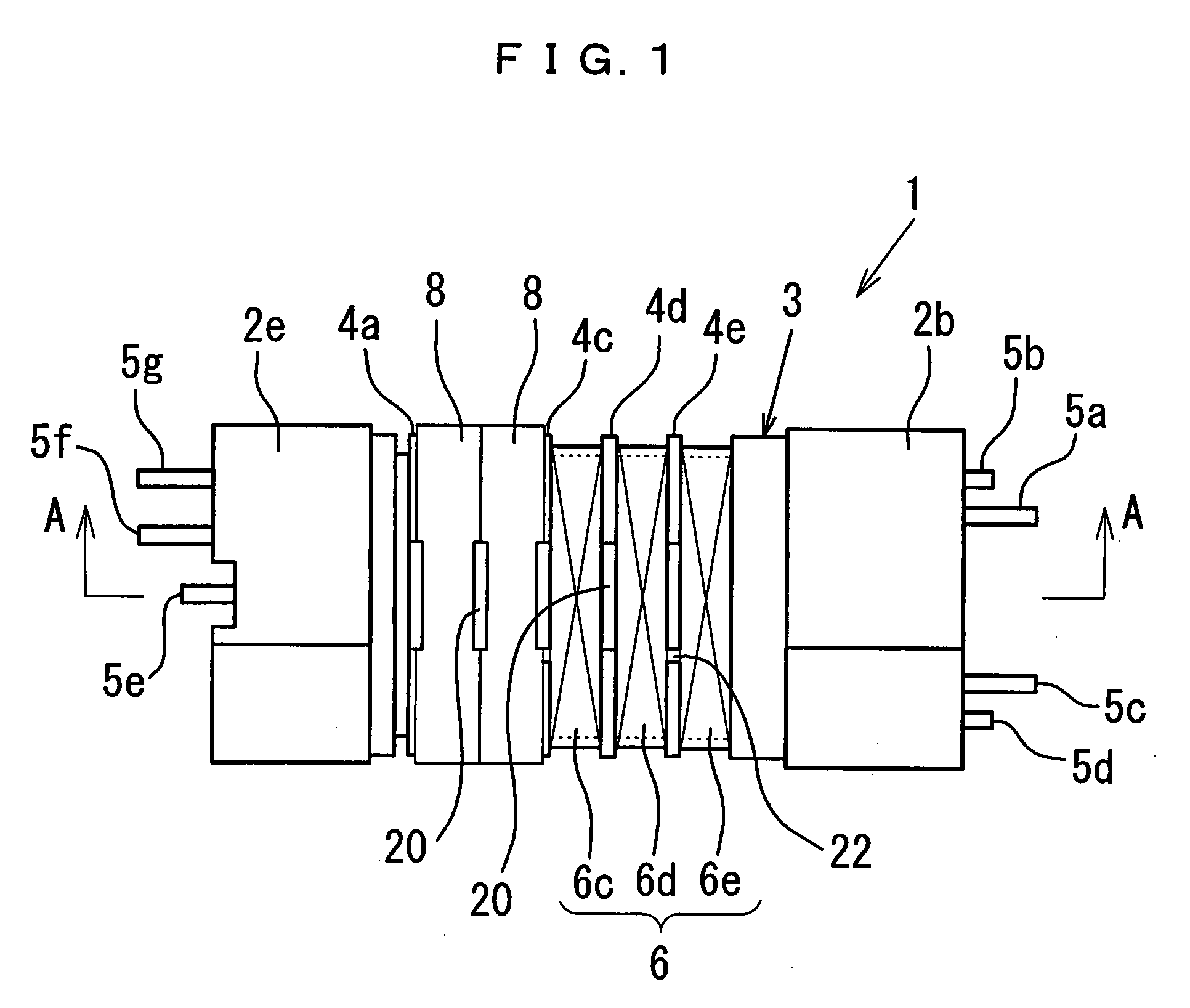

InactiveUS6741155B2Operational securityImprove reliabilityTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresTransformerEngineering

A transformer comprises E-type core parts, a cylindrical core part, a second substrate, first substrates, and an insulating sheet. Each of the second substrate and the fist substrates includes a penetration hole. A coil is wired around the penetration hole. The second substrate is wrapped with an insulating sheet, together with the cylindrical core part. The second substrate and the cylindrical core part are sandwiched between cylindrical core legs of the core parts, through the insulating sheet.

Owner:SANKEN ELECTRIC CO LTD

Plating method, semiconductor device fabrication method and circuit board fabrication method

InactiveUS20060084251A1Easy to stickSuitable roughnessPrinted circuit aspectsSolid-state devicesEngineeringInterconnection

The plating method comprises the step of forming a resin layer 10 over a substrate 16; the step of cutting the surface part of the resin layer 10 so that the ten-point height of irregularities of the surface of the resin layer 10 is 0.5-5 μm; the step of forming a seed layer 36 on the resin layer 10; and the step of forming a plating film 44 on the seed layer 36 by electroplating. Suitable roughness can be give to the surface of the resin layer 10, whereby the adhesion between the seed layer 36 and the resin layer 10 can be sufficiently ensured. Excessively deep pores are not formed in the surface of the resin layer 10, as are by desmearing treatment, whereby a micronized pattern of a photoresist film 40 can be formed on the resin layer 10. Thus, interconnections 44, etc. can be formed over the resin layer 10 at a narrow pitch with high reliability ensured.

Owner:FUJITSU LTD

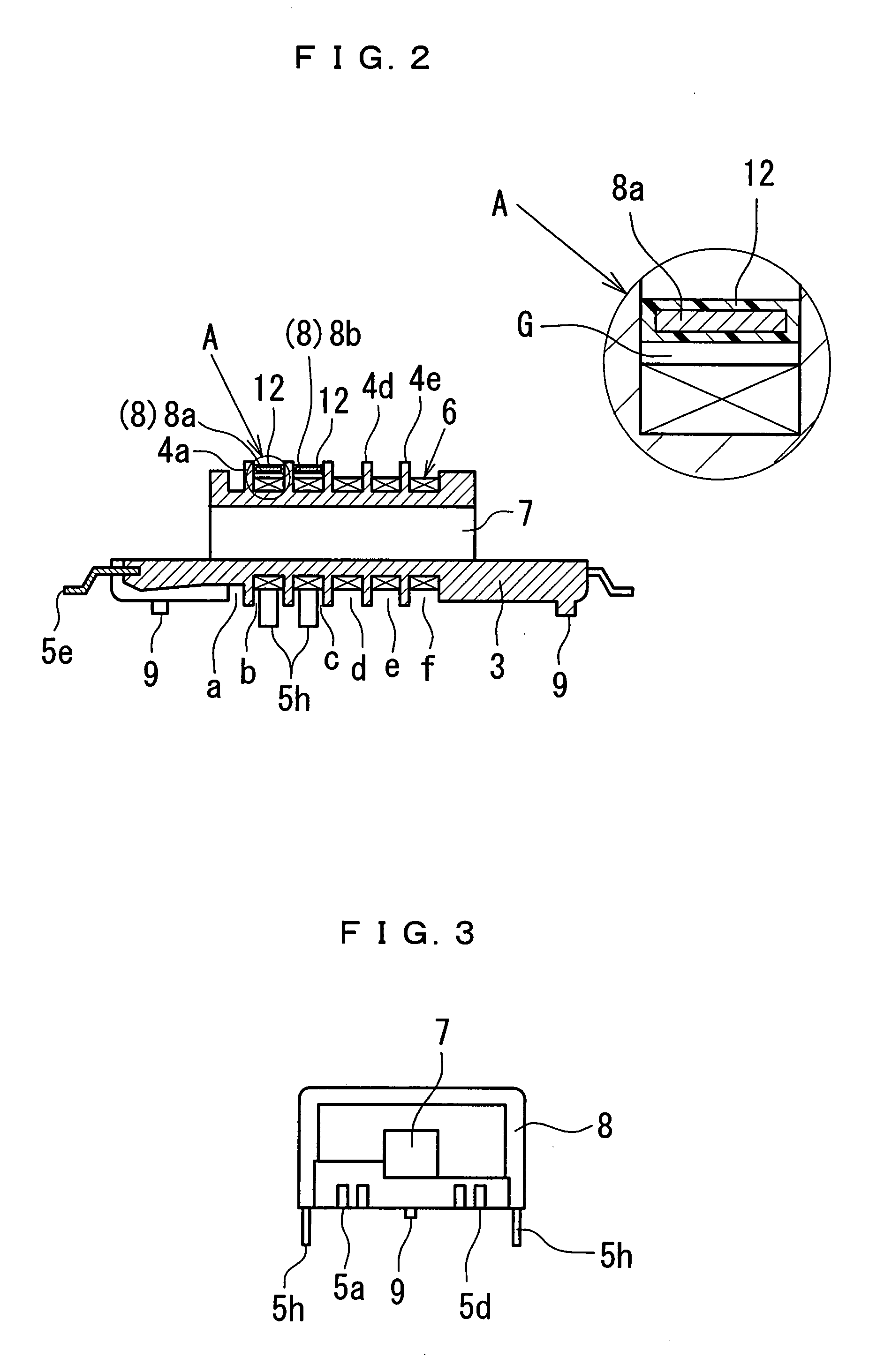

High Voltage Transformer

InactiveUS20080024261A1Improve efficiencyElectromagnetic couplingTransformersTransformers/inductances coils/windings/connectionsMagnetic coreBobbin

A high voltage transformer is provided in which a primary winding is located selectively and optimally with respect to a secondary winding, and so the primary winding is allowed to be tightly coupled electromagnetically to the secondary winding, while the workability in assembly is improved. In the high voltage transformer, a primary winding (8) and a secondary winding (6) are wound around a spool body (3) of a bobbin (1), and a magnetic core made of magnetic material is inserted in the hollow of the bobbin (1). The bobbin (1) includes terminal blocks (2a and 2b) disposed at the both ends of the spool body (3) and provided with a plurality of terminals (5a to 5g), the secondary winding (6) is wound on the outer circumferential surface of the spool body (3), and the primary winding (8) which is constituted by thin conductive sheet coils coated with resin is disposed around the secondary winding (6). A means for fixedly positioning the thin conductive coil sheet constituting the primary winding (8) is formed at the outer circumference of the bobbin (1) or at a board for attaching the bobbin, and the primary winding (8) can be disposed selectively by the positioning means around the secondary winding (6) at the arbitrary and optimal locations thereby modulating the electromagnetic coupling between the primary winding (8) and the secondary winding (6).

Owner:MINEBEA CO LTD

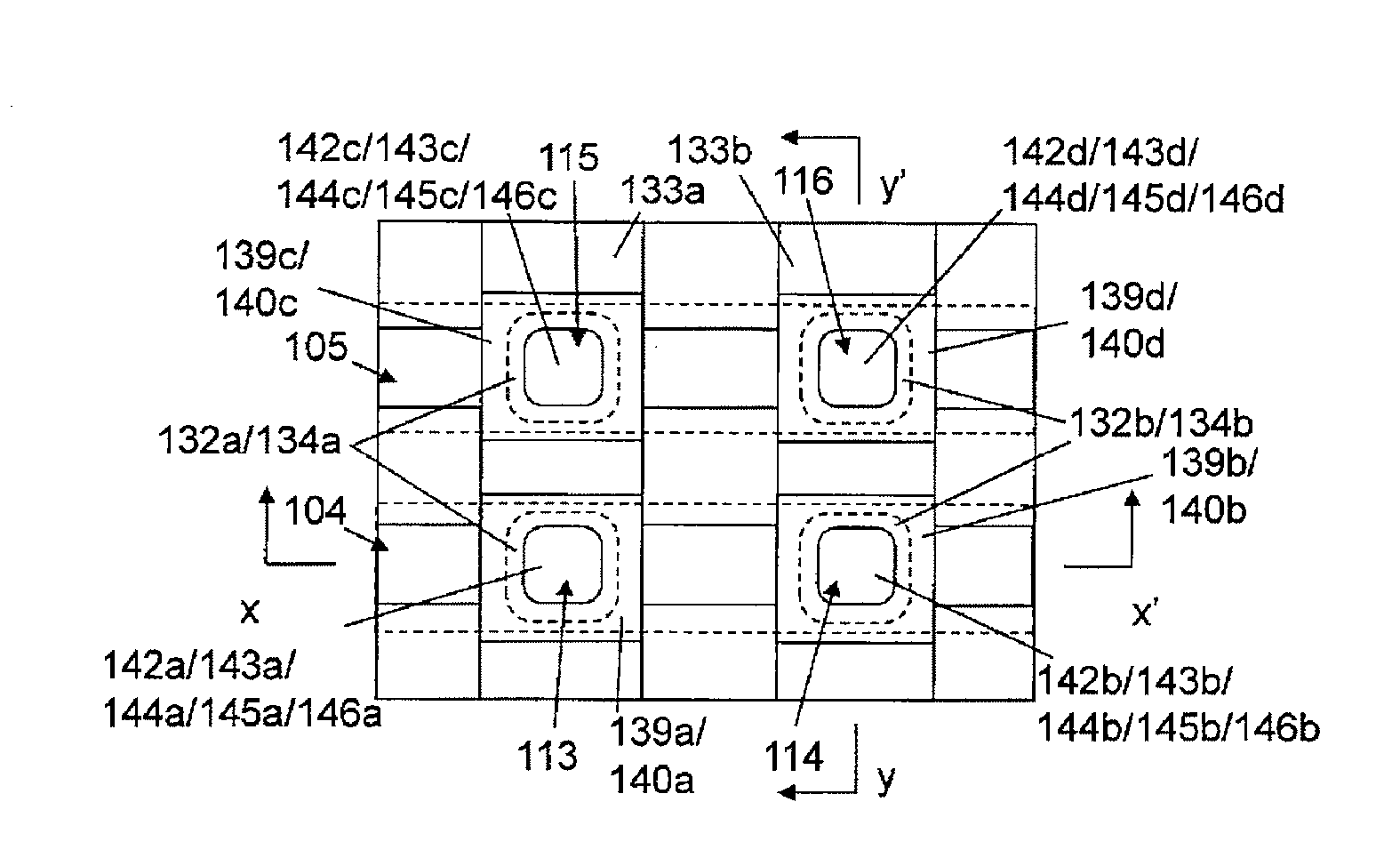

Semiconductor device, method for producing the same, circuit board, and electronic apparatus

InactiveUS20050230805A1Avoid warpingEnsure insulationSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorDevice material

A method for making a semiconductor device having an electrode penetrating a substrate includes (a) forming a concavity in an active face of the substrate; (b) forming an insulating layer on the active face of the substrate and the interior of the concavity; (c) removing at least part of the insulating layer formed outside the concavity; (d) forming the electrode by filling the interior of the concavity with a conductor; and (e) exposing the electrode from a rear face of the substrate opposite to the active face by milling the substrate from the rear face side. In this method, (a) to (e) are performed in that order.

Owner:SEIKO EPSON CORP

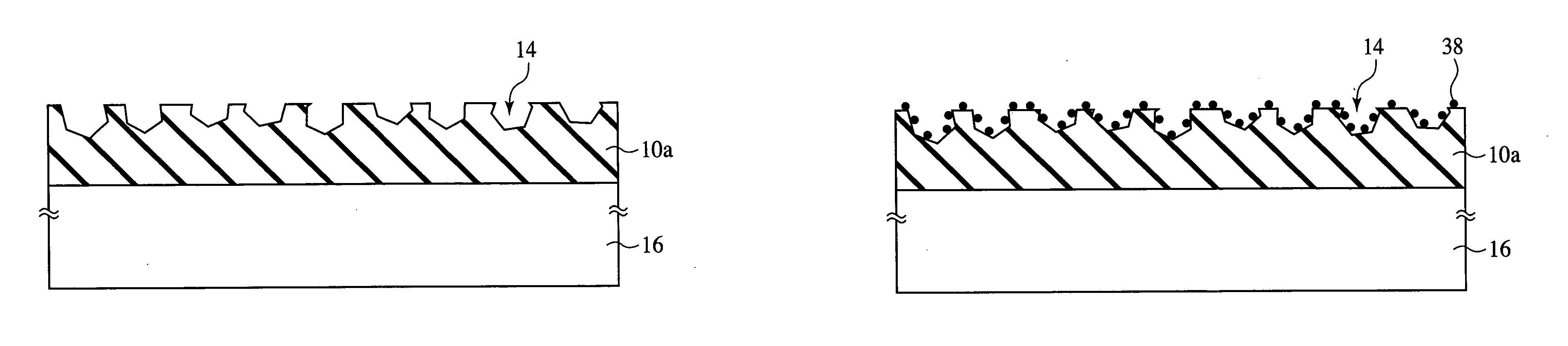

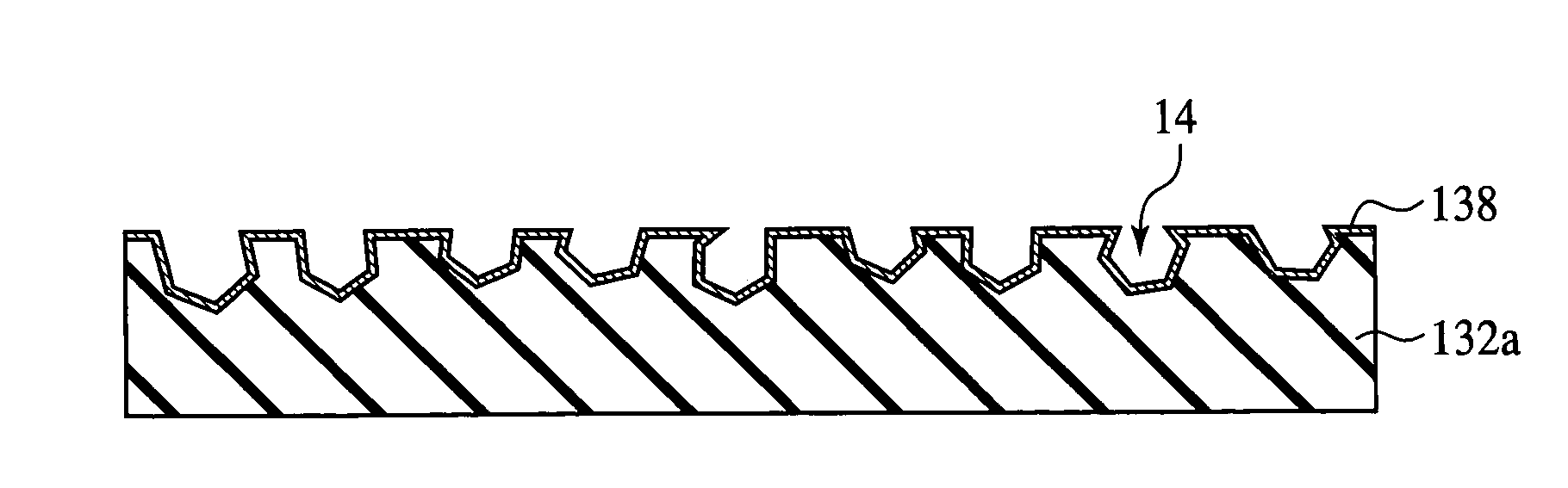

Stator for use in electric rotating machine

ActiveUS20110181143A1Increase surface areaImprove adhesionSynchronous generatorsWindings insulation shape/form/constructionPhysicsElectrical conductor

A stator for use in an electric rotating machine is provided which includes a stator winding wound through slots of a stator core. The stator winding is made up of a plurality of conductor segments connected together. Each of the conductor segments includes an in-slot portion disposed inside one of the slots and out-slot portions extending from the in-slot portion outside at least one of the ends of the stator core. Ends of the out-slot portions are joined together to form the stator winding. The joints of the ends of the out-slot portions have a given pattern of texture formed on surfaces thereof and coated with an insulating material. The pattern of texture enhances the adhesion of the insulating coatings to the surfaces of the joints and ensures the stability in electric insulation of the joints.

Owner:DENSO CORP

Electroacoustic converter film

ActiveUS20160014527A1Ensure resistance of electrodeEnsure insulationLoudspeakersMechanical vibrations separationThin film electrodeMetal foil

Provided is an electroacoustic converter film including thin film electrodes provided on both surfaces of a polymeric composite piezoelectric body in which piezoelectric body particles are dispersed in a viscoelastic matrix formed of a polymer material that exhibits viscoelasticity at normal temperature, and protective layers formed on the thin film electrodes. The electroacoustic converter film further includes electrode lead-out metal foils laminated on the thin film electrodes, and the electrode lead-out metal foils allows connection to wiring through soldering when electrodes are led out from the thin film electrodes.

Owner:FUJIFILM CORP

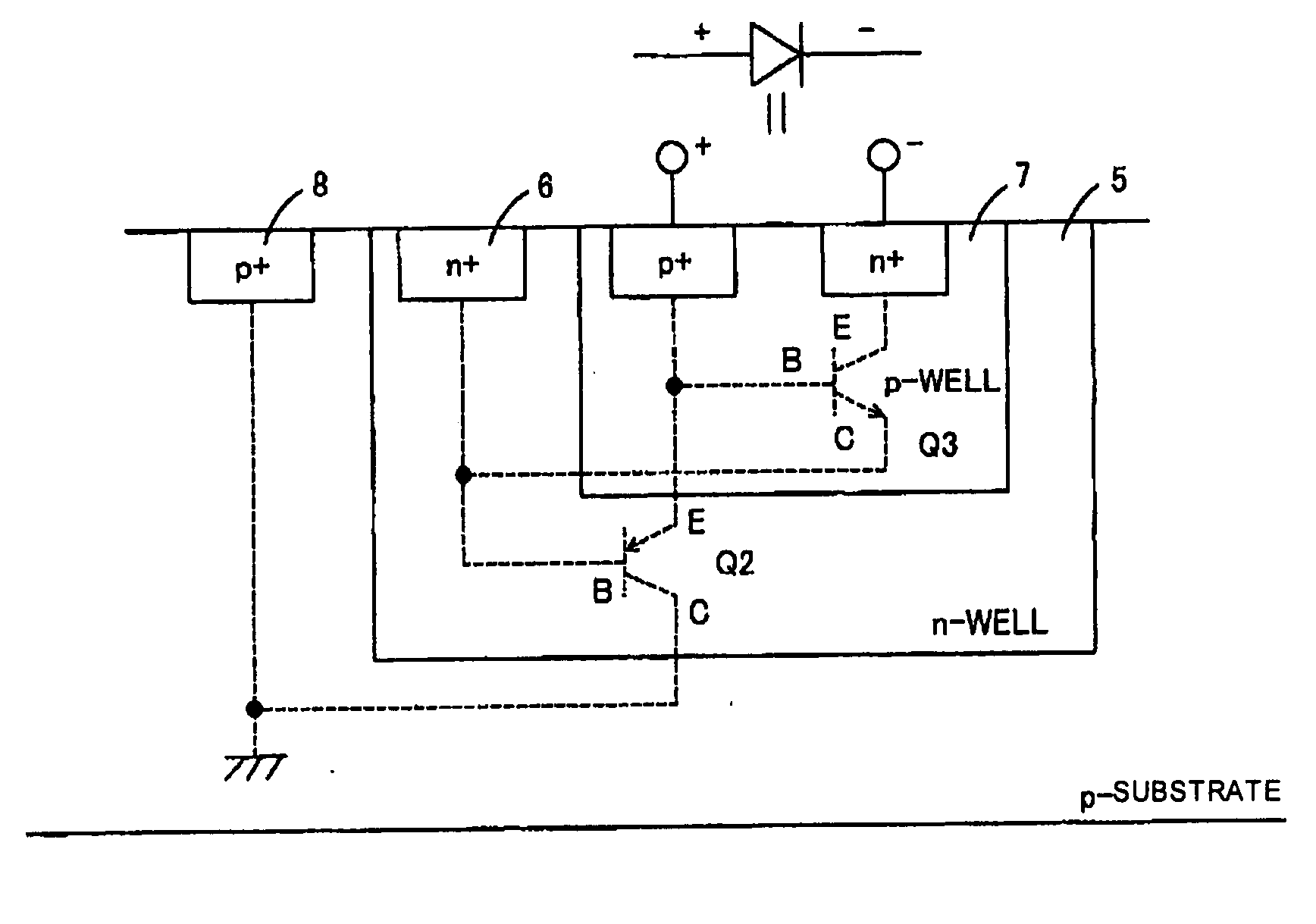

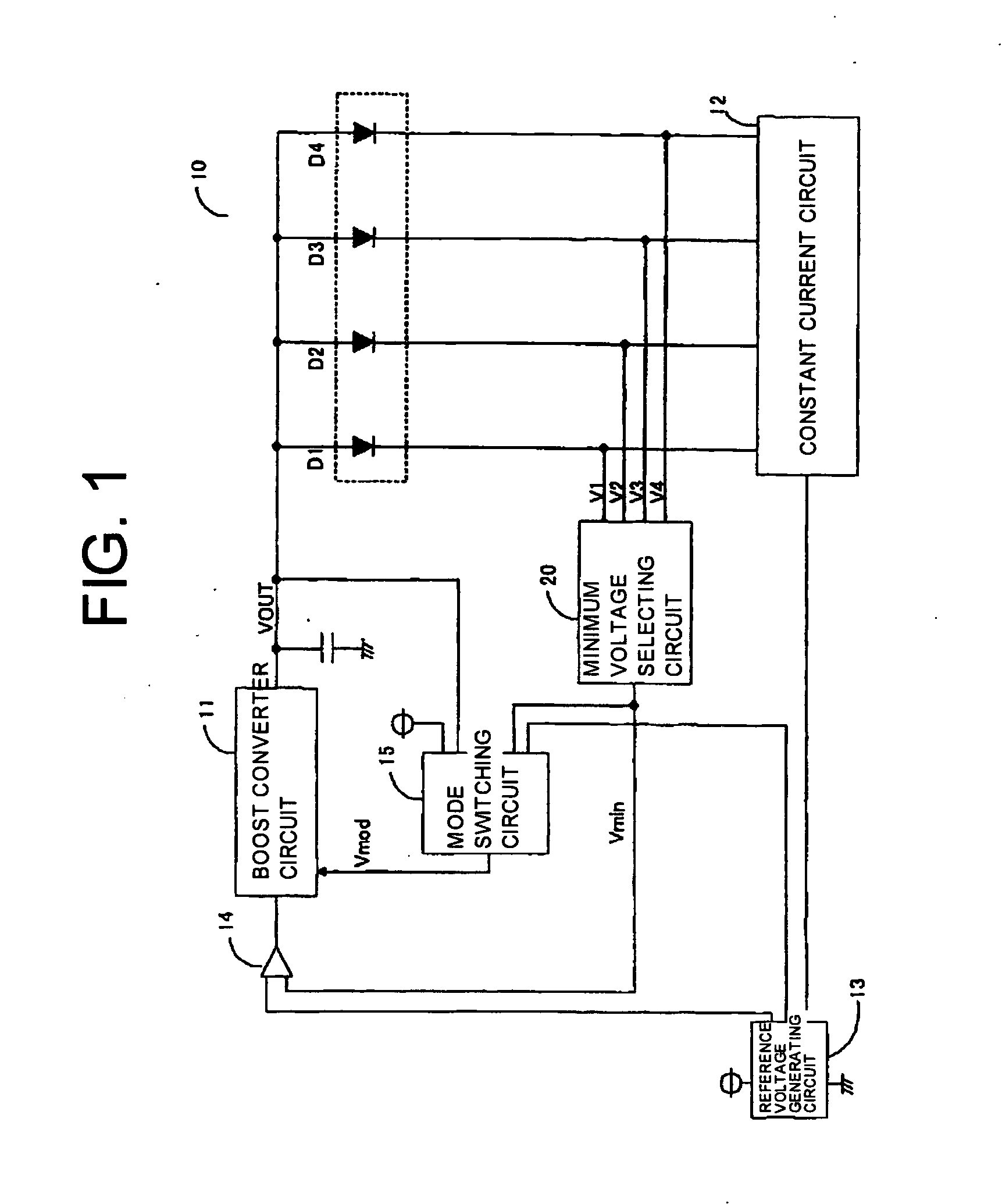

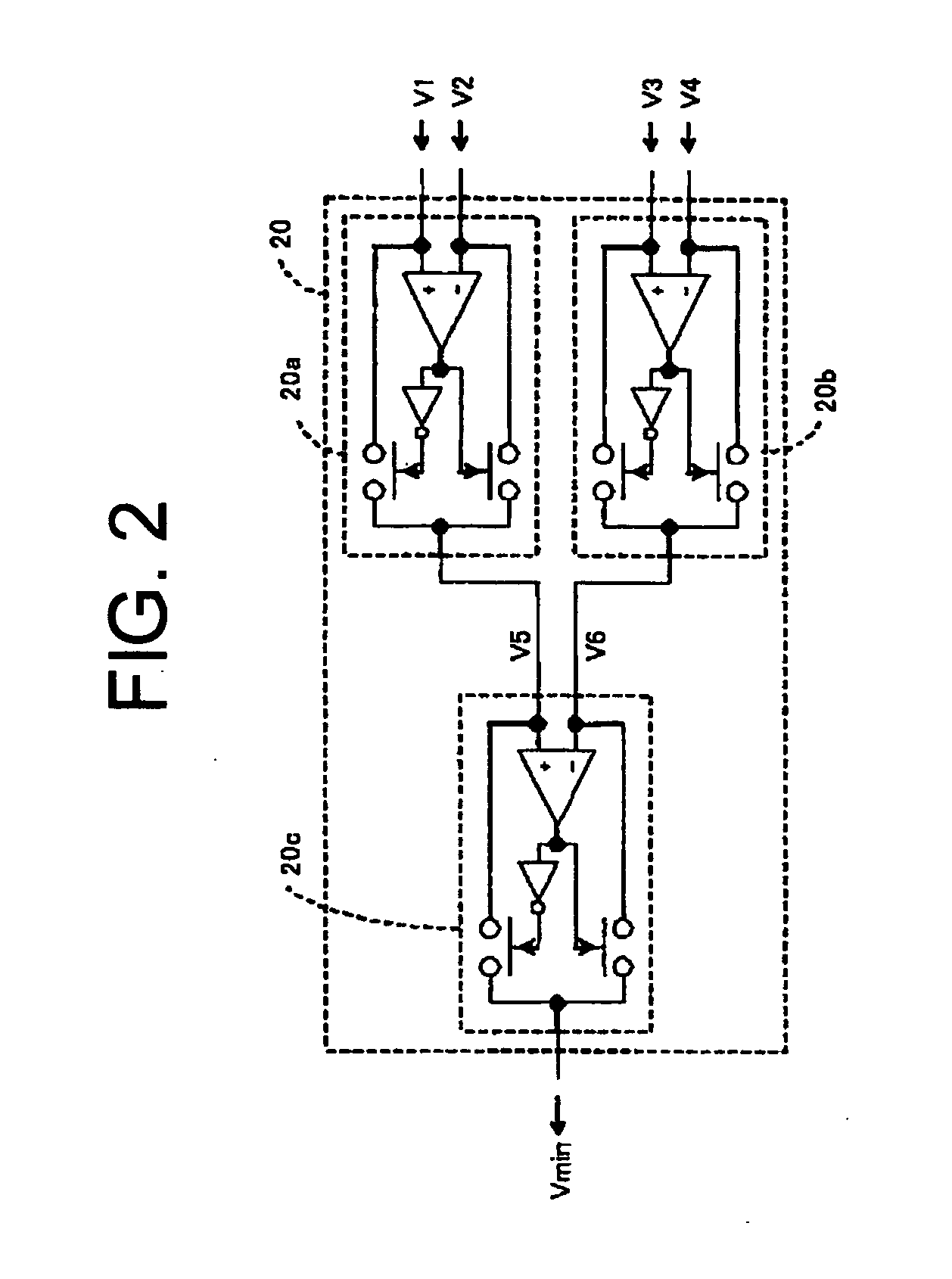

LED driver circuit

Disclosed is an LED driver circuit that can suitably detect a minimum voltage and can be produced at low cost. A selector circuit is comprised of a comparator C, an inverter I and analogue switches. A minimum voltage selecting circuit can be constructed by causing the selector circuit and a circuit constructed in the same manner as the selector circuit is done, to be combined with each other. Therefore, the minimum voltage selecting circuit can be comprised of active devices that comprise only p-MOSFETs and n-MOSFETs. Moreover, as a semiconductor process structure, there may be employed a so-called single WELL structure in which a WELL is not formed in another WELL. The LED driver circuit is formed at low cost.

Owner:AL SID

Insulating motor housing

ActiveUS7579732B2Increase the number ofLow production costWindingsMagnetic circuit characterised by insulating materialsElectrical and Electronics engineeringEngineering

Owner:MITSUBISHI ELECTRIC CORP +2

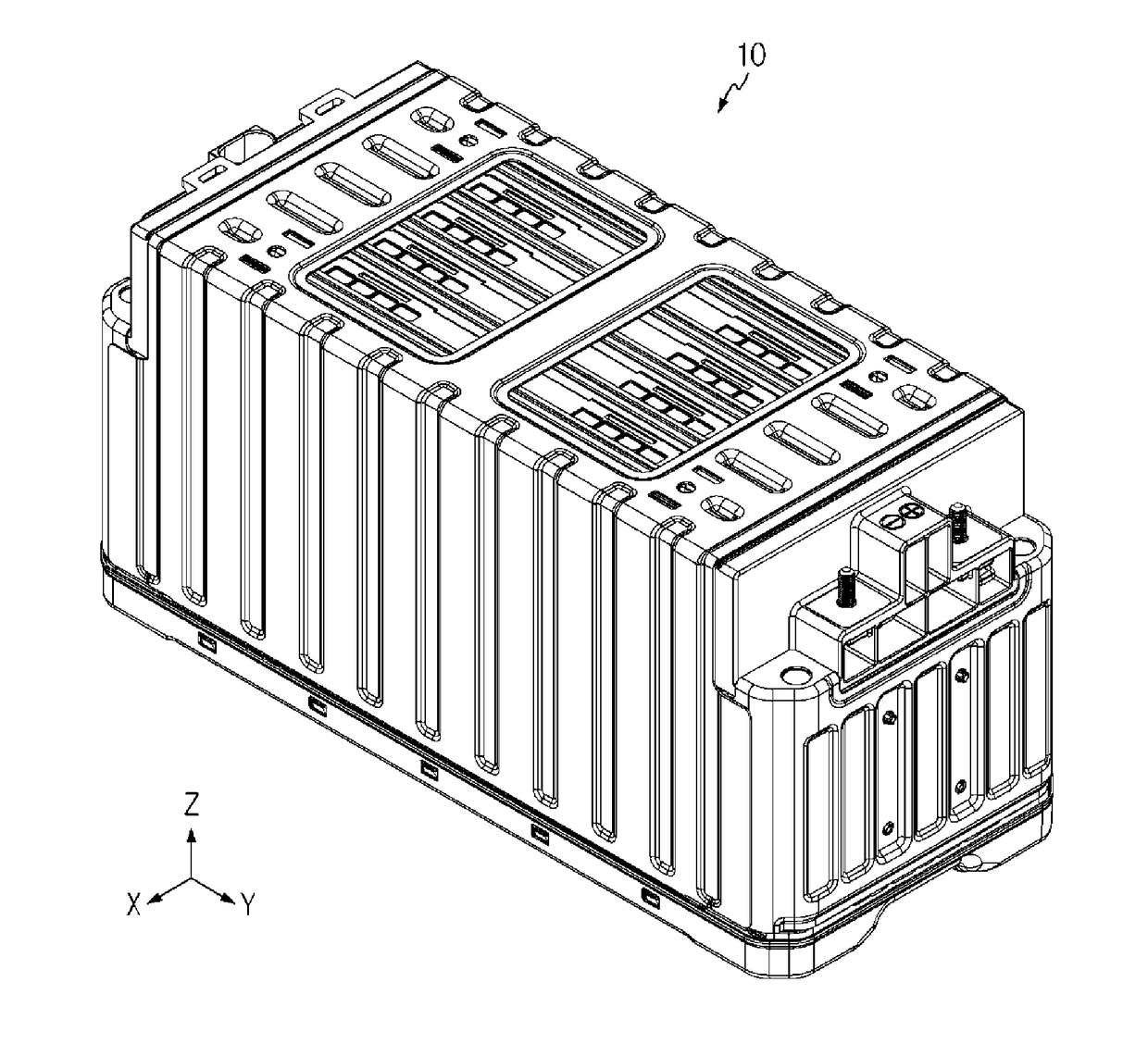

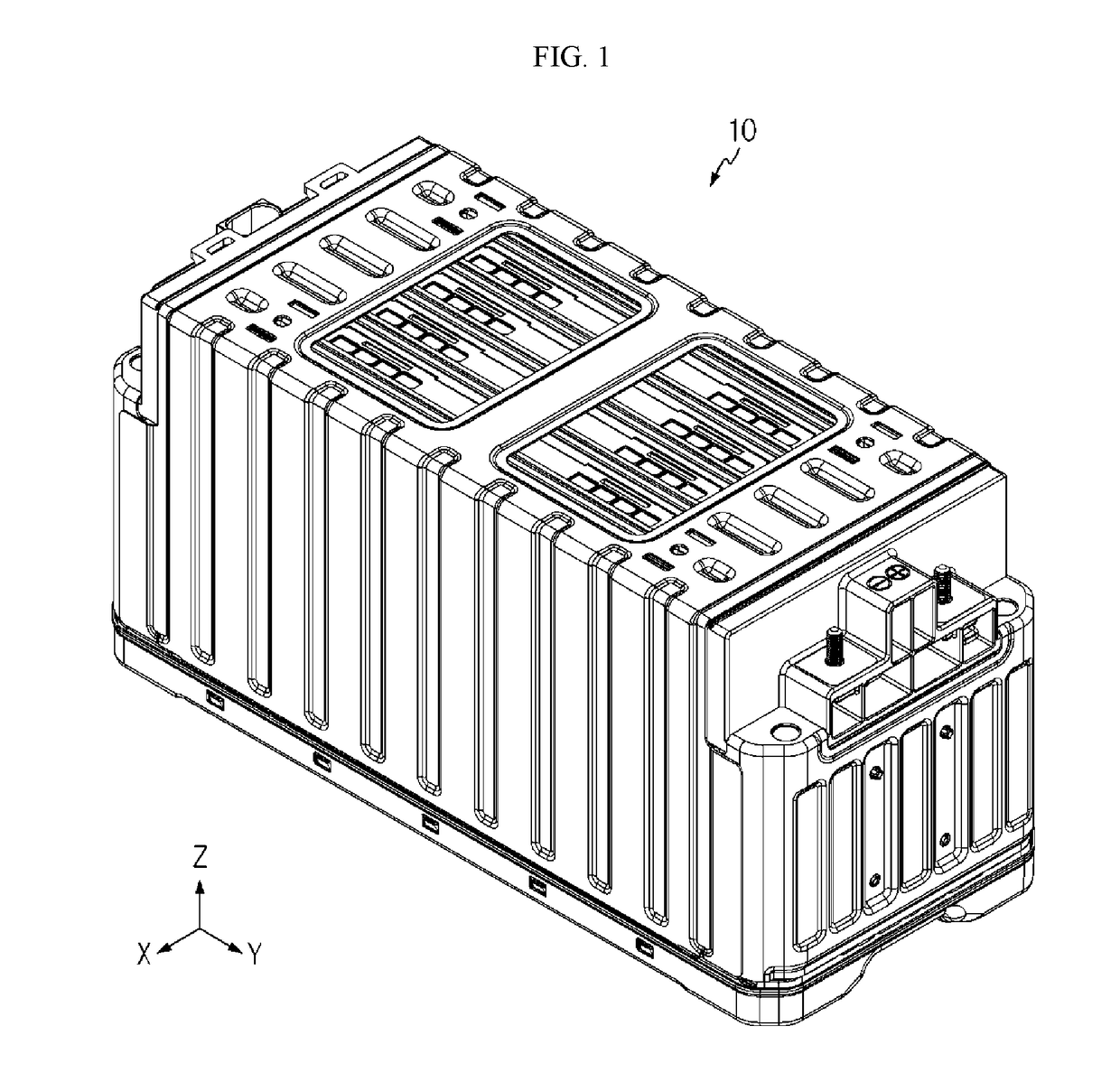

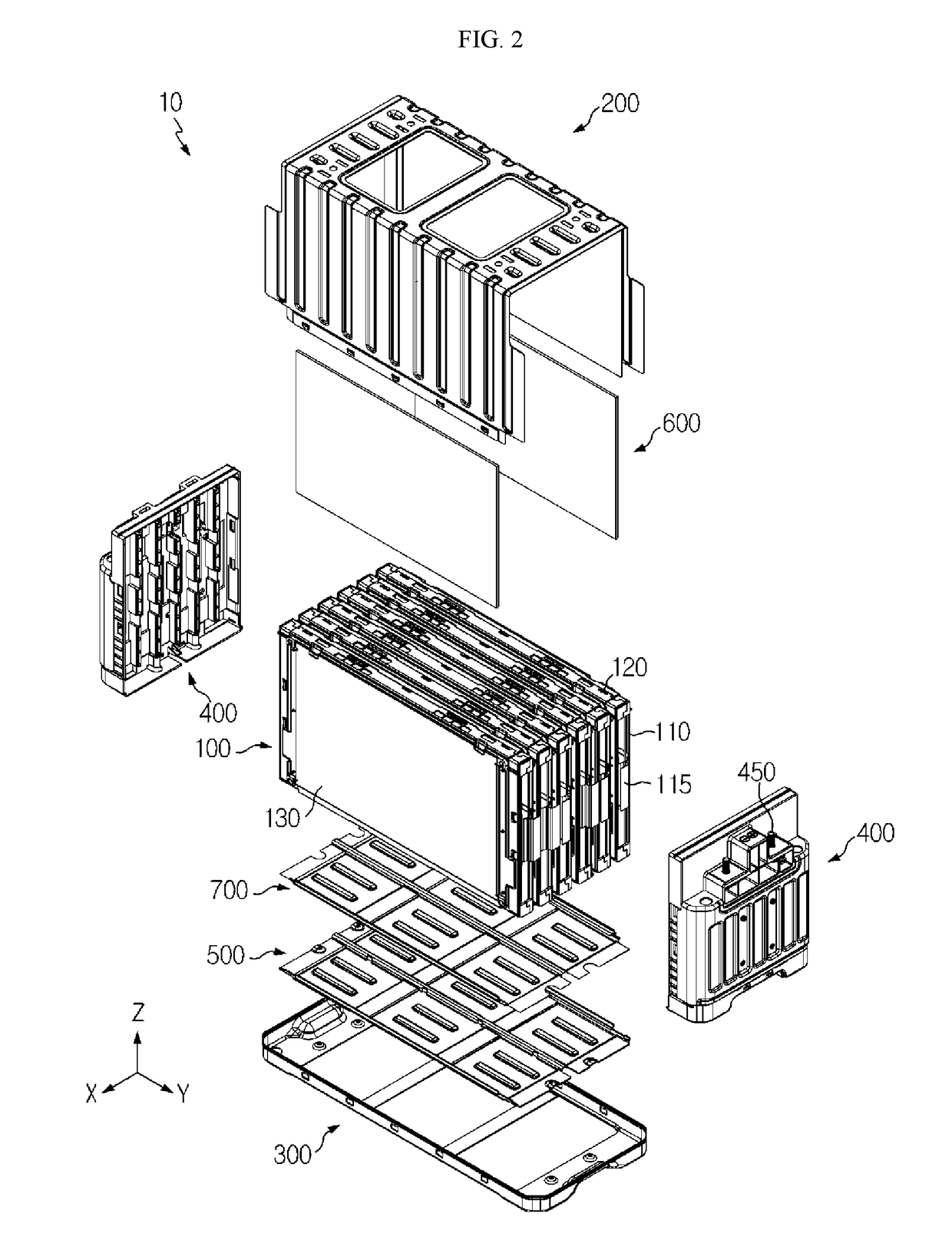

Battery module, battery pack comprising battery module, and vehicle comprising battery pack

Owner:LG ENERGY SOLUTION LTD

Electromagnetic relay

ActiveUS20190311871A1Inhibition formationEnsure insulationContacts enclosures/screensElectromagnetic relay detailsElectricityEngineering

An electromagnetic relay includes a box-shaped insulating housing in which a closed space is formed, a pair of fixed terminals fixed to the housing electrically independently of each other and each having a fixed contact placement surface in the closed space, a plate-shaped conductive movable contactor that is provided in the closed space, has a first surface facing the fixed contact placement surfaces of the pair of fixed terminals, and is movably disposed such that the first surface approaches and separates from the fixed contact placement surfaces of the pair of fixed terminals, a pair of fixed contacts respectively provided on the fixed contact placement surfaces of the pair of fixed terminals, and a pair of movable contacts that is respectively provided on the first surface of the movable contactor and respectively face the pair of fixed contacts.

Owner:ORMON CORP

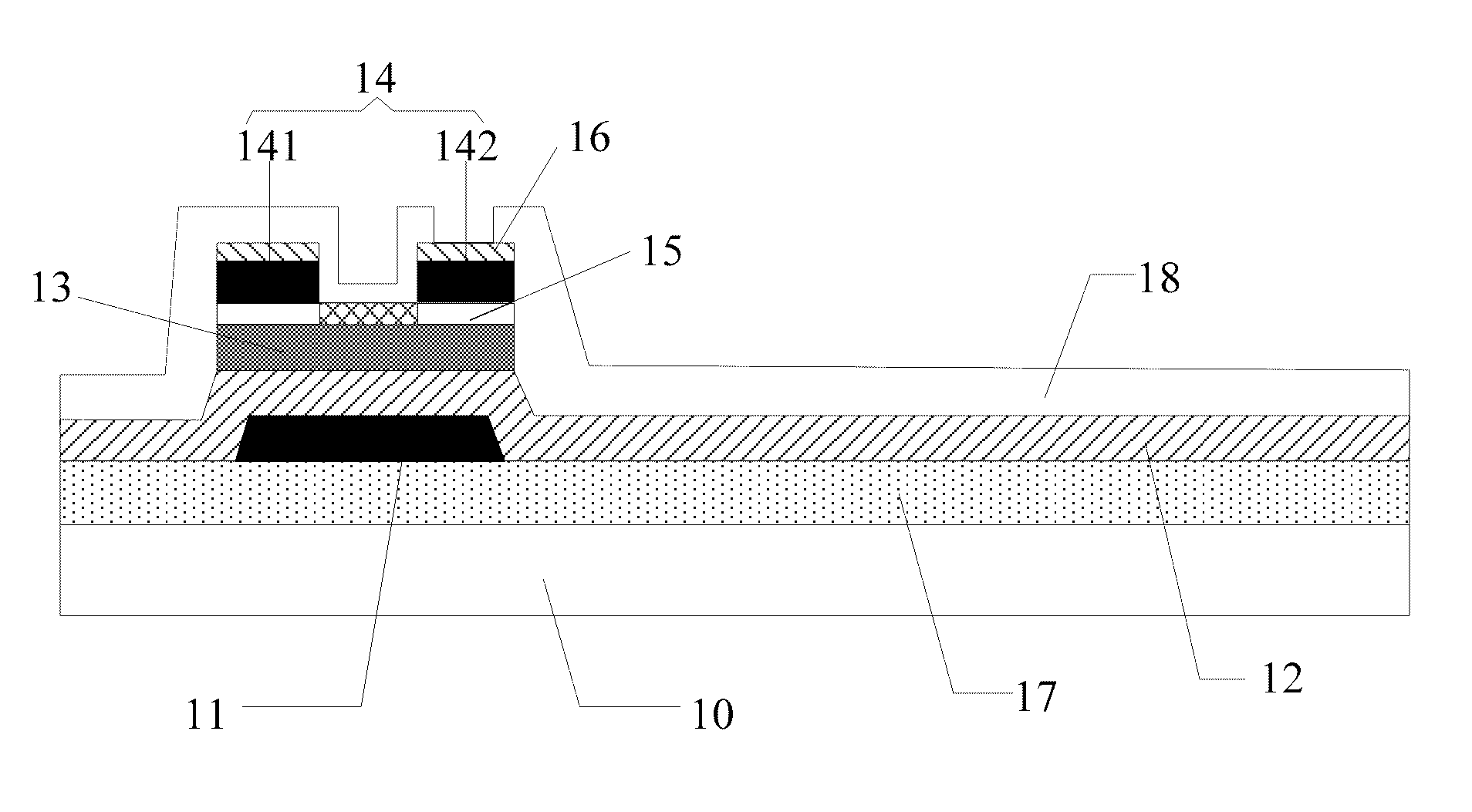

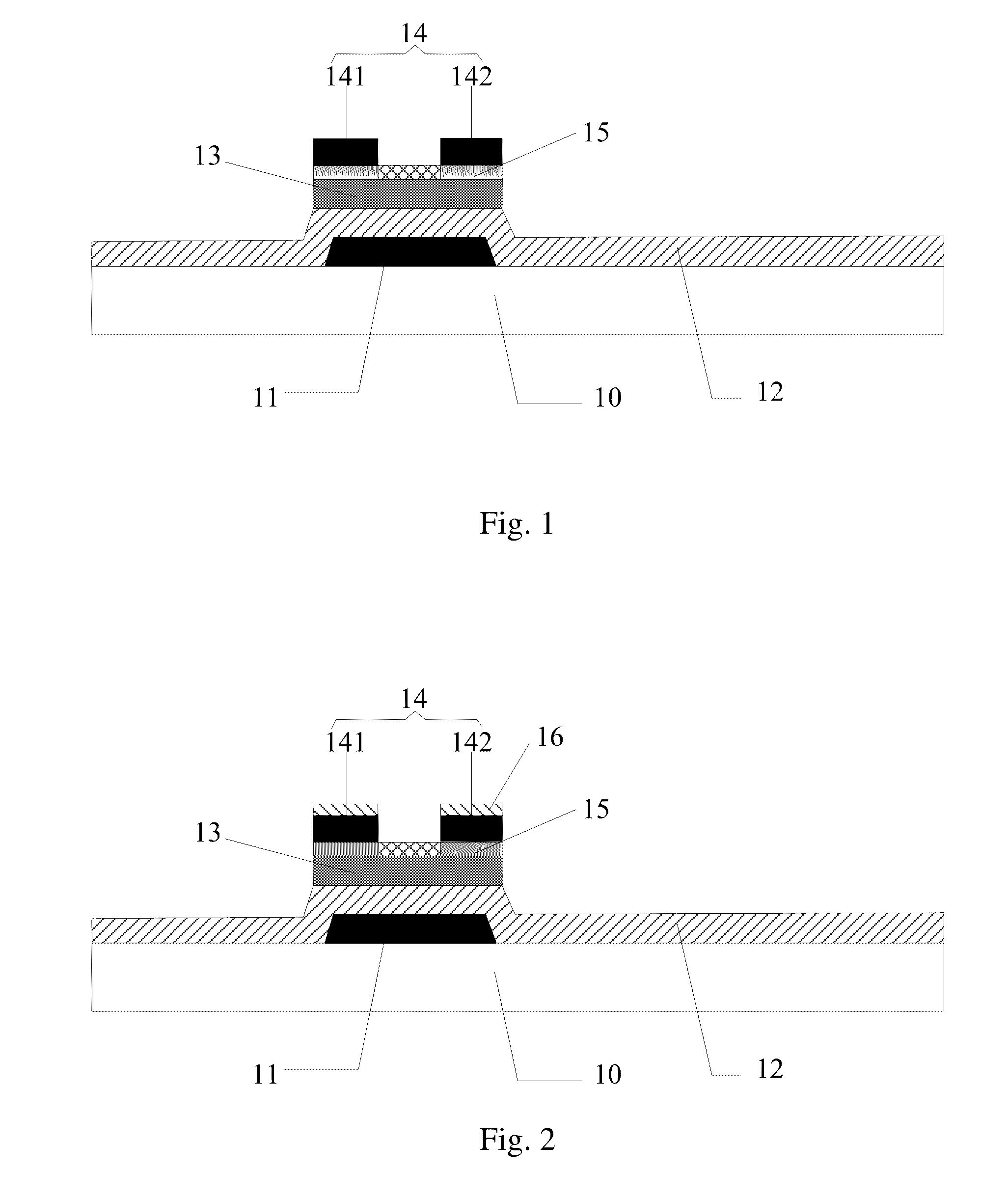

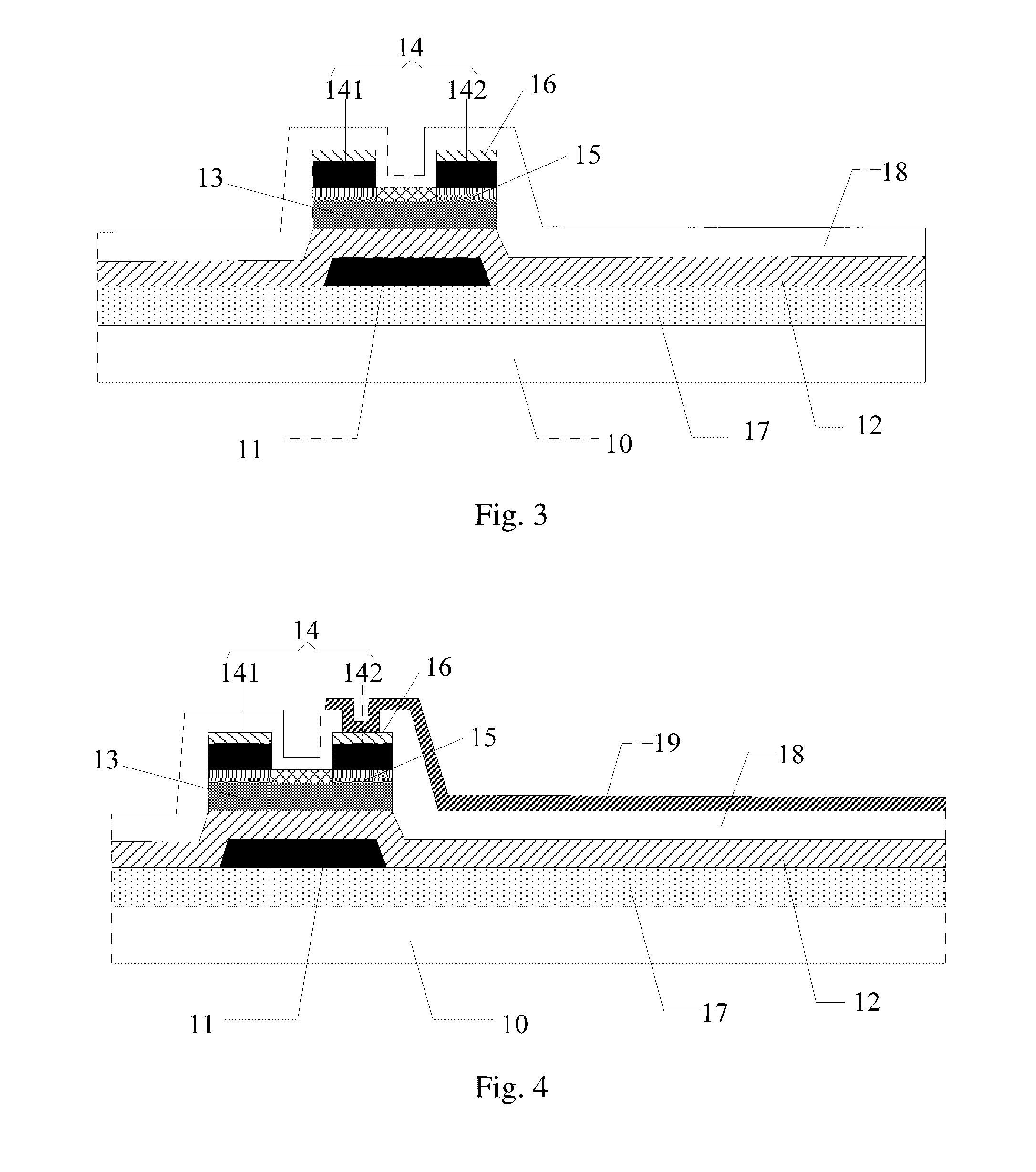

Thin film transistor, method of manufacturing thin film transistor, array substrate and display device

InactiveUS20160343739A1Avoid damageReduce resistanceTransistorSolid-state devicesHydrogenMetal alloy

Embodiments of the present invention disclose a thin film transistor, a method of manufacturing a thin film transistor, an array substrate and a display device, which may ensure electrical connection between source and drain electrodes and an active layer without configuring any through hole due to providing an etch stop layer between the active layer and the source and drain electrodes, a portion of the etch stop layer being in contact with the source and drain electrode is made of metal or metal alloy; and may ensure insulation between the source and the drain electrodes when the thin film transistor is turned-off, ensuring normal operation of the thin film transistor, by oxidating the portion of the etch stop layer at the position between the source and the drain electrodes as an insulating material. The etch stop layer may not only prevent the active layer from being damaged when etching the source and drain electrodes, but also prevent the active layer from other adverse effects from subsequent processes, such as adverse effects from water, hydrogen and oxygen, etc., thereby enhancing performance of the thin film transistor, just because of providing the etch stop layer between the active layer and the source and drain electrodes in the thin film transistor.

Owner:BOE TECH GRP CO LTD

Semiconductor device and method for manufacturing semiconductor device

InactiveUS20150206923A1Reduce areaForm differentTransistorSolid-state devicesDevice materialCondensed matter physics

A semiconductor device includes a first fin-shaped semiconductor layer on a semiconductor substrate, a first insulating film around the first fin-shaped semiconductor layer, a first pillar-shaped semiconductor layer on the first fin-shaped semiconductor layer, a first gate insulating film around the first pillar-shaped semiconductor layer, a first gate line formed around the first gate insulating film and extending in a direction perpendicular to the first fin-shaped semiconductor layer, a second diffusion layer disposed in a lower portion of the first pillar-shaped semiconductor layer, a third gate insulating film surrounding an upper portion of the first pillar-shaped semiconductor layer, a first contact electrode surrounding the third gate insulating film, a second contact electrode that connects an upper portion of the first contact electrode to an upper portion of the first pillar-shaped semiconductor layer, and a first magnetic tunnel junction memory element on the second contact electrode.

Owner:UNISANTIS ELECTRONICS SINGAPORE PTE LTD

Stator manufacturing method, stator, and motor

InactiveUS20120326550A1Without lowering in occupancy rateEnsure insulationWindings insulation shape/form/constructionMagnetic circuitElectrical conductorEngineering

A stator manufacturing method includes the steps of preparing an armature core, forming an insulating member including two opposing portions from a sheet-like insulating material, and deforming the insulating member to move the two opposing portions toward each other. The method also includes the step of inserting distal parts of the two opposing portions into the corresponding slit from the axial direction thereby covering an inner surface of each of the slot with the insulating member. Further, the method includes the steps of inserting a conductor forming a winding into each of the slots between the two opposing portions.

Owner:ASMO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com