Two-phase-flow, panel-cooled, battery apparatus and method

a battery pack and panel cooling technology, applied in lighting and heating apparatus, semiconductor devices, solid-state devices, etc., can solve the problem of limited convection on very short paths, and achieve the effect of enhancing the free convection of liquids and vapors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040]It will be readily understood that the components of the present invention, as generally described and illustrated in the drawings herein, could be arranged and designed in a wide variety of different configurations. Thus, the following more detailed description of the embodiments of the system and method of the present invention, as represented in the drawings, is not intended to limit the scope of the invention, as claimed, but is merely representative of various embodiments of the invention. The illustrated embodiments of the invention will be best understood by reference to the drawings, wherein like parts are designated by like numerals throughout.

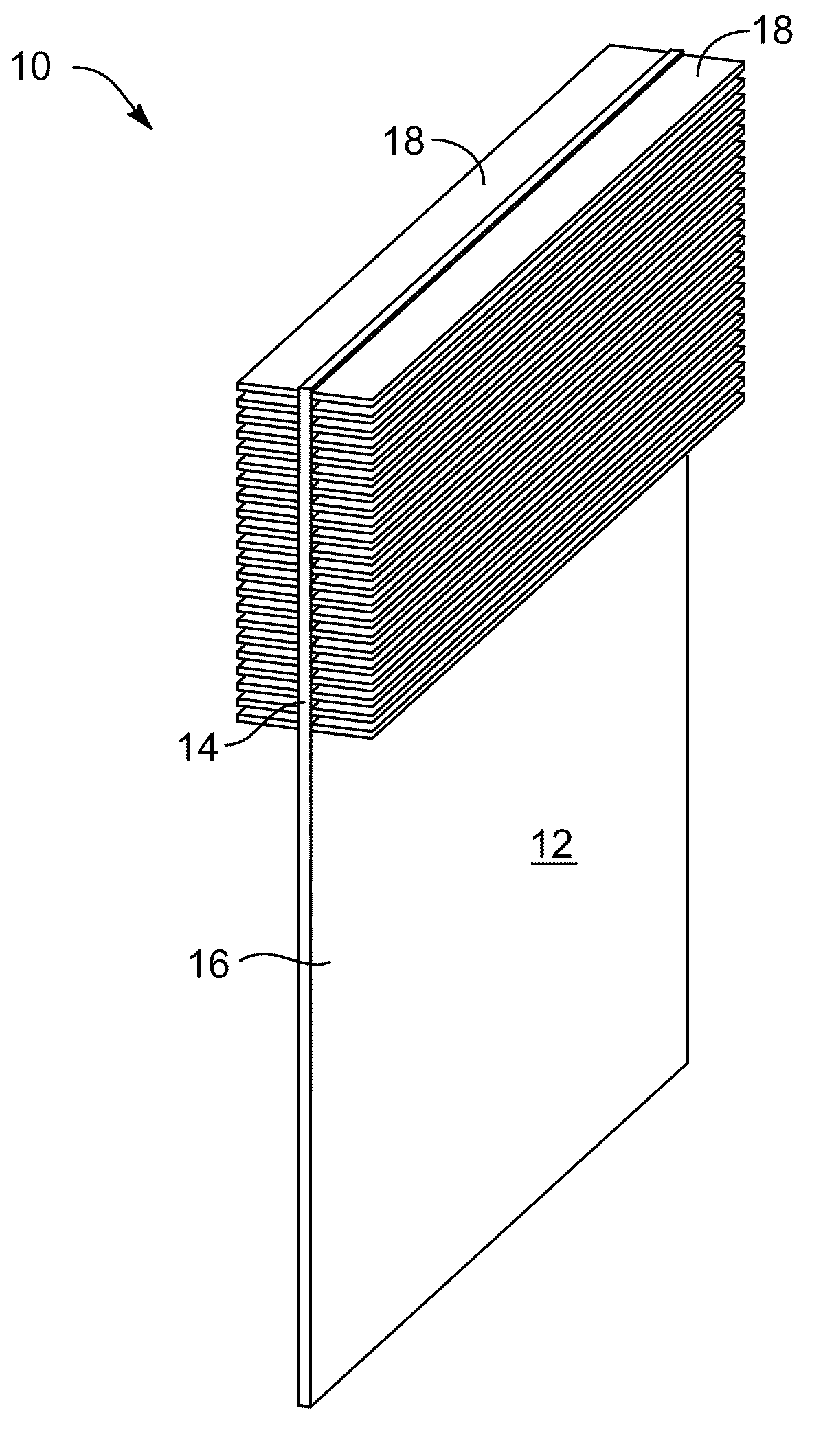

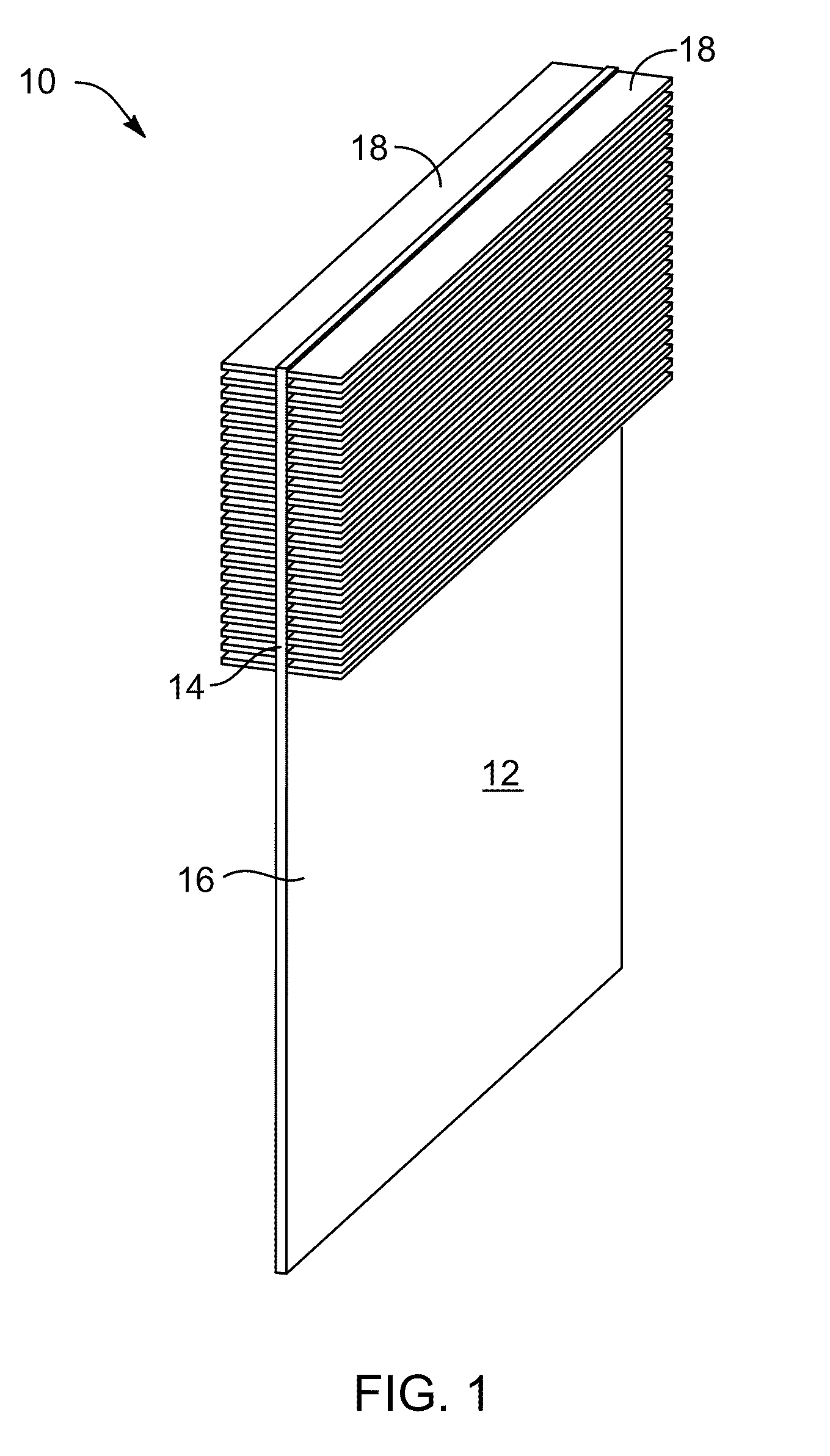

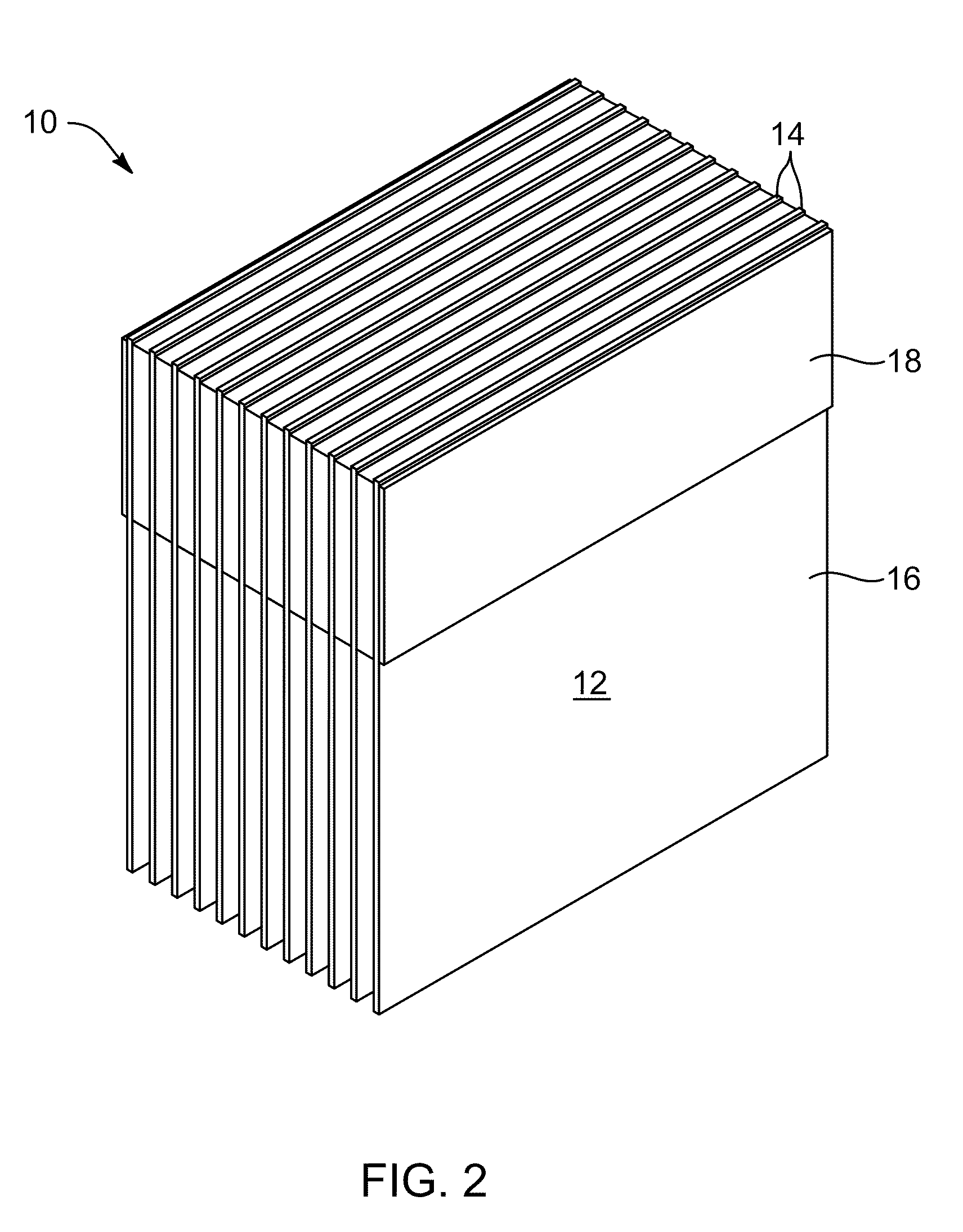

[0041]Referring to FIG. 1, a single (either open-pool, or hermetically sealed) narrow channel may receive heat into a working fluid. The narrow channel in this case may be filled completely or only partially with liquid, allowing for vapor to exit from or to re-condense in an upper portion thereof. Heat generating components may...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com