Flow direction control mechanism

a flow direction and control mechanism technology, applied in the direction of electrical apparatus casings/cabinets/drawers, domestic cooling apparatus, cooling/ventilation/heating modifications, etc., can solve the problems of increasing fabrication costs and structural complexity, reducing the heat dissipation reducing the efficiency of electronic devices, etc., to achieve the effect of increasing the fabrication cost of flow direction control mechanisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first preferred embodiment

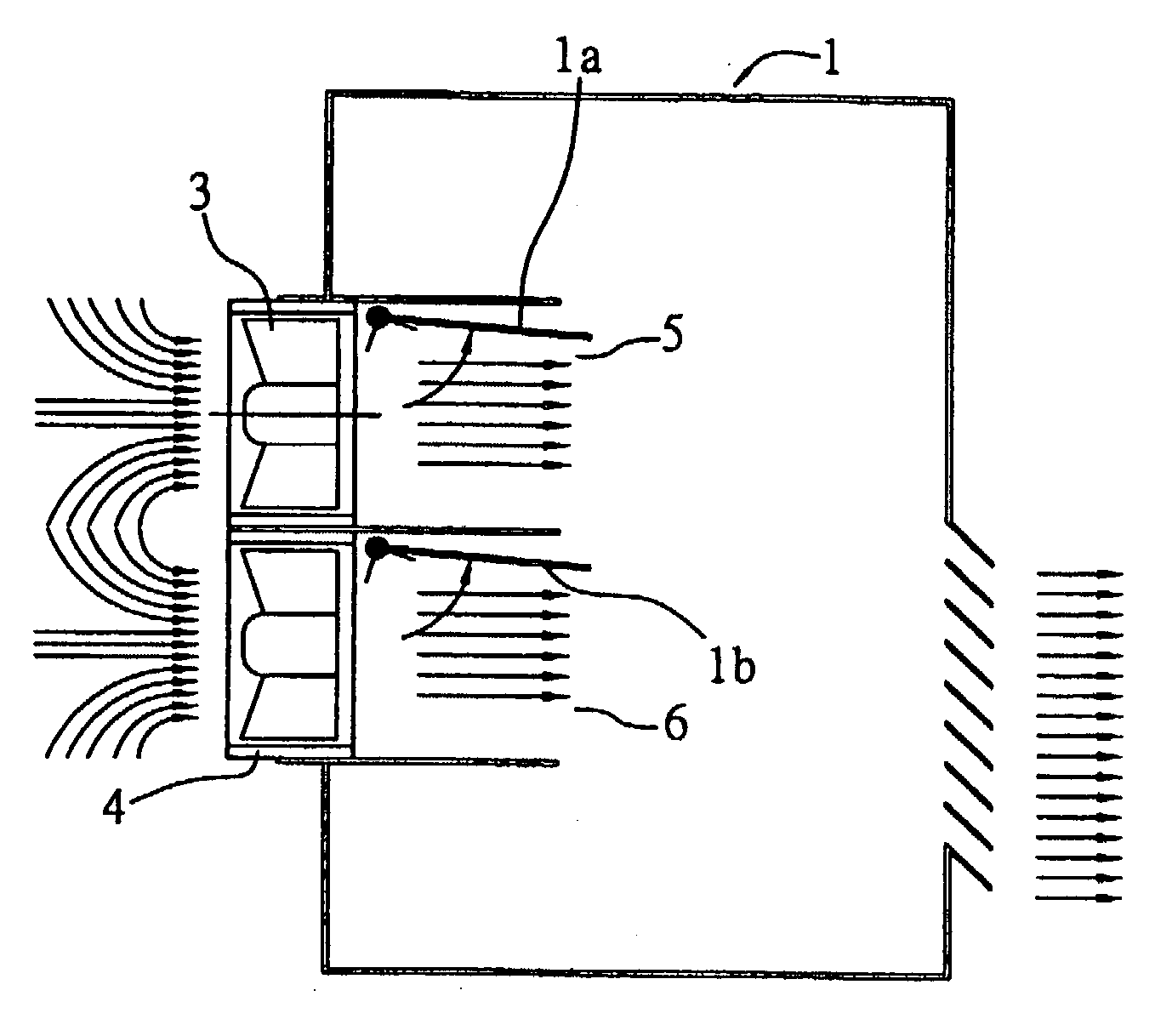

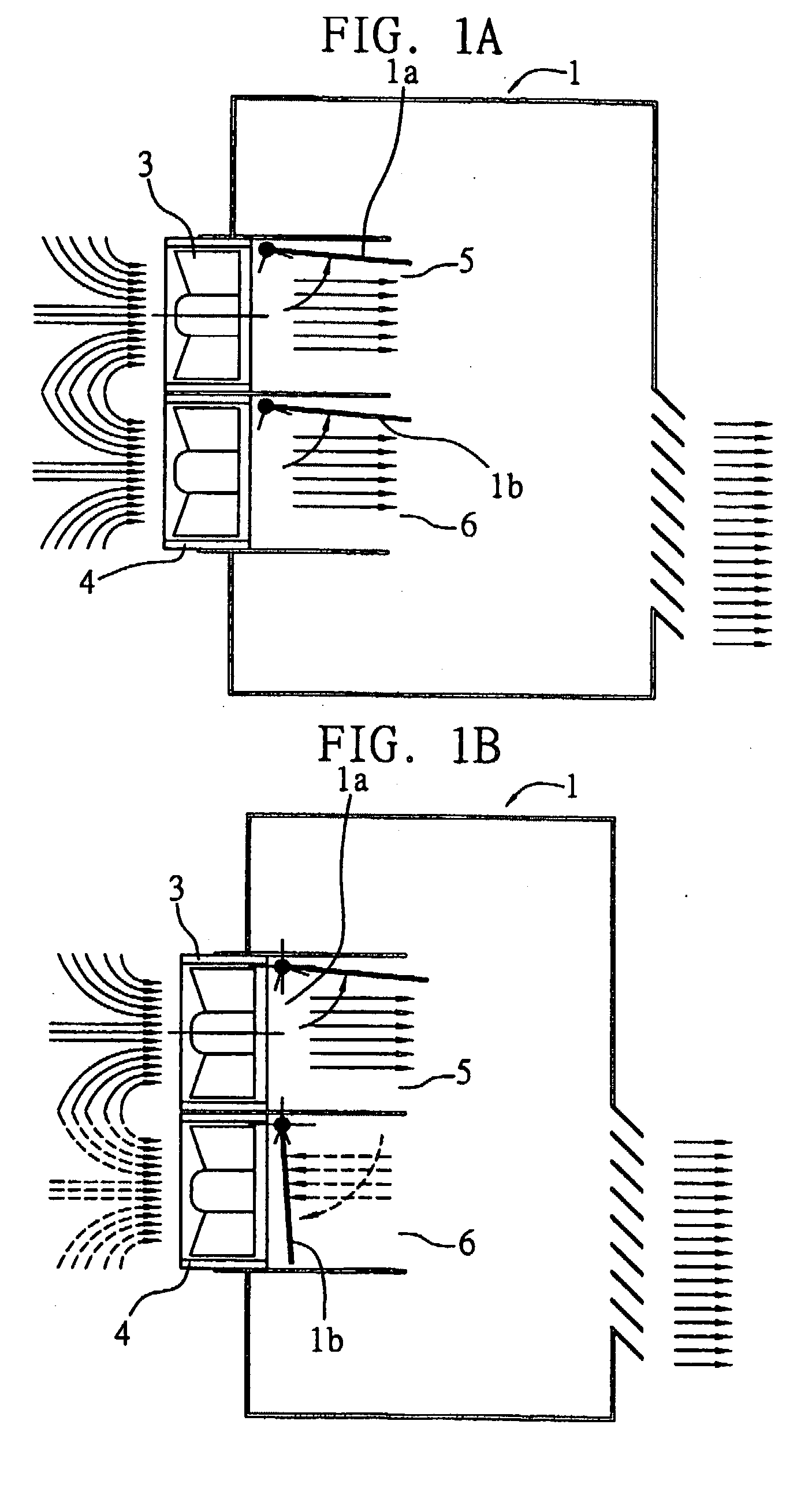

[0037]FIGS. 1A and 1B illustrate a flow direction control mechanism according to a first embodiment of the invention. A pair of these flow direction control mechanisms 1 having rotatable means 1a, 1b are disposed at air inlets 5, 6 of a passage of an electronic device and at inner positions with respect to heat dissipating devices 3, 4.

[0038] The rotatable means 1a, 1b can be rotatably mounted to a top, side or bottom wall of the passage of the electronic device, and spaced apart from the heat dissipating devices 3, 4 by a proper distance to avoid undesirably interference.

[0039] The heat dissipating devices 3, 4 are each mounted in the passage of the electronic device, and operate to produce airflow for directing air in the passage through air inlets 5, 6 toward outside for exhaust. The heat dissipating devices 3, 4 can be heat dissipating fans such as axial flow fans or centrifugal fans.

[0040] As shown in FIG. 1A, when the heat dissipating devices 3, 4 operate properly and respe...

second preferred embodiment

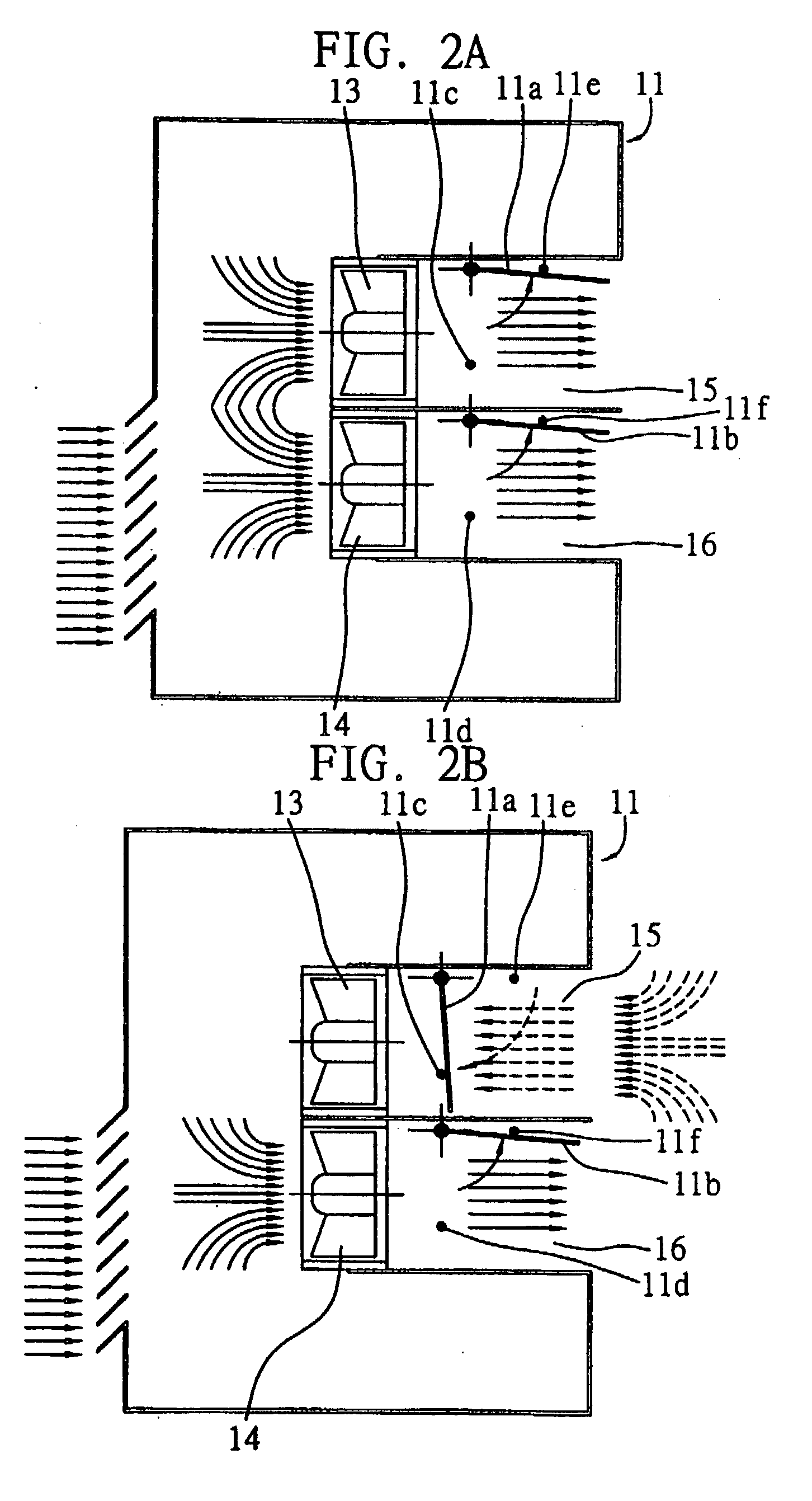

[0044]FIGS. 2A to 2D illustrate a flow direction control mechanism according to a second embodiment of the invention. A pair of these flow direction control mechanisms 11 are disposed at air outlets 15, 16 of the passage of an electronic device and at outer positions with respect to heat dissipating devices 13, 14. The flow direction control mechanisms 11 are formed with rotatable means 11a, 11b and restrictors 11c, 11d, 11e, 11f, wherein the restrictors 11c, 11d, 11e, 11f are each a protrusion formed on an inner side wall of the passage. The rotatable means 11a, 11b of the second embodiment are structured and have the same functions as those in the first embodiment; therefore, no further description thereto is to be here repeated. The second embodiment only differs from the first embodiment in that the rotatable means 11a, 11b are located near the air outlets 15, 16 of the passage and the restrictors 11c, 11d, 11e, 11f are provided.

[0045] As shown in FIG. 2A, when the heat dissipa...

third preferred embodiment

[0049]FIGS. 3A and 3B illustrate a flow direction control mechanism according to a third embodiment of the invention. This flow direction control mechanism 7 has the structure similar to that of the first embodiment with the only difference in that the flow direction control mechanisms 7 are installed at outside position rather than inner positions (first embodiment) with respect to heat dissipating devices 9, 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com